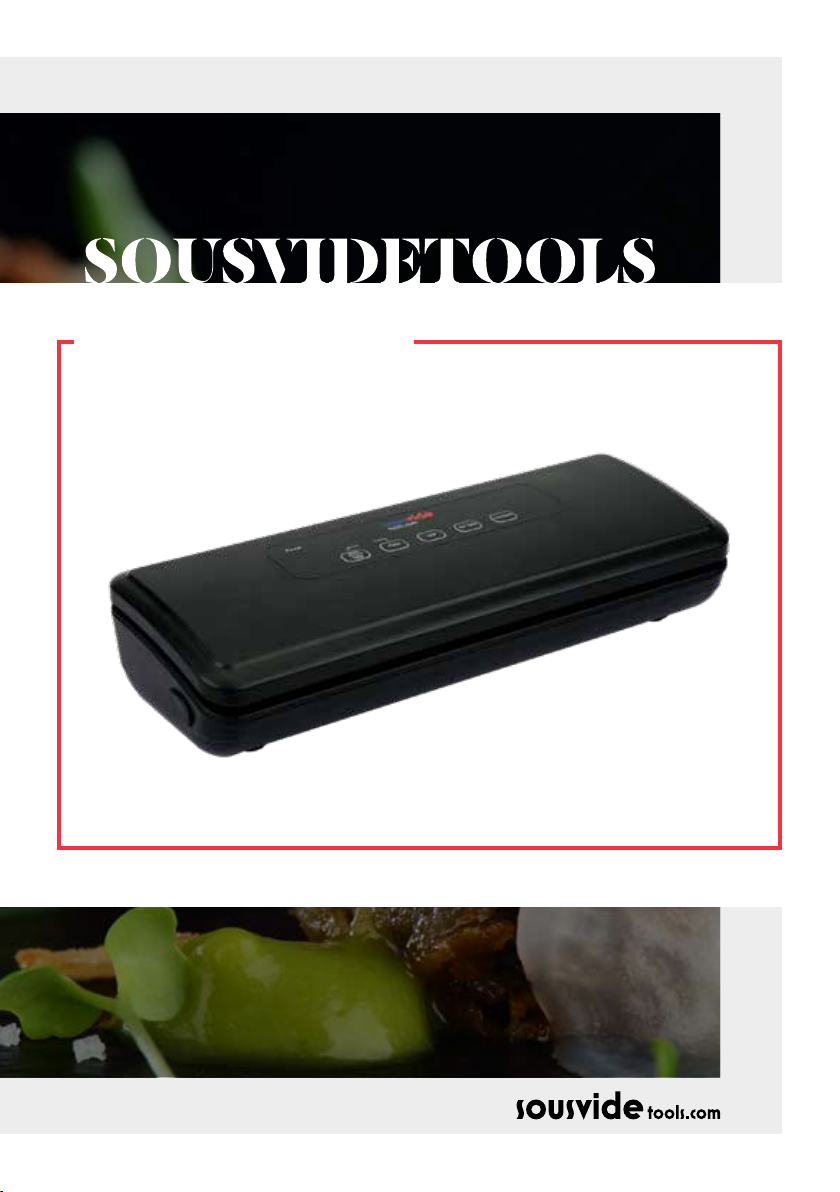

SousVideTools IVIDE PLUS User manual

IVIDE PLUS

VACUUM SEALER

USER GUIDE

2

IMPORTANT - READ BEFORE USE

Please read this user manual carefully before using the appliance.

Keep these instructions with the appliance.

SAFETY REGULATIONS

• Read the Manual carefully before using the machine for the rst time.

• This machine is for household using only, do not use it for not intended use.

• Unless under the supervision or guidance to guarantee the safety, this machine is not intended to be used

by persons (including children) who are physically impaired, feel or mentally impaired, or lack relevant

experience and knowledge.

• Take good care of the children when using the machine, in case of any accident.

• Make sure the operation platform at, stable, and heat resistant.

• Do not leave the machine alone when it is power on.

• Do not touch the sealed area immediately after sealing, in case of scald.

• Unplug the machine when is not using.

• Do not pull the power cord for unplugging.

• Please stop using the machine in case of any dangers if the plug, power cord or the machine is defect. Please

have it repaired by the manufacture or his designated maintenance department or professionals, do not

repair the machine personally.

• This machine is indoor household using machine, please do not use the machine outdoor or in moisture

place.

• Do not use the extension cord, if necessary, ask professionals to use extension cords matching various

technical specications.

• Keep the machine and power cord away from hot, heat, wet place.

• This machine does not require any lubricant or lubricating oil, do not wipe with organic solvent.

• Do not lock the two ends latches after using the machine, in case the seal foam is pressed and functions

inuenced.

• Do not let the power cord hang on the table or outside the edge of the work surface to prevent the product

from falling.

• Between every operation, stop 20s to cool down the components.

3

THE IVIDE PLUS VACUUM SEALER

IVIDE PLUS VACUUM SEALER PRODUCT FUNCTIONS

1Control Panel

2Lid

3Main Body

4Base Cover

5Lock button

6Rubber Feet

7Seal Rubber

8Hasps

9Gasket

10 Internal Panel

11 Vacuum Nozzle

12 Chamber

13 Liquid Tank

14 Seal Wire & Tape

CONTROL PANEL

1 Power

Power on, light on and machine on standby.

2 Auto & Stop - Automatic vacuum seal and stop

When the machine is on standby, pressing this button will automatically vacuum and seal. The indicating light

will turn green. Press this button to immediately stop the operation.

3 Pulse - Manual Vacuum

When the machine is on standby, press this button to select vacuum, release or operation stops.

4 Seal - Seal Only

When the machine is on standby, press this button to seal the vacuum bag without vacuuming.

When the machine is in operation, press this button to stop working but engage in the process of sealing.

1

8

2

6

3

4

5

87

9

10

11

12

13

14

4

5 Extended Seal Time

Press this button to extend the seal time for better sealing performance. This is to be used when the sealing of

the bag is not acceptable under the process of the normal seal time. The indicator light will turn on.

6 Accessory - Accessory Function

Open the lid and use the hose to connect the vacuum port of machine and canister, then press the button of

Accessory to vacuum the canister.

TECHNICAL SPECIFICATION

Rated voltage: 220-240 V~

Rated frequency: 50HZ

Rated power: 100 W

Pump: Double pump

Pressure: -18“Hg /-711mbar

Seal wire width: 2.2mm

Max bag width: 305mm

Size: 363x126x76mm

Weight: 1.3 Kg

FOOD SAFETY

Vacuum packaging extends the life of foods by removing most of the air from sealed containers and prevents

fresh air escaping into the sealed containers, there by reducing oxidation. Vacuum packaging helps preserve

avor and overall quality. It also helps inhibit the growth of aerobic microorganisms, which can lead to the

problems noted below under certain conditions:

Mold: Mold cannot grow in a low oxygen environment; therefore, vacuum packaging can virtually eliminate it.

Yeast: Results in fermentation, which can be identied by smell and taste. Yeast needs water, sugar and a

moderate temperature to grow. It can also survive with or without air. Slowing the growth of yeast requires

refrigeration, while freezing stops it completely.

Bacteria: Results in an unpleasant odor, discoloration and/or soft or slimy texture. Under the right conditions

clostridium botulinum (the organism that causes Botulism) can grow without air and cannot be detected by

smell or taste. Although it is extremely rare, it can be very dangerous. As with any other storage containers, it

is important to inspect food for spoilage prior to consuming.

To preserve foods safely, it is important to maintain low temperatures. You can signicantly reduce the growth

of microorganisms at temperatures of 4ºC or below. Freezing at -17ºC does not kill microorganisms, but stops

them from growing. For long-term storage, always freeze perishable foods that have been vacuum packaged.

It is important to note that vacuum packaging cannot reverse the deterioration of foods. It can only slow down

changes in quality. It is difcult to predict how long foods will retain their top-quality avour, appearance or

texture because it depends on the vital force and the condition of the food on the day it is vacuum packaged.

Note: vacuum packaging is not a substitute for refrigeration or freezing. Any perishable foods that require

refrigeration must still be refrigerated or frozen after vacuum packaging.

5

FOOD STORAGE & SAFETY

Storage Food Typical storage Vacuum packing

Freezer Meat 6 months 15-20 months

Freezer Fish & Seafood 6 months 10-12 months

Freezer Dried Fruit 6-9 months 18-24 months

Freezer Coffee Beans 6-9 months 18-24 months

Fridge Meat 2-3 days 12-13 days

Fridge Fish & Seafood 2-3 days 6-8 days

Fridge Cooked Meat 2-3 days 10-14 days

Fridge Eggs 2-3 days 30-50 days

Fridge Vegetables 2-3 days 7-10 days

Cupboard Bread 1-2 days 12 months

Cupboard Boxed biscuits 4-6 months 12 months

Cupboard Noodles 5-6 months 12 months

Cupboard Rice 5-6 months 12 months

Cupboard Flour 4-5 months 12 months

Cupboard Dry-salters 3-4 months 12 months

Cupboard Coffee 2-3 months 12 months

Cupboard Tea 5-6 months 12 months

Cupboard Milk Powder 1-2 months 12 months

OPERATING INSTRUCTIONS

How To Vacuum And Seal With Pre-cut Bags

1 Choose suitable vacuum bag, place food in bag, make sure the food away the bag mouth at least 1’’.

2 Open the lid to put the bag mouth end into the liquid groove of the chamber.

3 Close the lid and press slightly two ends of the lid, lock the lid.

4 Power is on. The indicator light will be on, then the machine enter standby mode.

5 Press “Auto & Stop” button, machine will vacuum and seal automatically, the button turns into red.

6 After operation completes, there will be beeps.

7 Release the lid by pressing the latches in two ends.

8 Check the sealing.

(Note: A positive seal will look clear upon inspection. If the seal is spotty, incomplete, wrinkled, white or milky,

remove sealed portion, run vacuum, and seal process again.)

6

How To Vacuum With Roll

1 Cut the suitable length bag from the roll.

2 Open the lid to put one of the open ends into the chamber.

3 Close the lid and latch.

4 Power is on. The indicator light will be on, then the machine enter standby mode.

5 Press “Seal” button, to seal one open end of the bag.

6 After sealing, put the food into the bag.

7 The following processes please refer to “How To Vacuum And Seal With Pre-cut Bags”.

Bag guidelines

1Not all kinds of bags can be used with this machine, please make sure the bags to be used with this machine

are with pattern which to have the channel for the air.

2 Delicate foods, moist foods and foods that need to hold their shape require pre-freezing. Foods like meat,

berries and bread can be frozen for up to 24 hours without harm of freezer burn. Once food is hard, it is

ready to be vacuum packaged.

3 To vacuum liquids like soups, stews and casseroles, pre-freeze in a dish or ice cube tray. Once frozen,

vacuum package, label and stack in your freezer.

4 For objects with sharp points or edges, pad the edges with paper towels to prevent the bag from puncturing.

5 Vacuum bags are reusable, boilable and microwavable. We do not recommend reusing bags that have been

boiled or micro-waved. Do not reuse bags that have been used to store fresh sh or greasy foods.

MAINTENANCE

1 Make sure the working platform at, clean and tidy.

2Do not lock the two ends latches after using the machine, in case the seal foam is pressed and functions

inuenced.

3 Do not put the machine or the power cord into liquid.

4 Unplug and cool down the machine before cleaning.

5 Do not brush the machine in case of damage the machine surface.

6 Clean up the food or liquid left inside the chamber with wet towel or tissue.

7 Make sure the machine total dry when use the machine again.

TROUBLESHOOTING

Error Troubleshooting

Machine not

work

Ensure the machine is plugged in.

Check the power cord for tears and frays.

7

Error

The Vacuum

Sealer does not

pull a complete

vacuum or seal

automatically

Fail to seal

Check if the bag open mouth is totally inside the chamber.

Check if the gasket is loose.

Check if for any particle on the seal foam or gasket, is the seal foam properly assembled.

Check if the lid is locked.

Check if there is leakage in the bag. Check by putting the bag into water, press the bag, if

there are bubbles then there is leak. Change bag.

The machine may have over run. Rest the machine between cycles. The break should

be at 20 seconds between every seal.

Any wrinkles, grease, liquid or other debris on the open end of the bag will cause an

issue. Try a new clean bag.

There may be moisture or debris on the sealing bar. Clean the bar, and seal again.

Vacuum bag

loses vacuum

after being

sealed

Any wrinkles, grease, liquid or other particles on the seal could cause this issue, please

open the bag, clean the bag mouth and vacuum again.

Check if there is any moisture or liquid on the food, if yes, open the bag and vacuum

again, or change to a new bag. If the food is juicy it is suggested you consider freezing

before vacuum.

WARRANTY & AFTER SALES SERVICE

1 Make sure the working platform is at, clean and tidy.

2 Warranty is limited to damage caused by production defects.

3 The cost of parts and maintenance will be charged due to improper use or other non-product quality problems.

4 Please keep the purchase vouchers.

Maintenance Card

First Name:

Phone:

Address:

Machine Model:

Supplier:

Last Name:

Email:

Purchase Date:

HEADQUARTERS

Central Barn, Claughton Business Park,

Hornby Road, Claughton, Lancaster, LA2 9JX

0800 678 5001

01524 770 060

www.sousvidetools.com

Table of contents