Southworth APCU Series Operating instructions

Operating and Maintenance Manual

APCU Series

All Purpose Container Unloader

Model #: APCU

Serial # _________________________________________

Placed in Service _________________________________

December 2018

Southworth Products Corp

P.O. Box 1380 • Portland, ME 04104-1380

Telephone: 207-878-0700 Fax: 207-797-4734

2APCU Owner’s Manual

This label (part # 10095524)

is required by California law.

For more information visit

www.65Warnings.ca.gov.

This label (part # 10095524)

is required by California law.

For more information visit

www.P65Warnings.ca.gov.

APCU Owner’s Manual 3

CONTENTS

INTRODUCTION ................................................................................................. 4

RESPONSIBILITY OF OWNERS AND USERS ................................................... 5

SAFETY ALERT SYMBOLS AND SIGNAL WORDS............................................ 6

SAFETY .............................................................................................................. 7

Safety devices ......................................................................................... 8

INSTALLATION INSTRUCTIONS .................................................................... 20

Preparation .......................................................................................... 20

Positioning the lift .................................................................................. 20

Hydraulic connections ......................................................................... 20

Testing ................................................................................................... 21

Electrical connections............................................................................ 21

Checking the hydraulic system.............................................................. 21

OPERATOR CONTROLS ................................................................................. 22

OPERATING INSTRUCTIONS........................................................................... 22

OPTIONAL APCU SUPPORT STANDS ............................................................. 27

MAINTENANCE ................................................................................................. 28

Hazards ................................................................................................ 28

Servicing the unit safely ....................................................................... 28

Routine maintenance-weekly .............................................................. 28

Routine maintenance-monthly ............................................................. 29

Routine maintenance - 6 months or 500 hours ................................... 29

TROUBLESHOOTING ..................................................................................... 29

Troubleshooting Table ..................................................................... 30-31

ADJUSTMENT & REPLACEMENT PROCEDURES.......................................... 33

Aligning the photo eyes ......................................................................... 33

About the proximity switches ................................................................. 33

Setting end of travel for “tilt down” function ........................................... 33

Setting end of travel for “tilt up” function................................................ 33

Setting end of travel for “dump up” function .......................................... 33

Setting end of travel for “dump down” function...................................... 34

Inspecting and cleaning a control valve................................................. 34

Removing a cylinder .............................................................................. 34

Repacking a cylinder ............................................................................. 35

Replacing a cylinder .............................................................................. 36

ORDERING REPLACEMENT PARTS ............................................................... 45

WARRANTY ...................................................................................................... 46

List of Figures and Tables

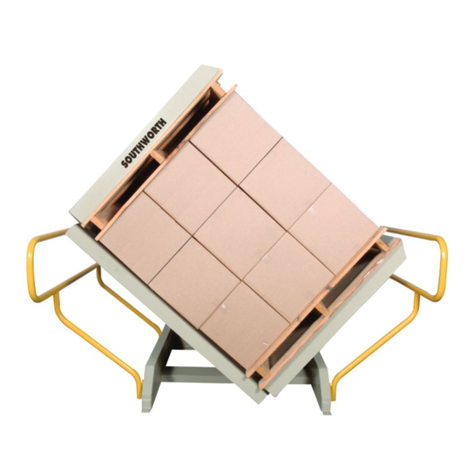

Fig. 1 Overall View - Load Enclosure Lowered ................................ 8

Fig. 2A Operating Sequence - Loading Position .................................. 9

Fig. 2B Operating Sequence - Tilt 90 degree Position ......................... 9

Fig. 2C Operating Sequence - Dump Position.................................... 10

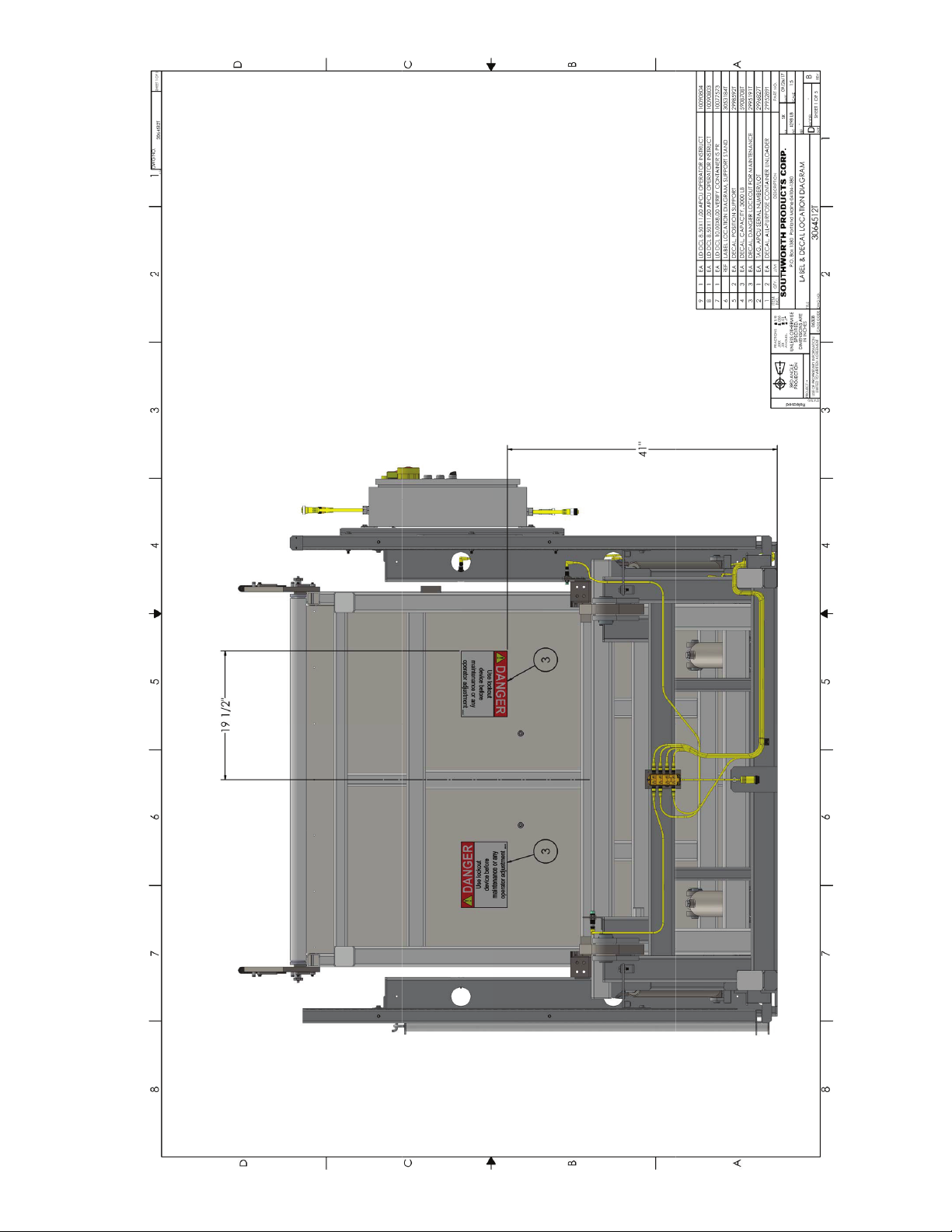

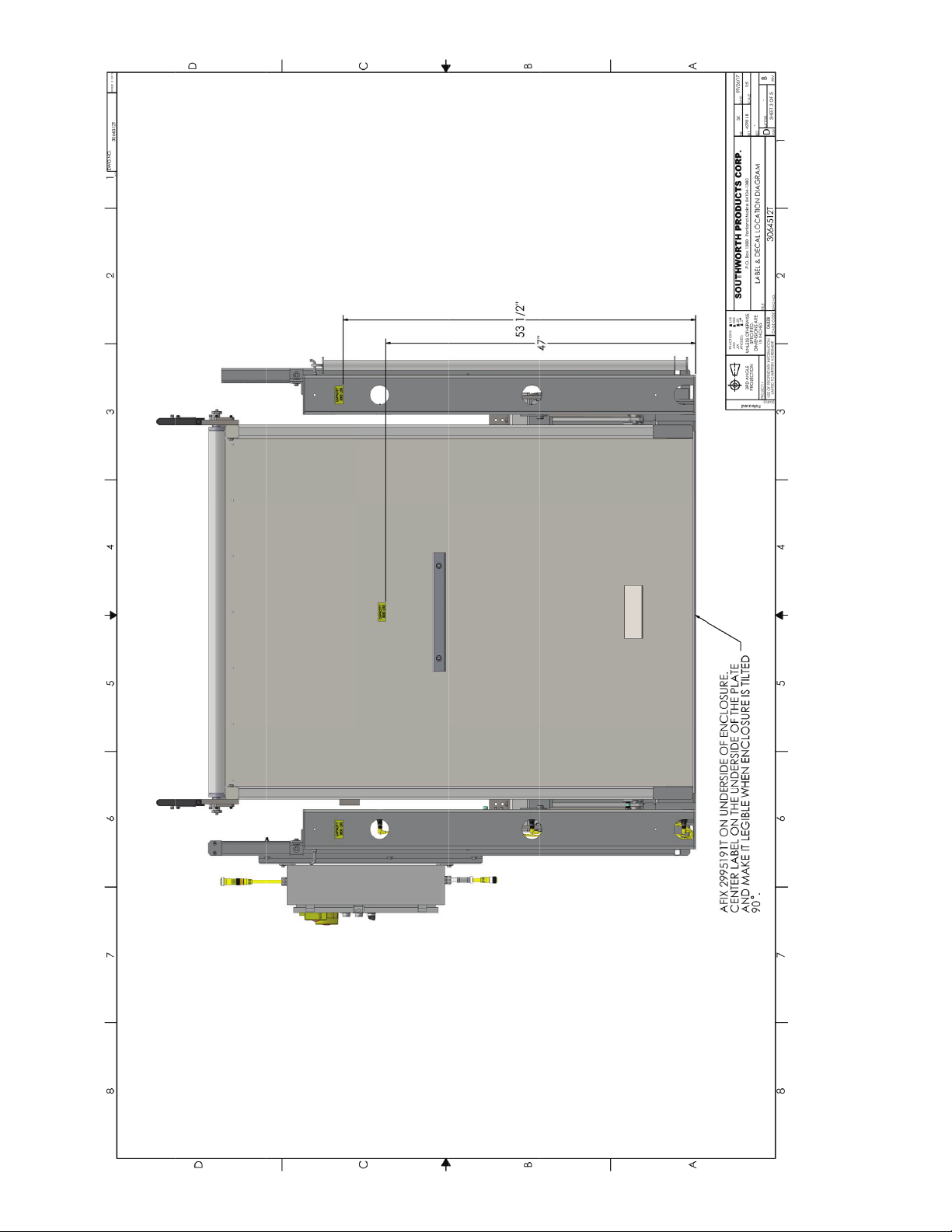

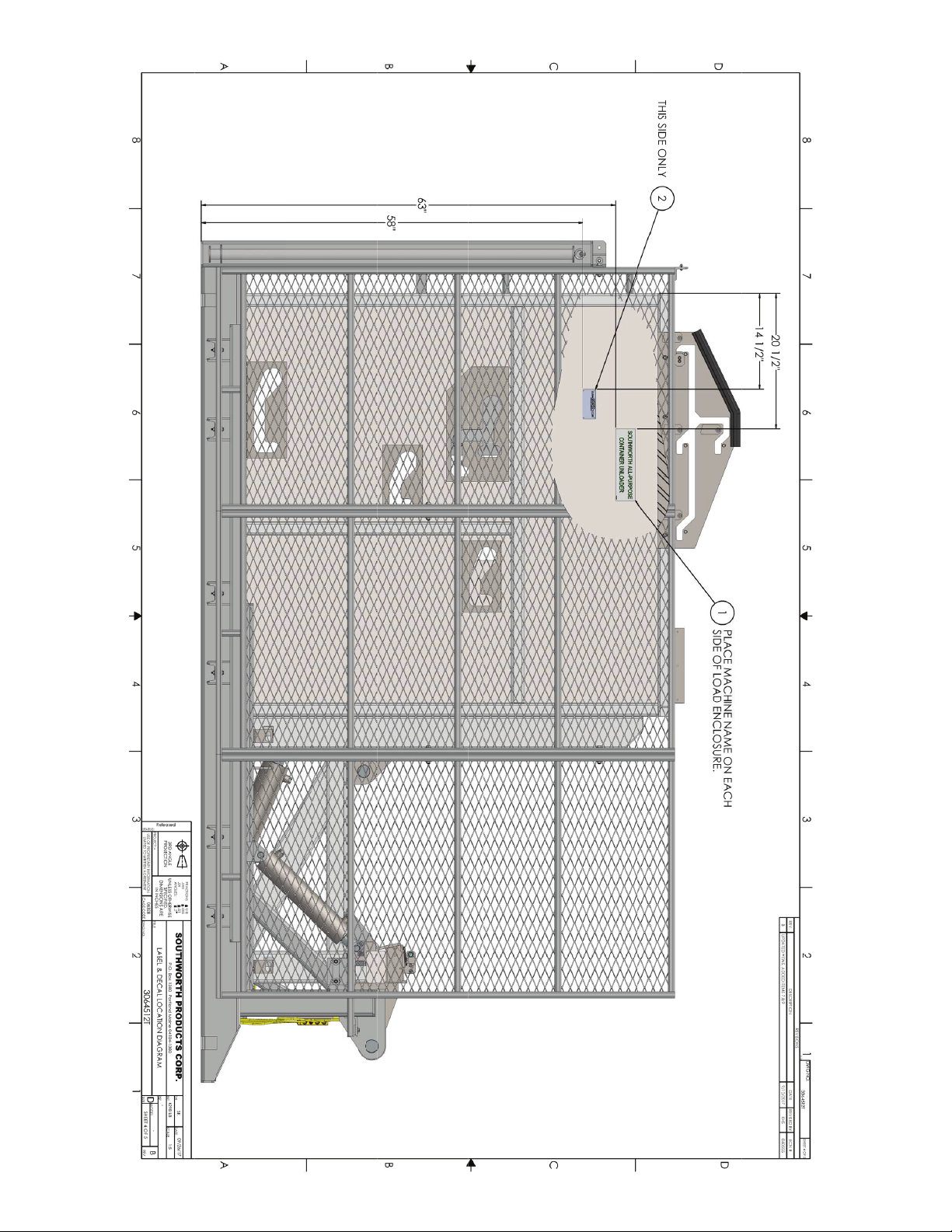

Fig. 3A-G Label diagrams and positions ......................................... 11-18

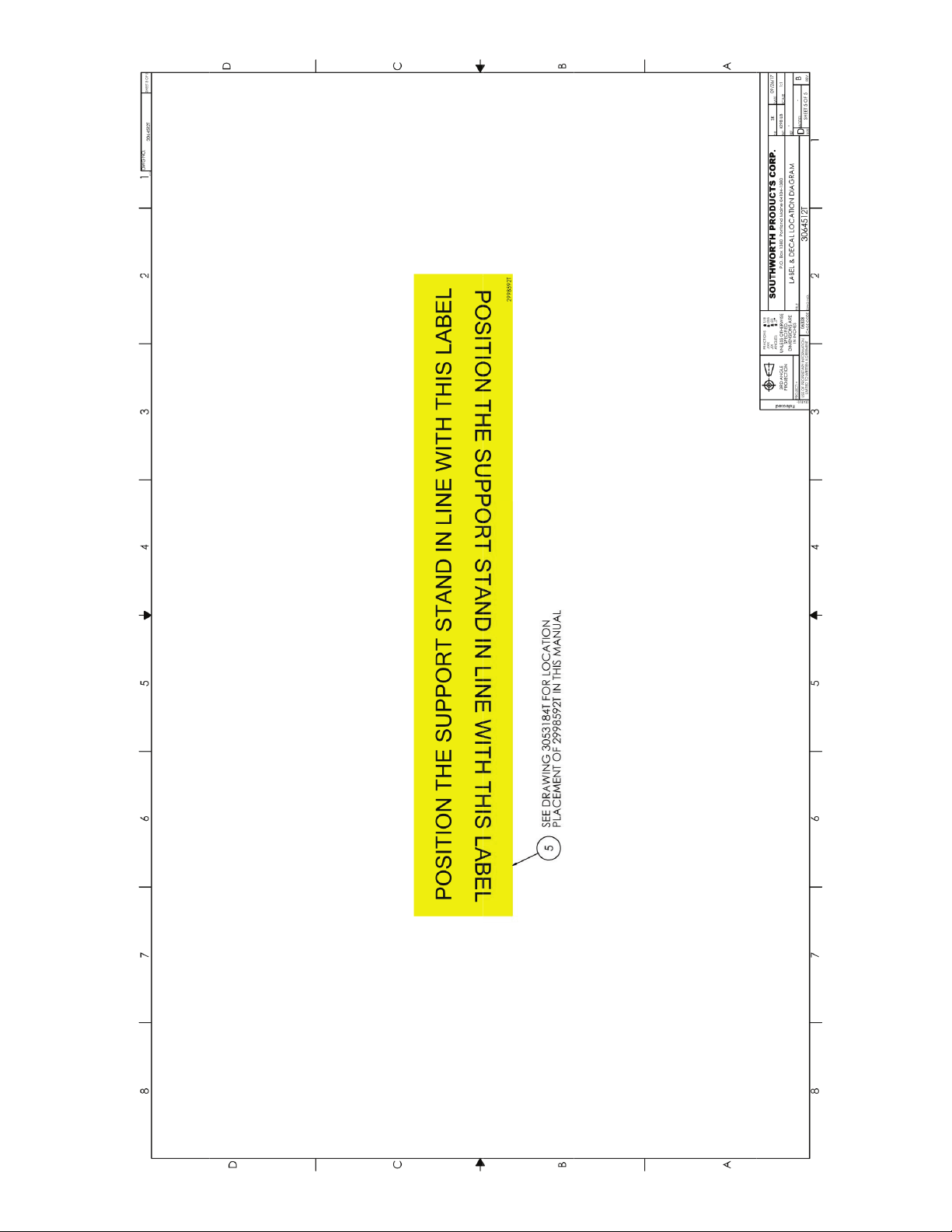

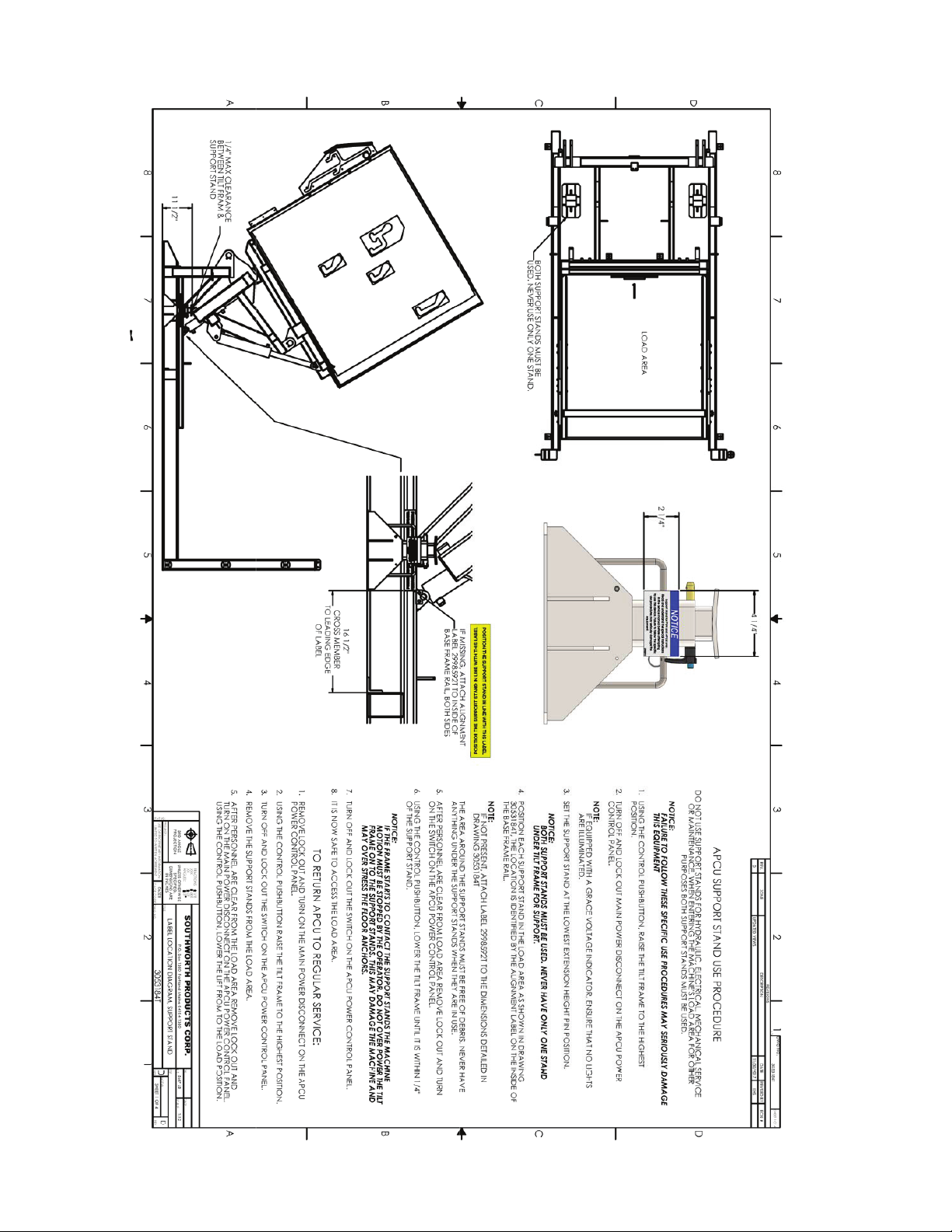

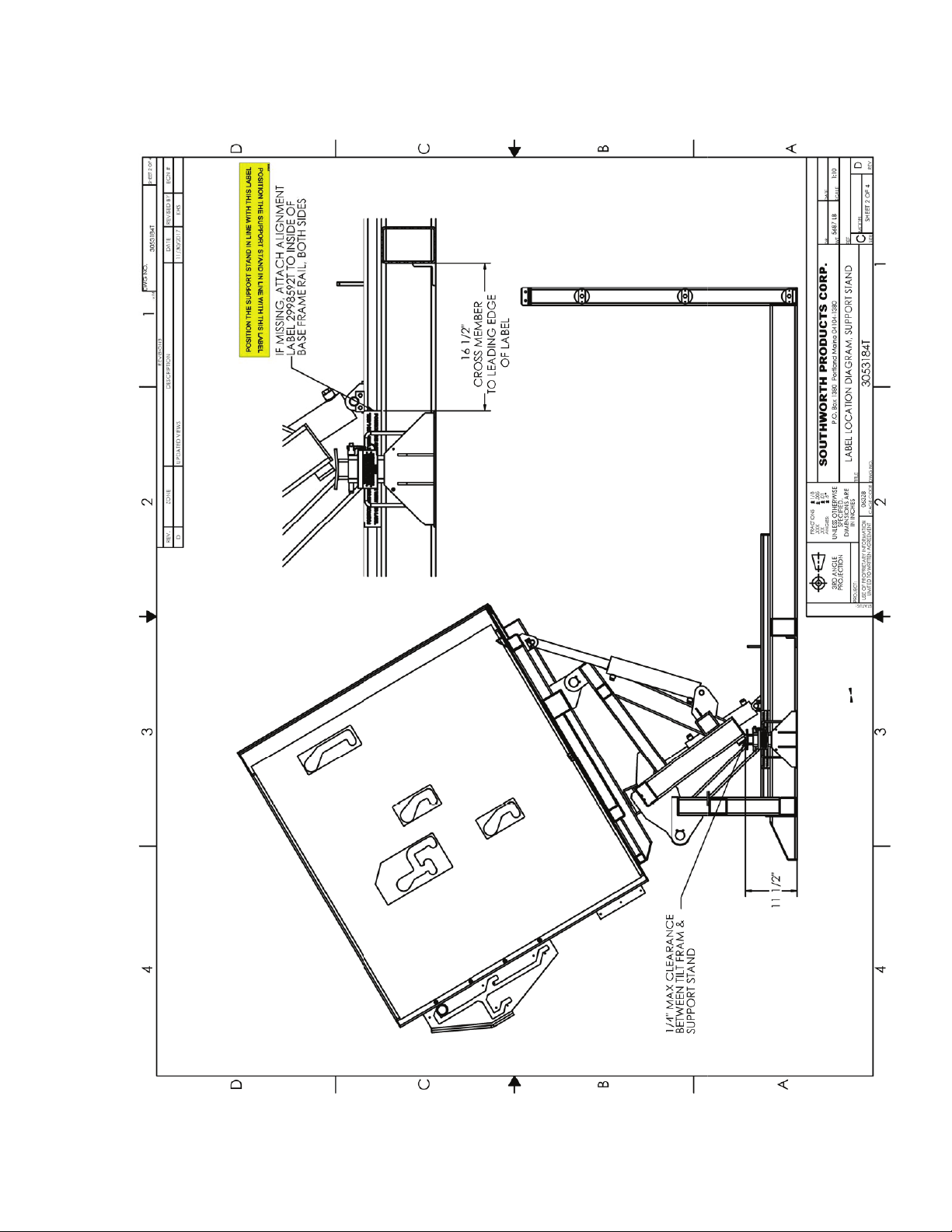

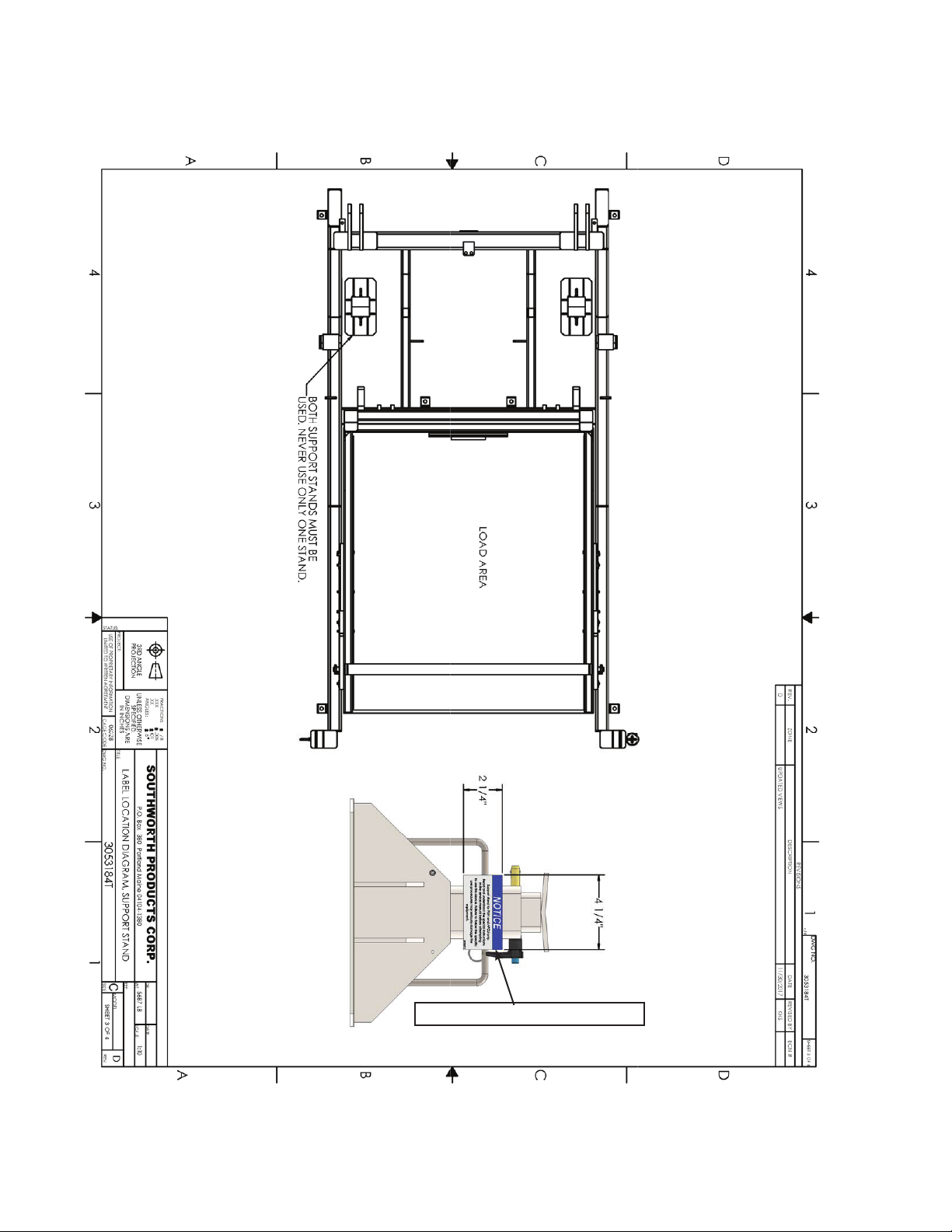

Fig. 3H APCU Support Stand Procedure............................................ 19

Fig. 4 Control panel.......................................................................... 22

Fig. 5A Using the retainer bar............................................................. 24

Fig. 5B Proper retaining...................................................................... 25

Table 1 Hydraulic Oil Specications.................................................... 32

Fig. 6 Repacking the cylinder ......................................................... 35

Fig. 7 Hydraulic schematic .............................................................. 37

Fig. 8 Wiring Diagram ................................................................ 38-39

Fig. 9 DC Power Supply Kit.............................................................. 40

Fig. 10 APCU Program Ladder Logic................................................. 41

Fig. 10A-C Hydraulic power unit ......................................................... 42-44

4APCU Owner’s Manual

Introduction

The Southworth All-Purpose Container Unloader (APCU) is designed to unload containers and pallets.

APCU units are designed for tilting and dumping of equipment and materials in a general indoor industrial

setting.

This manual contains instructions on the safe and proper installation, use, and maintenance of the All

Purpose Container Unloader unit. Be sure that this manual is available to the people who install, use, or

service the unit. Be sure that all personnel read this manual before they install, use, or service the unit.

The instructions in this manual are not necessarily all-inclusive, as Southworth cannot anticipate all

conceivable or unique situations. In the interest of safety, please read this whole manual carefully.

Please understand the material in this manual before you install, use, or service the APCU unit. If

you have any questions about any of the instructions in this manual, please contact Southworth

Products Corp.

Southworth’s product warranty is shown on the rear cover of this manual. This instruction manual is

not intended to be or to create any other warranty, express or implied, including any implied

warranty of merchantability or tness for a particular purpose, all of which are hereby expressly

excluded. As set forth more specically in the product warranty, Southworth’s obligation under that

warranty is limited to the repair or replacement of defective components, which shall be the buyer’s

sole remedy, and Southworth shall not be liable for any loss, injury, or damage to persons or property,

nor for any direct, indirect, or consequential damage of any kind resulting from the APCU unit.

This manual is intended for stand alone APCU machines

shipped about May 2015, and after with control panels supplied

Southworth Products. Please contact Southworth Products for

information about APCU machines shipped before May 2015 or

machines with control panels, control and hydraulic schematics,

PLC logic, or other differences that do not match those shown

in this manual.

APCU Owner’s Manual 5

Responsibility of Owners and Users

Inspection and Maintenance

The device shall be inspected and maintained in proper working order in accordance with South-

worth’s owner’s manual.

Removal from Service

Any device not in safe operating condition such as, but not limited to, excessive leakage, miss-

ing rollers, pins, or fasteners, any bent or cracked structural members, cut or frayed electric,

hydraulic, or pneumatic lines, damaged or malfunctioning controls or safety devices, etc. shall be

removed from service until it is repaired to the original manufacturer’s standards.

Deection

It is the responsibility of the user/purchaser to advise the manufacturer where deection may be

critical to the application.

Repairs

All repairs shall be made by qualied personnel in conformance with Southworth’s instructions.

Operators

Only trained personnel and authorized personnel shall be permitted to operate the lift.

Before Operation

Before using the device, the operator shall have:

• Read and/or had explained, and understood, the manufacturer’s operating instructions

and safety rules.

• Inspected the device for proper operation and condition. Any suspect item shall be care-

fully examined and a determination made by a qualied person as to whether it constitutes

a hazard. All items not in conformance with Southworth’s specication shall be corrected

before further use of the equipment.

During Operation

The device shall only be used in accordance with this owner’s manual.

• Do not overload.

• Ensure that all safety devices are operational and in place.

Modications or Alterations

Modications or alterations to any Southworth industrial positioning equipment shall be made

only with written permission from Southworth.

6APCU Owner’s Manual

SAFETY ALERT SYMBOLS AND SIGNAL WORDS

The safety of all persons operating, maintaining, repairing, or in the vicinity of this equipment is of paramount con-

cern. This is a powerful machine with moving parts, and is capable of causing personal injury if proper precautions are not

taken. Therefore, throughout this manual, certain hazards have been identied which may occur in the use of the machine,

and there are appropriate instructions or precautions which should be taken to avoid these hazards. In some cases, there

are consequences which may occur if instructions or precautions are not followed. Below are the symbols and signal words

along with their denitions referenced from ANSI Z535.4 - Product Safety Signs and Labels.

4.11 Safety Alert Symbols: A symbol that indicates a hazard. It is composed of an equilateral triangle surrounding

an exclamation mark. The safety alert symbol is only used on hazard alerting signs. It is not used on safety notice and safety

instructions signs.

4.14 Signal Words: The words used in the signal word panel. The signal words for hazard alerting signs are “DANGER,”

“WARNING,” and “CAUTION.” Safety notice signs use the signal word “NOTICE.” Safety instruction signs use signal words that

are specic to the situation.

DANGER indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE is used to address practices not related to physical injury.

SAFETY INSTRUCTIONS (or equivalent) signs indicate specic safety-

related instructions or procedures.

NOTE: DANGER, WARNING or CAUTION should not be considered for property damage accidents unless personal injury risk

appropriate to these levels is involved.

A): for use with DANGER signal word; (safety white triangle, safety red exclamation mark, safety red background)

B): for use with WARNING signal word; (safety black triangle, safety orange exclamation mark)

C): for use with CAUTION signal word; (safety black triangle, safety yellow exclamation mark)

D) and E): for use with DANGER, WARNING, or CAUTION signal word; (D: is a safety yellow triangle with a

black border and safety black exclamation mark; E: is a safety yellow triangle with a safety black exclamation mark and a

safety yellow border around a safety black band)

NOTE: D and E are provided to allow for consistency with certain ISO standards such as ISO 3864-1 and ISO 3864-2.

APCU Owner’s Manual 7

Safety

Southworth is concerned about the safety of everyone who operates, maintains, repairs, or

works near the APCU unit. The unit is a powerful machine with moving parts, and is capable of

causing personal injury if proper precautions are not taken.

For this reason, throughout this manual, we have pointed out some of the hazards which may

occur as you use the unit. We have also listed the instructions or precautions you should take

to avoid these hazards. In some cases, we have also pointed out the consequences which may

occur if you do not follow these instructions or precautions. We will use the following system to

identify the severity of the hazards:

DANGER! – Immediate hazard which will result in severe personal injury or death.

WARNING! – Hazard or unsafe practice which could result in severe personal injury

or death.

CAUTION! – Hazard or unsafe practice which could result in minor personal injury or

property damage.

Please read and follow this instruction manual, including all safety instructions

and precautions, carefully and completely.

8APCU Owner’s Manual

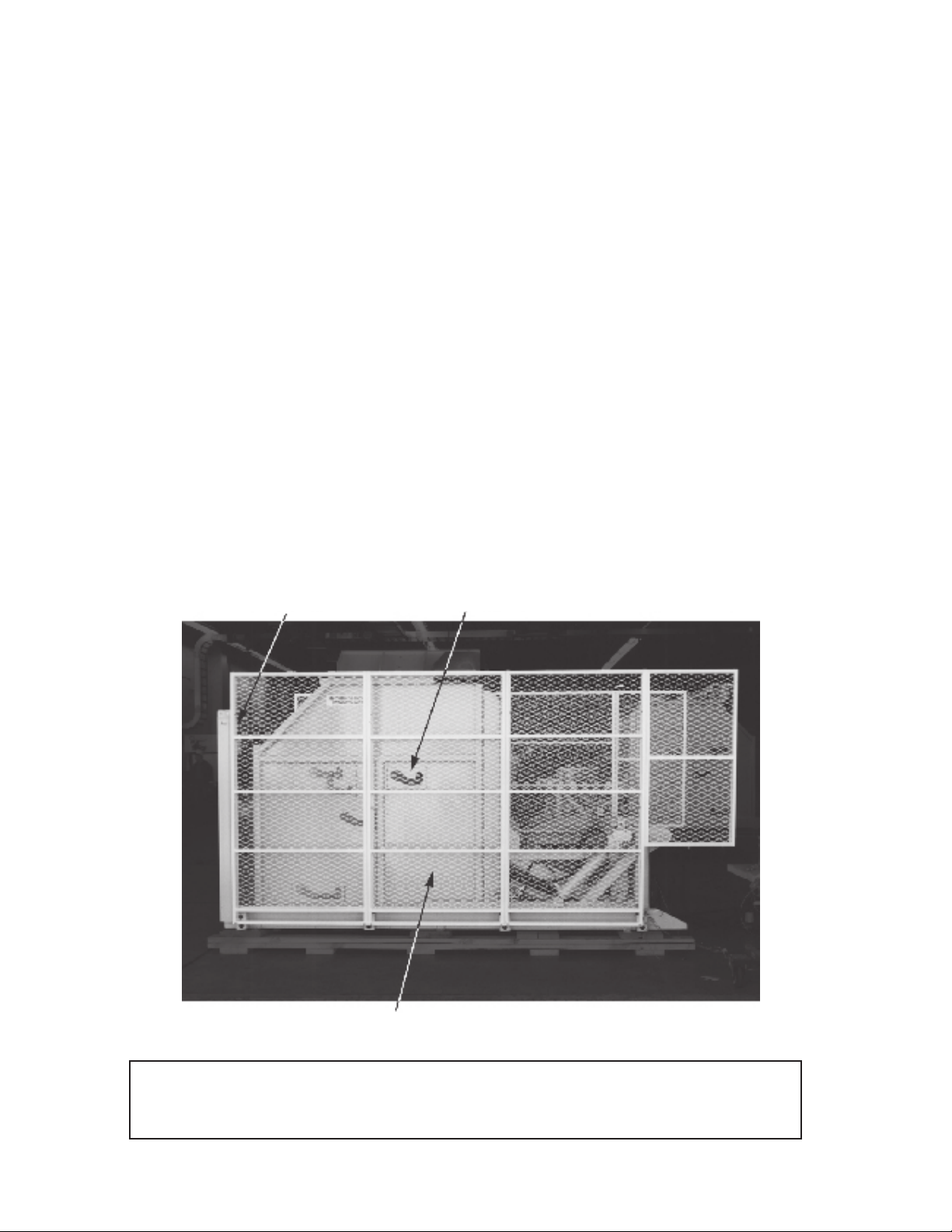

Safety Devices

This unit has two kinds of safety devices. Guard fences

protect each side of the unit. These are designed to

keep everyone away from the moving parts of the unit

while it is operating. These guards should always be

in place when the unit is operating normally.

There may be some cases where you will want to do

maintenance work with the safety guards removed. You

should be especially careful during these procedures.

As the load enclosure moves up and down, “pinch

points” are created where the moving parts meet. If you

are standing too close to the load enclosure when it is

moving, your arm or leg may be caught in the moving

parts, and you may be hurt. Stay away from the pinch

points when the safety guards are removed and the load

enclosure is moving. Always replace the safety guards

as soon as you are done with the maintenance work.

The unit also includes three photo-eye systems.

Each photo-eye system includes a light source on one

side of the unit, and a reector on the other side. If

any of the light beams is broken, the unit will not start,

and the load enclosure will not move. This helps to

ensure that everyone is out of the way before the load

enclosure moves.

Before using the unit, please be sure that the guards

are in place, and that the photo-eye system is work-

ing. If the guards are missing, or the photo-eyes are

not working, turn off the machine right away and call

a supervisor. Never operate the unit without these

important safety features.

Figure 3 shows the positions of the warning labels

on the unit. These labels have been included for your

safety. If you nd that the labels are worn or missing,

or have been painted over, ask Maintenance to replace

the labels before you use the unit.

You should never operate the unit with the safety guards removed. This machine is equipped

with an external power unit, which is mounted a short distance away from the machine.

Fig. 1 Overall View

Safety photo-eyes Slots for retainer bar

Wire mesh enclosure

APCU Owner’s Manual 9

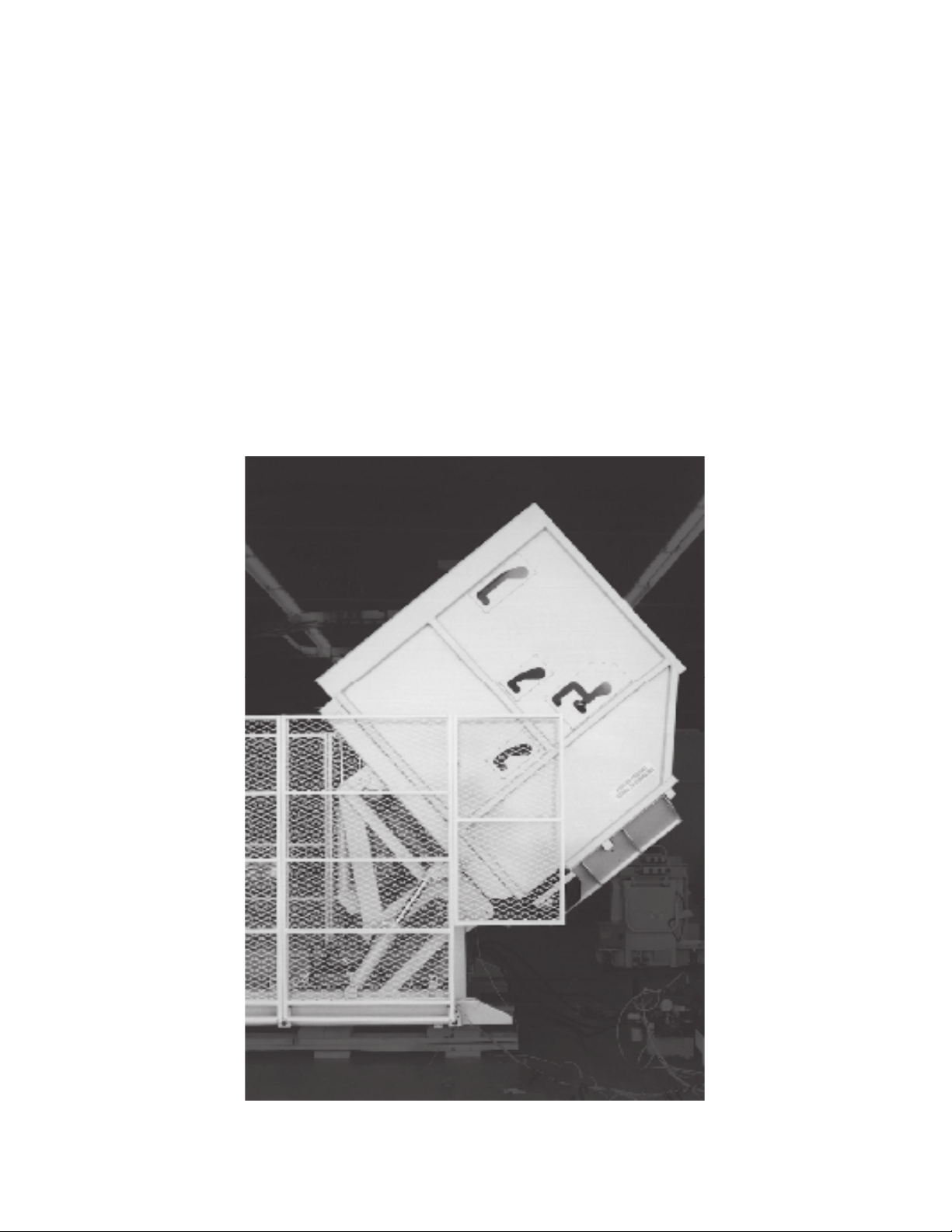

Fig. 2A Operating Sequence - Loading Position

Fig. 2B Operating Sequence - Tilt 90 degree Position

10 APCU Owner’s Manual

Fig. 2C Operating Sequence - Dump Position

Figure 2 shows the operating sequence for the unit.

At the start of the process, the operator places the pal-

let or container on the load enclosure. This enclosure

is positioned at ground level, so it is easy to load the

unit. (See Part A of the illustration.) During the “tilt”

part of the operating cycle, the load enclosure tilts up

90°. (See Part B.) Next, during the “dump” part of the

cycle, the enclosure can be tilted an additional 50° to

dump the items being loaded onto a conveyor or other

device. (See Part C.)

This manual contains information about the safe and

proper installation, use, and maintenance of an APCU

unit. Be sure that this manual is available to anyone

who works with the unit. Be sure that everyone who

uses the unit has read this manual.

The instructions included in this manual are not

necessarily all-inclusive, because Southworth cannot

anticipate all conceivable or unique situations.

In the interest of safety, please read this whole manual

carefully. Please understand the material in this manual

before you install, use, or service the APCU unit. If

you have questions about any of the instructions in this

manual, please contact Southworth Products Corp.

APCU Owner’s Manual 11

Fig. 3 - Label Diagrams and Positions

12 APCU Owner’s Manual

Fig. 3A - Label Diagrams and Positions

APCU Owner’s Manual 13

Fig. 3B - Label Diagrams and Positions

14 APCU Owner’s Manual

Fig. 3C - Label Diagrams and Positions

APCU Owner’s Manual 15

Fig. 3D - Label Diagrams and Positions

16 APCU Owner’s Manual

Fig. 3E - Label Diagrams and Positions

APCU Owner’s Manual 17

Fig. 3F - Label Diagrams and Positions

18 APCU Owner’s Manual

Fig. 3G - Label Diagrams and Positions

"NOTICE" label p/n-2998591T

APCU Owner’s Manual 19

TO RETURN APCU TO REGULAR SERVICE:

REMOVE LOCK OUT AND TURN ON THE MAIN POWER DISCONNECT ON THE APCU1.

POWER CONTROL PANEL.

USING THE CONTROL PUSHBUTTON RAISE THE TILT FRAME TO THE HIGHEST POSITION.2.

TURN OFF AND LOCK OUT THE SWITCH ON THE APCU POWER CONTROL PANEL.3.

REMOVE THE SUPPORT STANDS FROM THE LOAD AREA.4.

AFTER PERSONNEL ARE CLEAR FROM THE LOAD AREA REMOVE LOCK OUT AND5.

TURN ON THE MAIN POWER DISCONNECT ON THE APCU POWER CONTROL PANEL.

USING THE CONTROL PUSHBUTTON, LOWER THE LIFT FROM TO THE LOAD POSITION.

APCU SUPPORT STAND USE PROCEDURE

DO NOT USE SUPPORT STANDS FOR HYDRAULIC, ELECTRICAL, MECHANICAL SERVICE

OR MAINTENANCE. WHEN ENTERING THE MACHINE'S LOAD AREA FOR OTHER

PURPOSES BOTH SUPPORT STANDS MUST BE USED.

NOTICE:

FAILURE TO FOLLOW THESE SPECIFIC USE PROCEDURES MAY SERIOUSLY DAMAGE

THIS EQUIPMENT

USING THE CONTROL PUSHBUTTON, RAISE THE TILT FRAME TO THE HIGHEST1.

POSITION.

TURN OFF AND LOCK OUT MAIN POWER DISCONNECT ON THE APCU POWER2.

CONTROL PANEL.

NOTE:

IF EQUIPPED WITH A GRACE VOLTAGE INDICATOR, ENSURE THAT NO LIGHTS

ARE ILLUMINATED.

SET THE SUPPORT STAND AT THE LOWEST EXTENSION HEIGHT PIN POSITION.3.

NOTICE:

BOTH SUPPORT STANDS MUST BE USED. NEVER HAVE ONLY ONE STAND

UNDER TILT FRAME FOR SUPPORT.

POSITION EACH SUPPORT STAND IN THE LOAD AREA AS SHOWN IN DRAWING4.

3053184T, THE LOCATION IS IDENTIFIED BY THE ALIGNMENT LABEL ON THE INSIDE OF

THE BASE FRAME RAIL.

NOTE:

IF NOT PRESENT, ATTACH LABEL 2998592T TO THE DIMENSIONS DETAILED IN

DRAWING 3053184T

THE AREA AROUND THE SUPPORT STANDS MUST BE FREE OF DEBRIS. NEVER HAVE

ANYTHING UNDER THE SUPPORT STANDS WHEN THEY ARE IN USE.

AFTER PERSONNEL ARE CLEAR FROM LOAD AREA REMOVE LOCK OUT AND TURN5.

ON THE SWITCH ON THE APCU POWER CONTROL PANEL.

USING THE CONTROL PUSHBUTTON, LOWER THE TILT FRAME UNTIL IT IS WITHIN 1/4"6.

OF THE SUPPORT STAND.

NOTICE:

IF THE FRAME STARTS TO CONTACT THE SUPPORT STANDS THE MACHINE

MOTION MUST BE STOPPED BY THE OPERATOR. DO NOT OVER POWER THE TILT

FRAME ON TO THE SUPPORT STANDS. THIS MAY DAMAGE THE MACHINE AND

MAY OVER STRESS THE FLOOR ANCHORS.

TURN OFF AND LOCK OUT THE SWITCH ON THE APCU POWER CONTROL PANEL.7.

IT IS NOW SAFE TO ACCESS THE LOAD AREA.8.

REVISIONS

REV. ZONE DESCRIPTION DATE REVISED BY ECN #

D UPDATED VIEWS 11/30/2017 KHS

DATE

MODEL

PROJECT: C

4 32

1

1234

A

B

C

D D

C

B

A

v.14

DWG NO.

3053184T SHEET 4 OF 4

1:1

D

SOUTHWORTH PRODUCTS CORP.

3053184T REV

TITLE

USE OF PROPRIETARY INFORMATION

DWG NO.

SCALE

UNLESS OTHERWISE

SPECIFIED.

DIMENSIONS ARE

PROJECTION

LABEL LOCATION DIAGRAM, SUPPORT STAND

5687 LB

IN INCHES

SIZE

P.O. Box 1380 Portland Maine 04104-1380

STATUS:

3RD ANGLE

LIMITED TO WRITTEN AGREEMENT

WT

CAGE CODE

063Z8 SHEET 4 OF 4

DR

REF

FRACTIONS 1/

.XXX .005

.XX .01

ANGLES: .5

8

Fig. 3H

20 APCU Owner’s Manual

Installation Instructions

Preparation

1. Before you start to use the unit, check for local

codes and ordinances which may apply. It is your re-

sponsibility to obtain any necessary permits.

2. Read all of these installation instructions carefully.

Be sure to read and understand all of the warnings.

3. Select the location where the unit will be installed.

Choose a location where the oor is rm, at and level.

As the unit operates, it is very important that the front

edge (the load edge) of the load enclosure touches the

oor at the same time as the rest of the bottom plate

touches.

CAUTION!

If the middle or back edge of the bottom

plate touches the oor before the front

edge of the load enclosure, the machine

may try to tip itself off the oor. This can

happen if the oor surface is not at.

WARNING!

• If the unit is mounted on an unstable

surface, it may tip over when in use. You

may be hurt, and the unit and load may be

damaged.

• Protect the unit from rain or moisture.

If the electrical parts in the power unit get

wet, workers may be hurt by electrical

shock. The electrical parts may fail if they

are wet.

• The electric motor on the remote power

unit can create sparks. Do not install the

power unit in an area where ammable

gases may be present.

4. You will need these tools to install the unit:

• A lift truck that can lift the unit safely.

• Shims and appropriate lag bolts.

• A masonry drill and bit to drill the holes for the

lag bolts.

• Extra hydraulic oil for ushing the hydraulic

lines and relling the tank.

• Level.

Positioning the Lift

1. Remove the shipping material and unskid the unit.

On the front of this manual, write down the model num-

ber, serial number, and date the unit is placed in service.

You can nd the model number and serial number on

the name plate.

2. Move the unit into position, supporting the base of

the unit. The base frame is tted with eyes for the lag

bolts. Drill the necessary holes and install the bolts.

CAUTION!

Do not hang the unit from the load enclo-

sure. This can damage the unit.

3. Check the movement of the load enclosure through

its full range.

CAUTION!

Take care not to create any “pinch points”.

Hydraulic Connections

1. Install the power unit. Run the hydraulic line be-

tween the power unit and the APCU but do not make

the connections yet. Be sure that the hydraulic line is

protected from passing trafc, and that it will not be

damaged.

WARNING!

Be sure that the hydraulic line will not be

pinched by the unit as it raises or lowers.

If you allow the line to be pinched, the unit

may not work properly. A hose may break,

the load enclosure may drop suddenly, and

someone may be hurt.

2. Before connecting the power unit, blow out the

hydraulic lines with compressed air.

CAUTION!

It is very important to keep the hydraulic

oil free of dirt, dust, metal chips, water, and

other contamination. Most of the problems

with hydraulic systems are caused by con-

tamination in the oil. Be sure all hydraulic

lines are free of contamination before con-

necting them to the remote power unit.

Table of contents

Other Southworth Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley MicroLogix 1100 quick start

ABB

ABB HT846784 Operation manual

SWF

SWF SB Series installation manual

Eaton

Eaton NZM1-XDTV Series Instruction leaflet

Heinzmann

Heinzmann StG 40.90-09 PD instruction manual

Baldwin

Baldwin DAHL 300 Series Installation, Operation, Parts, Service Information