OPERATING PROCEDURE

1. Unpacking the Lift

Remove the lift from the shipping pallet by

cutting the bands and rocking the lift back

on the 8” transportation wheels. Carefully

roll the lift back off of the pallet onto a

smooth, level surface. Place the lift back

into it’s upright stored position.

The lift has been shipped with the Mast

Hold Down

Strap en-

gaged. The

purpose of

the Mast

Hold Down,

is to keep the

mast sec-

tions from

extending

during transportation. To use your lift, dis-

connect the Safety Latch attached to the

carriage.

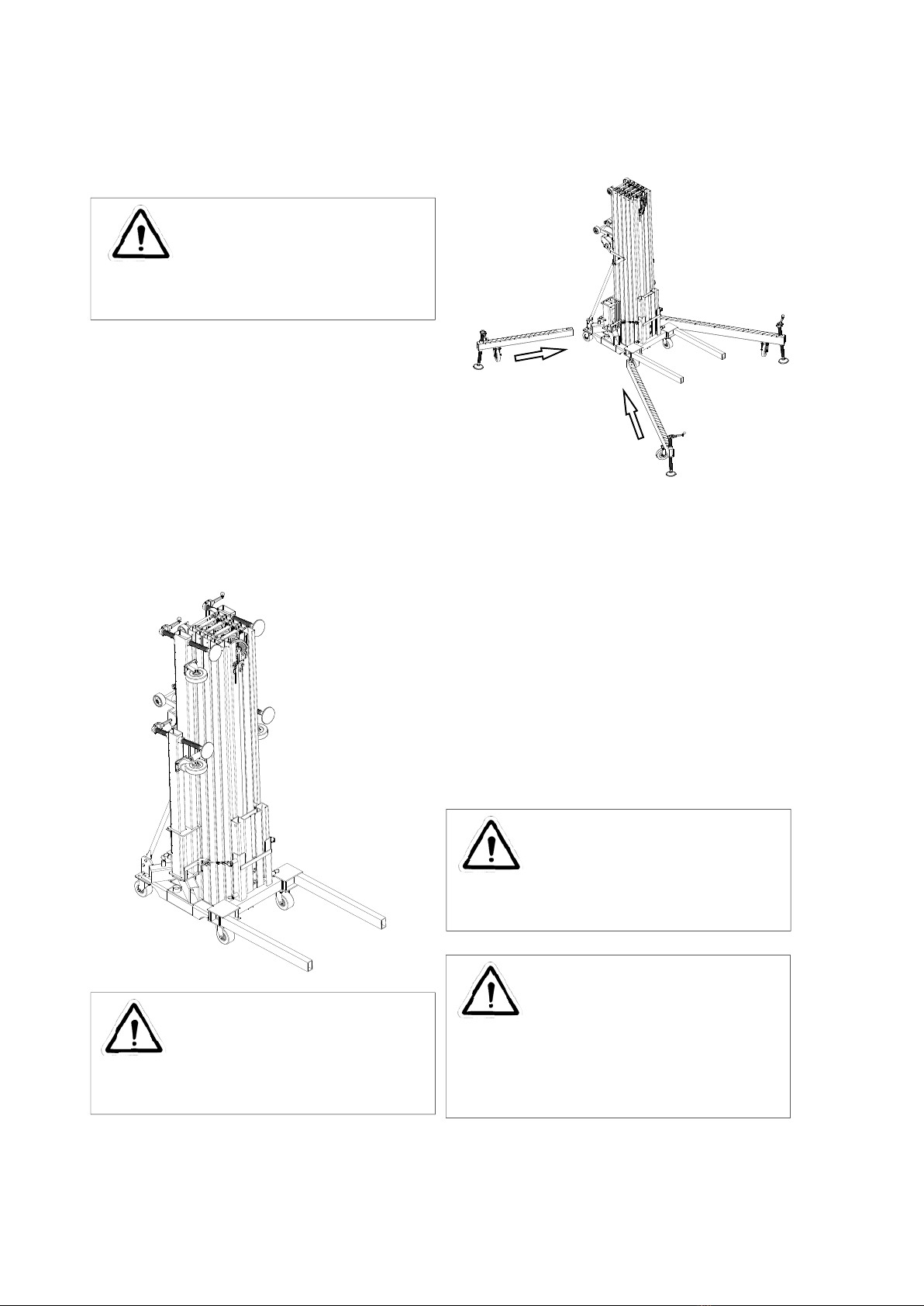

2. Moving Lift to Work Area

(No Load)

The lift is normally moved to the job site by

rolling on its four caster wheels. Note: Do

not pull by the load lifting cable.

IMPORTANT Before tilting unit to reclined

position, the carriage must be in the down

position and the mast hold down strap must

be engaged.

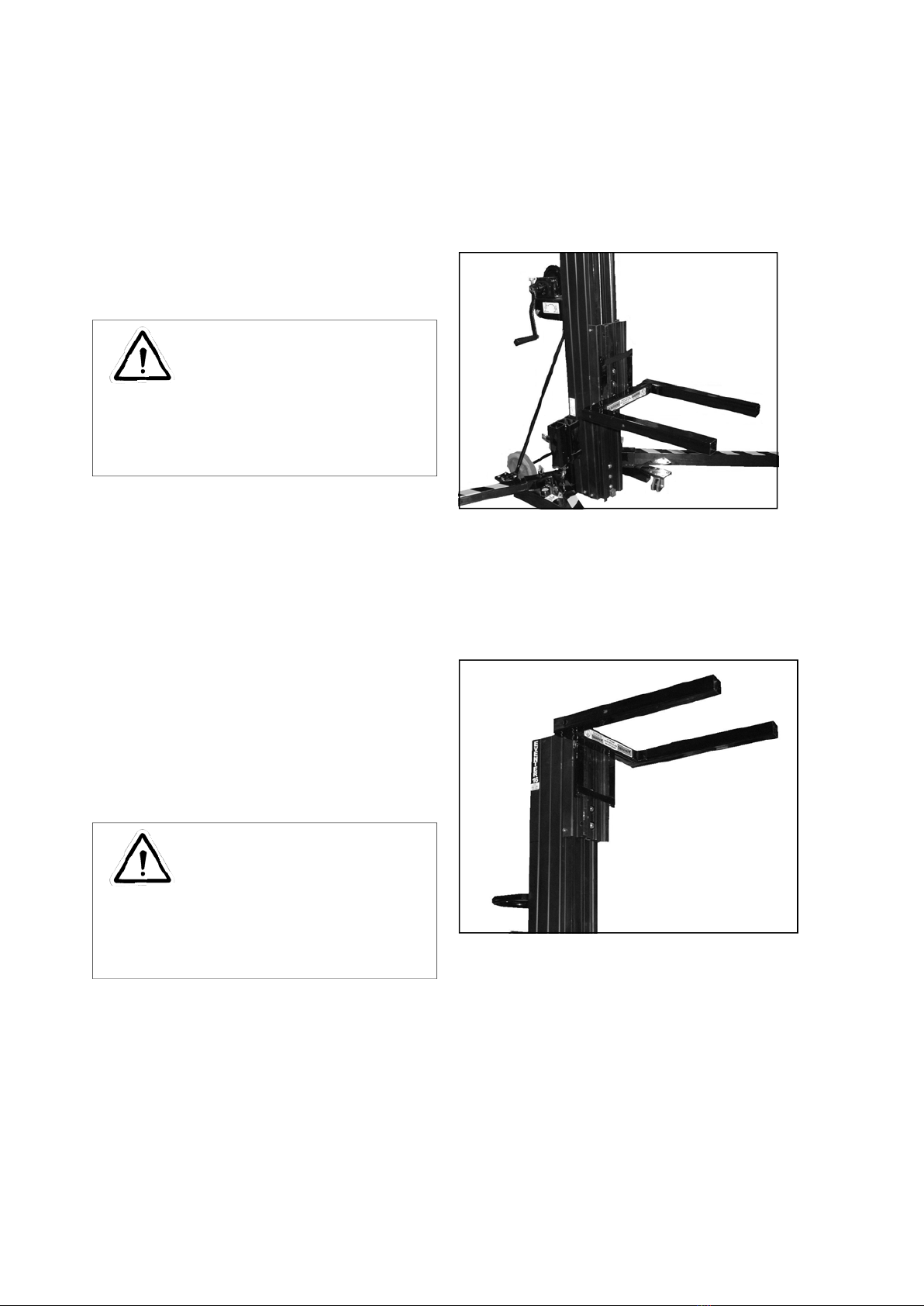

To Tilt the unit into position for transport;

from a squatting position, grasp the legs

just past the front casters and while keep-

ing your back straight, lift upwards to a

standing position while someone supports

the unit from behind. The unit is now ready

to transport.

3. Moving Lift in Work Area

(With Load)

Although it is best to move the unit to the

job site unloaded, light loads may be trans-

ported as long as the stabilizer legs are in-

stalled and the unit is rolled on the eight

caster wheels and on a level surface. Al-

ways have the load in the lowest possible

position before moving the unit.

7

CAUTION

Always use proper lifting techniques.

CAUTION

If a load is being transported,

it should be secured to the fork

to avoid shifting.

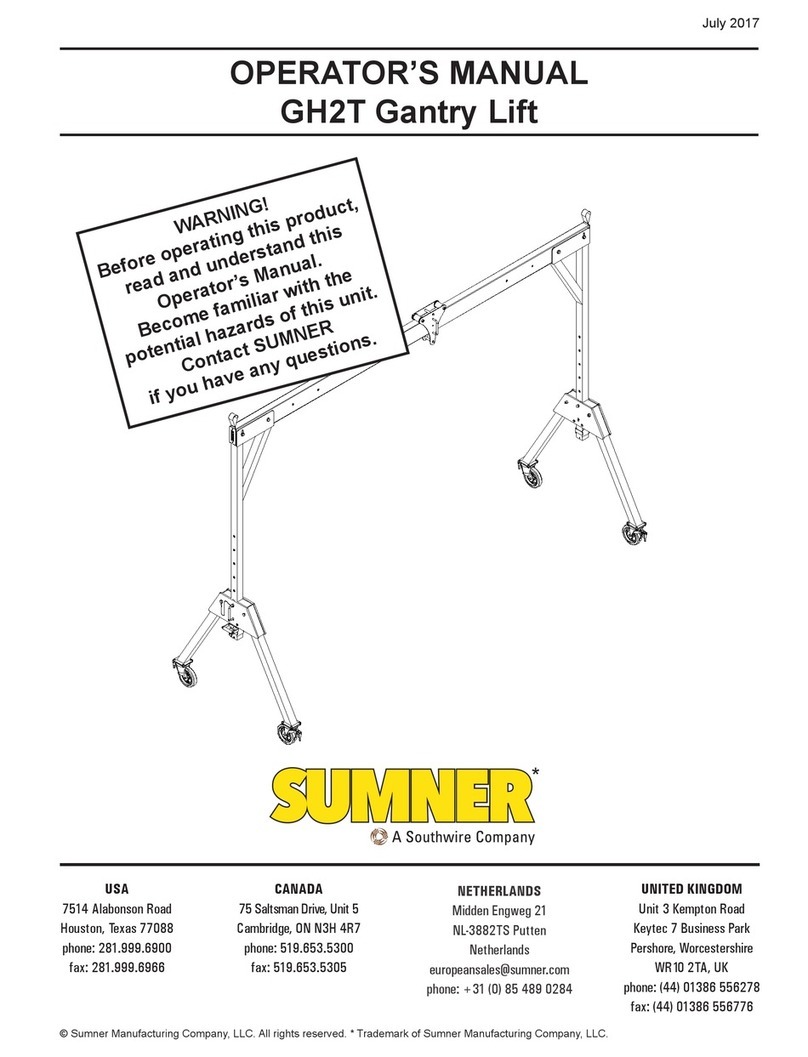

The winch handles

have been placed in

the stored position.

To place the winch

handles in the oper-

ating position, pull up

on the locking pin

and slide the handle

off of the winch

shaft. Rotate the

handle assembly

around so that the

black plastic grip is

facing away from the

winch. While pulling

up on the locking

pin, slide the handle

back on to the winch

shaft. Repeat this

procedure for the

other handle.

When properly in-

stalled, the winch han-

dles should be

mounted 180 degrees

apart, as shown in the

picture. Do not attempt to raise or

lower a load with the handles

mounted in any other manner.