Sovema ERX-3 Series User manual

OPERATION & MAINTENANCE MANUAL Revision 2022

_____________________________________________________________________________________

CONTENTS - 1/1

CONTENTS

INTRODUCTION

I – GENERALITY

I.A – SYMBOLS

I.B – GENERAL INFORMATIONS

II – SAFETY

II.A – LABELS

II.B – RECOMMENDATIONS

III – OPERATION

III.A – C ECKLIST

III.B – TEC NICAL DATA

III.C – ITC ING

III.D – PREPARATION FOR WORK

III.E – USAGE

III.F – UN ITC ING

III.G – TROUBLES OOTING

IV – STORAGE

V – MAINTENANCE

VI – TOXICOLOGICAL INFORMATIONS

VII – DISPOSAL & RECYCLING

VIII – WARRANTY

8.A – TERMS & CONDITIONS

8.B – WARRANTY REGISTRATION

INDEX

ANNEX

A1 – EU DECLARATION OF CONFORMITY

A2 – SOVEMA PRODUCT RANGE

A3 – SPARE PARTS CATALOGUE

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

INTRODUCTION - 1/1

INTRODUCTION

Dear Owner,

thank ou for bu ing a SOVEMA product.

Your new implement has been carefull designed and manufactured to give ou excellent

performance and dependable service, if properl operated and maintained.

Do not use the implement for operations far from the “intended use” of the manufacturer.

You will find this implement to be stead and reliable when matched to the suggested

tractor power.

Much time has been invested in providing safet and protection. Read carefull the present

manual, giving guidance for the correct, safel and easil , use and routine basic

maintenance of implement. Moreover, it contains warnings for foreseeable hazards as well

as definitions of terms, s mbols and pictograms used compl with the relevant international

standard. Keep manual for future reference.

Be sure that ou and an other operator carefull follow the recommended safet practices

at all times. Failure to do could result in personal injur or propert damage.

Of course, if ou should have an problems or questions, please do not hesitate to contact

our local SOVEMA dealer or, alternativel , to contact us at the addresses or numbers

indicated in this manual.

The reproduction in whole or in part of this manual is prohibited without prior written

agreement with SOVEMA.

SOVEMA manufactures a wide variet of agricultural equipment. If ou are interested in

discovering our entire range, please contact us.

Thanks for our choice.

Pier Silvio Ma er

President

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

I - 1/2

I - GENERALITY

The manual is the translation of the ori inal manual in italian lan ua e (official lan ua e).

If you should notice any unclear points, omissions, etc., feel free to contact SOVEMA.

I.A - SYMBOLS

These followin safety picto rams appear throu hout the manual.

Remember their meanin .

READ CAREFULLY!

YOUR SAFETY IS IN DANGER!

USE PERSONAL PROTECTIVE EQUIPMENT!

(safety shoes, protective loves, helmet, o les, overalls and FFP1 mask)

IMPORTANT INFORMATION!

OPERATION & MAINTENANCE MANUAL Revision 2022

_____________________________________________________________________________________

I - 2/2

I.B - GENERAL INFORMATIONS

All implements with movin parts are potentially hazardous. The manufacturer has desi ned

the implement to be used with all the uards properly fitted.

The purpose of this manual is to provide important informations on technical specifications,

safety, operatin , maintenance and troubleshootin of the implement, so you can use it in a

proper, safe and efficient way. Compliance with this manual contributes to avoid risks,

reducin repair costs and downtime and increasin the reliability and lifetime of the

implement.

This manual have been filled in by our decennial experience. Followin the instructions, you

should be able to develop operatin procedures suitable to your needs.

The ima es contained in this manual are indicative and may differ from reality, their purpose

is illustrative only.

Illustrations used in this manual may vary sli htly in some details compared to your

implement.

Even if some illustrations in this manual could show the implement with safety uards

removed for a better understandin , never operate in these conditions.

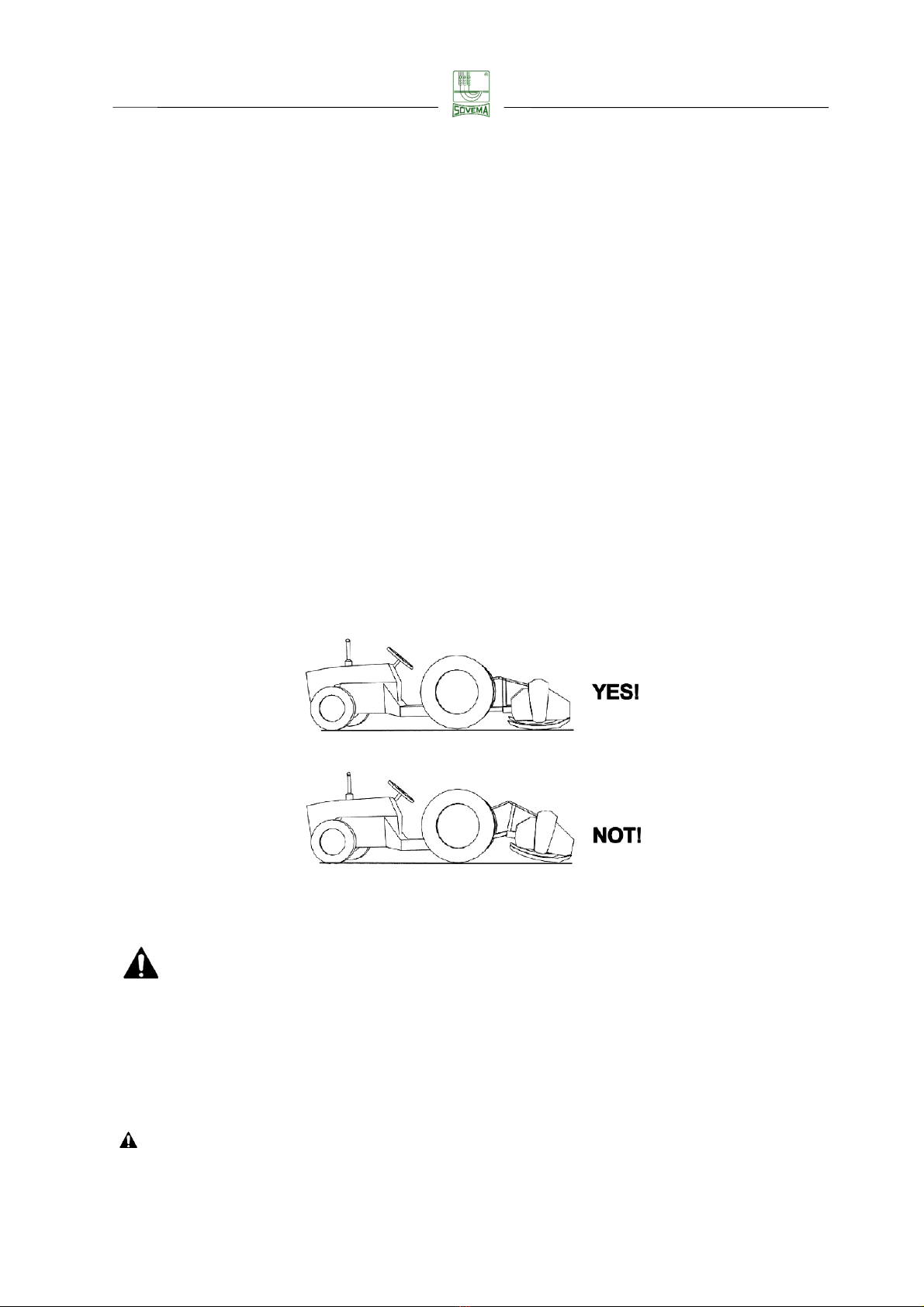

In this manual references to “forward”, “ri ht” and “left” are referred as indicated in ima e

below, with the implement connected to the tractor on its rear three-point hitch.

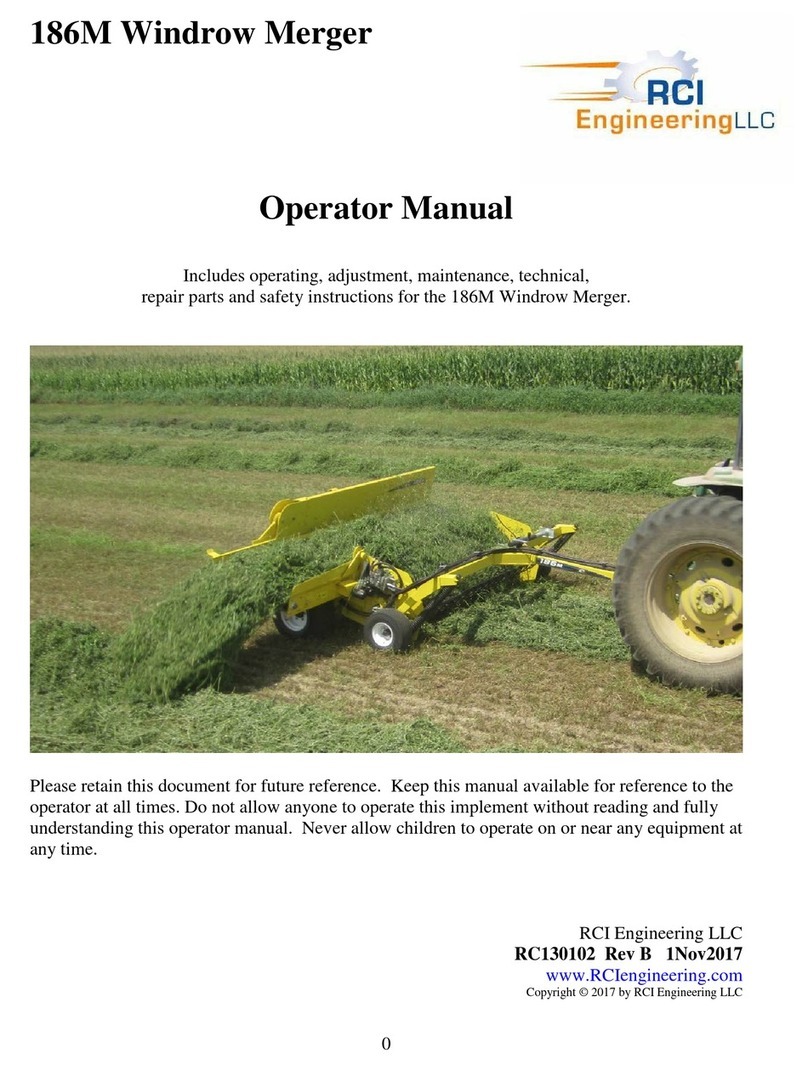

FIELD OF USE : The implement must be used for a ricultural activities. The operator, on the

basis of workin conditions always available, must pay particular attention to the

performance limits of the implement. At the first si n of overloadin , the implement must be

stopped immediately.

This manual is protected under copyri ht law. Any reproduction and distribution, partial or

complete, of document is not permitted unless expressly permitted in writin .

BEFORE OPERATING THE IMLEMENT ALL SAFETY GUARDS MUST BE

MOUNTED!

KEEP THE MANUAL IN A

SAFE AREA FOR ALL OF LIFE OF

THE IMPLEMENT. IF IT IS PARTIALLY RUINED OR LOST YOU

HAVE TO REQUEST A NEW ONE CONTACTING A DEALER

SOVEMA OR SOVEMA ITSELF.

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

II - 1/6

II – SAFETY

This section is very important ecause even if the implement is well-designed and even if

safety guards are present on the implement, residual risks remain and the operator have to

know them in order to avoid injuries.

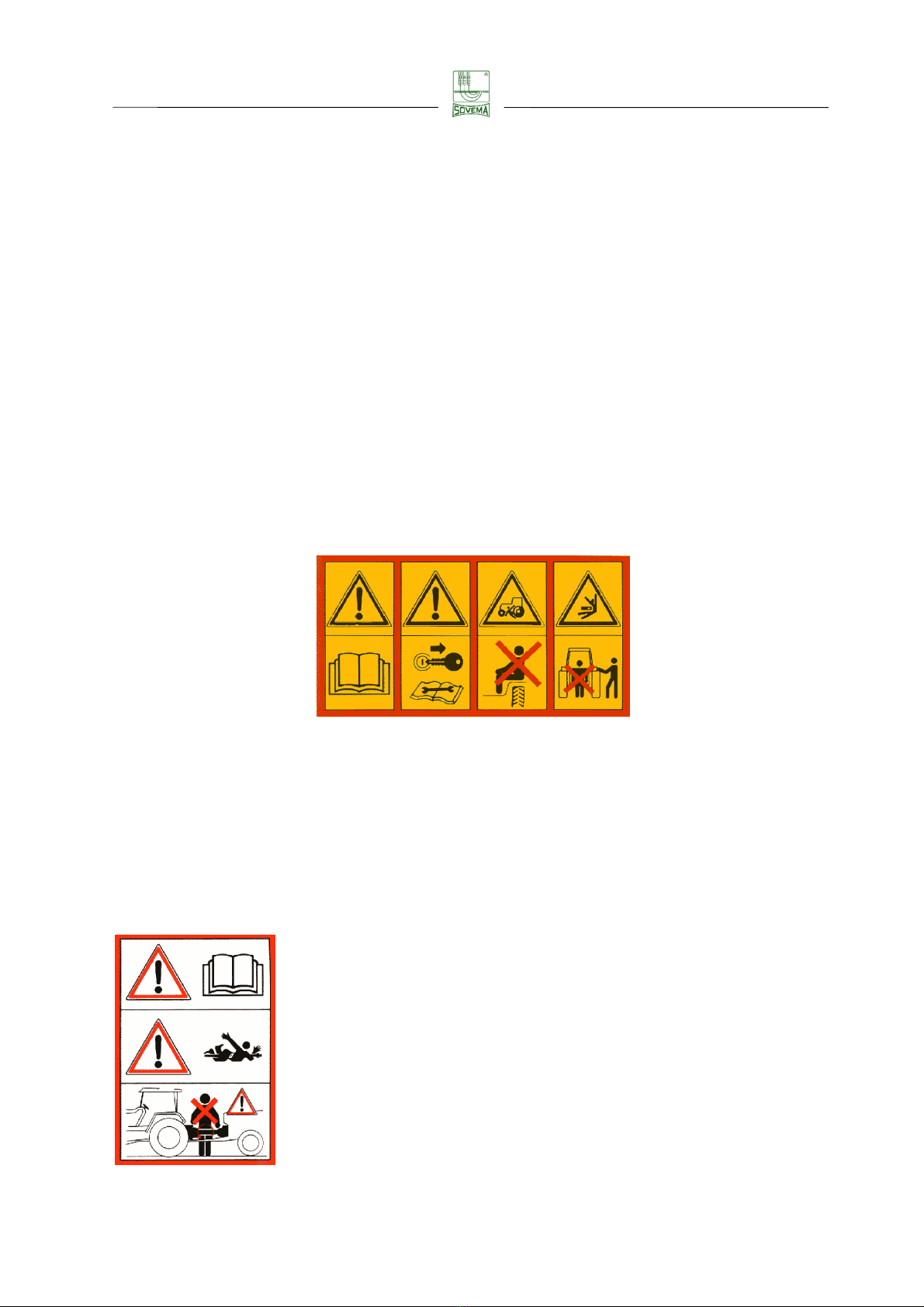

II.A - LABELS

Safety pictograms (hereafter decals), placed in a visi le position on the implement contain

important safety warnings. To prevent injuries the operator have to read and understand

them carefully and keep them clean and visi le.

Check that all the decals are on the implement and in a good condition. If not, do not use the

implement without decals and refer to the dealer immediately to get them.

The meaning of decals that are on the implement is the following:

1 2 3 4

1

Before starting operations, read carefully the instruction manual

2

Before performing the maintenance, lower the implement to the ground, turn off

the engine, disengage the PTO and read the operator manual

3

People, animals or o jects must never e transported on wrong place of the

tractor or of the implement, fatal injuries may occur

4

Do not stand ehind the tractor during operations

5

Before connecting the implement to the PTO, read

carefully the operation & maintenance manual

6

Hazard of entanglement in PTO drive shaft

7

Keep away from the PTO drive shaft in operation: the

contact can cause death

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

II - 2/6

8 9 10 11

8 Hands and feet can e injured y moving tines. Keep away from the

implement

9 Your feet can e injured. Keep away from the implement

10 Your hands can e injured. Do not remove safety guards and keep away from

moving parts

11 Your hands can e injured. Do not remove the cover and keep away from

moving parts

The implement is designed for 540 rpm PTO

The implement is designed for 1000 rpm PTO

During working operations all ystanders must stay

eyond the shown distances from the implement

Do not step or stand on this surface

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

II - 3/6

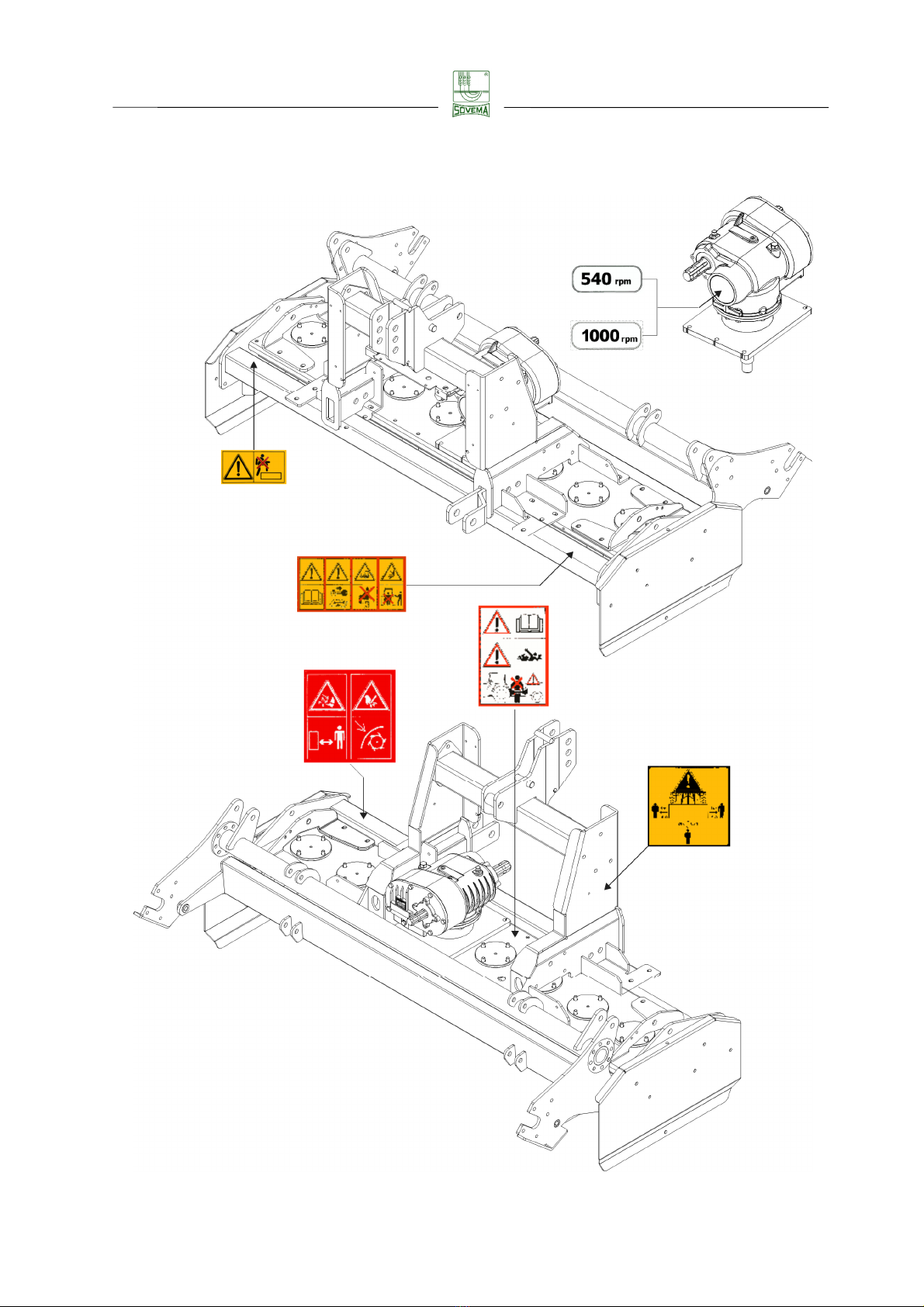

In the following figure it is indicated the location of decals descri ed a ove.

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

II - 4/6

II.B - RECOMMENDATIONS

Before using the implement you must e sure to know the main safety recommendations;

many accidents are caused y not o serving these simple rules.

SOVEMA Srl declines to the full extent allowed y the applica le laws all lia ility and

responsi ility for any damages of any kind resulting from the non-o servance of the rules

and guidelines expressed in this manual

PRE-OPERATIONAL AND OPERATIONAL SAFETY RULES

This manual must e always availa le and should e read and studied y any person

who is authorized to work with the implement

Keep all guards and safety decals in place and in a good condition efore operating

the implement. Guards can e removed for maintenance or cleaning purpose only

Only operate with a tractor equipped with an approved Roll Over Protective System

(ROPS) and always fasten seat elt

Operate with daylight or good artificial light only

Be sure that only trained personnel operate/maintain the tractor the implement

Personal protection equipment, including overalls, safety shoes, goggles, helmet,

gloves and mask are recommended during the operations of

hitching/usage/unhitching of implement

Do not leave seat until the implement is lowered to the ground, engine is completely

turned off, rakes engaged, ignition key removed

Do not allow to other people to stay on wrong place of the tractor or on implement at

any time

Before starting operations, make sure that the tractor PTO is set to match the PTO

requirements of implement. The speed is indicated on the implement and in this

manual on “III.B - TECHNICAL DATA” section

Always use the PTO drive shaft supplied y the manufacturer

Make sure that the PTO drive shaft is firmly connected to the tractor and

to the

implement and locked in position

For hitching and unhitching the PTO drive shaft, please refer to the manufacturer’s

instructions manual and to your tractor’s instructions manual

Hitching and unhitching of the PTO drive shaft must e performed with the tractor’s

engine turned off

Keep hands, feet, long hair, loose clothing and jewelry away from moving parts

To prevent injury y thrown o jects do not operate unless all personnel, livestock

and pets are 20 m (65 ft) away

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

II - 5/6

The rotating parts of the implement have een designed and tested for rugged

use. However they can damage due to impact with heavy solid o jects. Such

impact can cause fragments to e thrown outward at very high speed. To reduce

the possi ility of serious injury, or even death, never allow the rotating parts to go

to the contact with such o stacles

Stop the implement and tractor immediately upon hitting an o stacle. Turn off the

engine, remove the ignition key, inspect and repair any damage efore resuming

operation

No repairs or adjustments should e carried out while the implement is connected

to the tractor and turned on

Disengage tractor PTO and place transmission into neutral position efore

attempting to start tractor engine

USE AFTER A LON PERIOD OF INACTIVITY

Before using the implement after a long period of inactivity, please follow these steps:

Make sure the implement is not damaged

Check all mechanical parts. They must e in good condition and must not show

signs of rust

Check wear of tools

Verify that the implement does not present loss of oil from couplings or tu es

Lu ricate all moving parts

Verify that all safety guards are correctly positioned and assem led

Verify that all safety decals are correctly positioned and assem led

ROAD TRANSPORT SAFETY

Plan route to avoid heavy traffic

Make sure that all moving parts e firmly secured

Be sure that the implement is in the raised position for transport

When you drive never drink

Pay attention to traffic when operating near or crossing roadways

Drive at low speed to avoid ouncing and loss of steering control

Before transportation, remove any dirt, soil, crop residue or other elements that

might e dangerously dispersed during transport

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

II - 6/6

Before transportation, pay particular attention to the integrity of the coupling pins

and to the presence of their safety pins

In case of transport on pu lic roads, o serve the traffic code of the State where the

implement is, pay particular attention to the requirements relating to the visual

signalling devices, to the overall dimensions and the admitted weight

MAINTENANCE SAFETY

Good maintenance is your responsi ility. Poor maintenance is an invitation to fault

Please follow these common practices:

1. keep service area clean

2. use adequate illumination for the working place

3. make sure the electric tools are properly grounded

4. make sure the service area is properly ventilated

Before performing maintenance of implement, e sure that area is level, turn off the

engine, disengage the PTO, lower the machine, engage the rakes and remove the

ignition key

Keep all people away from the service area while performing maintenance

Always use personal protective equipment included, esides safety shoes and

protective gloves, overalls, goggles, and helmet

When replacing a mechanical part, always use original spare parts in order not to

compromise the implement and your own personal safety. SOVEMA assumes no

lia ility if the replacement of non original parts is performed

After servicing, e sure that all safety guards are re-installed properly

After servicing, make sure that all safety decals are reinstalled on the implement

and in good condition

If the implement is modified from the original design, no responsi ility for the

manufacturer can e claimed

In case of lifting of the implement the operator have to use the lifting holes indi-

cates in this manual on “V - MAINTENANCE” section

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.A - 1/1

III – OPERATION

III.A – CHECKLIST

Before connecting the im lement to the tractor, lease read the following instructions:

Make sure that the weight and ower of the tractor is suitable to the im lement you

want to connect. If you have any doubt, lease refer to the “III.B – TECHNICAL

DATA” section

Make sure that all safety ictograms (decals) are ro erly installed and clean

Check the oil level in the gearbox. A low oil level can damage the gears

Make sure that all safety guards are ro erly installed and in good condition

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.B - 1/1

III.B - TECHNICAL DATA

The implement descri ed in this manual is a fixed rotary harrows from the ERX-3 series.

The identification plate is located on the right-upper side of implement frame.

The image shown is for illustrative purpose only

MODEL

WORKING

WIDTH

POWER WEIGHT

WIDTH

“A”

DEPTH

“B”

HEIGHT

“C”

cm/in

hp/kw

kg/l

cm/in

cm/in

cm/in

ERX

-

3 200

200/79" 60÷80/44÷59 890/1960 214/84" 135/53" 123/48"

ERX

-

3 250

250/98" 70÷90/51÷66 995/2191 264/104" 135/53" 123/48"

ERX

-

3 300

300/118"

80÷100/59÷74

1135/2500

314/124"

135/53"

123/48"

MODEL HITCH

CAT.

WORKING

DEPTH

NO. ROTORS

NO TINES (RH + LH)

THREE-POINT HITCH

POSITION

COMPARED TO RAME

SX

DX

cm/in

no.

–

no.

cm/in

ERX

-

3 200

II 29/11" 8 - 16 (8 RH + 8 LH) 100/39" 100/39"

ERX

-

3 250

II 29/11"

10 - 20 (10 RH + 10 LH) 125/49" 125/49"

ERX

-

3 300

II 29/11"

12 - 24 (12 RH + 12 LH) 150/59" 150/59"

PTO

SPEED

GEARBOX RATIO ROTORS SPEED

rpm no. no. rpm

540 26 31 220

540 31 26 310*

1000

26

31

405

NOISE LEVEL UNDER NO LOAD

*in order to operate with this speed follow the instructions indicated on “III.D-PREPARATION FOR WORK” chapter

B

A

C

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.C - 1/3

III.C HITCHING

The implement descri ed in this manual can e connected to any kind of tractor provided of

universal three-point linkage.

The characteristics of this linkage depend on the type of tractor, therefore it is necessary to

setting up the tractor in order to properly connect the implement.

This operation must e carried out on a flat and firm area as it is dangerous.

Do not allow anyone to stay etween tractor and implement while the engine is

running

Follow these instructions:

1. Connect the tractor two lifting arms to the lower plates of the implement y using two

hitch pins and two cotter keys to lock pins in place (see Fig. 1)

Figure 1

2. Connect the tractor top link to the mast of implement y using hitch pin and a cotter

key to lock pin in place (see Fig. 1)

MAST

LOWER PLATES

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.C - 2/3

3. Lift up the implement off the ground

4. While remaining in the driving seat, put the tractor PTO in neutral position

5. When the PTO drive shaft has completely stopped, turn off the engine, engage the

parking rake and remove the ignition key

6. Get off the tractor and place wheels in a desired working position y using the

ru er ushes

7. Connect the PTO drive shaft to the implement

8. Connect the PTO drive shaft to the tractor. If the shaft is too long you have to

shorten it, please refer to the instructions on the next page

9. (if present) Connect implement hydraulic hoses to the tractor distri utor

10. Get on the tractor, insert the ignition key and turn on the engine

11. Lower the implement and adjust it so that it is parallel to the ground. Do this y

adjusting the tractor top link (see Fig. 2). This will improve the life-span of the

implement and the PTO shaft

Figure 2

Always check that the tractor PTO is in neutral position efore connecting the

PTO drive shaft!

NOTE ON THE PTO DRIVE SHAFT

Always refer to the manufacturer’s instructions manual.

Read it carefully

!

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.C - 3/3

Shorten the PTO drive shaft

Due to the many different types of tractors, it may e necessary to shorten the PTO shaft.

Listed elow are some asic guidelines on performing this modification. First, determine

the length that has to e removed

1) remove plastic protection on oth sections

2) cut the excess length of oth tu es using a saw

3) de urr and clean the ends of each tu e

4) cut the plastic protections to the same length you have cut the tu es

5) grease the the tu e and reassem ly the drive shaft

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.D - 1/1

III.D - PREPARATION FOR WORK

Working depth adjustment

In order to set up the implement s working depth, adjust the rear roller actuating the

hydraulic cylinders, as indicated in figure 1 :

Figure 1

After adjusting the rear roller it is necessary to adjust the position of the levelling bar as

follows (see figure 2):

unblock the screw register crank of the levelling bar by taking out the stop of the crank

itself

rotate the crank until the levelling bar reaches the desired position

block the crank using the stop

Figure 2

In order to obtain an even soil, for each wheel, please adjust the two supports at

the same height.

CYLINDER

CYLINDER

REGISTER SCREW

CRANK

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.E - 1/1

III.E - USAGE

After having com leted all safety checks and made sure the harrow is arallel to the

ground, roceed as follows:

• raise the im lement off the ground in order to let the tines start moving without

touching ground to avoid damages

• kee ing the im lement raised, engage the tractor PTO at suggested engine’s revs

• start moving the tractor forward and then gradually lower the im lement

OPERATING TIPS

Pro er ground s eed for harrow will de end u on the ty e of soil and its

conditions. However we suggest not to exceed 5 km/h (3.1 m h)

Lower ground s eed allows to grind the soil with better erformance. In order to obtain a

o osite result roceed more quickly

During the o eration, in order to not cause damages to the harrow,

avoid to steer the im lement and avoid to work in reverse. It is always

necessary to raise the im lement before making a turn or change of

course, otherwise damages to the skid or roller su orts can occur.

The im lement must be used only if equi ed with all its com onents as

su lied by SOVEMA (safety devices included). No com onents can be

modified

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.F - 1/1

III.F – UNHITCHING

The disconnection of the implement f om the t acto must be ca ied out on a flat and fi m

su face. It’s a dange ous ope ation, pay attention. Please ead the following inst uctions

ca efully:

1. Once eached the pa king position, while emaining in the d iving seat, put the

t acto PTO in neut al position

2. When the PTO d ive shaft has completely stopped, tu n off the engine, engage the

pa king b ake and emove the ignition key

3. Get off the t acto and place the ea olle in a desi ed position

4. Get on the t acto , inse t the ignition key, tu n on the engine and lowe the

implement on the g ound (check that tines and ea olle co ectly and fi mly est on

the g ound)

5. (if p esent) Disconnect implement hyd aulic hoses f om t acto dist ibuto and place

them in thei holde s o inse t the plug on each hose end

6. Remove PTO d ive shaft f om the t acto

7. Remove PTO d ive d ive shaft f om the implement

8. Disconnect the t acto top link then

9. At the end, p oceed disconnecting the t acto two lowe links

Always check that the t acto PTO is in neut al befo e disconnecting the PTO

d ive shaft

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.G - 1/3

III.G TROUBLESHOOTING

During the operation o implement several problems can happen:

UNUSUAL NOISES

During working, i the implement produces unusual noises, the operator must

immediately stop it and ollow these instructions:

• Make sure that there are no broken/bent mechan cal parts

• Check that the gearbox conta ns the correct amount of o l

I the oil level is too low (please see the section “V - MAINTENANCE”), the gears

are not adequately lubricated and i the gearbox continues to rotate will determine

a signi icant increase in oil temperature. This will quickly produce damages to the

gears and bearings

• Check t nes cond t ons

I some o the tines are broken, bent or present excessive wear, the balance o

the rotor will be compromised. During working, the rotating movement o the rotor

will produce vibrations that will inevitably damage and break bearings and welded

parts o the rame. In order to avoid damages, please replace all the tines at the

same time with the new genuine ones supplied by SOVEMA

• Check the lubr f cat on of the gears conta ned n the box

As a consequence o inadequate lubrication, damage to some gears can occur in

short time. Continuing to work in this way can occur the block o the transmission

in short time

• Check the lubr cat on and cond t on of the rotor shafts bear ngs

As a consequence o reduced lubrication, one or both the bearings supporting the

rotor sha t may have broken down. The rotor begins to oscillate producing

excessive vibrations against the rame, producing damages to the welded parts

o the rame

OPERATION & MAINTENANCE MANUAL Revision 2022

____________________

____________________

____________________

____________________

_____

III.G - 2/3

Another possible cause or breaking rotor sha t bearings can be the impact with

heavy objects on the ground such as stones, metallic objects, etc.

Another possible cause or breaking rotor sha t bearings is the improper use o

the implement; esplecially using it at high speed, changes on direction, u-turns

while working

• Check the mplement

During the working i the implement jumps over the soil or vibrates may be that

tines mounting is incorrect or blunt edges o tines are penetrating the soil irst

WORKING ANOMALIES

I a ter the operation the implement ailed to obtain an acceptable tillage, the operator must

ollow these instructions:

• Check t nes

The tines can be worn and less e ective. Please replace them. Use original tines

SOVEMA only.

During the working i the the tines rub along the soil instead o penetrating it,

please advance more slowly.

During the working i the tines are clogged raise the levelling bar in order to keep

clods away the tines

• Check f the work ng depth has been properly set up

The adjustment o the implement may be uneven. Check that roller is parallel to

the soil

• Check gears cond t on after remov ng the frame l d

It is possible that the gears are not in good condition, thus ailing to transmit

enough power to the tines.

I a gear looks marginally damaged, the operator must replace it immediately

• Check f rotors are free from fore gn bod es

It is possible that objects, such as clods, stones, metal parts etc., are attached to

the rotor sha ts or tines prevent it works in the best condition. I it is happened this

above mentioned please remove the oreign parts

• Check advancement tractor speed

A less-than-adequate result can be produced by an incorrect working speed. The

speed must be set up in relation to the rotor turns, type o soil and tractor power.

Advancing too quickly doesn’t allow the tines to grind thoroughly

This manual suits for next models

3

Table of contents

Other Sovema Farm Equipment manuals