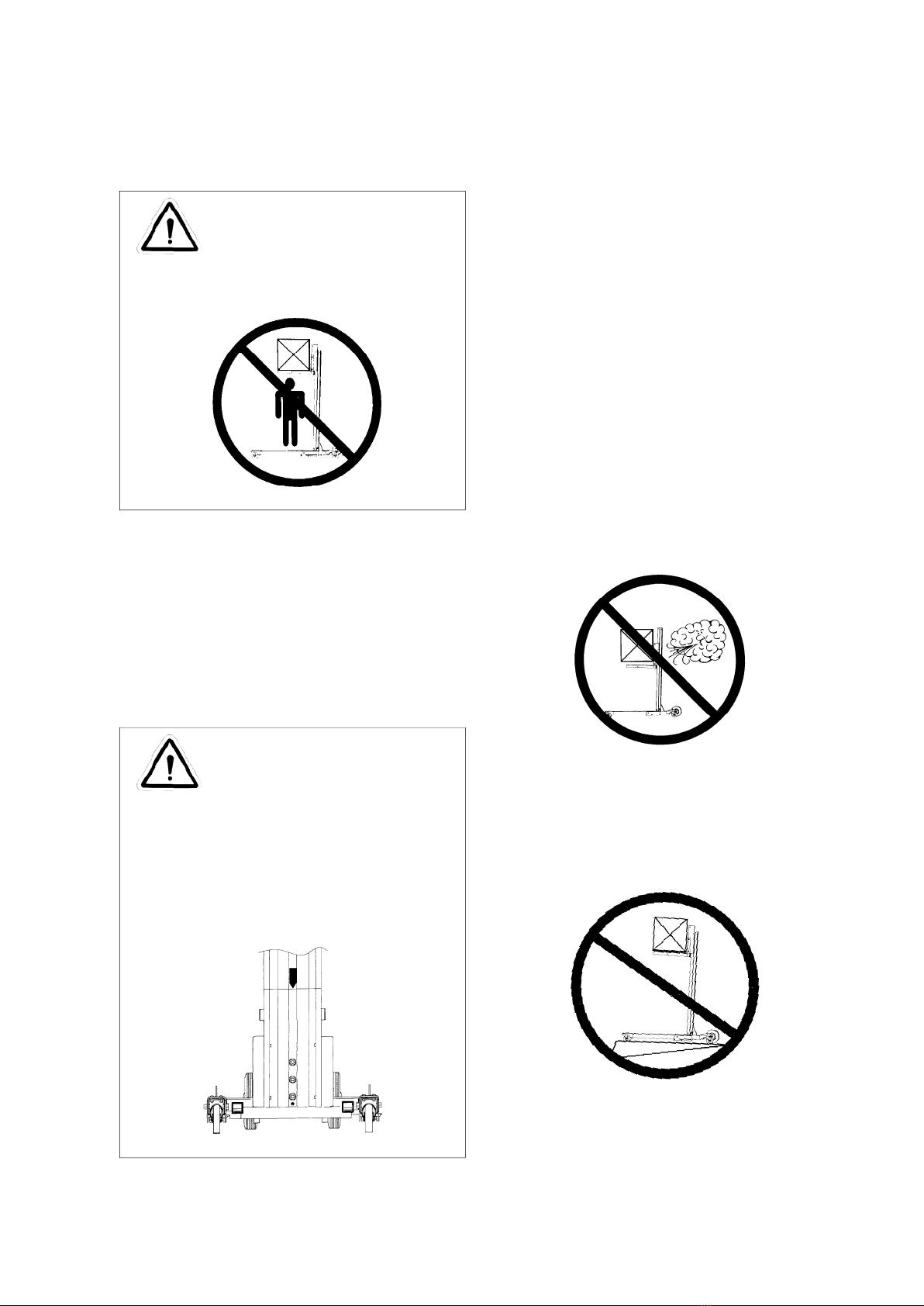

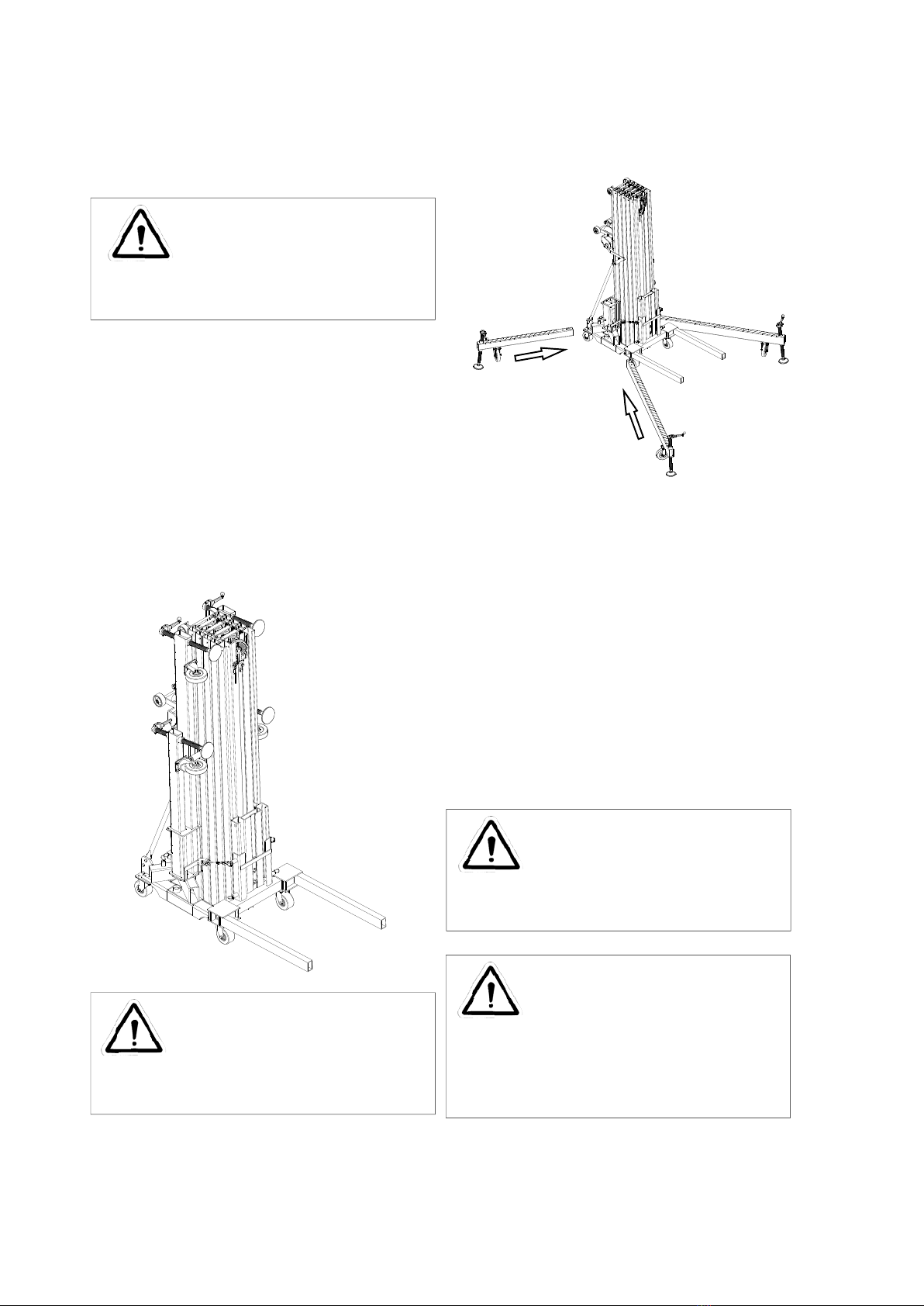

OPERATING PROCEDURE

1. Moving Lift to Work Area

(No Load)

The lift is normally moved to the job site

by rolling on its four caster wheels. Note:

Do not pull by the load lifting cable.

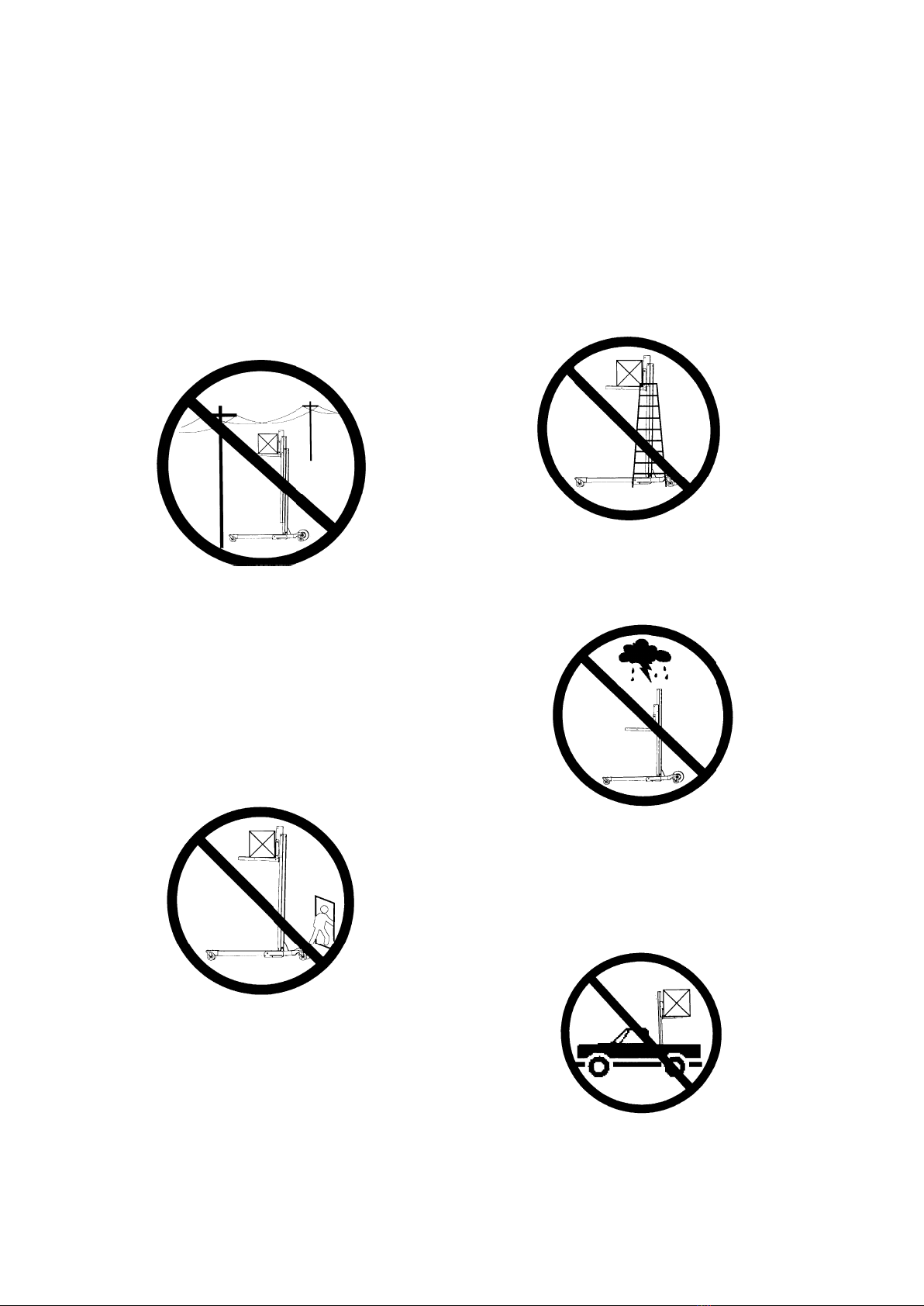

IMPORTANT Before tilting unit to reclined

position, the carriage must be in the down

position below the red arrows, and ensure

that the safety latch is engaged.

To Tilt the unit into position for transport;

from a squatting position, grasp the legs

just past the front casters and while keep-

ing your back straight, lift upwards to a

standing position while someone supports

the unit from behind. The unit is now

ready to transport.

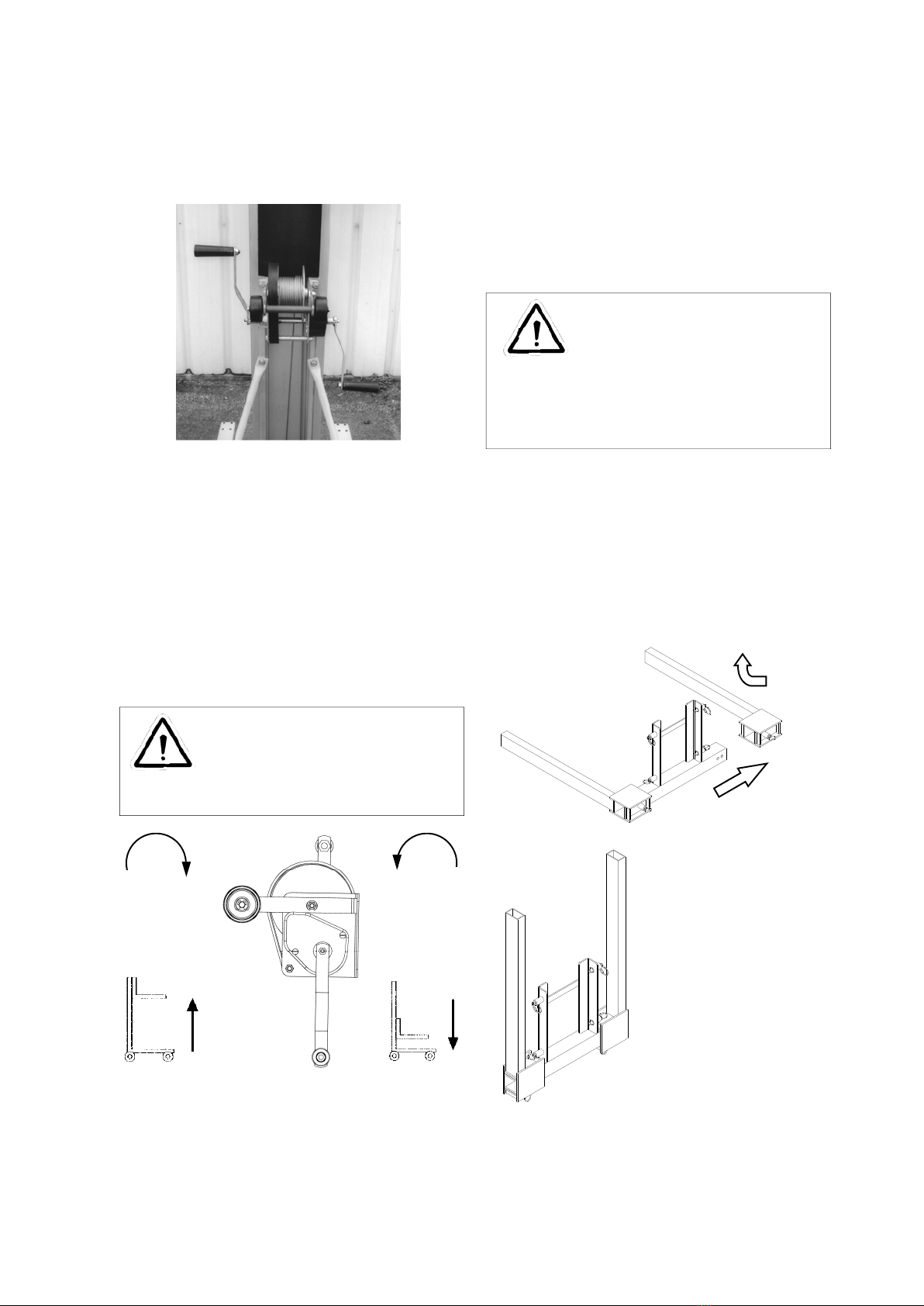

2. Moving Lift in Work Area

(With Load)

Although it is best to move the unit to the

job site unloaded, light loads may be

transported as long as the stabilizer legs

are installed and the unit is rolled on the

eight caster wheels and on a level sur-

face. Always have the load in the lowest

possible position before moving the unit.

If it is necessary to move the unit with an

elevated load:

Make sure the area is clear of obstruc-

tions

Keep personnel away from the load

and behind the operator’s position.

Move the unit slowly, avoiding sudden

jerky starts and stops

Make sure the load is secure and prop-

erly balanced Note load capacity at

given centers below.

Make sure the stabilizer legs are in-

stalled and locked into position.

7

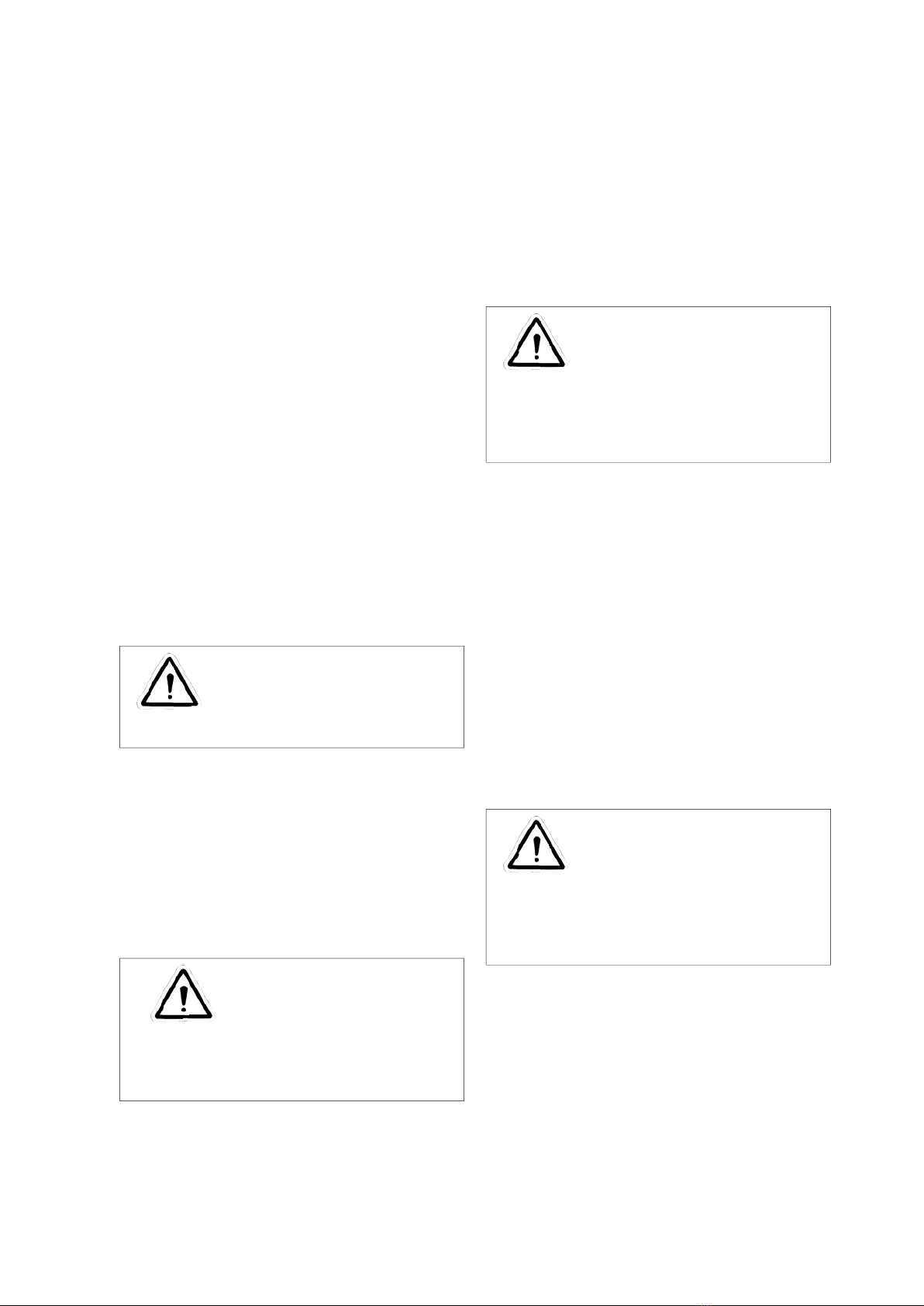

CAUTION

Always use proper lifting techniques.

CAUTION

If a load is being transported,

it should be secured to the fork

to avoid shifting.

WARNING

Moving the unit with elevated loads

should be contained to short

distances; i.e., 10-15 feet/4-5 meters.

WARNING

Do not extend load centers beyond

fork ends by modifying the lift.

Lift may become unstable.