WHISPER 100/WHISPER 200 24 Foot Tower Manual Document #0026 REV E

SOUTHWEST WINDPOWER 5/20/05 3

Introduction

This tower kit is designed specifically for the Southwest Windpower WHISPER 100 and

WHISPER 200 wind turbines. To our knowledge this is the most economical and user-friendly

tower kit available for the Whisper wind turbines. One level, guy wire supported construction

allows the use of lightweight tubing while providing plenty of strength, even in high wind

conditions. With the help of a winch, beast of burden or vehicle, two people can easily erect the

tower in a few hours. All that is required is the necessary tubing and the proper anchors for your

type of soil. At least two people should be present to safely raise the tower.

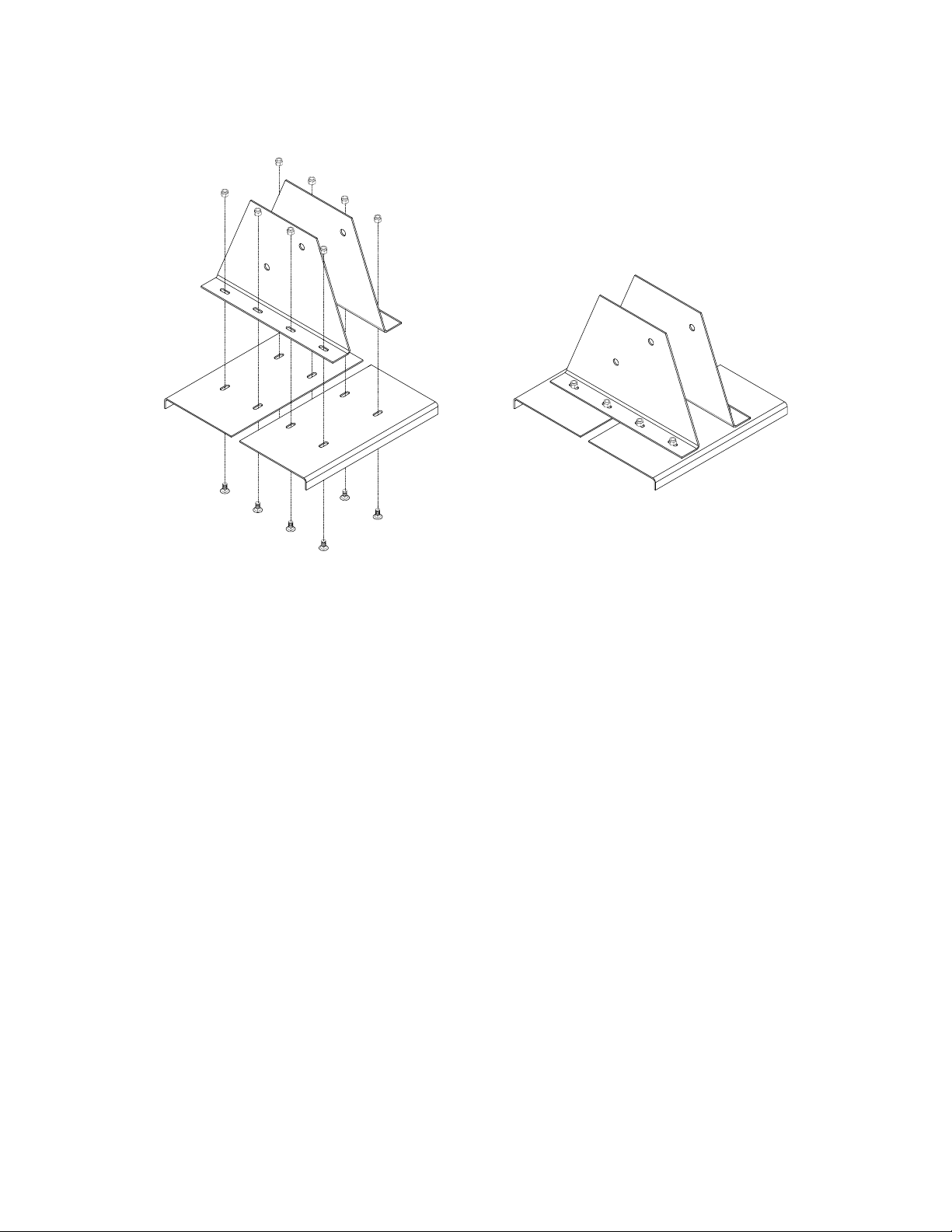

This Whisper tower kit includes a custom made galvanized base with separate pivots for both the

tower and gin pole (not used on 24 foot tower). The tower base has a footprint of 16 inches square.

In most cases a concrete pad for the tower base is not necessary.

A simple extruded aluminum coupling clamp allows the use of different wall thickness of tubing,

depending on site requirements. Threaded coupling points are eliminated, allowing lighter

materials to be used with the same or greater strength than a threaded pipe tower. The guy wire

attachment clamps onto the upper mast section. This reduces the number of pieces of tubing used

to construct the tower and reduces the stresses concentrated at this point. Pre-cut and swaged guy

wires eliminate wire measuring and cutting. We believe this kit and assembly method is the easiest

way possible to put the WHISPER 100 or WHISPER 200 up in the air.

Thank you for purchasing our products and for your interest in renewable energy. We are confident

that you will enjoy the benefits of your wind powered electrical system for many years to come. If,

after reading this manual, you have any further questions please contact your local dealer or

Southwest Windpower and we will do our best to assist you.

Safe Installation

Safety is the most important consideration to take into account when installing a tower and

wind turbine. It is very important to remember that any wind turbine has high speed spinning

parts and can be very dangerous if not installed properly! Be sure the tubing or pipe used for the

tower is of adequate strength, all bolted connections are tightened to the proper torque and the guy

wire anchors are suitable for your conditions, terrain and size of tower. All of these elements are

explained in further detail later in this manual. Important! Choose a very calm day to do your

installation. A gust of wind at the wrong moment could cause VERY SERIOUS

PROBLEMS!

PLEASE…. READ THIS ENTIRE MANUAL BEFORE DOING ANYTHING!