Civemasa GDFH User manual

OPERATOR'S MANUAL

GDFHGDFH

Civemasa Implementos Agrícolas 1

GDFH

Introduction

The GDFH disk harrow is specially designed to perform

secondary tillage by clod breaking and leveling the surface,

eliminating air pockets and leaving the soil ready to any type of

crop.

The equipment tires are placed at strategic points. They are

easy to handle and can quickly set the disk harrow to transport

position, allowing it to transit at greater speeds through narrow

places and long distances.

The GDFH model also features a central articulation in the

frame with ideal buoyancy to follow the surface unevenness or

even to perform a finishing job on broad-based terraces.

This operator's manual contains the necessary information

for the best performance of this disk harrow. The operator must

carefullyreadtheentiremanualbeforeworkingwiththeequipment.

Also, read and understand the safety recommendations.

For any further clarification or in the event of technical

problems that may arise during the service, consult your dealer

and the Technical Support department of the factory. They can

ensure the fully functioning of your Civemasa disk harrow.

Civemasa Implementos Agrícolas

2GDFH

Table of contents

1. To the owner 3

2. To the operator 4 to 10

3. Data sheet 11 & 12

4. Components 13

5. Assembly 14 to 28

Using the set of wrenches 14

Assembly of bearings and spacer spools 15 to 20

Disc gangs assembly sequence 21 & 22

Assembly of disc gangs on the frame 23

Frames junction / Scrapers assembly 24

Disk harrow opening system assembly 25

Tires assembly / Drawbar set assembly 26

Hydraulic circuit assembly 27 & 28

6. Set-up instructions 29 to 33

Preparing the tractor / Preparing the disk harrow / Hitching to the tractor 29

Procedures to transport the equipment 30 to 33

7. Adjustments and operations 34 to 40

Cutting depth adjustment 34 & 35

Ways to start the harrowing 36

Direction of the maneuvers 37

Troubleshooting guide 38 & 39

Operations - Important points 40

8. Maintenance 41 to 48

Lubrication 41

Lubrication points 42

Wheelset hubs lubrication 43

Disk harrow maintenance 44

Tires inflation 45

Hydraulic cylinder maintenance / assembly 46 & 47

Hydraulic safety 48

9. Important data 49 to 51

Calculation of hourly income 49

Average income table 50

Torque table 51

10. Important 52

Civemasa Implementos Agrícolas 3

GDFH

To the owner

General information

Important

Right and left hand side indication are made observing the equipment from the rear.

To order any parts or request technical assistance services, it is required to provide

the data contained on the nameplate, which is located on the equipment frame.

• Only people who own a full knowledge of the tractor and equipment

must transport, operate and carry out any maintenance on them;

• Civemasa is not responsible for any damage caused by accident on

transporting, incorrect utilization or inadequate storage, either by

negligence and/or lack of experience from any person;

• Civemasa is not responsible for any damage caused by unpredictable

situations or the incorrect use of the equipment.

The warranty shall not be applied to any equipment or any part thereof which

has been altered elsewhere than at the place of manufacture or which the

original purchaser thereof at retail has used or allowed to be used parts, not

made or supplied by Civemasa.

NOTE

The acquisition of any Civemasa product assures to the original purchaser the following

rights:

• Warranty certificate;

• Operator's manual;

• Technical assistance by the dealer on equipment delivery.

However, the owner must check the condition of the equipment on delivery, as well as

knowing the warranty terms.

Special attention should be given to the safety recommendations, operation precautions

and maintenance of the equipment.

The instructions in this manual indicates how to get the best performance and allow

the operator to get maximum income, increasing the equipment lifetime.

This manual should be read by operators and maintenance staff.

Civemasa Implementos Agrícolas

4GDFH

To the operator

Dear operator!

Respect the ecology. Do not throw trash away. This gesture

of goodwill helps to protect our environment.

Be careful with the environment

Working safely

• Security aspects must be carefully observed to avoid accidents.

• This symbol is a warning used to prevent accidents.

• The instructions near this symbol refers to the safety of the

operator or third parties, therefore it should be carefully read

and observed. When the safety instructions are not being

followed, a serious accident or even death may occur.

U

U

s

s

o

o

d

d

e

e

E

E

.

.

P

P

.

.

I

I

.

.

O

O

B

B

R

R

I

I

G

G

A

A

T

T

Ó

Ó

R

R

I

I

O

O

Uso de

E.P.I.

OBRIGATÓRIO

Products such as oil, fuel, filters, batteries and others must

not be spilt over the soil as they can penetrate the underground

layers, compromising nature. Ecological and conscious disposal

of them should be done.

Read and understand the information before making any

adjustment or maintenance.

The GDFH disk harrow is simple to operate, requiring however

the basic and essential cautions to its handling.

Always keep in mind that safety requires constant attention,

observation and prudence during the harrowing, transportation,

maintenance and storage.

Have extreme caution when operating with the power take-off

(PTO). Do not get closer during operation.

Civemasa Implementos Agrícolas 5

GDFH

To the operator

Never use your bare hands to check hydraulic leaks, the high

pressure can cause injuries.

Never attempt to change the adjustments, clean or lubricate the

equipment when the same is switched on or in movement.

Be careful while driving on slopes. Risk of overturn.

Prevent that chemical products (i.e: fertilizers, treated seeds)

make any contact with your skin or clothes.

Keep access and work places clean or free from oil and grease.

Risk of accidents.

The presence of any other people on the tractor or equipment

is stricly forbidden.

Have extreme caution when driving under electrical power lines.

Any contact may result in severe shocks, injuries or death.

For your protection and safety, always wear adequate clothes

and footwear while operating the equipment.

Always use the seat belt.

XX

Always use the safety locks to carry out maintenance operations

and to transport the equipment.

Civemasa Implementos Agrícolas

6GDFH

To the operator

• Only trained and qualified personnel are allowed to operate the equipment.

• While working or during transportation, only the presence of the operator is

allowed on the tractor.

• Do not allow children to play near or over the equipment while it is operating,

during transportation or storage.

• Have full knowledge of the soil before starting to work. Provide the delineation

of obstacles or hazardous locations. Use the speed which is suitable to the

conditions of the ground or pathways to be covered.

• Use personal protective equipment (PPE).

• Wear appropriate clothes and footwear. Avoid clothes that are either loose or

hanging from the body, which may become entangled in moving parts.

• Never operate the equipment without its proper protective devices.

• Be careful while hitching the equipment to the tractor.

• Wear protective gloves to work near the disc blades.

• Never attempt to change the adjustments, clean or lubricate the equipment

while it is moving.

• Carefully check the transport width on narrow locations.

• When setting the disk harrow to transport position, check if there are no people

or animals close or under it.

• In case of emergency, know how to stop the tractor and equipment quickly.

• Always shut down the engine, remove the key and use the handbrake before

leaving the tractor seat.

• Do not drive the equipment under the influence of alcohol or any soothing/

stimulating medicine, as it may result in a serious accident.

• In case of a fire outbreak or any possible hazard, the operator must leave the area

as fast as possible and look for a safe place. Always have emergency numbers

at hands.

• Do not allow people or animals to get under the equipment at any time.

• Whenever you unhitch the equipment, either in the field or shed, do it on a

flat and firm surface and use the parking jacks. Make sure the equipment is

properly supported.

• We suggest that you carefully read the manual, as it will be a guide for periodic

verifications that need to be done and will allow that you assure the maintenance

of your equipment.

• If there is any doubt left after reading it, ask your dealer. For more complicated

operations, there will be the right person to help you there.

• Please check the general safety instructions on the back cover of this manual.

Civemasa Implementos Agrícolas 7

GDFH

Transportation over truck or trailer

To the operator

Civemasa does not advise the equipment traffic on highways, because this

practice involves serious security risks in addition to being prohibited by the

current existing traffic law. The transportation for long distances should be done

on truck, trailer or others by following these safety guidelines:

• Use adequate ramps to load or unload the equipment. Do not make the loading

on ditch banks, it can cause a serious accident.

• When lifting with a hoist, use the appropriate points to lift.

• Underpin the equipment appropriately.

• Use chock blocks and safety chains to secure the equipment to the truck or

trailer during the transport.

• After 8 to 10 km transporting, please inspect the load condition. Repeat this

procedure every 80 to 100 km. Give more attention when transporting the

equipment on rough roads, slopes and other adverse conditions.

• Always be careful with the load height, especially when passing under electrical

power lines, bridges and others.

• Check all laws and regulations regarding the height limits and load width while

transporting the equipment on truck or trailer. If necessary use banners, lights

and other devices in order to give adequate warning to the other drivers.

Civemasa Implementos Agrícolas

8GDFH

To the operator

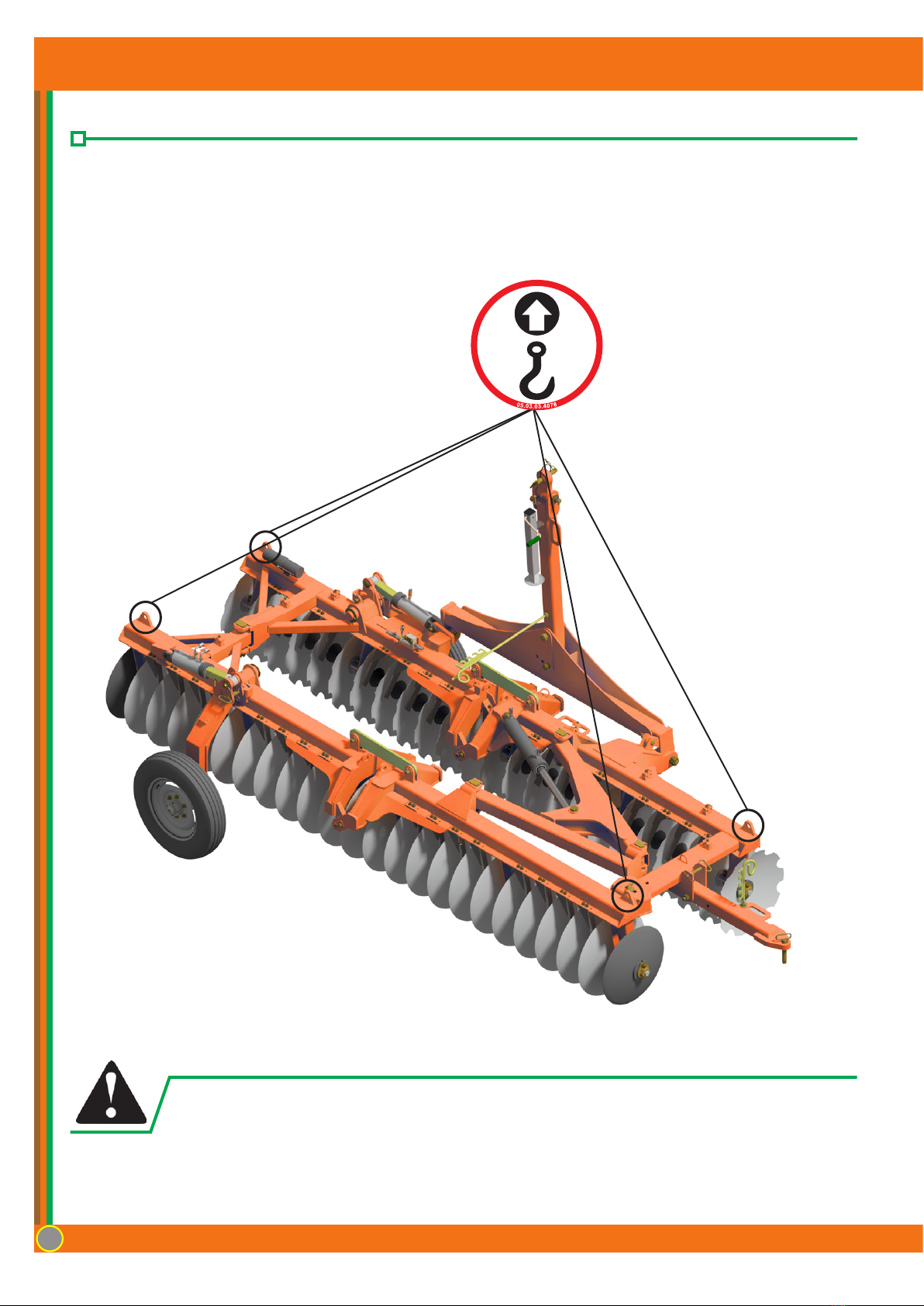

Lifting points

The equipment has adequate lifting points located on the frame. When carrying out

any maintenance or when transporting the equipment, hitch the cables to all lifting points.

Use chains, of at least 3 meters long, to lift the equipment safely.

Use the adequate points for lifting and be sure that the equipment is safe.

Avoid accidents.

Always keep a safe distance from the equipment.

Civemasa Implementos Agrícolas 9

GDFH

To the operator

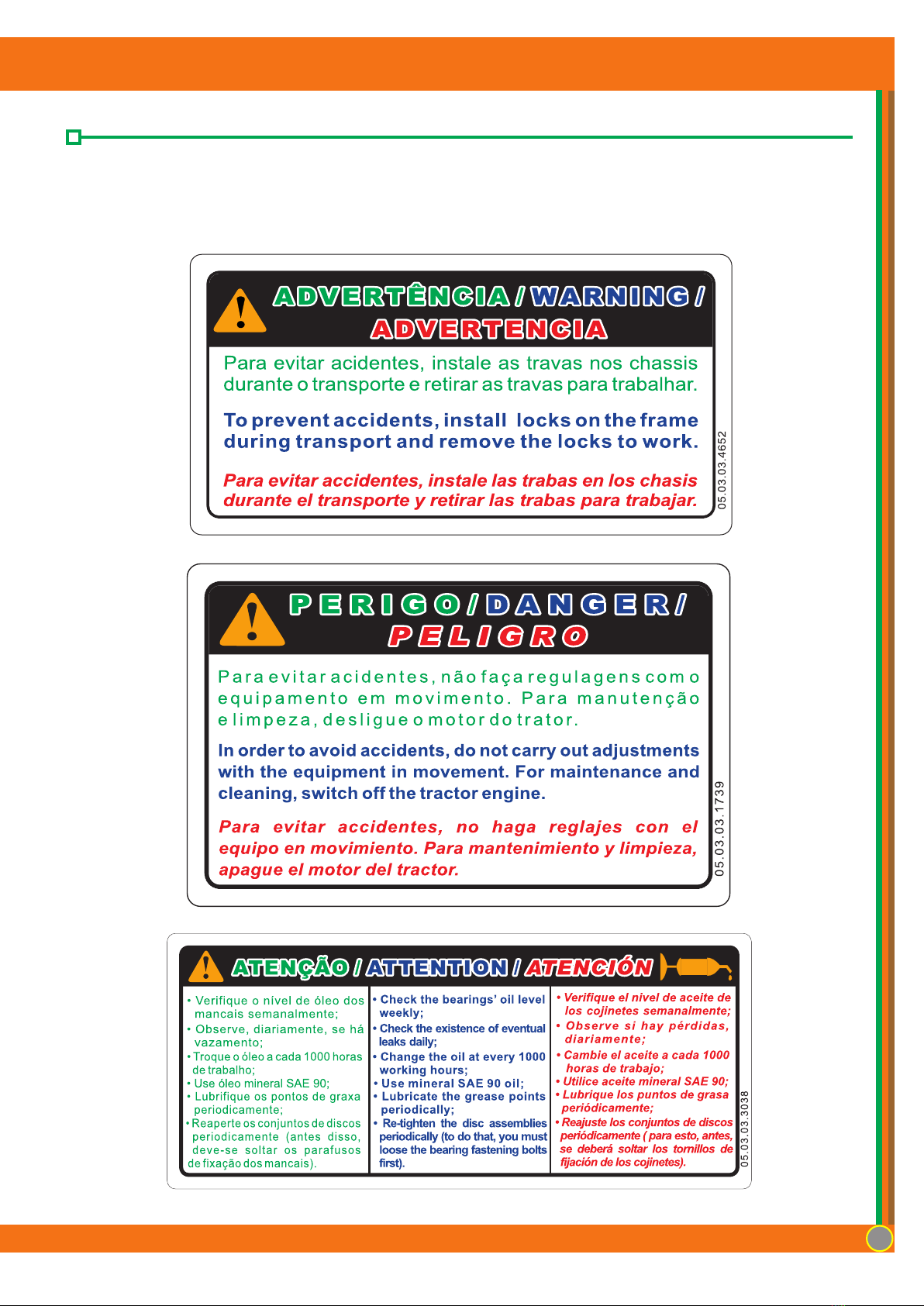

The safety decals warn about the equipment points that require more attention and they

should be kept in good repair. If these decals become damaged or illegible, replace them.

Civemasa provides decals, upon request and indication of the respective serial number.

Safety decals

Civemasa Implementos Agrícolas

10 GDFH

Decal set

Model Serial number

GDFH decal 05.03.03.4707

Civemasa logotype decal 05.03.03.5341

To the operator

Safety decals

Civemasa Implementos Agrícolas 11

GDFH

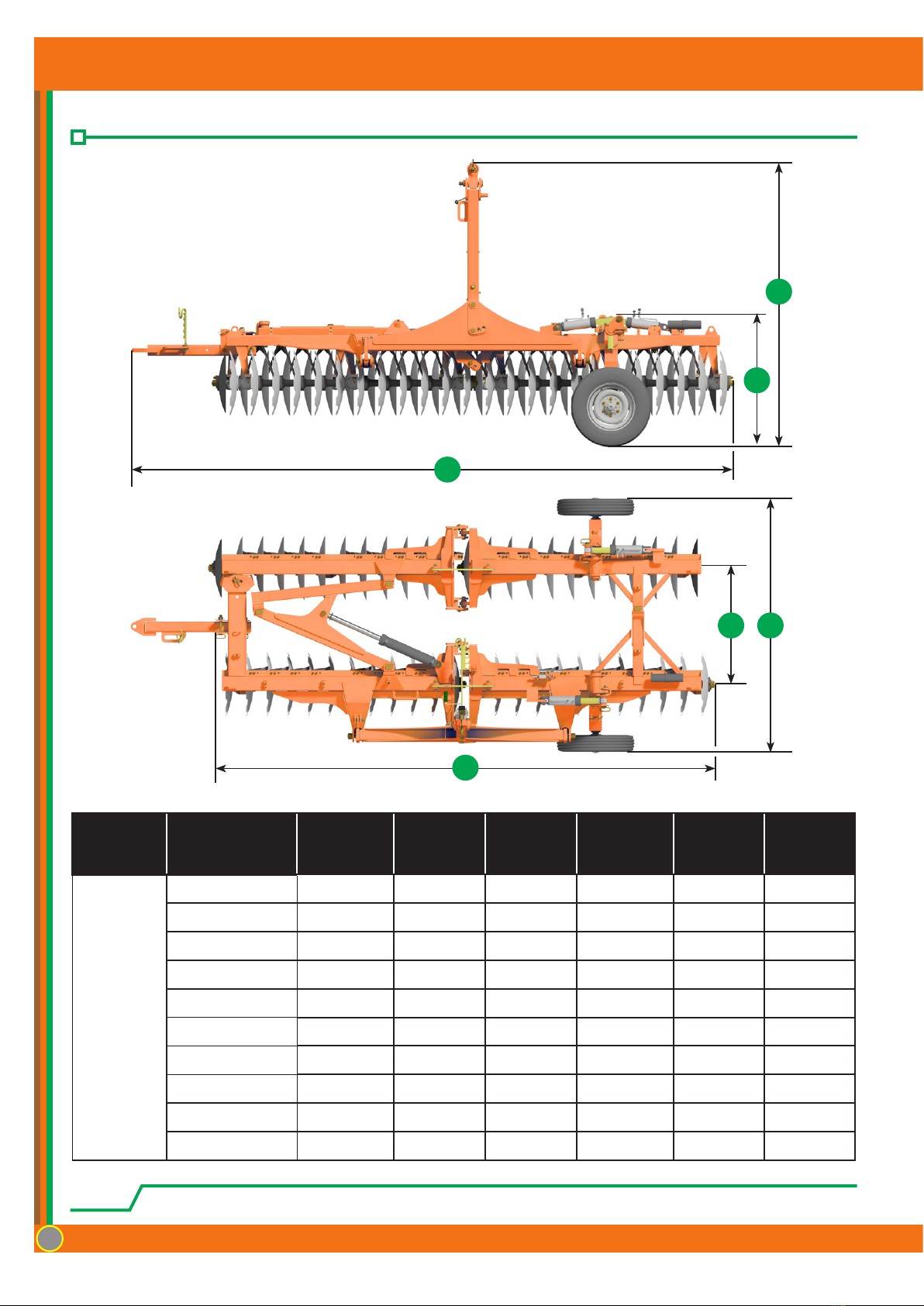

Data sheet

NOTE The weights above were obtained using Ø 24" x 4.5 mm disc blades.

The required tractor engine power may change according to the conditions

of the field.

Type: ............................................................................................................. Disk Harrow

Model: .................................................................................................................... GDFH

Spacing between disc blades:...............................................................................195 mm

Disc blades dimension: ................................................... Ø 20" x 3.5 mm, Ø 20" x 4.5 mm

....................Ø 22" x 3.5 mm, Ø 22" x 4.5 mm and Ø 24" x 4.5 mm

Number of disc blades: ....................................... 48, 52, 56, 60, 64, 68, 72, 76, 80 and 84

Disc blade type:.................................................. Front gang - notched / Rear gang - plain

Bearings - Length: .............................................................................................192.5 mm

- Type: ........................................................Regreasable tapered roller bearings

Oil volume on the bearings: ....................................................................................110 ml

Spacer spools - Length: .....................................................................................192.5 mm

- Type: ..........................................................................................Iron cast

Axle diameter: .....................................................................................Ø 38.1 mm (1.1/2")

Hitching type: ......................................................................................................Drawbar

Tires: .......................................................................................................... 11L15 - 10 ply

........................................................................................................ 600 x 16 - 6 ply

..................................................................................................... 7.50 x 16 - 10 ply

Working speed:............................................................................................. 7 to 12 Km/h

Model Number of

disc blades

Cutting width

(mm) Weight (Kg) Tractor required (hp)

GDFH

48 4480 2490 110 - 120

52 4870 2590 120 - 130

56 5260 2760 130 - 140

60 5650 2920 140 - 160

64 6040 3100 160 - 180

68 6430 3200 180 - 200

72 6820 3300 200 - 220

76 7245 3480 220 - 240

80 7620 3660 240 - 260

84 8000 3840 260 - 280

Civemasa Implementos Agrícolas

12 GDFH

Data sheet

Dimensions for transportation and storage

Model Number of

disc blades A B C D E F

GDFH

48 5680 1200 2555 4740 1100 2400

52 6065 1200 2555 5125 1100 2400

56 6465 1200 2555 5525 1100 2400

60 6860 1200 2555 5920 1100 2400

64 7230 1200 2555 6290 1100 2400

68 7620 1200 2555 6680 1100 2400

72 8040 1200 2555 7100 1100 2400

76 8440 1200 2555 7500 1100 2400

80 8840 1200 2555 7900 1100 2400

84 9225 1200 2555 8285 1100 2400

Measures in millimeters.

NOTE

FF

DD

EE

CC

BB

AA

Civemasa Implementos Agrícolas 13

GDFH

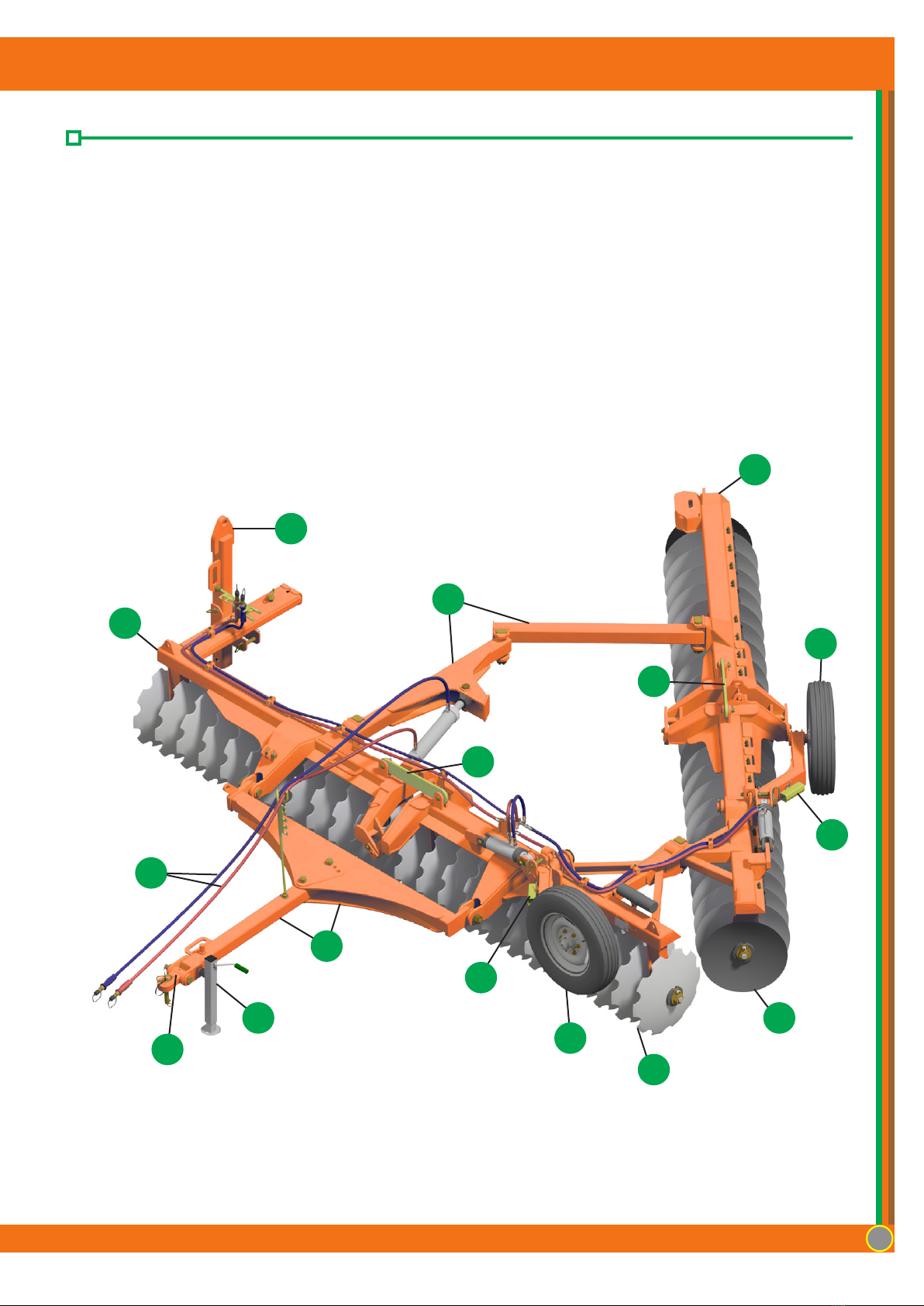

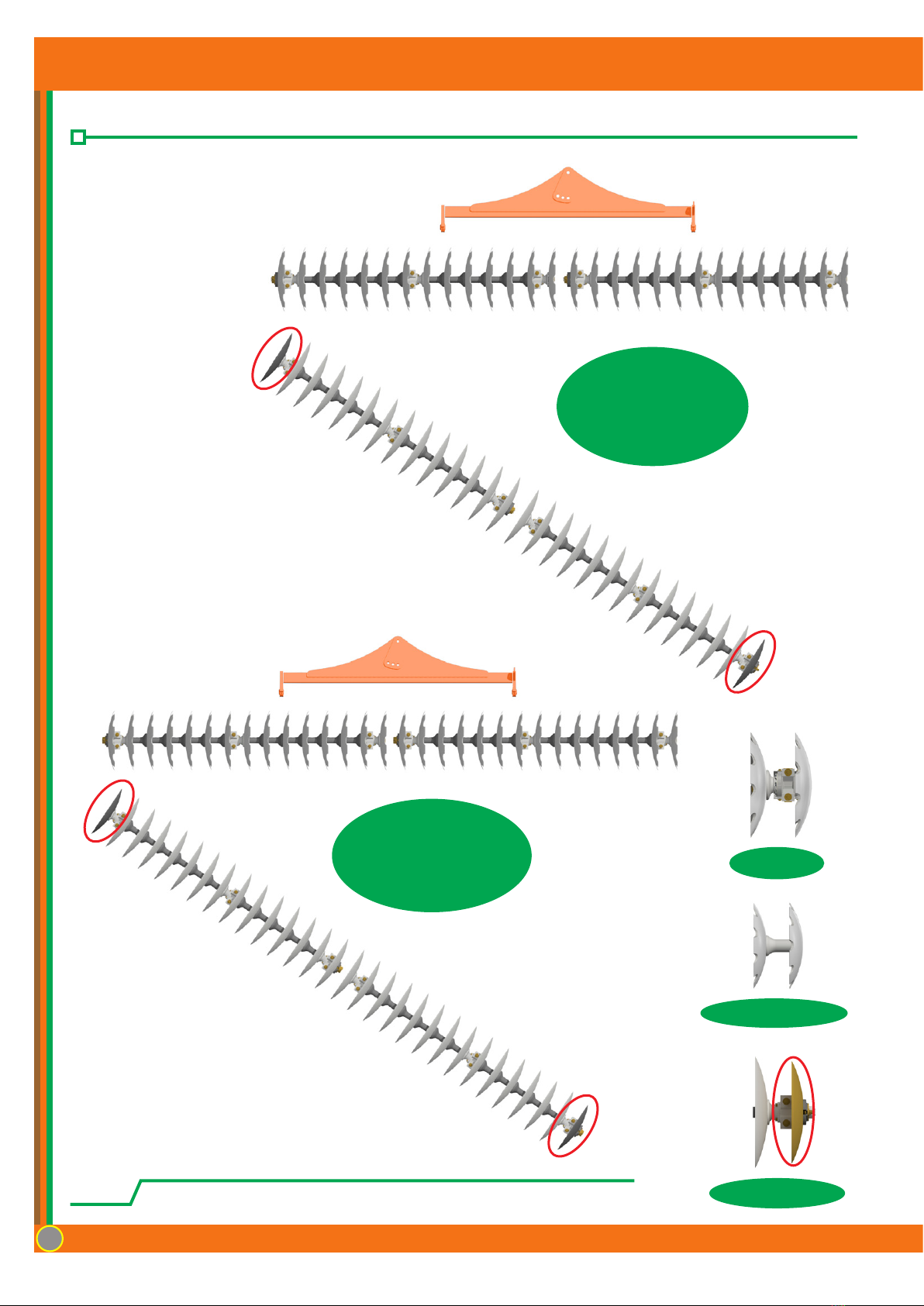

Components

GDFH

77

88

99

99

99

99

1111

55

55

11

33

22

4466

1010

1212

01 - Front frame 07 - Drawbar set

02 - Rear frame 08 - Tractor hitch

03 - Front disc gang 09 - Transport lock

04 - Rear disc gang 10 - Transport bar

05 - Wheelset 11 - Hoses

06 - Parking jack 12 - Opening system

Civemasa Implementos Agrícolas

14 GDFH

Assembly

First of all, put the parts in a clean place to identify them easier. Check the parts using

the list that comes inside the packing box.

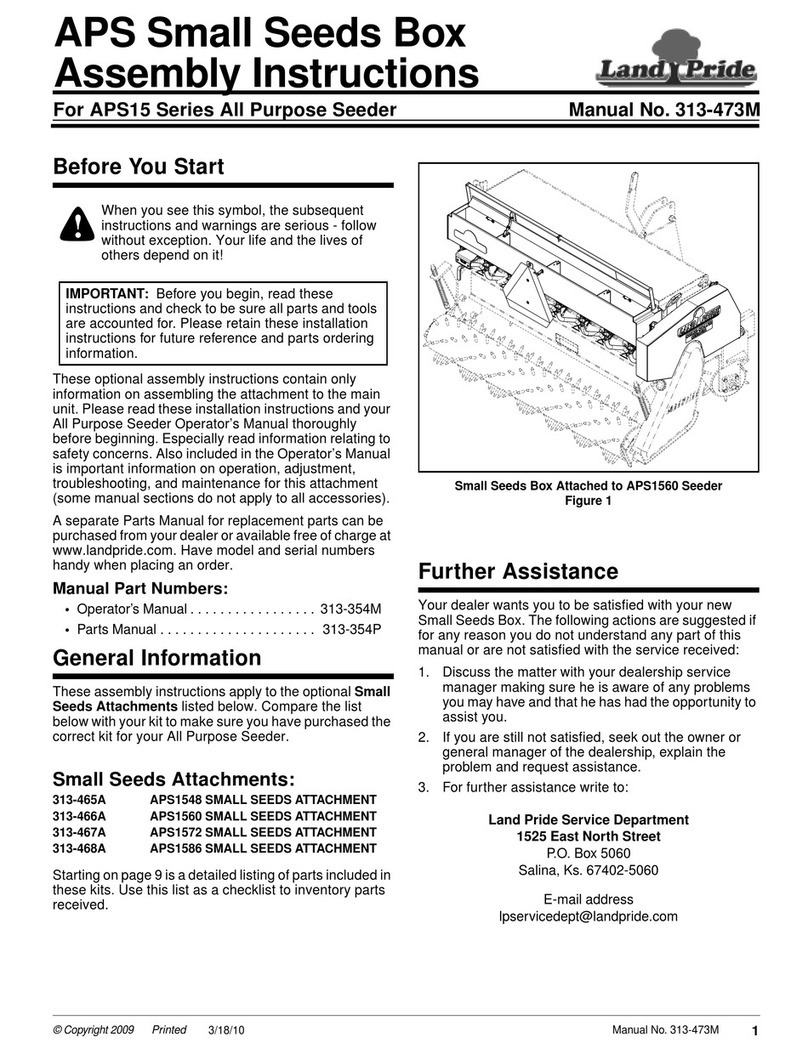

Using the set of wrenches

NOTE

• Use two box end wrenches (A) to tighten the nuts of the disc gangs, being one to

hold the axle nut on one side while the other tighten the nut on the other end, thereby

preventing the axle from rotating.

• Use the L-shaped wrench (B) to tighten the nuts of the bearing bolts.

• Use the L-shaped wrench (C) to tighten the nuts of the traction set.

We recommend wearing gloves, especially while assembling the disc gangs.

BB

AA

CC

Civemasa Implementos Agrícolas 15

GDFH

Assembly

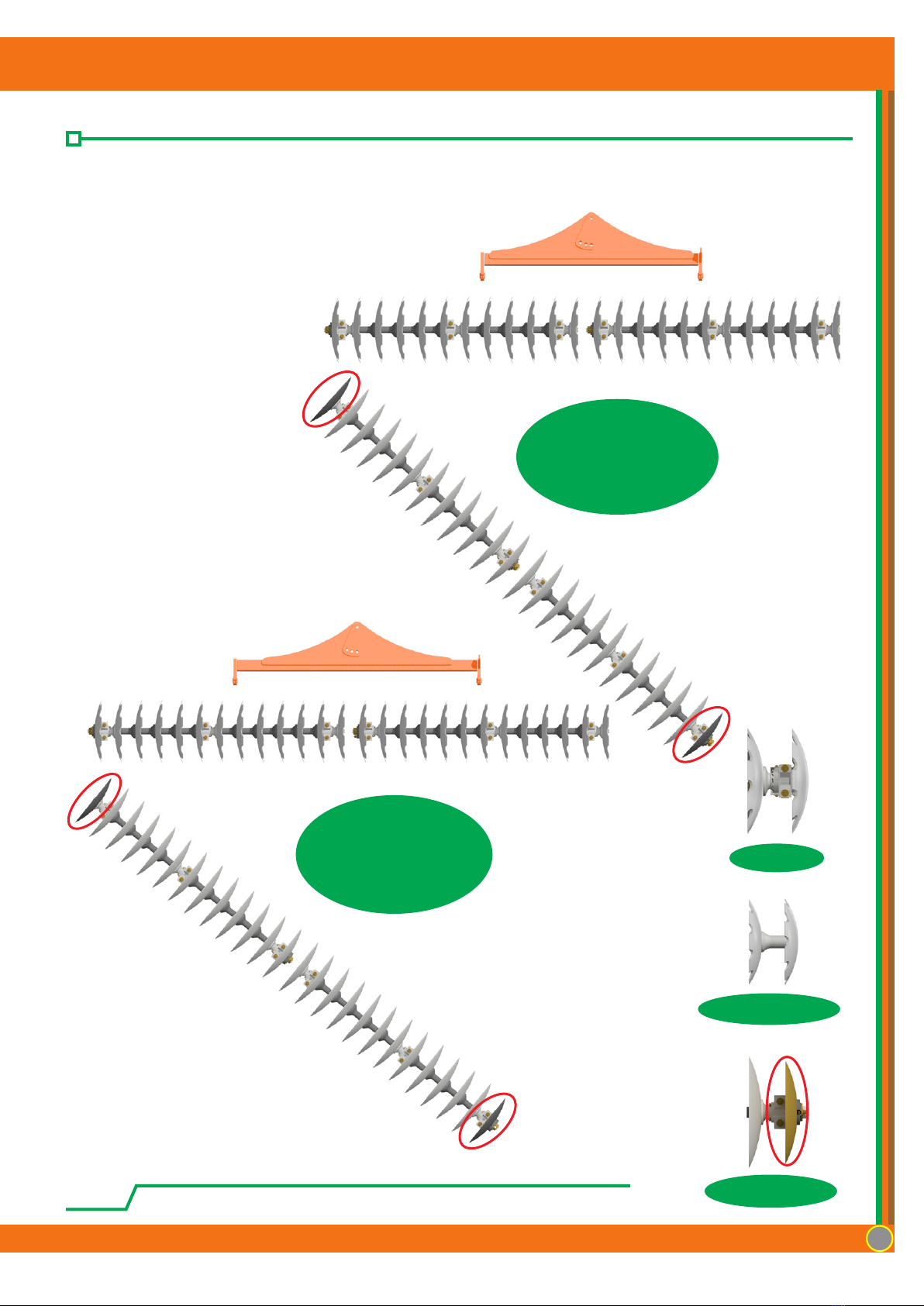

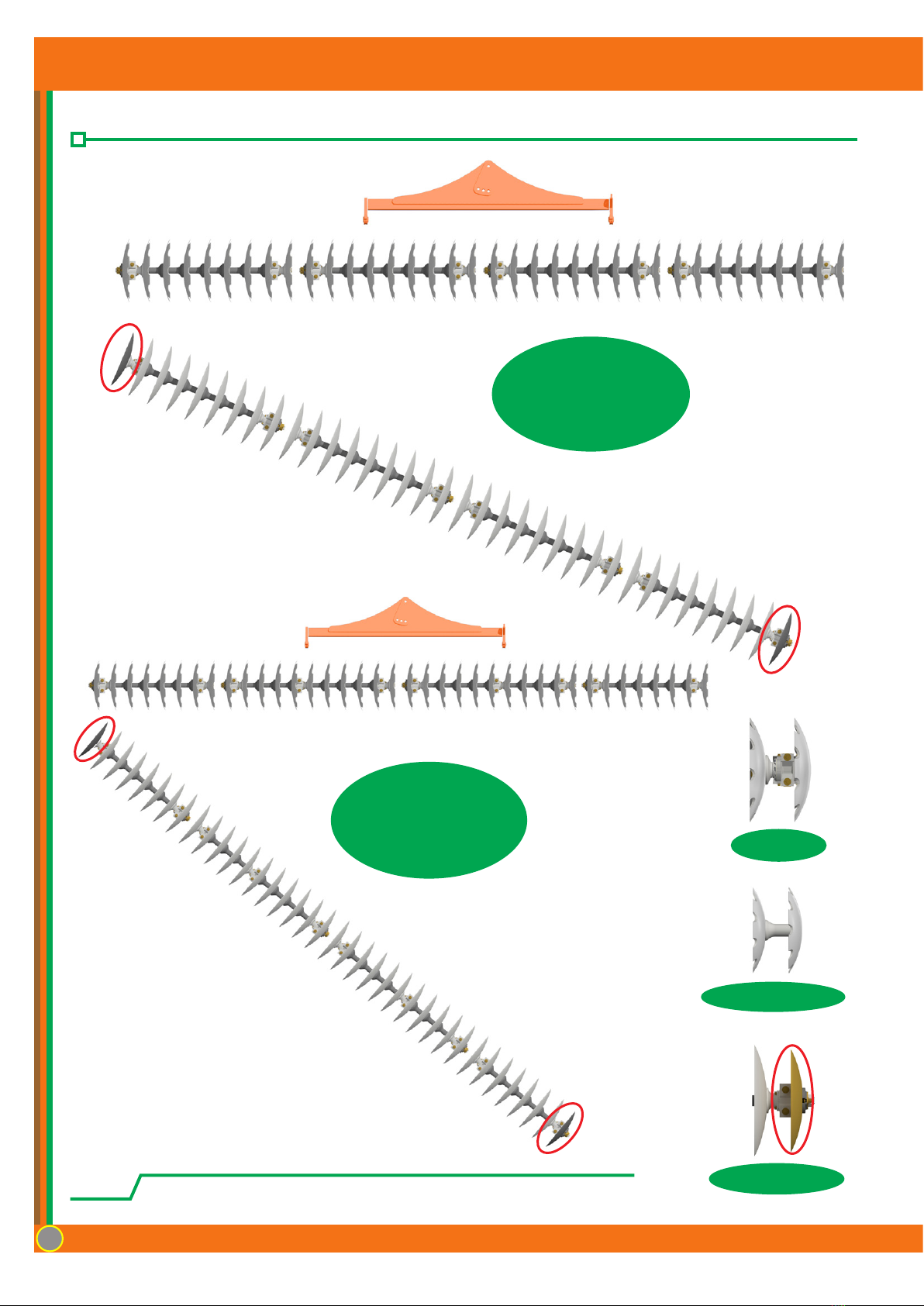

Assembly of bearings and spacer spools

• Before starting to assemble the disc gangs, check the correct position of the bearings

and spacer spools:

The first and last disc on the rear gangs are smaller.

NOTE

46 disc blades46 disc blades

12 bearings12 bearings

32 spacer spools32 spacer spools

2 furrow fillers2 furrow fillers

50 disc blades50 disc blades

12 bearings12 bearings

36 spacer spools36 spacer spools

2 furrow fillers2 furrow fillers

BearingBearing

Spacer spoolSpacer spool

Furrow fillerFurrow filler

Civemasa Implementos Agrícolas

16 GDFH

Assembly

Assembly of bearings and spacer spools

BearingBearing

Spacer spoolSpacer spool

Furrow fillerFurrow filler

54 disc blades54 disc blades

12 bearings12 bearings

40 spacer spools40 spacer spools

2 furrow fillers2 furrow fillers

58 disc blades58 disc blades

12 bearings12 bearings

44 spacer spools44 spacer spools

2 furrow fillers2 furrow fillers

The first and last disc on the rear gangs are smaller.

NOTE

Civemasa Implementos Agrícolas 17

GDFH

Assembly

Assembly of bearings and spacer spools

BearingBearing

Spacer spoolSpacer spool

Furrow fillerFurrow filler

62 disc blades62 disc blades

16 bearings16 bearings

40 spacer spools40 spacer spools

2 furrow fillers2 furrow fillers

66 disc blades66 disc blades

16 bearings16 bearings

44 spacer spools44 spacer spools

2 furrow fillers2 furrow fillers

The first and last disc on the rear gangs are smaller.

NOTE

Civemasa Implementos Agrícolas

18 GDFH

Assembly

Assembly of bearings and spacer spools

70 disc blades70 disc blades

16 bearings16 bearings

48 spacer spools48 spacer spools

2 furrow fillers2 furrow fillers

74 disc blades74 disc blades

20 bearings20 bearings

48 spacer spools48 spacer spools

2 furrow fillers2 furrow fillers BearingBearing

Spacer spoolSpacer spool

Furrow fillerFurrow filler

The first and last disc on the rear gangs are smaller.

NOTE

Civemasa Implementos Agrícolas 19

GDFH

Assembly

Assembly of bearings and spacer spools

78 disc blades78 disc blades

20 bearings20 bearings

52 spacer spools52 spacer spools

2 furrow filler2 furrow filler

BearingBearing

Spacer spoolSpacer spool

Furrow fillerFurrow filler

The first and last disc on the rear gangs are smaller.

NOTE

Table of contents

Other Civemasa Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Opico

Opico Air 8 Electronic operating instructions

Goldacres

Goldacres Pro-Reel Operator's & parts manual

Amazone

Amazone Catros 2503 Special Original operating manual

Horst

Horst Contour SHCF36 Operator's manual

Strautmann

Strautmann Super-Vitesse CFS 3101 operating instructions

New Holland

New Holland VL5060 Service manual