Southwest Microwave 300B User manual

Southwest Microwave, Inc.

Security Systems Division

TECHNICAL MANUAL

FOR

MIL PAC MODELS

300B, 310B, 380 and 385

MIL PAC 380 or 385

MIL PAC 300B or 310B

SOUTHWEST MICROWAVE, INC

Security Systems Division

9055 South McKemy Street

Tempe, Arizona 85282

Tel: (480) 783-0201

Fax: (480) 783-0401

E-mail: [email protected]

Web: www.southwestmicrowave.com

2

TABLE OF CONTENTS

Introduction............................................................................................................................................................3

Equipment Supplied............................................................................................................................................... 3

Optional Equipment...............................................................................................................................................9

Applications.........................................................................................................................................................10

Unpacking and Tripod Setup ...............................................................................................................................12

MIL PAC 300B Operating Instructions............................................................................................................... 12

MIL PAC 300B Setup and Testing...................................................................................................................... 13

MIL PAC 310B Operating Instructions............................................................................................................... 15

MIL PAC 310B Setup and Testing...................................................................................................................... 16

MIL PAC 380 and MIL PAC 385 Operating Instructions................................................................................... 17

MIL PAC 380 and MIL PAC 385 Setup and Testing.......................................................................................... 18

Powering Down and Packing Up......................................................................................................................... 19

Limited Warranty................................................................................................................................................. 19

Returning Equipment under Warranty.................................................................................................................20

Returning Equipment for Non Warranty Repair.................................................................................................. 20

Replacement Parts................................................................................................................................................20

Copyright Southwest Microwave, Inc. November 2003 – MIL PAC.................................................Printed in USA

3

INTRODUCTION____________________________________________________________________

This manual covers the setup and operation of the Models MIL PAC 300B and MIL PAC 310B Relocatable Rapid Deployment

Microwave Intrusion Links and Models MIL PAC 380 and MIL PAC 385 Relocatable Rapid Deployment Microwave

Transceivers. Please refer to the individual Data Sheets and Technical Manuals for Models 300B, 310B, 380 and 385 for

additional information not covered in this manual.

These portable relocatable sensors are ideal for short-term protection of vital assets such as parked aircraft, construction sites,

freight yards or anywhere the perimeter may be moved or changed.

EQUIPMENT SUPPLIED______________________________________________________________

Each MIL PAC 300B consists of one Model 300BT Transmitter, one Model 300BR Receiver, one MP01 Monitor Pac with

mating connector, charging transformer and cable, one BP01 Battery Pac with mating connector, charging transformer and

cable, two MT10 Tripods, two interconnect cables, one RF radio alarm transmitter with two foot whip antenna and two fitted

carrying cases.

Each MIL PAC 310B consists of one Model 310BT Transmitter, one Model 310BR Receiver, one MP01 Monitor Pac with

mating connector, charging transformer and cable, one BP01 Battery Pac with mating connector, charging transformer and

cable, two MT10 Tripods, two interconnect cables, one RF radio alarm transmitter with two foot whip antenna and two fitted

carrying cases.

Each MIL PAC 380 consists of one Model 380 Transceiver, one MP01 Monitor Pac with mating connector, charging

transformer and cable, one MT10 Tripod, one interconnect cable, one RF radio alarm transmitter with two foot whip antenna

and fitted carrying case.

Each MIL PAC 385 consists of one Model 385 Transceiver, one MP01 Monitor Pac with mating connector, charging

transformer and cable, one MT10 Tripod, one interconnect cable, one RF radio alarm transmitter with two foot whip antenna

and fitted carrying case.

Reference Figures 1-8 for supplied equipment.

Figure 1 shows a side view of the various sensors with the tilt and swivel limits of the swivel assembly plus the MS connector

location where the interconnect cable attach from the MP01 or BP01 to the sensor.

Figure 1 – MS Connector Locations

20

o

MAX TILT

ANY DIRECTION

10.6 in.

(27cm)

Dia.

10.125 in.

(25.7cm)

380 385

300BR or 310BR300BT or 310BT

4

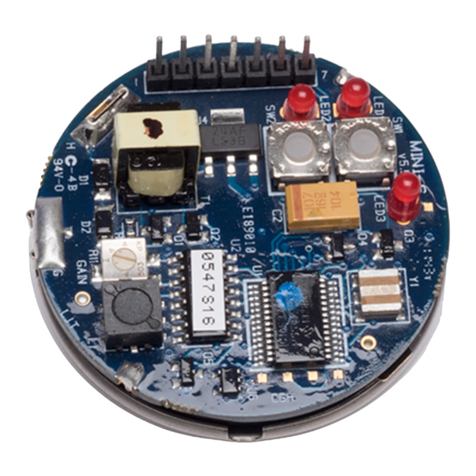

Figure 2 shows the MP01 Monitor Pac. The MP01 connects to the MIL PAC 300BR receiver, MIL PAC 310BR receiver, MIL

PAC 380 transceiver or MIL PAC 385 transceiver with the supplied interconnect cable. It houses a 5 AH battery to power the

sensor and associated electronics, a RF alarm transmitter, a test/alignment meter to assist with setup, audible and visual alarm

indicators, a shielded terminal strip and on/off switches. On the case side is the mount for the two-foot whip antenna. There

are two MS style connectors on the outside of the MP01. One is for connecting to the sensor and the other for connecting to an

optional external DC source such as a power supply, solar panel or larger battery. A mating connector is provided.

Figure 2 – MP01 Monitor Pac

6 inches

(152mm)

MILLIAMPERES

2A

ONONOFF OFF ONOFF

LIGHT OFF

COM

12VDC

N.O. N.C.

FUSE

MP01

MODEL

SOUTHWEST

MICROWAVE

MADE IN USA

AUDIO

0

.4 .6

.2

D.C.

DO NOT TURN ON RADIO WITHOUT

ANTENNA PROPERLY CONNECTED.

DAMAGE TO RADIO MAY RESULT.

WARNING

BATTERYPOWER RADIO

CHARGER

REG P/S

RADIO

-+

16VAC

OFF

P/S ALIGN

SENS

.8

1

12 inches

(305mm)

9 inches

(229mm)

NEG

NEG

TO TRANSCEIVER

A

EXT 12VDC

A

5

Figure 3 shows the BP01 Battery Pac. The BP01 connects to the MIL PAC 300BT transmitter or MIL PAC 310BT transmitter

with the supplied interconnect cable. It houses a 5 AH battery to power the sensor and associated electronics, a shielded

terminal strip and on/off switches. There are two MS style connectors on the outside of the BP01. One is for connecting to the

sensor and the other for connecting to an optional external DC source such as a power supply, solar panel or larger battery. A

mating connector is provided.

Figure 3 – BP01 Battery PAC

TO TRANSMITTER

NEG

NEG

A

EXT 12 VDC

A

6 inches

(152mm)

OFF ON

POWER

FUSE

1A

MADE IN USA

MICROWAVE

SOUTHWEST

POS

POS

NEG

NEG

SP2SP1TEST

-

12VDC 16VAC

+

CHARGER

MODEL

BP01

OFF ON

BATTERY

12 inches

(305mm)

9 inches

(229mm)

6

Each Model BP01 and MP01 includes a step-down transformer to charge the internal batteries through the 16.5 VAC

terminals. It can also be used to power the system. Figure 4 shows the Model PT61 220 VAC to 16.5 VAC transformer and the

Model PT62 110 VAC to 16.5 VAC transformer.

Figure 4 – PT61 and PT62 Transformers

Each MP01 Monitor Pac includes a RF alarm transmitter to transmit the relay closure of the sensor. When activated the

transmitter will send a 10 watt, 27.255 MHz, digital encoded, FSK modulated, signal to its companion receiver. The

transmitter has full supervision capabilities. Two 8-position switches set the units system code to one of 65,536 possibilities. A

two-foot whip antenna is also included. The antenna hardware is mounted to the side of the MP01 as shown in Figure 2. The

maximum range is 1 (one) mile when the MP01 is at ground level. Figure 5 shows the RF alarm transmitter and antenna. Other

optional radios are also available. Please contact the factory.

Figure 5 – RF Alarm Transmitter and Antenna

PT62PT61

DO NOT TURN ON RADIO WITHOUT

ANTENNA PROPERLY CONNECTED.

DAMAGE TO RADIO MAY RESULT.

WARNING

7

Figure 6 shows three views of the MT10 heavy-duty military style, lightweight olive drab tripod. (It is also shown in the

pictures on the front page). An extended view when set up, a collapsed view when in the carrying case and a top view. One

MT10 is included with each MIL PAC 380 and MIL PAC 385. Two MT10 tripods are included with each MIL PAC 300B and

MIL PAC 310B. The MT10 has a maximum leg extension of 36 inches (914.4mm). With the legs fully extended, the height

adjustment with the center shaft is 18 to 32 inches (457.2 to 812.8mm). The tripod weights approximately 10 pounds (4.5 kg).

Each foot of the MT10 tripod has a hole that can be staked to the ground or weighted with sandbags. The tripod has the ball

swivel assembly with handle attached to the shaft socket. This connects the sensor to the MT10 tripod.

Figure 6 – MT10 Tripod

27.9"

(708mm)

9.9"

(251mm) 8.2"

(208mm)

8

Each MIL PAC system includes a fitted carrying case as show in Figure 7. One case is included for the MIL PAC 380 and

MIL PAC 385. Two cases are included for the MIL PAC 300B and MIL PAC 310B (one case for the transmitter and one case

for the receiver). The case will hold one sensor, one MT10 tripod, one MP01 or BP01, one AC transformer, one interconnect

cable, one charger cable, and one RF alarm transmitter antenna.

Figure 7 – Fitted Carrying Case

The interconnect cable that is supplied is factory assembled. The mating connector for the optional DC input is a bare

connector that requires soldering wires to pin “A” (+12 VDC) and pin “D” (Ground). The distance between the optional

source and MP01 or BP01 determines the wire length and gauge. The connectors on the wire are determined by optional

source requirements. The wiring and soldering of this connector is the responsibility of the contractor or installer. Figure 8

shows a side view and soldering side of the connector.

Figure 8 – Mating Connector

A

D

9

OPTIONAL EQUIPMENT_____________________________________________________________

RP01 Relocatable Receiver Monitoring Unit is used to monitor alarm activity from the MIL PAC sensors. The RP01 has a 16

channel receiver (compatible with the MIL PAC systems transmitters), a LCD display for transmitter alarm with low battery

and transmitter status, audible alarm, LED alarm, a 5 AH internal battery, 16.5 VAC transformer, antenna, 12 VDC input

terminals and 16.5 VAC input terminals. The RP01 is shown in Figure 9.

Figure 9 – RP01

OFF ON

POWER

FUSE

1A

CHARGER

OFF ON

RADIO

AUDIOLIGHT

OFF

12VDC

16VAC

-

+

ALARM

ONOFF

BATTERY

CAUTION:

12VDC-16VAC MUST BE DISCONNECTE

AND BATTERY SWITCH IN THE "OFF"

POSITION PRIOR TO SERVICING BATTERY.

CHANNEL CONDITION

TRANSMITTER

ALARM

LOW BATTERY

STATUS ALERT

=

=

=

A

L

S

TRANSMITTER

TRANSMITTER

12 A

SOUTHWEST

MICROWAVE

MADE IN USA

MODEL RP01

NEG

6.0 in.

12.0 in.

9.0 in.

(152mm)

(305mm)

(228mm)

10

LN-XR1 is a single channel RF alarm receiver used for annunciating alarms from one MIL PAC sensor. The output is a relay

contact closure that needs to be interfaced with an alarm panel. It includes an antenna with mounting hardware and cable but

no enclosure or power supply. The receiver operates on 12 VDC @ 30mA in standby and 70mA when the output is active.

Status and low battery outputs are also available from the terminal strip. A green indicator for power and a red indicator for RF

reception are visible through a window on the weather resistant metal case.

LN-XR4 is a four-channel RF alarm receiver used for annunciating alarms from MIL PAC sensors. The outputs are relay

contact closures that needs to be interfaced with an alarm panel. It includes an antenna with mounting hardware and cable but

no enclosure or power supply. The receiver operates on 12 VDC @ 30mA in standby and 190mA when all outputs are

active. Status and low battery outputs are also available from the terminal strip. A green indicator for power and a red indicator

for RF reception are visible through a window on the weather resistant metal case.

A LN-XR1 or LN-XR4 with antenna is shown in Figure 10.

Figure 10 – LN-XR1 or LN-XR4

APPLICATIONS_____________________________________________________________________

Every day there are new applications for portable and relocatable sensors.

•Parked aircraft

•Construction sites

•Freight yards or vital assets

•VIP residences or aircraft

•Supplementing existing fixed intrusion detection systems

•Anywhere the perimeter may be moved or changed

In Figure 11 a truck-parking pad with cargo must be secured against unauthorized access. The area is secured using two MIL

PAC 300B links and two MIL PAC 380 transceivers.

DO NOT TURN ON RADIO WITHOUT

ANTENNA PROPERLY CONNECTED.

DAMAGE TO RADIO MAY RESULT.

WARNING

4.25 in

(108mm)

6.25 in

(159mm)

Height: 2.25 in (64mm)

Weight: 1 lb (0.454Kg)

11

Figure 11 – Cargo and Truck Pad

The three large aircraft as well as a single aircraft and vital assets need secured from unauthorized access. Figure 12 shows the

large aircraft secured with two MIL PAC 310B links and two MIL PAC 385 transceivers with the other secured with three

MIL PAC 310B links and three MIL PAC transceivers (380 or 385).

Figure 12 – Securing Aircraft and Vital Assets

RECEIVER

RECEIVER

TRANSCEIVER

TRANSMITTER

TRANSMITTER

TRANSCEIVER

100 FEET

(30m)

150 FEET

(46m)

400 FEET (122m)

RECEIVER

RECEIVER

TRANSCEIVER

TRANSMITTER

TRANSMITTER

TRANSCEIVER

300 FEET

(91m)

350 FEET

(107m)

700 FEET (213m)

12

UNPACKING & TRIPOD SETUP_______________________________________________________

1. Open carrying case and remove MP01 and BP01. Connect transformer to “16VAC” terminals and set “BATTERY”

switch to “ON” position. Allow 12 hours for full charge of internal battery.

2. Remove MT10 tripod and loosen the center ring adjustment lug to set the tripod leg spacing.

3. Loosen the leg adjustment lugs to extend the tripod legs to the appropriate height.

4. Loosen the shaft-locking knob to adjust the center shaft to the appropriate height.

5. Tighten all adjustments once the positions are set.

6. Remove the plastic bag from the swivel assembly mounting hardware on center shaft of the MT10 tripod. Attach the

swivel assembly by inserting the threads into the center hub of the sensor. Tighten the swivel assembly to the sensor with

the small hex nut and to the MT10 tripod with the large nut.

MIL PAC 300B OPERATING INSTRUCTIONS__________________________________________

A single MIL PAC 300B may cover a distance up to 600 feet (183m). Three pattern elements are supplied – short range with

maximum range of 100 feet (30m), medium range with maximum range of 350 feet (107m) and extended range with

maximum range of 600 feet (183m). The receiver is equipped with automatic gain-control (AGC) that automatically adjusts

receiver for the distance to be covered.

Maximum width is attained when Transmitter-Receiver distance is maximum and Receiver “Sensitivity” control is set to

maximum. Figure 13 illustrates how pattern width varies with Transmitter-Receiver distance and sensitivity setting for each

protection pattern element. Actual patterns will vary somewhat with site topography and surface condition. Generally, lower

mounting height or rougher surface will increase pattern width.

Figure 13 – MIL PAC 300B Detection Patterns

NOMINAL BEAM WIDTH - FEET

20

(6m)

15

(4.5m)

10

(3m)

5

(1.5m)

020

(6m) 40

(12m) 60

(18m) 80

(24m) 100

(30m)

TOTAL LINK DISTANCE - FEET

0

SHORT-RANGE 100 FEET (30m) - WIDE ANGLE

SENSITIVITY

MAX.

MIN.

NOMINAL BEAM WIDTH - FEET

20

(6m)

15

(4.5m)

10

(3m)

5

(1.5m)

050

(15m) 100

(30m) 150

(45m) 200

(60m) 250

(75m) 300

(90m)

TOTAL LINK DISTANCE - FEET

0

MID-RANGE 350 FEET (107m)

350

(107m)

SENSITIVITY

MAX.

MIN.

NOMINAL BEAM WIDTH - FEET

40

(12m)

30

(9m)

20

(6m)

10

(3m)

0100

(30m) 200

(60m) 300

(90m) 400

(121m) 500

(152m) 600

(183m)

SENSITIVITY

MAX.

MIN.

TOTAL LINK DISTANCE - FEET

0

EXTENDED-RANGE 600 FEET (183m)

13

Vertical protection pattern will also depend upon pattern element selected as well as Transmitter-Receiver distance, mounting

height and “sensitivity” setting. The protection pattern above centerline will be approximately half of the horizontal patterns

shown in Figure 13. The protection pattern below centerline will tend to fill area between centerline and ground except for a

“dead zone” immediately in front of and below the transmitter and receiver. This “dead zone” requires that the transmitters and

receiver be overlapped to provide continuous detection. Figure 14 show a typical corner overlap and intermediate overlap for

minimum to medium security applications where detection of walking and running targets is the only requirement.

Figure 14 – MIL PAC 300B Overlaps

For maximum-security applications where detection of prone “commando” style crawl is required, the intermediate overlap

should be 50 feet (15m) minimum with parallel beam centerline offset of 18 inches (46cm) maximum. The corner overlaps

should be 25 feet (7.5m) minimum. Terrain flatness should be no more than plus three inches (7.62cm) or minus three inches

(7.62cm) deviation from a plane drawn between the transmitter and receiver. The zone length (transmitter to receiver) should

not exceed 400 feet (121m).

The MIL PAC 300B must be located in an area that is free of obstructions and moving objects such as chain link fences, trees,

bushes, tall grass and large areas of water to avoid unwanted nuisance alarms. The clear area (both sides of centerline) for

installation depends upon the distance to be covered by the link. The area should be wider than the maximum detection pattern

for a specific distance as shown in Figure 13.

Figure 15 – MIL PAC Transmitter and Receiver

SETUP & TESTING

1. Complete steps 1-6 in the Unpacking and Tripod Setup on page 12.

2. Remove the radome of the transmitter by removing the six-radome screws to reveal the electronics as shown in Figure 15.

3. Connect the Modulation Frequency jumper wire E10 to one of the four field selectable modulation channels, A, B, C or D.

Note: Use different channels on links operating within close proximity.

15 to 25 FEET

(4.5 to 7.5m)

TOP VIEW

CORNER OVERLAP OFFSET

18" - 20"

(46 - 51cm)

INTERMEDIATE OVERLAP

BEAM

CENTERLINE

TOP VIEW

30 - 50 FEET (9 - 15m)

POWER

MODULATION

FREQUENCY

TAMPE

R

SWITC

H

INPUT

12

VDC

T

E

S

T

AC

BD

MODULATION

FREQUENCY

ALIGN/LATCH

TAMPE

R

SWITC

H

INPUT

12

VDC

R

E

S

E

T

ALAR

M

RELA

Y 1

ALAR

M

RELA

Y 2

NORMAL

RELAY HOLD

C

B

D

A

SENSITIVITY

ALIG

N

TP1

E1

WRONG CHANNEL

JAM

ALARM

RECEIVER TRANSMITTER

14

4. Connect the BP01 to the transmitter with the interconnect cable. Turn the Power and Battery On/Off switches to “On” and

make sure the Power LED indicator illuminates.

5. Remove the radome of the receiver by removing the six-radome screws to reveal the electronics as shown in Figure 15.

6. Connect the Modulation Frequency jumper wire E9 to the field selectable modulation channel that you set on the

transmitter (A, B, C or D). NOTE: Once you have set the same modulation channel on both transmitter and receiver, mark

the units with that channel for future use. Once set and marked, steps 3 and 6 can be omitted.

7. Connect the MP01 to the receiver with the interconnect cable. Attach RF alarm transmitter antenna. Turn the Power and

Battery On/Off switches to “On”.

8. Set function switch to “P/S” (power supply). Meter should read between 0.4 and 0.6 corresponding to 11.0 to 13.8 VDC

from battery.

9. Set function switch to “REG P/S” (regulated power supply). Meter should read between 0.4 and 0.6 indicating that the

receivers 8 VDC regulated voltage is present.

10. Visually aim the transmitter and receiver for “bore sight” (pointing at each other) alignment. Set the function switch to

“ALIGN”.

11. Move the Align/Latch – Normal jumper wire E1 (see Figure 15) on the receiver to the Latch position.

12. Slowly swivel transmitter a few degrees horizontally and vertically. Watch the meter and secure transmitter at position that

produces highest alignment signal. Raise and lower height of transmitter to position that produces highest alignment

signal. Repeat same process for the receiver. The minimum meter reading for proper operation is 0.1.

13. Move the Align/Latch – Normal jumper wire E1 (see Figure 15) on the receiver to the Normal position.

14. Set function switch to “SENS” (sensitivity). The meter should read mid scale, indicating ambient (no intrusion) condition.

Set alarm selector to “LIGHT” or “AUDIO”.

15. Test the link for desired coverage. While watching the meter, an alarm should occur when the meter gets below 0.2 or

above 0.8. Adjust the detection pattern by turning the sensitivity potentiometer (R40) on the receiver (see Figure 15).

Clockwise will increase the sensitivity and counterclockwise will decrease the sensitivity. The antenna elements can be

changed at this point to also adjust the detection pattern.

16. Observe meter for effect of possible nuisance alarm sources such as close proximity fences or vegetation that may move in

the wind. The meter in the sensitivity setting should be relatively stable. Large fluctuations on the meter need to be

investigated.

17. Set Radio switch to “ON”. Generate an alarm to ensure the RF alarm signal is transmitted and displayed at the radio

receiver/annunciator.

18. Replace radomes using all screws. Close BP01 and MP01 covers. Connect external DC source, if used, to MP01 or BP01.

The 5-amp/hour battery in the BP01 will power the MIL PAC 300B transmitter for 191 hours at 32º F (0ºC). The 5 amp/hour

battery in the MP01 will power the MIL PAC 300B receiver for 191 hours at 32º F (0ºC) without any RF alarm transmissions.

The LN-XT-1 RF alarm transmitter draw about 12 microamps in standby and about 2 amps during transmission. Each RF

alarm transmitter is marked in each MP01. Instructions are provided in the event you need or want to change the channel.

For additional information or details, please see the MIL PAC 300B data sheet and the Model 300B Technical Manual.

15

MIL PAC 310 OPERATING INSTRUCTIONS____________________________________________

A single MIL PAC 310B may cover a distance up to 1500 feet (457m). The receiver is equipped with automatic gain-control

(AGC) that automatically adjusts receiver for the distance to be covered.

Maximum width is attained when Transmitter-Receiver distance is maximum and Receiver “Sensitivity” control is set to

maximum. Figure 16 illustrates how pattern width varies with Transmitter-Receiver distance and sensitivity setting. Actual

pattern will vary somewhat with site topography and surface condition. Generally, lower mounting height or rougher surface

will increase pattern width.

Figure 16 – MIL PAC 310B Pattern

Vertical protection pattern will also depend upon Transmitter-Receiver distance, mounting height and “sensitivity” setting. The

protection pattern above centerline will be approximately half of the horizontal patterns shown in Figure 16. The protection

pattern below centerline will tend to fill area between centerline and ground except for a “dead zone” immediately in front of

and below the transmitter and receiver. This “dead zone” requires that the transmitters and receiver be overlapped to provide

continuous detection. Figure 17 show a typical corner overlap and intermediate overlap for minimum to medium security

applications where detection of walking and running targets is the only requirement.

Figure 17 – MIL PAC 310B Overlaps

For maximum-security applications where detection of prone “commando” style crawl is required, the intermediate overlap

should be 60 feet (18.3m) minimum with parallel beam centerline offset of 18 inches (46cm) maximum. The corner overlaps

should be 30 feet (9.2m) minimum. Terrain flatness should be no more than plus three inches (7.62cm) or minus three inches

(7.62cm) deviation from a plane drawn between the transmitter and receiver. The zone length (transmitter to receiver) should

not exceed 600 feet (183m).

NOMINAL BEAM WIDTH - FEET

40

(12m)

30

(9m)

20

(6m)

10

(3m)

0250

(75m) 500

(152m) 750

(229m) 1000

(305m) 1250

(381m) 1500

(457m)

SENSITIVITY

MAX.

TOTAL LINK DISTANCE - FEET

0

MIN.

30 FEET

(9.2m)

TOP VIEW

CORNER OVERLAP OFFSET

18" - 20"

(46 - 51cm)

INTERMEDIATE OVERLAP

BEAM

CENTERLINE

TOP VIEW

60 FEET (18.3m)

16

The MIL PAC 310B must be located in an area that is free of obstructions and moving objects such as chain link fences, trees,

bushes, tall grass and large areas of water to avoid unwanted nuisance alarms. The clear area (both sides of centerline) for

installation depends upon the distance to be covered by the link. The area should be wider that the maximum detection pattern

for a specific distance as shown in Figure 16.

SETUP & TESTING

1) Complete steps 1-6 in the Unpacking and Tripod Setup on page 12.

2) Remove the radome of the transmitter by removing the six-radome screws to reveal the electronics as shown in Figure 15.

3) Connect the Modulation Frequency jumper wire E10 to one of the four field selectable modulation channels, A, B, C or D.

Note: Use different channels on links operating within close proximity.

4) Connect the BP01 to the transmitter with the interconnect cable. Turn the Power and Battery On/Off switches to “On” and

make sure the Power LED indicator illuminates.

5) Remove the radome of the receiver by removing the six-radome screws to reveal the electronics as shown in Figure 15.

6) Connect the Modulation Frequency jumper wire E9 to the field selectable modulation channel that you set on the

transmitter (A, B, C or D). NOTE: Once you have set the same modulation channel on both transmitter and receiver, mark

the units with that channel for future use. Once set and marked, steps 3 and 6 can be omitted.

7) Connect the MP01 to the receiver with the interconnect cable. Attach RF alarm transmitter antenna. Turn the Power and

Battery On/Off switches to “On”.

8) Set function switch to “P/S” (power supply). Meter should read between 0.4 and 0.6 corresponding to 11.0 to 13.8 VDC

from battery.

9) Set function switch to “REG P/S” (regulated power supply). Meter should read between 0.4 and 0.6 indicating that the

receivers 8 VDC regulated voltage is present.

10) Visually aim the transmitter and receiver for “bore sight” (pointing at each other) alignment. Set the function switch to

“ALIGN”.

11) Move the Align/Latch – Normal jumper wire E1 (see Figure 15) on the receiver to the Latch position.

12) Slowly swivel transmitter a few degrees horizontally and vertically. Watch the meter and secure transmitter at position that

produces highest alignment signal. Raise and lower height of transmitter to position that produces highest alignment

signal. Repeat same process for the receiver. The minimum meter reading for proper operation is 0.1.

13) Move the Align/Latch – Normal jumper wire E1 (see Figure 15) on the receiver to the Normal position.

14) Set function switch to “SENS” (sensitivity). The meter should read mid scale, indicating ambient (no intrusion) condition.

Set alarm selector to “LIGHT” or “AUDIO”.

15) Test the link for desired coverage. While watching the meter, an alarm should occur when the meter gets below 0.2 or

above 0.8. Adjust the detection pattern by turning the sensitivity potentiometer (R40) on the receiver (see Figure 15).

Clockwise will increase the sensitivity and counterclockwise will decrease the sensitivity.

16) Observe meter for effect of possible nuisance alarm sources such as close proximity fences or vegetation that may move in

the wind. The meter in the sensitivity setting should be relatively stable. Large fluctuations on the meter need to be

investigated.

17) Set Radio switch to “ON”. Generate an alarm to ensure the RF alarm signal is transmitted and displayed at the radio

receiver/annunciator.

18) Replace radomes using all screws. Close BP01 and MP01 covers. Connect external DC source, if used, to MP01 or BP01.

17

The 5-amp/hour battery in the BP01 will power the MIL PAC 310B transmitter for 25 hours at 32º F (0ºC). The 5 amp/hour

battery in the MP01 will power the MIL PAC 310B receiver for 191 hours at 32º F (0ºC) without any RF alarm transmissions.

The LN-XT-1 RF alarm transmitter draw about 12 microamps in standby and about 2 amps during transmission. Each RF

alarm transmitter is marked in each MP01. Instructions are provided in the event you need or want to change the channel.

For additional information or details, please see the MIL PAC 310B data sheet and the Model 310B Technical Manual.

MIL PAC 380 and MIL PAC 385 OPERATING INSTRUCTIONS____________________________

A single MIL PAC 380 may cover a distance up to 200 feet (61m). A single MIL PAC 385 may cover a distance up to 400 feet

(122m). The transceiver is equipped with a continuously variable Range Cutoff (RCO) circuit that allows maximum detection

range to be established, thereby eliminating alarms caused by objects beyond the desired detection range. The transceiver is

also equipped with Zero Range Suppression (ZRS) circuitry that reduces sensitivity to very close small objects. These

transceivers are built with staggered RF frequencies (Channel A and B) to help minimize mutual interference.

Maximum distance and width is attained when the transceiver is set to maximum RCO and “Sensitivity” control is set to

maximum. The MIL PAC 380 RCO is adjustable from 50 to 200 feet (15 to 61M) with a pattern width variable from 3 to 24

feet (0.91 to 7.3m). The MIL PAC 385 RCO is adjustable from 100 to 400 feet (30 to 122m) width a pattern width variable

from 3 to 20 feet (0.91 to 6.1m). Figure 18 shows the vertical and horizontal pattern. The RCO control adjusts the maximum

range of the system and the sensitivity control primarily adjusts the width.

Figure 18 – MIL PAC 380 and MIL PAC 385 Patterns

In order to provide uninterrupted detection and secure the “dead zone” immediately in front of and below the transceiver, an

additional unit must provide overlap. Figure 19 shows some typical overlap configurations.

For maximum-security applications where detection of prone “commando” style crawl is required, additional overlap or special

site preparation may be required. Terrain flatness should be no more than plus three inches (7.62cm) or minus three inches

(7.62cm) deviation. The detection area for the MIL PAC 380 should not exceed 150 feet (45.8m). The detection area for the

MIL PAC 385 should not exceed 350 feet (106.7m).

The MIL PAC 380 or MIL PAC 385 must be located in an area that is free of obstructions and moving – shaking - vibrating

objects such as chain link fences, trees, bushes, tall grass, metal structures and large areas of water to avoid unwanted nuisance

alarms. The sensitivity should always be adjusted to the absolute lowest setting that will meet site security requirements. An

excessively high sensitivity setting may make the transceiver susceptible to nuisance alarms from outside sources. These

sensors respond to any motion within the detection pattern. The clear area (both sides of centerline) for installation depends

upon the distance to be covered. The area should be wider than the maximum detection pattern.

SENSITIVITY MINIMUM

SENSITIVITY MAXIMUM

ACTIVE

DETECTION

PATTERN

CUTOFF

RCO

CONTINUOUSLY

VARIABLE

100' MIN 400' MAX

(3.4m)

(30m) (122m)

A) HORIZONTAL PATTERN

B) VERTICAL PATTERN

11' MAX

PATTERN

HEIGHT

SENSITIVITY MINIMUM

SENSITIVITY MAXIMUM

ACTIVE

DETECTION

PATTERN

CUTOFF

RCO

CONTINUOUSLY

VARIABLE

50' MIN 200' MAX

(4.5m)

(15m)

(61m)

A) HORIZONTAL PATTERN

B) VERTICAL PATTERN

15' MAX

PATTERN

HEIGHT

MIL PAC 380 MIL PAC 385

18

Figure 19 – MIL PAC 380 or MIL PAC 385 Overlaps

The SYNC SWITCH and ADDRESS SELECT SWITCH as shown in Figure 20 is not used in the MIL PAC 380 or MIL PAC

385 configurations. These are used, when required, in fixed installation projects.

Figure 20 – MIL PAC 380 and MIL PAC 385 Transceivers

SETUP AND TESTING_________________________________________________________________________________

1) Complete steps 1-6 in the Unpacking and Tripod Setup on page 12.

2) Remove the radome of the transceiver by removing the six-radome screws to reveal the electronics as shown in Figure 20.

3) Orient the MIL PAC transceiver in the direction of the required detection zone.

4) Set the transceivers RCO and Sensitivity to the nominal desired range.

5) Connect the MP01 to the transceiver with the interconnect cable. Attach RF alarm transmitter antenna. Turn the Power and

Battery On/Off switches to “On”.

6) Set function switch to “P/S” (power supply). Meter should read between 0.4 and 0.6 corresponding to 11.0 to 13.8 VDC

from battery.

OVERLAP AREA

Overlap Area

Overlap Area

30 FEET (9.1M)

POWER LED

LOCK LED

ALARM LED

RANGE CUT-OFF ADJUST

(Side Front of Enclosure) SENSITIVITY ADJUST

(Top Front of Enclosure)

ADDRESS SELECT

SWITCH, (CAPPED)

POWER

ALARM

LOCK

ADRS

FUSE 1A

SYNC

SWITCH

TAMPER

SWITCH

MIL PAC 385

POWER LED

LOCK LED

ALARM LED

RANGE CUT-OFF ADJUST SENSITIVITY ADJUST

(Top Front of Enclosure)

ADDRESS SELECT

SWITCH, (CAPPED)

POWER

ALARM

LOCK

ADRS

FUSE 1A

SYNC

SWITCH

TAMPER

SWITCH

MIL PAC 380

19

7) Set function switch to “REG P/S” (regulated power supply). Meter should read between 0.4 and 0.6 indicating that the

receivers 8 VDC regulated voltage is present.

8) Set the function switch to “ALIGN”. The meter should read between 0.3 and 0.6. A lower or higher reading may indicate

high reflections from the site that may cause nuisance alarms.

9) Set function switch to “SENS” (sensitivity). The meter should read mid scale, indicating ambient (no signal) condition.

Reflected signals will cause the meter to swing about this point. Set alarm selector to “LIGHT” or “AUDIO”. An alarm

will occur when the meter gets below 0.2 or above 0.8. Note: the meter may be to slow to fully react to very rapid

movement.

10) Test the transceiver for desired coverage. Adjust the detection pattern by turning the sensitivity potentiometer and the RCO

potentiometer (see Figure 20). Clockwise will increase the sensitivity and RCO and counterclockwise will decrease the

sensitivity and RCO.

11) Observe meter for effect of possible nuisance alarm sources such as close proximity fences or vegetation that may move in

the wind. The meter in the sensitivity setting should be relatively stable. Large fluctuations on the meter need to be

investigated.

12) Set Radio switch to “ON”. Generate an alarm to ensure the RF alarm signal is transmitted and displayed at the radio

receiver/annunciator.

13) Replace radomes using all screws. Close MP01 covers. Connect external DC source, if used, to MP01.

The 5 amp/hour battery in the MP01 will power the MIL PAC 380 or MIL PAC 385 transceiver for 25 hours at 32º F (0ºC)

without any RF alarm transmissions. The LN-XT-1 RF alarm transmitter draw about 12 microamps in standby and about 2

amps during transmission. Each RF alarm transmitter is marked in each MP01. Instructions are provided in the event you need

or want to change the channel.

For additional information or details, please see the MIL PAC 380 or MIL PAC 385 data sheet and the Model 380 or Model

385 Technical Manual.

POWERING DOWN and PACKING UP__________________________________________________

1) Turn all “On/Off” switches on the BP01 or MP01 to the “Off” position.

2) Disconnect the Interconnect Cable from the BP01 and MP01 and the transmitter, receiver or transceiver. Pack cable in

carrying case.

3) Remove antenna from the MP01 and pack in carrying case.

4) Close covers on BP01 and MP01 and pack in carrying case. Charge batteries as needed.

5) Remove sensor from tripod and pack in carrying case.

6) Collapse tripod and pack in carrying case.

LIMITED WARRANTY_________________________________________________________________

Southwest Microwave, Inc. warrants each of its Security Products to be free from defects in materials and workmanship. The limit

of liability under this warranty is to repair or replace any Security Product or part thereof which shall within one year after

delivery to the original user, be returned, shipping costs prepaid and insured, to Southwest Microwave, Inc., at its plant in Tempe,

Arizona, or authorized Warranty Service Company, and which shall have been found to be defective upon examination by

Southwest Microwave, Inc. or authorized Warranty Service Company.

20

This warranty shall be limited to the repair or replacement of Southwest Microwave, Inc. equipment and shall not extend to any

incidental or consequential damages therefrom. Disassembly of any Security Product by anyone other than an authorized

representative of Southwest Microwave, Inc. voids the obligations of Southwest Microwave, Inc., to repair or replace any product

so disassembled.

Excluded from this warranty, are light bulbs, fuses and batteries except to the extent that the original manufacturer warrants such

parts and such warranty are marked on the product. Claim under warranty for the purchaser should make light bulbs, fuses or

batteries directly to the manufacturer.

Warranty returns must first be authorized by Southwest Microwave, Inc., or an authorized Warranty Service Company.

Southwest Microwave, Inc., reserves the right to make changes in design on any of its products without incurring any obligation to

make the same changes on units previously purchased.

This warranty is the extent of the obligations or liabilities assumed by Southwest Microwave, Inc. with respect to its

products and is in lieu of all other warranties, express or implied, including, but not limited to, any warranty or

merchantability or fitness. Southwest Microwave, Inc. shall not be liable for consequential damages and its liability is

expressly limited to the obligations expressed herein. Southwest Microwave, Inc. neither assumes nor authorizes any other

person to assume for it any other warranty concerning its products.

THIS DEVICE COMPLIES WITH FCC RULES PART 15. Operation of this device is subject to the

following two condition: 1. This device may not cause harmful interference. 2. This device must accept

any interference that may be received, including interference that may cause undesired operation.

RETURNING EQUIPMENT UNDER WARRANTY_______________________________________

As per the provisions set forth in our security products warranty, any person desiring to return equipment to Southwest

Microwave, Inc. for any reason, must first contact Southwest Microwave, Inc. for authorization of return.

An authorization number will be issued at the time of authorization, and this number will appear on all correspondence, invoices

and credits pertaining to subject equipment.

All Southwest Microwave, Inc. sensors and power supplies are provided with a serial number at the time of manufacture. In order

to accurately and efficiently supply replacement parts, perform repair service, or issue credit on equipment being returned to

Southwest Microwave, Inc. it is essential that Southwest Microwave, Inc. be advised of the serial number of the equipment prior

to authorization for return. This notification may be made by telephone or by mail.

RETURNING EQUIPMENT FOR NON-WARRANTY REPAIR______________________________

Southwest Microwave, Inc., at which time a return authorization number will be issued, must first authorize return of equipment

out of warranty. The returned equipment must be accompanied by an evaluation repair purchase order. Returned equipment will

be examined and customer advised of cost of repair or replacement.

REPLACEMENT PARTS_______________________________________________________________

To order a replacement or module, specify the complete part number and serial number and address the order to:

SOUTHWEST MICROWAVE, INC.

Service Department

9055 S. McKemy Street

Tempe, Arizona 85284-2946

TEL (480) 783-0201

FAX (480) 783-0401

www.southwestmicrowave.com

This manual suits for next models

3

Table of contents