Southwest martin yale CR828 Owner's manual

Electric Smart Crease

Model CR828

Owner/Operator Manual

Specifications

Speed 800 Cycles/Hour

Sheet Size Minimum (L x W) 2.00” x 0.25” (8.0cm x 0.5cm)

Sheet Size Maximum (L x W) 28.00” x 18.20” (71.0cm x 46.2cm)

Maximum Paper Weight 16 pt / 0.016” Caliper/ 130# Cover / 341 gsm

Crease Width 0.075” (1.9mm)

Crease Depth 0.015” (0.4mm)

Dimensions (L x W x H) 24” x 20.6” x 6.9” (61cm x 52.3cm x 17.5cm)

Shipping Weight 40 lbs

Electrical 110-120VAC, 50/60 Hz, 2.5 Amp

Plug (North America) Nema 5-15

Serial No. __________________________________

Martin Yale Electric Smart Crease Model CR828

1.0 Introduction

Thank you for selecting the Martin Yale Electric Smart Crease. We recommend that you familiarize

yourself with the creaser by carefully reading these instructions. A thorough understanding of the

information contained within these instructions will help to eliminate most operator associated errors

and ensure years of trouble-free performance.

2.0 Safety Notes

The creaser may not be operated by more than one person at any given time! The machine

was designed for safe operation by “one person only”.

During the creasing process no other work may be performed on the machine (for example

cleaning, etc.).

The Creaser is not a toy, and is not suitable for use by children! The overall technical safety

concept of this machine (dimensions, feed opening, etc.) does not provide for any guarantee

regarding hazard-free operation by children.

Danger of injury! Keep all loose articles of clothing, ties, jewelry, long hair, or other loose

objects away from opening.

Danger of injury! Never insert fingers into opening.

In case of danger, switch the creaser off with the mains switch or unplug the machine.

Always unplug the machine from the mains power supply before opening the machine.

Repairs may only be performed by trained personnel!

Warning: Moving parts can crush and cut!

Warning: Electrical Hazard!

This unit should be fed with card stock! Creasing other types of materials can cause injuries

or may damage the electric creaser (e.g. destruction of the unit)

The socket outlet shall be installed near the equipment and shall be easily accessible.

Only operate this machine in an enclosed office environment. Keep enough distance to the

surroundings when installing the machine.

3.0 Features

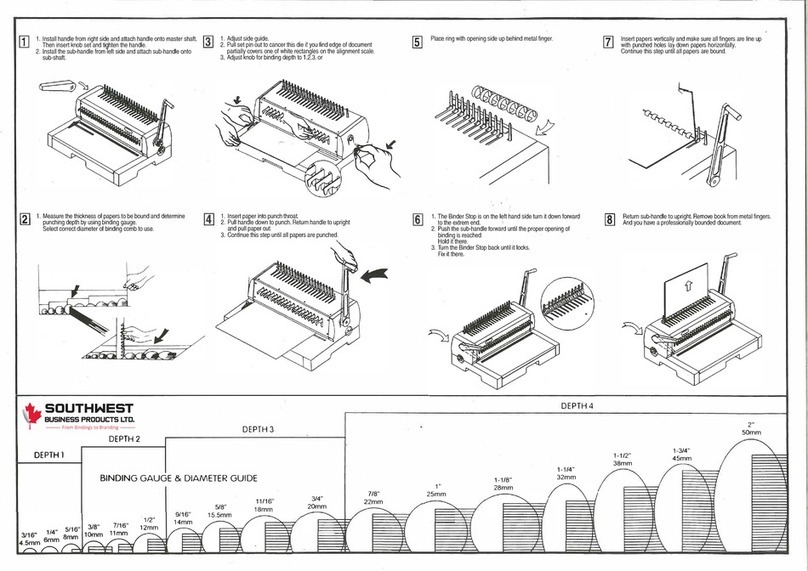

3.1 Overview (Figure 1)

1. Back Paper Stop

2. Paper Guides with Rulers

3. Front Paper Stop

4. Work Surface

5. Power Supply

6. Control Panel

7. Footpedal

FIGURE 1: Overview

3.2 Control Panel (Figure 2)

1. Green Power Indicator

2. Footpedal On/Off Indicator

3. Reverse (Dejam) Indicator

4. Cycle Pushbutton

5. Footpedal On/Off Pushbutton

6. Reverse (Dejam) Pushbutton

FIGURE 2: Control Panel

3.3 Rear View (Figure 3)

1. Power Switch

2. Footpedal Cable

3. Power Supply Jack

FIGURE 3: Rear View

4.0 Setup

4.1 Prepare a flat, level, sturdy work area on which to set the creaser.

4.2 Carefully remove the creaser from the packaging and set on work area.

4.3 All six (6) rubber foot pads should be in contact with the work area.

4.4 Inspect creaser for shipping damage and/or missing components.

4.5 Remove two (2) Paper Stops from packaging and install as shown. (Figure 1)

4.6 Position Foot Pedal on the floor in a convenient and comfortable location.

4.7 Plug the Power Adapter into the back of the machine next to the Foot Pedal cable, then

plug the Power Adapter into power outlet. (Figures 1 and 3)

Congratulations! Your brand new Martin Yale Electric Smart Crease is now ready for use!

2

1

5

7

4

6

3

1

2

3

4

5

6

1

2

3

5.0 Operation

5.1 Slide each Paper Stop into the desired position, then hand-tighten thumb screws. (Figure 4)

See the chart below as a guide for some common paper/card sizes and fold types.

Paper Size

Fold Type

Back Paper Stop

Front Paper Stop

8½” x 11”

Card

5 ½”

Not Used

Letter/Z

7 5/16”

7 5/16”

11” x 17”

Card

8 ½”

Not Used

Letter/Z

5 ⅝”

Rotate Paper

Card Size

Fold Type

Back Paper Stop

Front Paper Stop

A2 (4¼” x 5½”)

Card

4¼”

Not Used

Gate

2 1/8”

2 1/8”

A6 (4½” x 6¼”)

Card

4½”

Not Used

Gate

2¼”

2¼”

A7 (5” x 7”)

Card

5”

Not Used

Gate

2½”

2½”

NOTE: Always test setup on scrap paper to ensure proper settings; adjust as necessary.

5.2 The Footpedal control is turned on by default; to turn off the Footpedal, press the center

button on the Control Panel. (Figure 2)

NOTE: Cycle Pushbutton will work with foot pedal either on or off.

5.3 With insideface DOWN, slide paper into Creaseralong thepaperguide until it contacts Back

Paper Stop. (Figure 5)

NOTE: Align edge of paper with Paper Guides; DO NOT align edge of paper with Paper Stops.

FIGURE 4: Adjust Paper Stops FIGURE 5: Paper Against Back Paper Stop

5.4 While holding paper in place, press the Footpedal (Figure 1) or Cycle Pushbutton (Figure 2).

5.5 Wait for the Creaser to cycle once; cycle time is approximately 1 second.

5.6 For single crease operation only: remove paper and fold as shown (Figures 6 and 7).

5.7 For performing a second crease operation:

5.7.1 Slide paper to Front Paper Stop (flip inside face up for Z fold); repeat steps 5.4-5.5.

5.7.2 For larger paper where 2 stops are not used, rotate paper 180°, slide paper to Back

Paper Stop (flip inside face up for Z fold) and repeat steps 3.4-3.5.

5.7.3 Remove paper and fold all creases as shown (Figures 6 and 7).

5.8 Check edges for alignment and square. Make any fine adjustments as necessary.

FIGURE 6: Note Orientation of Crease FIGURE 7: Fold Panels Downward as Shown

6.0 Maintenance

The Martin Yale Model CEZ Creasertypically requires very little maintenance, however the following

items will ensure years of trouble-free, safe and satisfactory use:

6.1 Clean unit as needed with a slightly damp rag using water or window cleaner.

6.2 Periodically use a can of compressed air to blow out dust and debris from the Creaser slot.

6.3 Frequently check the Power Supply and Footpedal wires for damage and wear.

7.0 Troubleshooting

7.1 No Power, Green Power LED is off:

1. Unit not plugged in or outlet is dead; check connections.

2. Power switch is off; turn switch on.

3. Desktop power supply is damaged; replace power supply.

4. Electrical failure; have unit serviced by qualified technician.

7.2 Creaser will not function, Green Power LED is on:

1. Creaser unit jammed; see “Machine Jam”instructions below.

2. Self-resetting circuit breaker in Creaser has tripped; turn unit off for 15 seconds to reset.

3. Electrical failure; have the unit serviced by qualified technician.

7.3 Machine Jam: If the Creaser jams, both yellow lights will blink on and off repeatedly.

1. Press the Reverse (Dejam) Pushbutton (Figure 2). The Reverse (Dejam) Indicator light

will now be lit continuously.

2. Press the Cycle Pushbutton; this will cause the machine to reverse, releasing the jam.

3. Remove paper and correct the cause of the jam before attempting another crease.

Typical causes of jams include foreign objects and improper paper size or thickness.

4. If jam will not clear, contact Technical Support.

Note on the Reverse (Dejam) function: Under normal machine operation, the creaser is

not allowed to run in reverse. To test the reverse feature, hold the Reverse (Dejam)

Pushbutton down while pressing the Cycle Pushbutton. This action forces the Creaser torun

in reverse and should only be used to confirm proper function of the reverse feature.

For continued malfunction or other issues, contact Technical Support at 1-800-225-5644.

Other Southwest Binding Machine manuals