contents

I

CONTENTS

CONTENTS........................................................................................................................................ I

LIST OF FIGURES..........................................................................................................................II

1.GENERAL...............................................................................................................................1-1

1. 1USERS OF THIS MANUAL............................................................................................1-1

1. 2REFERENCE DOCUMENTATION................................................................................1-1

1. 3SYMBOLS........................................................................................................................1-1

1. 4SAFETY RECOMMENDATIONS..................................................................................1-3

1.4.1 PROJECT CRITERIA ......................................................................................................1-3

1.4.2 SAFETY DEVICES...........................................................................................................1-3

1.4.3 WARNINGS AND RECOMMENDED BEHAVIOR.........................................................1-5

1.4.4 RECOMMENDED USE OF THE SYSTEM.....................................................................1-6

1.4.5 IMPROPER USE..............................................................................................................1-6

1.4.6 RESIDUAL HAZARDS.....................................................................................................1-6

1.4.7 WARNINGS FOR MAINTENANCE ACTIVITIES ...........................................................1-6

1. 5REQUIREMENTS FOR CORRECT OPERATION........................................................1-7

1.5.1 ENVIRONMENT..............................................................................................................1-7

1.5.2 TECHNICAL SPECIFICATIONS....................................................................................1-7

1.5.3 WEIGHT...........................................................................................................................1-7

1.5.4 OVERALL DIMENSIONS................................................................................................1-8

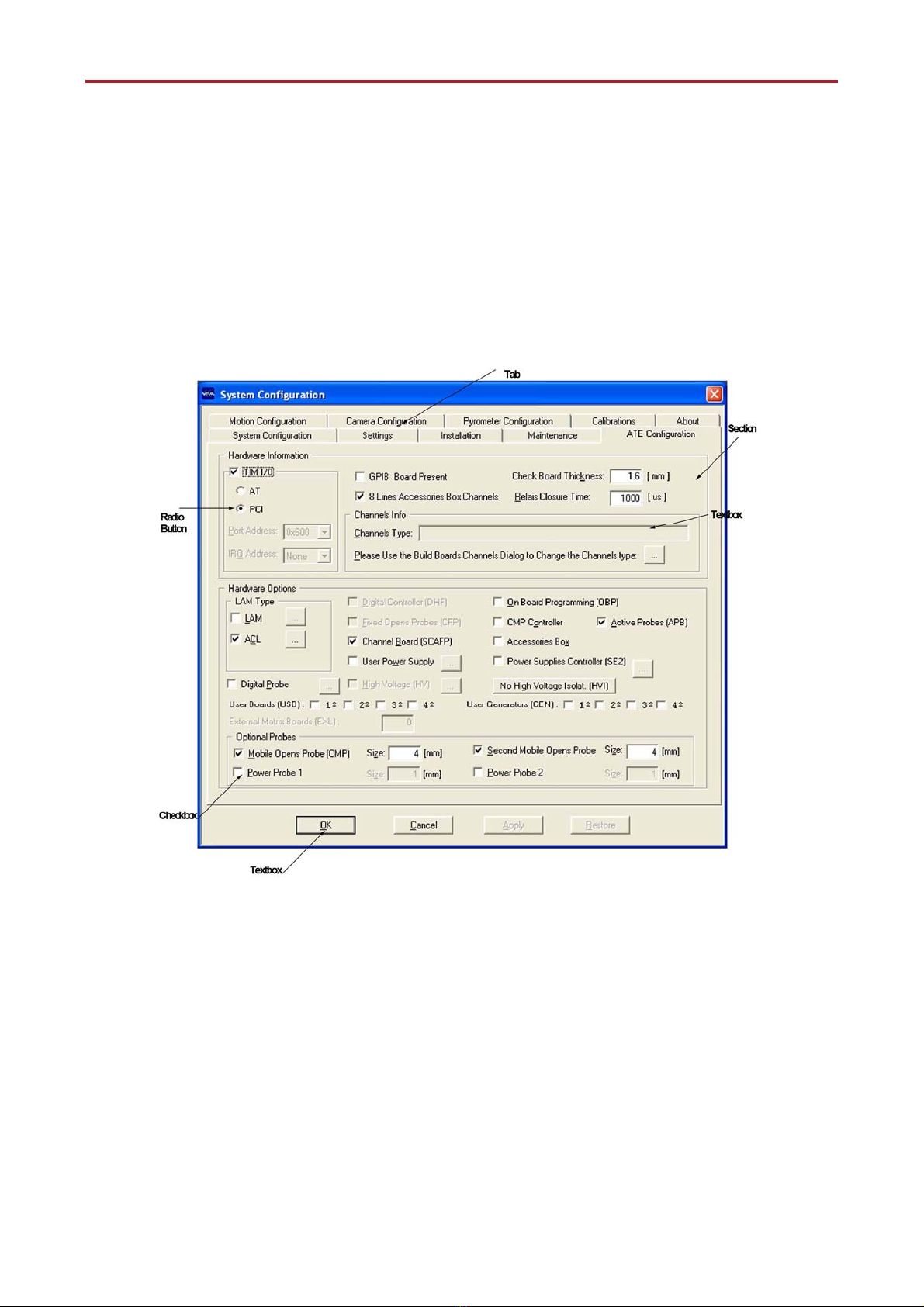

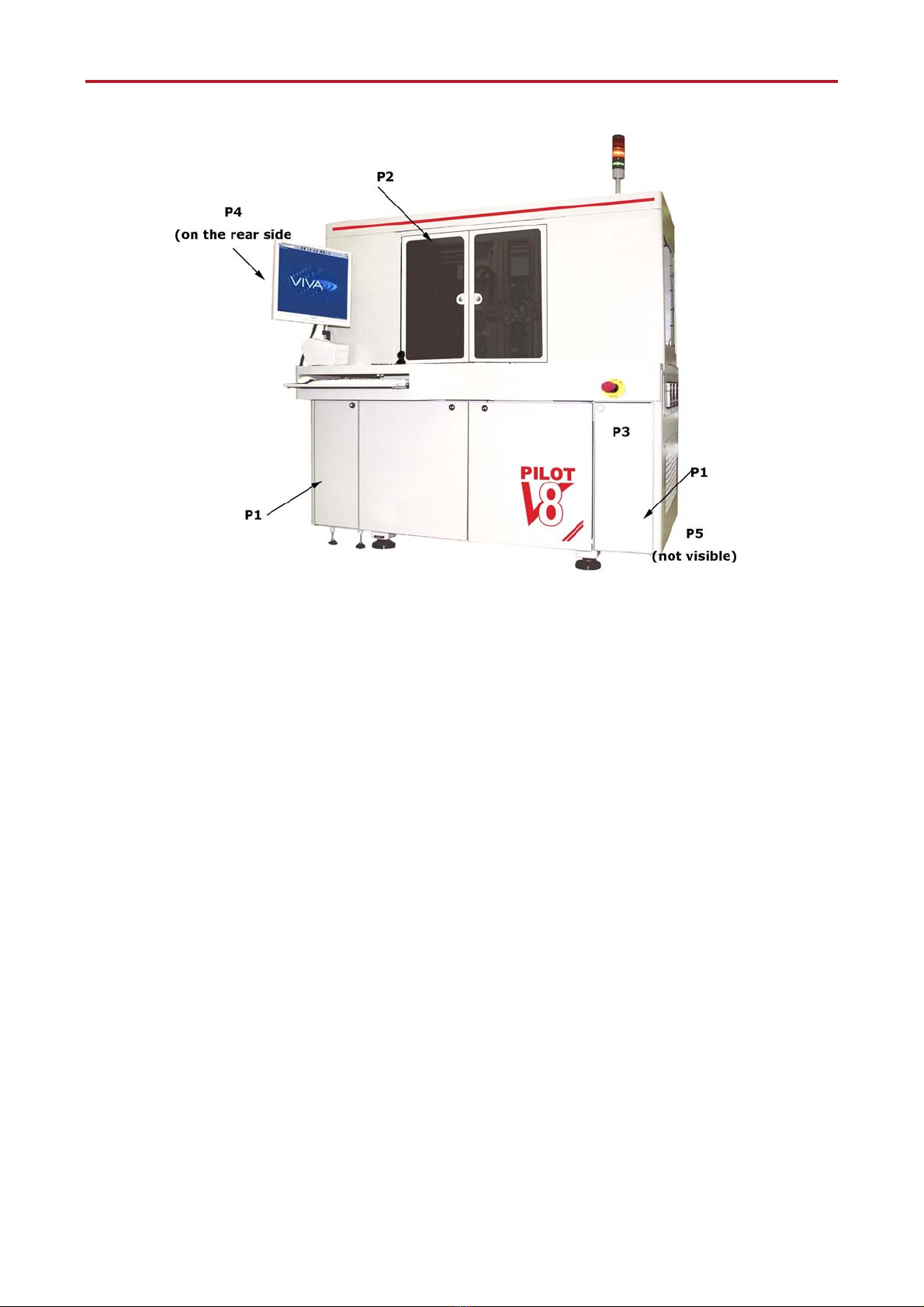

2.CONTROL PANELS..............................................................................................................2-1

2. 1THE CONTROL PANEL.................................................................................................2-2

2. 2LIGHT INDICATOR........................................................................................................2-6

2. 3SMEMA............................................................................................................................2-6

3.MAINTENANCE....................................................................................................................3-1

3. 1CLEANING THE SYSTEM.............................................................................................3-2

3. 2INSPECTION OF THE AIR FILTERS............................................................................3-2

3. 3REPLACEMENT OF THE FILTERS..............................................................................3-3

3. 4SYSTEM DIAGNOSTICS...............................................................................................3-3

3.4.1 MEANING OF THE ERROR MESSAGES.......................................................................3-5

3.4.2 ARRANGEMENT OF THE MODULES IN THE ATE RACK..........................................3-6

3. 5REPLACING THE PROBE NAIL...................................................................................3-8

3. 6REPLACING THE PROBE HOLDER ............................................................................3-9

3. 7CALIBRATIONS ...........................................................................................................3-10

3.7.1 JOYSTICK CALIBRATION............................................................................................3-13

3.7.2 CAMERA CALIBRATION..............................................................................................3-13

3.7.3 ELECTRICAL PROBES CALIBRATION.......................................................................3-13

3.7.4 MOBILE CAPACITIVE PROBE CALIBRATION..........................................................3-22

3.7.5 POWER PROBES CALIBRATION ................................................................................3-25

3.7.6 STAMPER CALIBRATION............................................................................................3-27

3. 8UPS (UNINTERRUPTIBLE POWER SUPPLY)..........................................................3-30

4.GETTING STARTED............................................................................................................4-1

4. 1SYSTEM STARTING......................................................................................................4-2

4. 2SELECT A TEST PROGRAM.........................................................................................4-2

4.2.1 Wizard Environment – Start page....................................................................................4-2

4.2.2 Create a new board..........................................................................................................4-3

4.2.3 Select a board ..................................................................................................................4-3

4. 3Translation ........................................................................................................................4-5