Dickey-John Control Point User manual

OPERATOR'S MANUAL

CONTROL POINT™ SYSTEM DESCRIPTION/ 1

11001-1100-199904 Revision A

CHAPTER 1 – SYSTEM DESCRIPTION

The DICKEY-john Control Point™ system uses three-channels (three separate

controlled servo loops) on spreader vehicles to simultaneously control the

spreading of granular and liquid ice-control materials. Two channels control

granular and liquid application rates and the third channel precisely controls

spinner speed to maintain even material coverage over the desired spread

width. The dispensing rate varies directly with ground speed to ensure accu-

rate product application.

Material can also be spread at a preset “BLAST” application rate. This is

normally a very large rate to instantly adjust the target APR (application rate)

for covering bridges and intersections with a much heavier amount of material.

GRANULAR CHANNEL CONFIGURATION

The granular channel controls the amount of material dumped onto the

spinner plate(s). To do this, the Control Point™ monitors a tachometer style

feedback sensor located on the V-box drag chain or tailgate auger. A resultant

drive signal adjusts the conveyor mechanism speed to deliver the target

application rate (APR) by regulating the hydraulic valve position.

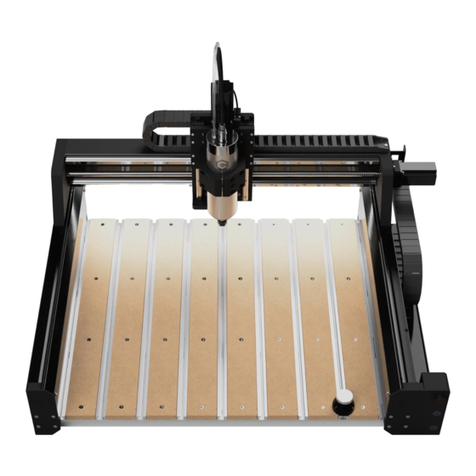

Figure 1. System Components

OPERATOR'S MANUAL

2/ SYSTEM DESCRIPTION CONTROL POINT™

11001-1100-199904 Revision A

LIQUID CHANNEL CONFIGURATION

The liquid channel controls the application rate of prewetting or deicing

materials. When prewetting, the Control Point™ Console monitors a flowmeter

style feedback sensor. When deicing, either a flowmeter or pressure style

feedback can be used. Using feedback data, the pumping mechanism output

adjusts the target application rate by either regulating pump speed or flow

blocking.

Deicing systems use up to five boom inputs for applying material to more than

one lane at a time.

SPINNER CHANNEL CONFIGURATION

The spinner channel controls the spinner plate(s) speed with either a closed-

loop (precision) or an open-loop configuration. In the closed-loop configura-

tion, a tachometer style feedback sensor, mounted on the spinner assembly,

monitors spinner activity. Using the feedback data, the spinner mechanism

speed adjusts for the target setting by controlling the hydraulic valve position.

In open loop systems, the hydraulic valve position is relative to the WIDTH

ADJUST knob setting on the Control Point™ Switch Module.

The customer must determine the spread-width accuracy needed. DICKEY-

john Marketing and Product Service personnel are available with additional

information to help with this decision.

PRODUCT APPLICATION MECHANISMS

The granular and spinner channels use, in addition to feedback (shaft rotation)

sensors, either servo valve actuators or proportional valves to control the

product application and spinner speed. The liquid channel uses, in addition to

feedback sensors (flowmeter or pressure transducer), a liquid pump to control

product application. The liquid pump output is controlled by either a 12 volt

DC motor, servo valve actuator, or proportional valve.

OPERATOR'S MANUAL

CONTROL POINT™ SYSTEM DESCRIPTION/ 3

11001-1100-199904 Revision A

SYSTEM FEATURES AND CAPABILITIES

1. Easy installation - surface-mounting Console kit.

2. Switch Module located anywhere in the cab to allow optimum

placement for the operator.

3. Large 160X128 dot-matrix LCD display with backlighting for

nighttime viewing.

4. Single Console button for system power on/off and screen selec-

tion.

5. RS-232 port for PC uploading and downloading of data.

6. Detachable keyboard for easy supervisor programming and

calibration using multilevel, menu-driven screens.

7. Custom programming available to minimize setup time.

8. Compatibility with a variety of sensors, servo valve actuators, and

proportional valves available from DICKEY-john or other manu-

facturers.

9. Audible and visual alarms for system and operator errors.

SYSTEM COMPONENT DESCRIPTIONS

A DICKEY-john Control Point™ system consists of six basic components;

(1) Console, (2) Switch Module, (3) ground speed sensor, (4) feedback devices to

monitor material application, (5) actuator devices to regulate material application,

and (6) harnesses to interconnect all system devices. The detachable keyboard

(optional) and PC (not provided) are programming aids and not actually a part of

a basic Control Point™ system.

Figure 1 illustrates the Console, Switch Module, and keyboard. Figure 2 shows

components in a block diagram. The Console and Switch Module are located

inside the truck cab. These two items may be mounted side-by-side or the Switch

Module can be positioned for operator convenience.

A. Console

The Console displays information on a dot-matrix LCD and uses a single push-

button switch to control system power and to view several operator screens.

Using an external keyboard for programming and placing operator controls on

the Switch Module greatly simplify the Console.

An RS-232 port connector, located on the Switch Module harness, permits data

transfer to and from the Console. This port interfaces to a PC for downloading

accumulator and alarm information. When replacing a console or when identical

vehicles require programming/calibrating, uploading and downloading configura-

tion information through the port is extremely useful. For multiple units, only one

system needs to be programmed and then the constants can be transferred

(downloaded) from that console, stored in a PC file, and uploaded to the other

vehicle's console. Note: This is only useful on identical vehicles.

OPERATOR'S MANUAL

4/ SYSTEM DESCRIPTION CONTROL POINT™

11001-1100-199904 Revision A

B. Switch Module

The Switch Module harness plugs into the Console and contains connectors for

both keyboard and PC interface as described above.

The operator controls the real-time functions of the Control Point ™ system

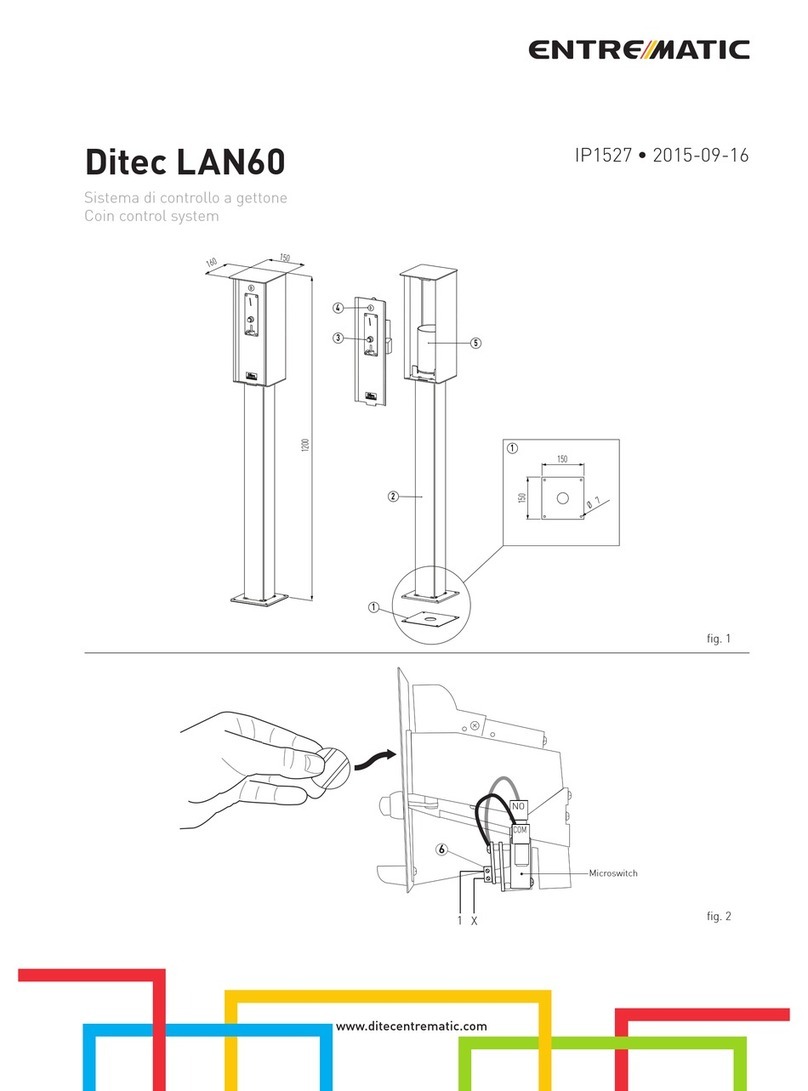

from the seven switches on the Switch Module. (See Figure 3).

C. Keyboard

The keyboard is the means the operator uses to program and calibrate the

system. The 86-key, alphanumeric, PC-compatible keyboard has been environ-

mentally hardened for use in the ice-control field. After programming and

calibration are finished, the keyboard is usually disconnected and stored.

D. Ground Speed Sensor

The ground speed sensor generates vehicle speed information for the console.

Sensor electrical pulses proportional to the vehicle ground speed are vital to

system operation because true vehicle ground speed is necessary for accurate

product application. The system can function with a wide variety of electronic

and mechanical speedometer sensors, including Hall-Effect and Reluctance

sensors.

Figure 2. System Block Diagram

OPERATOR'S MANUAL

CONTROL POINT™ SYSTEM DESCRIPTION/ 5

11001-1100-199904 Revision A

E. Feedback Sensors

The feedback sensors send product flow information to the console for accurate

product application. Both granular and spinner channels require pulsed

electrical sensors having an output proportional to the mechanism speed. The

liquid channel accepts either electrical pulsed sensors or analog sensors with

outputs proportional to material flow (pulsed) or system pressure (analog). A

liquid prewetting system only accepts pulsed feedback while higher capacity

anti-icing systems accept either pulsed or analog.

F. Actuator Devices

Actuator devices regulate material flow for accurate control of product applica-

tion rates. Normally, granular and spinner channels regulate the hydraulic oil

flow rate to a motor. Liquid channels use several different configurations. Many

prewetting systems use a DC pump to regulate flow by controlling pump speed.

Other systems use hydraulically driven pumps similar to agricultural applica-

tions.

G. Hopper Level Sensor (Optional)

The optical light beam of this level sensor is blocked by the granular material in

the spreader bed. When the material level falls beneath the sensor mounting

level, a repetitive beep sounds and an appropriate message displays in the

warning/alarm area of the OPERATE screen.

I. Harnesses

The Main Harness assembly connects the Console to the ground speed sensor,

feedback sensors, channel valve (or DC motor) actuators, vehicle battery,

ignition, and additional optional connections (including two-speed axle, hopper

level sensor, and boom sense inputs). An optional Extension Harness, allows

the Main Harness to extend outside the cab, contains duplicate connectors to

permit hookup flexibility. Other extension harnesses are available to allow

flexible sensor arrangement.

HOW TO OBTAIN TECHNICAL SUPPORT

For prompt and courteous assistance and answers to your questions, call

DICKEY-john Technical Support at (217) 438-3371 or Fax (217) 438-6012 or

438-6539. For toll-free calls in either the USA or Canada, dial 1-800-637-3302.

OPERATOR'S MANUAL

6/ SYSTEM DESCRIPTION CONTROL POINT™

11001-1100-199904 Revision A

OPERATOR'S MANUAL

CONTROL POINT™ OPERATING PROCEDURES/ 7

11001-1100-199904 Revision A

CHAPTER 2 – OPERATING PROCEDURES

This chapter explains how the operator (driver) of an ice-control vehicle uses

the controls on the Switch Module and Console to perform standard operator

functions. Note: The detachable keyboard (optional) is required to program and

calibrate the system as described in the next Chapter.

Depending upon programming, the operator can view three or four different

screens of data. The OPERATE screen is the home screen for monitoring

spreader operation; the remaining screens are supportive – MATERIAL

SELECT/MANUAL SPEED, CURRENT TOTALS, and SEASON TOTALS.

The MATERIAL/MANUAL SPEED SELECT screen is only accessible if the

system is stationary (no ground speed).

PREPARING FOR OPERATION

Perform the following procedures only after the system is installed, properly

programmed and calibrated. Practice the following procedures with the vehicle

stationary to gain familiarity with the operating controls and screens before

applying product.

Figure 3. Switch Module Controls and Definitions

OPERATOR'S MANUAL

8/ OPERATING PROCEDURES CONTROL POINT™

11001-1100-199904 Revision A

STARTING THE SYSTEM

1. Verify the MASTER Switch on

the Switch Module is in the

OFF position (See Figure 3).

If the Master Switch is in the

AUTO position during power up,

a warning message with audible

alarm occurs until the switch is

turned OFF (See Figure 4).

2. Turn on the ignition switch.

If the Console was on when the

ignition was last turned off, the

display comes on with the

ignition switch. A screen briefly

shows the DICKEY-john logo

followed by the OPERATE screen (See Figure 6).

If the console does not power on, the console button was used to

properly power down the unit. Proceed to Step 3.

3. Briefly press the Console button (less than a second) to apply

power to the Console (See Figure 5).

If the button is held too long, a beep sounds indicating

the Operate screen is skipped and an accessory screen

appears instead (This screen described later). If the beep

is heard, turn the console off as indicated in Step 4 and

start again.

During start-up (power up), the Console automatically

closes all system actuators and performs self-tests, includ-

ing system configuration and application data. If an error

occurs at power up or during operation, an appropriate

error message displays with recovery information.

4. Turn the Console off by pressing and holding the

Console button until a beep sounds and the text on

the screen disappears (approx. 3 seconds) and then

release.

Power is removed when the screen goes dark. To restart,

repeat Step 3.

Figure 4. Master Switch

Warning Message

Figure 5. Console Showing Functional Items

OPERATOR'S MANUAL

CONTROL POINT™ OPERATING PROCEDURES/ 9

11001-1100-199904 Revision A

OBSERVING THE OPERATE SCREEN DIVISIONS

1. Study the OPERATE screen layout (See Figure 6).

Three windows across the upper portion display Granular, Liquid,

and true (actual) Ground Speed data. Directly above, status of the

booms graphically display. Below the windows, error messages

appear briefly for system errors along with an audible alarm. In the

lower third, the Spread Width Bar graphically indicates percentage

of spinner activity via a black bar. At the bottom, the current date

and time display.

2. At the Switch Module, turn the Granular and Liquid ON/OFF

switches off, then back on again (See Figure 3).

Notice, the window for each product reads OFF and then returns to

the material and target (APR) values again.

Ground speed is independent of product application and therefore

displays only when the vehicle is moving.

Product application begins with vehicle motion if the Master Switch

is in the AUTO position. The actual APRs display in roughly twice

the size of the target APRs (See Figure 7).

3. Change the target rate of either product channel by pressing

the respective “INC/DEC +/-” switch on the Switch Module.

The value increments/decrements as a beep is heard for each inc/

des step. If the switch is held, the value repeats until reaching a

preset limit. If changed while the vehicle is moving, the new target

APR displays for approximately two seconds, then reverts to the

actual APRs.

Figure 6. Divisions of the OPERATE Screen

OPERATOR'S MANUAL

10/ OPERATING PROCEDURES CONTROL POINT™

11001-1100-199904 Revision A

4. Rotate the WIDTH ADJUST knob on the Switch Module

while observing the SPREAD WIDTH bar on the display.

The rotational speed of the spinner changes with the knob setting.

The horizontal bar graphically represents the position of the

SPREAD WIDTH knob. The bar is at the 100% position when the

knob is fully clockwise, corresponding to maximum spinner speed.

The operator determines the correct setting by observing the spread

pattern. The bar is hollow until the spinner is operating.

5. Note the date and time across the bottom edge of the screen.

6. Observe the boom graphics across the top of the screen.

All boom sections appear as rectangle blocks during anti-ice

operation. Each section is hollow until activated.

7. Observe the area for alarm messages.

Alarm messages appear (flashing) in the middle of the screen, above

the SPREAD WIDTH bar (See Figure 7).

Figure 7. OPERATE Screen Showing Product Application

OPERATOR'S MANUAL

CONTROL POINT™ OPERATING PROCEDURES/ 11

11001-1100-199904 Revision A

MATERIAL/MANUAL SPEED SELECT SCREEN

This screen is divided into two major divisions. The Material Select portion

(upper half) lists the products programmed for use. The Manual Speed

portion (lower half) allows selecting of an artificial ground speed signal in the

event the standard ground speed sensor fails. Without a ground speed signal,

the system is inoperative unless manual speed operation is selected.

This screen can only be accessed if (1) the vehicle is stationary (zero ground

speed), (2) the MASTER Switch is in the OFF position, and (3) more than

one material is listed in either list or manual ground speed has been enabled

during programming.

A. Selecting a different Dispersal Material

1. Press the Console button and release immediately after a

beep.

Figure 8 illustrates the MATERIAL/MANUAL SPEED SELECT

screen showing four materials for each product channel enabled.

2. Verify that the Granular ON/OFF and/or Liquid ON/OFF

switches on the Switch Module are ON.

The channel ON/OFF switch must be ON to select a different

material.

3. Press the INC/DEC +/-” switch of the appropriate channel

(granular or liquid), in either direction, to move the point-

er up or down on the left side of either list.

Figure 8. Screens Available to

Operator by Cycling

OPERATOR'S MANUAL

12/ OPERATING PROCEDURES CONTROL POINT™

11001-1100-199904 Revision A

B. Substituting Manual Speed for Standard Speed Sensor

If the ground speed signal is lost, the system ceases to function. If this occurs

due to a loss of sensor, cabling problems, etc., an artificial ground speed signal

can be substituted to continue limited operation. The fixed ground speed must

be previously programmed and then can be selected from the MATERIAL/

MANUAL SPEED SELECT screen (See Figure 8).

1. Stop the vehicle and turn the MASTER switch OFF. From the

OPERATE screen, press the Console button and release after

the beep to access the MATERIAL/MANUAL SPEED SE-

LECT screen.

2. Press the BLAST button to change the selection as prompted

at the bottom of the screen.

Notice the line stating “MANUAL ON”. As the BLAST button is

pressed, NO changes to YES. Releasing the button reverts to the

OPERATE screen. The ground speed window now displays the

word MANUAL at the bottom.

3. Continue spreading material, maintaining displayed speed as

closely as possible, to ensure accurate application.

The system spreads material but no accumulators are updated since

system accuracy cannot be assured. The related sensor and harness

should be inspected and repaired as soon as possible to restore

normal operation.

C. Returning to the OPERATE screen

1. Press the Console button three times, waiting for the beep

before releasing, to cycle back to the OPERATE screen (See

Figure 8 for all screens).

The OPERATE screen now shows the material name(s) just select-

ed, along with the correct (programmed) target APR.

ACCESSING THE CURRENT TOTALS SCREEN

If MANUAL SPEED operation has been selected (see heading MATERIAL/

MANUAL SPEED), this must first be deselected before the CURRENT

TOTALS screen can be cleared.

1. From the OPERATE screen, press and release the Console

button after the beep. Press a second time, if necessary, to

display the CURRENT TOTALS screen (See Figure 9).

The MASTER Switch must be in the OFF position before any other

screen can be accessed.

The CURRENT TOTALS screen (See Figure 9) appears showing

totals accumulated for the current product selected.

To see other totals, return to the MATERIAL/MANUAL SELECT

screen and select those products.

Figure 9. CURRENT TOTALS

Screen

OPERATOR'S MANUAL

CONTROL POINT™ OPERATING PROCEDURES/ 13

11001-1100-199904 Revision A

CLEARING THE CURRENT TOTALS

The ability to clear the CURRENT TOTALS screen is programmable in

the Programming mode (See PROGRAMMING chapter). If so pro-

grammed, all totals on this screen should be recorded before clearing, then

proceed as follows.

1. With the Granular switch on, (top half of the screen), press

the Granular +/- (left) switch up and release when the

beep sounds.

A message “PRESS DEC TO CONFIRM CLEAR (product)

ACCUMS (accumulators)” appears.

2. Next, press the same switch down (decrement) and the

totals reset to zero (See Figure 10).

To clear the bottom half, repeat the steps for the liquid channel

with the Liquid +/- (right) switch (See Figure 11). Press the

console button to stop the clear operation.

ACCESSING THE SEASON TOTALS SCREEN

1. From the OPERATE screen, press and release the Console

button after the beep. Repeat until the SEASONS TOTAL

screen appears (See Figure 12).

This screen shows the amount

of material applied, miles

traveled during application,

and hours elapsed this season

for each product in both the

AUTO and BLAST modes.

The totals can only be cleared

in the Program Mode (key-

board).

Figure 12. SEASON TOTAL

Screen

Figure 10. Clearing top half of

CURRENT TOTALS Screen

Figure 11. Clearing Bottom Half

of CURRENT TOTALS Screen

OPERATOR'S MANUAL

14/ OPERATING PROCEDURES CONTROL POINT™

11001-1100-199904 Revision A

USING THE BLAST BUTTON

Pressing the red BLAST button (on the left side of the Switch Module) causes

material to dispense at a higher, programmed rate. The BLAST button per-

forms several functions, depending upon programming options.

1. With the Operate screen displaying, press the Blast button on

the side of the Switch Module.

When the Blast button is pressed, the Operate screen displays

BLAST ON above the SPREAD WIDTH bar.

This either initiates a timed blast cycle (programmed length) or

momentary (blasts only with the button pressed). A timed blast

period can be terminated early by activating the BLAST button a

second time. Blasting can be initiated with the MASTER Switch in

AUTO or OFF.

With a timed blast cycle, a programmed minimum ground speed

establishes the material flow rate until that speed is exceeded by the

actual ground speed.

MASTER SWITCH IN THE UNLOAD POSITION

The UNLOAD position of the MASTER Switch is used to quickly remove

material from the truck.

Warning: If the spinner is programmed to operate during UNLOAD,

be sure that no one is in the vicinity before performing this procedure

to avoid possible injury!

1. Back up to the appropriate location and momentarily press

UNLOAD.

The actuators open fully for those channels turned on from the

switch module.

2. To stop the unload operation, move the MASTER switch to

the OFF position.

OPERATOR'S MANUAL

CONTROL POINT™ KEYBOARD PROGRAMMING/ 15

11001-1100-199904 Revision A

CHAPTER 3 – KEYBOARD PROGRAMMING

Programming allows the operator to enter rates, limits, and other

parameters into the Control Point™ memory for regulating system

product application. These parameters are entered through a detachable

keyboard. Specifics include (1) calibration constants, (2) configuration

parameters (sensor and actuator specifications), (3) granular and liquid

material information, and (4) product application rates (APRs). It also

includes resetting system accumulators for vehicle mileage, material

usage, and time totals.

Programming must be performed before attempting system calibration.

Accurate system calibration constants are determined through regular

calibration routines. However, known constants at the time of program-

ming can be entered thus reducing the calibration procedures required.

Calibration corrections can be revised anytime to fine tune accuracy.

LOGGING CONFIGURATION DATA

All calibration constants and other system parameters should be re-

corded on the CALIBRATION DATA RECORD sheets at the rear of this

manual. In the event of Console damage or lost data, rapid recovery is

assured. If the Control Point™ Console ever requires replacement, all

values can be transferred directly to the new Console via the keyboard.

PREPROGRAMMING

Each Control Point™ system is shipped from DICKEY-john pre-pro-

grammed. Specific parameters can be custom pre-programmed by

DICKEY-john to minimize customer programming. This simplifies

calibration but final SYSTEM RESPONSE (See CALIBRATION chap-

ter) must be performed after installation on every truck.

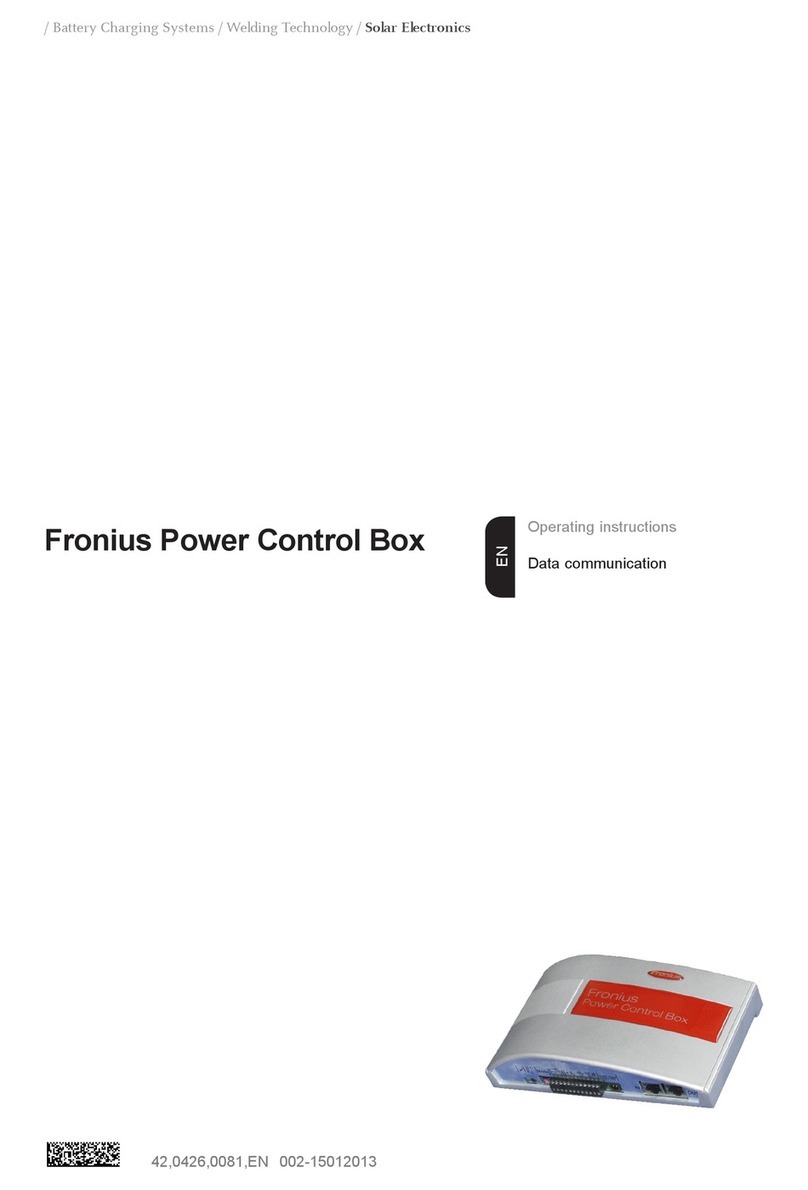

Figure 13. Keyboard Layout and Functions

OPERATOR'S MANUAL

16/KEYBOARD PROGRAMMING CONTROL POINT™

11001-1100-199904 Revision A

USING THE KEYBOARD AND SCREENS

Programming and calibration is accomplished using the keyboard and on-

screen, menu-driven instructions. The keyboard (See Figure 13) detaches

and can be stored after programming and calibration is complete. To use

the keyboard, proceed as follows;

1. If the Control Point™ is on, turn the power off and then

connect the keyboard to the console harness connector (See

Figure 1).

2. Place the MASTER Switch on the Switch Module in the OFF

position and then turn power back on.

Each time power is applied, the Operate Mode (F1) comes up and

normal system operation can be performed. However, the remain-

ing functions (F2 through F12) cannot be selected unless the

MASTER Switch is in the OFF position.

3. Examine the keyboard layout and the twelve functions keys

(F-keys).

The decal immediately above the Function Keys, F1 through F12,

identifies each function. Pressing any F-key immediately enters and

displays that function. Transferring to another function is as simple

as pressing another F-key.

4. Examine the display for several functions (See Figure 14).

a. Function screen (top level) – Each screen lists items with

numbers to the left side (except F8). Pressing the indicated key

number displays that screen, usually one with parameters for

editing.

b. Parameter screens (second level) – An index arrow appears

to the left of the first item and an underscore beneath the first

digit of that parameter.

c. Editing a parameter – The up and down arrow keys move the

index arrow to other parameters for editing. To change the

selected parameter, key in the desired value. When finished,

press the ENTER key to accept the new value and advance the

index arrow to the next line. Failing to use the ENTER key

(except for YES/NO and serial port configurations) loses the

new value.

Figure 14. Basic Screens Layout

OPERATOR'S MANUAL

CONTROL POINT™ KEYBOARD PROGRAMMING/ 17

11001-1100-199904 Revision A

d. Other keys – The Backspace key erases incorrectly keyed

numbers or text. To restore a previous values after keying in a

new number, press either arrow key instead of ENTER.

Invalid keystrokes are not accepted for entry and cause an

audible warning.

Pressing the Esc key returns to the previous screen. Pressing

any function key (F1 through F12) transfers directly to that

function.

e. Screen prompts – If ”MORE...” appears on a screen, addi-

tional parameters are on an extended screen. Access this

screen by moving the index arrow to the “MORE...” line (See

Figure 24).

5. Programming system from the keyboard.

Begin with the following paragraphs for programming procedures

of each function and explanations of screen parameters. All

programming steps should be performed in the order given to

ensure proper entries for all parameters. The MASTER Switch

must be OFF before functions can be selected with the keyboard.

OPERATOR'S MANUAL

18/KEYBOARD PROGRAMMING CONTROL POINT™

11001-1100-199904 Revision A

USING THE MISCELLANEOUS MENU (F12)

Before channel programming begins, a few basic settings require atten-

tion. With system on and keyboard connected, proceed as follows:

1. Press F12 to view the MISC Menu (See Figure 15).

This screen displays six subjects. Each subject is accessed with the

number key indicated in front of the item.

2. From MISC MENU, select BLAST SETUP (1) (See Figure 16).

Two values require editing; length of blast time and minimum

ground speed.

BLAST TIMER – Determines the length of the BLAST cycle (0 to

99 seconds). When set to zero (0), the blast cycle lasts only as long

as the BLAST button is pressed.

BLAST SPEED – Establishes an artificial vehicle ground speed

for computing the rate materials dispenses during blasting when

the vehicle is standing still or moving very slowly. For speeds

faster than this value, the actual vehicle ground speed determines

the spread rate.

When the BLAST SPEED is set to zero, blasting cannot be

initiated with the vehicle stopped. The blast APR is programmed

from the material application rate functions (F1, F4).

3. Select F12 to return to the MISC MENU and select TIME/

DATE (2). (See Figure 17).

Verify or correct the following settings;

a. 24 HOUR – Select YES for 24 hour time; NO for standard

12 hour time.

b. HOUR – Enter the correct hour.

c. MINUTES – Enter the correct minutes.

d. AM/PM – Enter A for AM or P for PM (This selection

does not appear for 24 hour time).

e. MONTH – Enter the correct numerical month.

f. DAY – Enter the correct day of the month.

g. YEAR – Enter the last two digits of the year.

4. Select F12 to return to the MISC MENU and select SYSTEM

UNITS (3) (See Figure 18).

This screen allows displaying either ENGLISH or METRIC units.

Changing causes parameter values on all screens to immediately

convert to the equivalent numerical values.

a. Select either Y(YES) or N(NO). Y changes units to metric; N

retains the units in English.

b. After selecting English or Metric, select units of measure from

the remaining list. Choices are in miles, miles-feet, square feet,

or square yards. If Metric, choices are in kilometers, kilometers-

meter, and square meter. This list only allows one selection.

Pressing the ENTER key is not necessary to accept the choice.

Figure 16. Verifying BLAST

SETUP Menu Adjustments

Figure 17. Setting Time and

Date

Figure 15. Displaying Miscella-

neous Menu Selections

OPERATOR'S MANUAL

CONTROL POINT™ KEYBOARD PROGRAMMING/ 19

11001-1100-199904 Revision A

5. Select F12 to return to the MISC Menu and select SERIAL

PORT CONFIGURATION using the 4 key. (See Figure 19).

This menu allows setting of the serial port for communicating with

other devices. Values must match the serial data format of the other

serial devices. The Esc key accepts the values instead of the ENTER

key. The pre-programmed values are appropriate for use with other

Dj equipment and software.

a. Press 1 for the BAUD RATE SELECT screen. Use the up/down

arrow keys to change the baud rate. Press Esc key when finished.

b. Press 2 for the DATA BIT SELECT screen. Use the up/down

arrow keys to change the data bits to be used. Press Esc key when

finished.

c. Press 3 for the PARITY SELECT screen. Use the up/down arrow

keys to change the data bits to be used. Press Esc key when

finished.

6. Select F12 to return to the MISC Menu and select the

CHANGE LANGUAGE/KEYBOARD screen with the 5 key

(See Figure 20).

This menu allows selecting the language for displaying text and the

keyboard for entering constants.

a. Select a language and key-

board from the screen. Key in

Y (YES) to display French (or

other), NO to display English.

The system displays English

and one other language,

usually French Canadian.

Contact DICKEY-john for

available alternative languages.

b. Select KEYBOARD from the

screen. N (NO) selects an

English keyboard, Y (YES)

selects French.

7. Select F12 to return to the

MISC Menu and select the

SERVICE MENU screen with

the 6 key (See Figure 21).

Figure 18. Setting up System

Units

Figure 19. Configuring RS-232

port

Figure 20. Choosing Displayed

Language and Keyboard

OPERATOR'S MANUAL

20/KEYBOARD PROGRAMMING CONTROL POINT™

11001-1100-199904 Revision A

This menu is not intended for general customer use but for ice

personnel to incorporate future product enhancements, trouble-

shooting, and to identify the currently installed software version.

a. UPDATE SOFTWARE – Used by qualified personnel to

install new software or updates.

b. DISPLAY SOFTWARE VERSION – Displays the currently

installed software version.

c. SYSTEM RESET – Can be used to return all parameters to

factory setting. This is useful in starting over when the present

settings become uncertain or confused.

d. SYS RESPONS – Displays System Response data which is

useful for troubleshooting. This screen can be viewed but not

changed.

ACCESSING THE OPERATE MODE (F1)

F1 accesses the OPERATE screens anytime during programming to

verify selections. No programming parameters are available from this

screen. The following information is a brief outline of the Operate mode

screens. For full details, see Chapter 2.

a. OPERATE screen – Shows programmed values ready for

spreading product in a normal fashion with keyboard connect-

ed.

b. MATERIAL/MANUAL SPEED SELECT screen – A dual

screen showing only items configured. The MATERIAL

SELECT half displays if more than one granular and/or liquid

products are enabled in the Granular (F2) and Liquid (F4)

Application Rate functions. The MANUAL SPEED SELECT

appears if MANUAL DRIVER is programmed YES in the

Ground Speed Configuration function (F7, selection 1).

c. CURRENT TOTALS screen – Shows totals accumulated for

each product dispensed since the last reset (See Accumulator

Function - F9). These totals are those products selected on the

Material/Manual Speed Select Screen. To see other totals,

select those products from that screen.

d. SEASON TOTALS screen – Shows the amount of material

applied, miles traveled during application, and hours elapsed

this season for each product in both the AUTO and BLAST

modes. The season totals can only be cleared from the Accu-

mulator Function (F9).

Figure 21. Viewing the SERVICE

MENU Items

Other manuals for Control Point

1

Table of contents

Other Dickey-John Control System manuals

Popular Control System manuals by other brands

Alstom

Alstom DS Agile C26 Series Technical manual addendum

Opencockpits

Opencockpits B737 MAX AFT Overhead Installation & user manual

WEIHONG

WEIHONG PM53B Manufacturer's manual

J.R. Clancy

J.R. Clancy SceneControl 500 operating manual

Vaillant

Vaillant VRC 700/6 operating instructions

Balboa Instruments

Balboa Instruments GS520DZ manual