SP tools SP61062 User manual

USER MANUAL

IMPORTANT

ALL PERSONS WHO ARE TO USE THIS EQUIPMENT MUST THOROUGHLY READ

AND UNDERSTAND THIS INSTRUCTION MANUAL PRIOR TO OPERATION.

SP61062

DELUXE BATTERY

ANALYSER /

CHARGING

SYSTEM TESTER /

CRANKING

SYSTEM TESTER

RETAIN THESE INSTRUCTIONS

AND ATTACH RECEIPT TO

MANUAL FOR FUTURE

REFERENCE

NOTE: Proof of purchase must be retained by

the customer as it will be required in the

event of a claim under warranty.

AFTER SALES SUPPORT:

AUSTRALIA: Visit the website’s contact page to get in

touch with your local service department.

WWW.SPTOOLS.COM

INTERNATIONAL: Use the county selector to get in touch

with your service department in your country or region.

2

CONTENTS

Product Profile 3

Product Function 3

Technical Parameters 4

Technical Specifications 4

Intended Use 4

Scope of Delivery 4

Security Precautions and Warnings 5

Tool Description 5

Internal Resistance Explanation 6

Voltage Explanation 6

Operating Instructions 6

Before Testing 6

Product Setup 7

Battery Test 8

Battery In-Vehicle Test 8

Battery System Standard and Rating 9

Rating Range 10

Battery In-Vehicle Test Result 10

Cranking Test 11

Charging System and Rectifier Diode Test 12

Battery Out-of-Vehicle Test 14

Battery Out-of-Vehicle Test Result 16

Review Data 17

Print Data 17

Cleaning and Maintenance 18

Disposal and Recycling Information 18

Warranty Information 19

3

PRODUCT PROFILE

The SP61062 Battery Tester adopts what is currently the world's most advanced conductance

testing technology to easily, quickly and accurately measure the actual cold cranking amps (CCA)

capability of the vehicle starting battery, and its state of health. This tool assists maintenance

personnel to find the problem quickly and accurately. It will test all automotive cranking lead acid

batteries, including ordinary lead acid battery, AGM flat plate battery, AGM spiral battery, Gel

battery and EFB battery.

•Tests a battery with low charge, no need to full charge the battery before testing.

•Detects a bad battery cells.

•Indicates health status (or condition) of connected battery.

•Includes reverse polarity protection; incorrect battery connection will not damage the

tester or affect the vehicle or its battery.

•Testing standards include currently the world's majority of battery standards, CCA, BCI, CA,

MCA, JIS, DIN, IEC, EN, SAE, GB.

•Supports multi-languages, customer can select different language package, which includes:

English, French, German, Spanish, Italian and Polish.

PRODUCT FUNCTION

Battery test analyses a battery’s healthy status by calculating the actual cold cranking capability of

the battery and comparing this against its rated (new) capacity. This provides a reliable analysis of

the battery’s condition and what maintenance may be required for the battery. It can thereby

notify the user when to replace a battery in advance of its ultimate failure.

The Battery test is targeted to analyse the battery condition and calculate the actual cold cranking

capability of the battery including its aging extent. This provides reliable analysis evidence for the

test and maintenance of the battery. It notifies the user when to replace the battery prior to in

service failure.

The Cranking test is used to test and analyse the starter motor. By testing the actual cranking

current and cranking voltage of the starter motor, it is possible to determine starter motor

condition.

The Charging test is to monitor the charging system. Including alternator output and rectifier

diode function. This will find out whether the output voltage of the alternator is correct, the

rectifier is working and the charge current is normal.

4

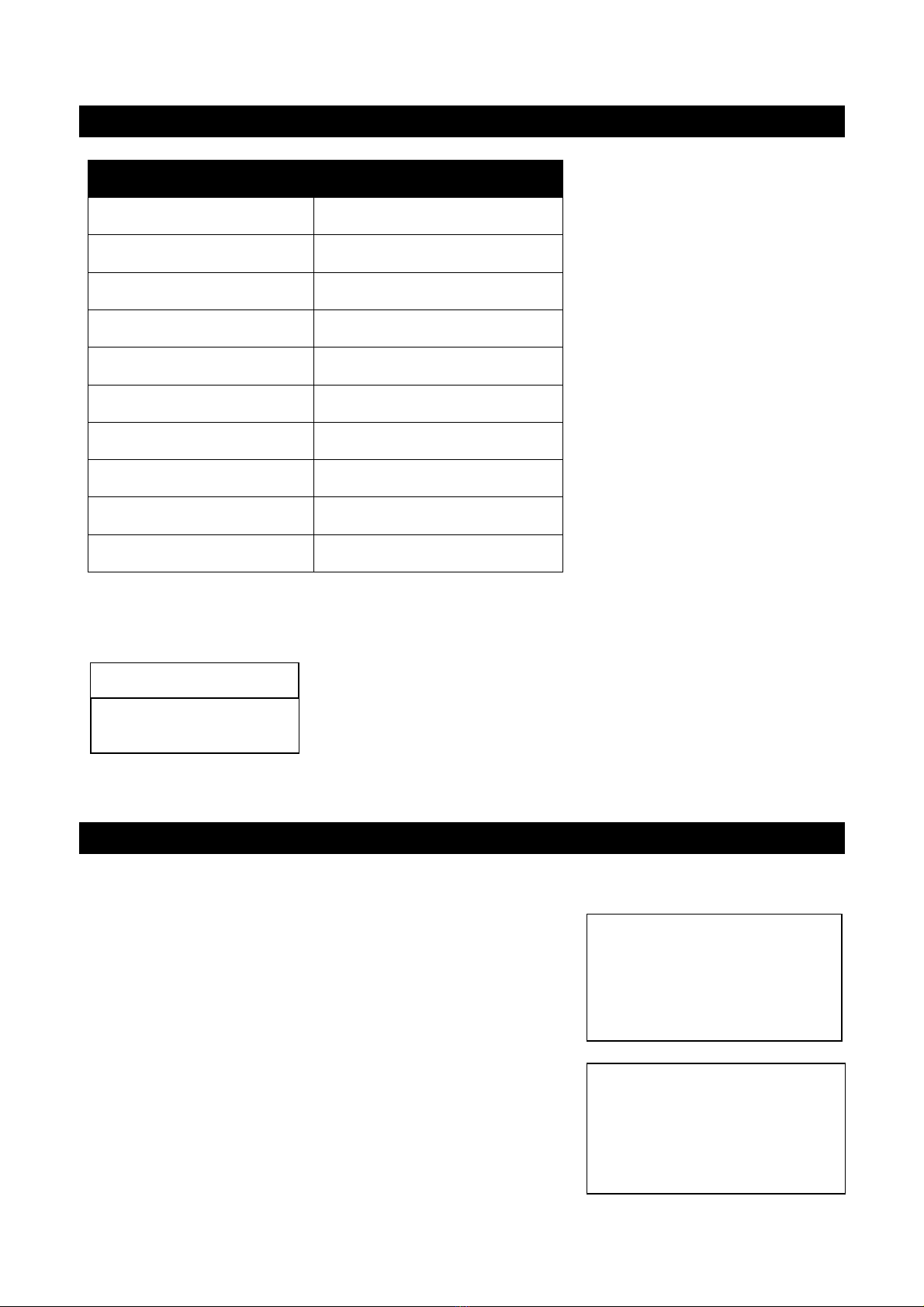

TECHNICAL PARAMETERS

Cold Cranking Amps Measure range:

Measure Standard

Measure Range

CCA

100-2000

BCI

100-2000

CA

100-2000

MCA

100-2000

JIS

26A17--245H52

DIN

100-1400

IEC

100-1400

EN

100-2000

SAE

100-2000

GB

30Ah-220Ah

Voltage Measure Range: 9-15V DC

TECHNICAL SPECIFICATIONS

1. Display: LCD, backlit

2. Operating Temperature: 0 to 50°C (32 to 122 F°)

3. Storage Temperature: -20 to 70°C (-4 to 158 F°)

4. Power provided via vehicle

5. Dimensions: Length 115mm, Width 72mm, Height 20mm

6. Cable Length 1000mm

7. Weight: 240g

8. Voltage Tolerance: 9 -15V DC (for 12v batteries only)

9. Working Environment Temp.: -20°C-60°C

10. Measurement range 100 –2000 CCA

INTENDED USE

This device is intended for automotive and or marine, trade or commercial applications, in dry, non-

explosive environments.

SCOPE OF DELIVERY

•User Manual: Instructions on tool operations.

•SP61062 Battery Analyser with cable and terminal clamps.

•USB cable

•CD

5

SAFETY PRECAUTIONS & WARNINGS

1. To prevent personal injury or damage to vehicles and/or the Battery Analyser, read this

instruction manual first and observe the following safety precautions at a minimum

whenever working on a vehicle:

2. Always perform automotive testing in a safe environment.

3. Wear safety eye protection that meets the AS/NZS 1337.1 standards.

4. Keep clothing, hair, hands, tools, test equipment, etc., away from all moving or hot engine

parts.

5. Operate in a well-ventilated work area; charging batteries can create explosive gases.

6. Chock drive wheels and never leave vehicle unattended while running tests.

7. Use extreme caution when working around the ignition coil, distributor cap, ignition wires

and spark plugs. These components create hazardous voltages when the engine is running.

8. Put transmission in PARK (for automatic transmission) or NEUTRAL (for manual

transmission) and make sure the parking break is engaged.

9. Keep a fire extinguisher suitable for petrol / chemical / electrical fires nearby.

10. Don't connect or disconnect any test equipment with ignition on or engine running.

TOOL DESCRIPTION

1. LCD DISPLAY -- Indicates test results. It is backlit.

2. ENTER BUTTON -- Confirms a selection (or action) from a menu list.

3. EXIT BUTTON -- Exit to previous menu

4. SCROLL BUTTON -- Scrolls through menu items or cancel an operation.

5. CLIPS -- Connects unit to the vehicle's battery + (red) and –(black) terminals.

1

2

3

4

5

6

INTERNAL RESISTANCE EXPLANATION

Internal Resistance (IR) is an important factor for accessing a battery’s capability. When a battery’s

internal resistance exceeds a specific value, the engine can't be started. The normal IR value of

cars should be less than 10mW, but there will be differences between different battery types and

those with greater or lesser CCA.

Normally, for the same kind of batteries, the lower the IR, the healthier the battery is, (short

circuit excepted).

VOLTAGE EXPLANATION

It is impossible for the voltage of the battery to show 100%. The maximum value is normally 98%

even after just being charged.

•98% Charged = Battery voltage above 12.59V

•75% Charged = Battery voltage 12.45V

•50% Charged = Battery voltage 12.15V

•Discharged condition = Battery voltage less than 12.00V

OPERATING INSTRUCTIONS

If testing batteries of low-frequency use, it is necessary to cycle (charge and discharge) the battery

several times before testing, normally 3-5 times will achieve a reliable test result. Only after

cycling the battery can the chemical properties of the battery be restored. This is particularly

important after long periods of no use. If after 3-5 times of battery charge and discharge, the

battery health state is still lower than 60%, battery replacement should be considered.

1. To extend battery life, Low use batteries, should be recharged every 2 months.

2. Please turn off the engine before testing.

3. When charging is finished, do not test immediately. Wait at least 10 minutes to allow the

battery charge to stabilise, then test. Even when testing an in vehicle battery, after the

engine is turned off (for the most accurate results) wait 10 minutes before testing.

4. In general, if the battery voltage is below 12.40V, recharge it.

BEFORE TESTING

Before testing, use a wire brush (not included) and alkaline cleaner (not included) to clean the

battery terminals, as any surface resistance on the terminal will negatively affect the test result.

Before testing an in-vehicle battery, ensure the ignition key is turned off. Make sure there is no

power drain from any other vehicle electronics and keep the car doors closed so interior lights do

not illuminate.

7

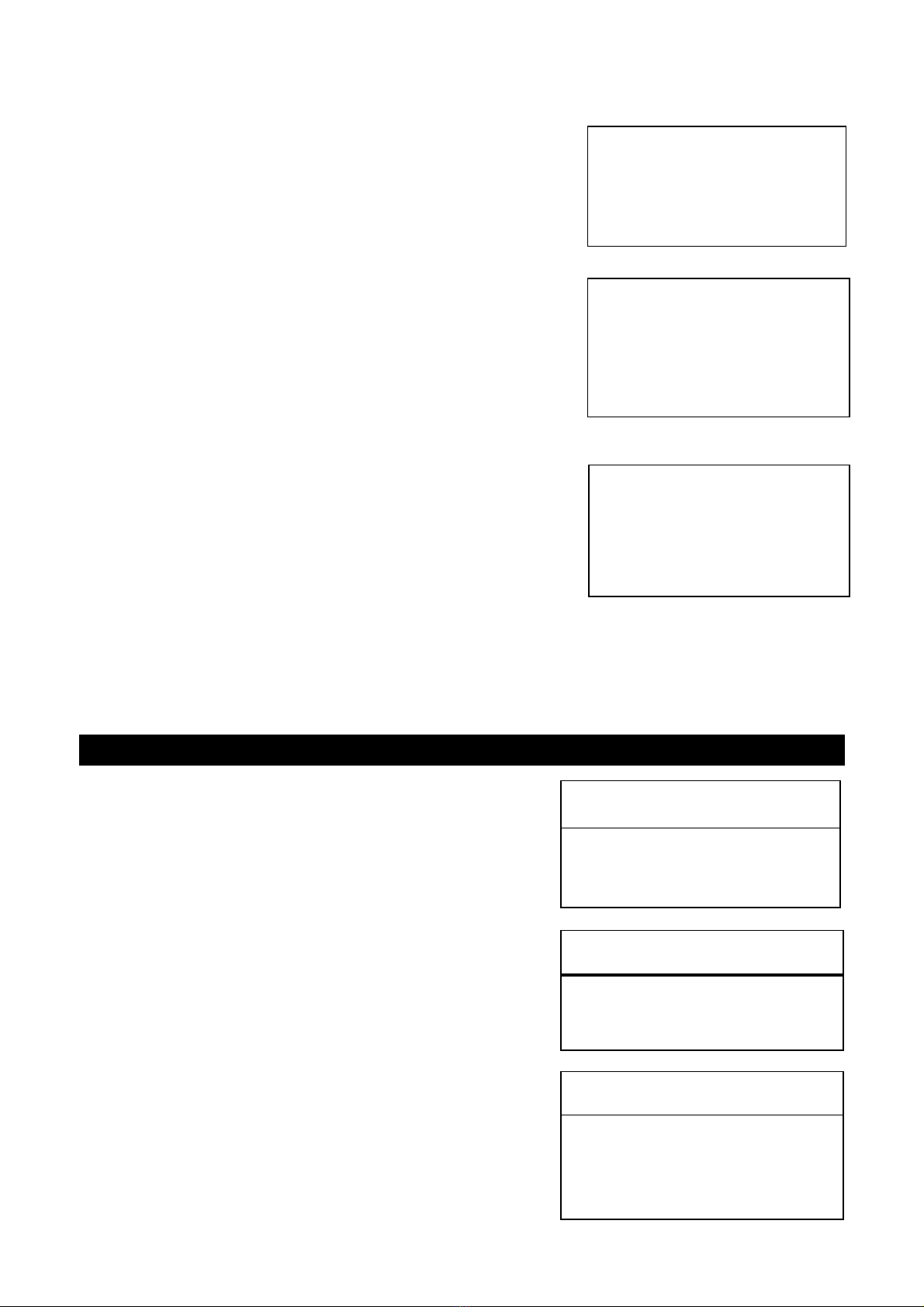

1. Language

2. Contrast

3. Tool Information

System Setup

Attach the red test clip to the battery positive terminal, the black test clip to battery negative

terminal. Note: Tester has an automatic reverse polarity protection, if accidentally misconnected it

will not cause any adverse effects.

In order to ensure a good electrical connection with no resistance, please wiggle the test clips on

the terminal posts a few times when connecting.

The tester draws its operating power from the battery being tested; it will only operate when

connected to a battery with more than 6 volts available. T battery analyser will not operate if

connected to a dead flat battery.

PRODUCT SETUP

The tool allows you to make the following adjustments and settings:

•Language –Select the desired language

•Contrast adjustment –Adjusts the contrast of the LCD display

•Tool information –The tool shows the software and hardware version.

TO ENTER THE SETUP MENU

When hooked up with power, the tool will

automatically enter main menu.

Press the down button to select the tool setup

function.

LANGUAGE

From the tool setup menu, use the enter

button to select a language.

CONTRAST

•From the tool setup menu, use the

enter button to select contrast.

•Use the up and down button to select

the contrast value and press enter

button to save your selection and

return to the previous menu.

1. English

2. French

3. German

4. Spanish

5. Italian

6. Polish

Language

8

Software Version:

1.00

Hardware Version:

1.00

Tool Information

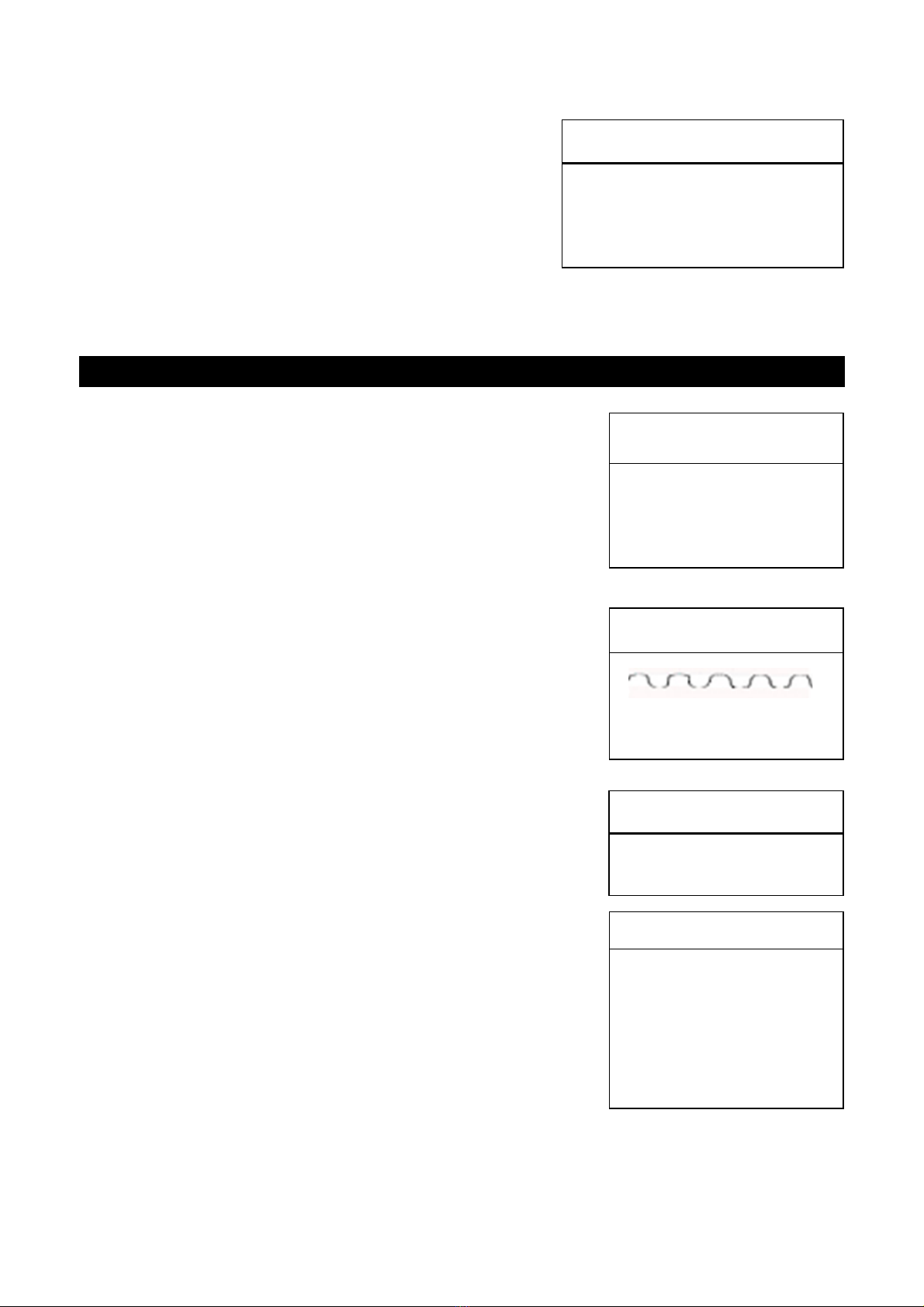

1. Battery In-Vehicle

2. Out Of-Vehicle

3. Review Data

4. Print Data

5. System Setup

Main Menu

1. Battery Test

2. Cranking Test

3. Charging Test

Test in-Vehicle

TOOL INFORMATION

From the tool setup menu, use the enter

button to select tool information.

Press exit to return to the previous screen.

BATTERY TEST

The SP61062 battery tester activates once the clamps have been correctly connected and

automatically enters the battery test program. It will display the following content in a sequence,

select accordingly.

BATTERY IN-VEHICLE OR BATTERY

OUT-OF-VEHICLE

Select UP/DOWN key to select the battery

location, in vehicle or out of vehicle. Then

press the ENTER key to confirm. Battery in

vehicle means the battery is connected to the

vehicles alternator. Battery out of vehicle

means the battery is not connected to the

vehicle at all.

BATTERY IN VEHICLE TEST

BATTERY IN-VEHICLE

For the battery in vehicle test, select BATTERY

IN VEHICLE, and press the ENTER key, the

below menu will appear.

BATTERY TEST IN-VEHICLE

When surface charge is detected by the

tester, it prompts, “SURFACE CHARGE, TURN

LIGHTS ON”. Turn on lights as prompted to

eliminate battery surface charge.

Now the tester detect that the surface charge has been eliminated, turn of the lights as prompted,

then press the ENTER key. The tester will recover the automatic test.

1. Check surface charge, turn

lights on

2. Leave headlights

3. Turn headlights off

Battery Test

9

SELECT BATTERY TYPE

The tester will now prompt you to choose a

battery type, i.e. Regular Flooded, AGM Flat

Plate or AGM spiral, Gel and EFB battery.

Press the UP/DOWN key to select a battery

type, and then press the OK key to confirm.

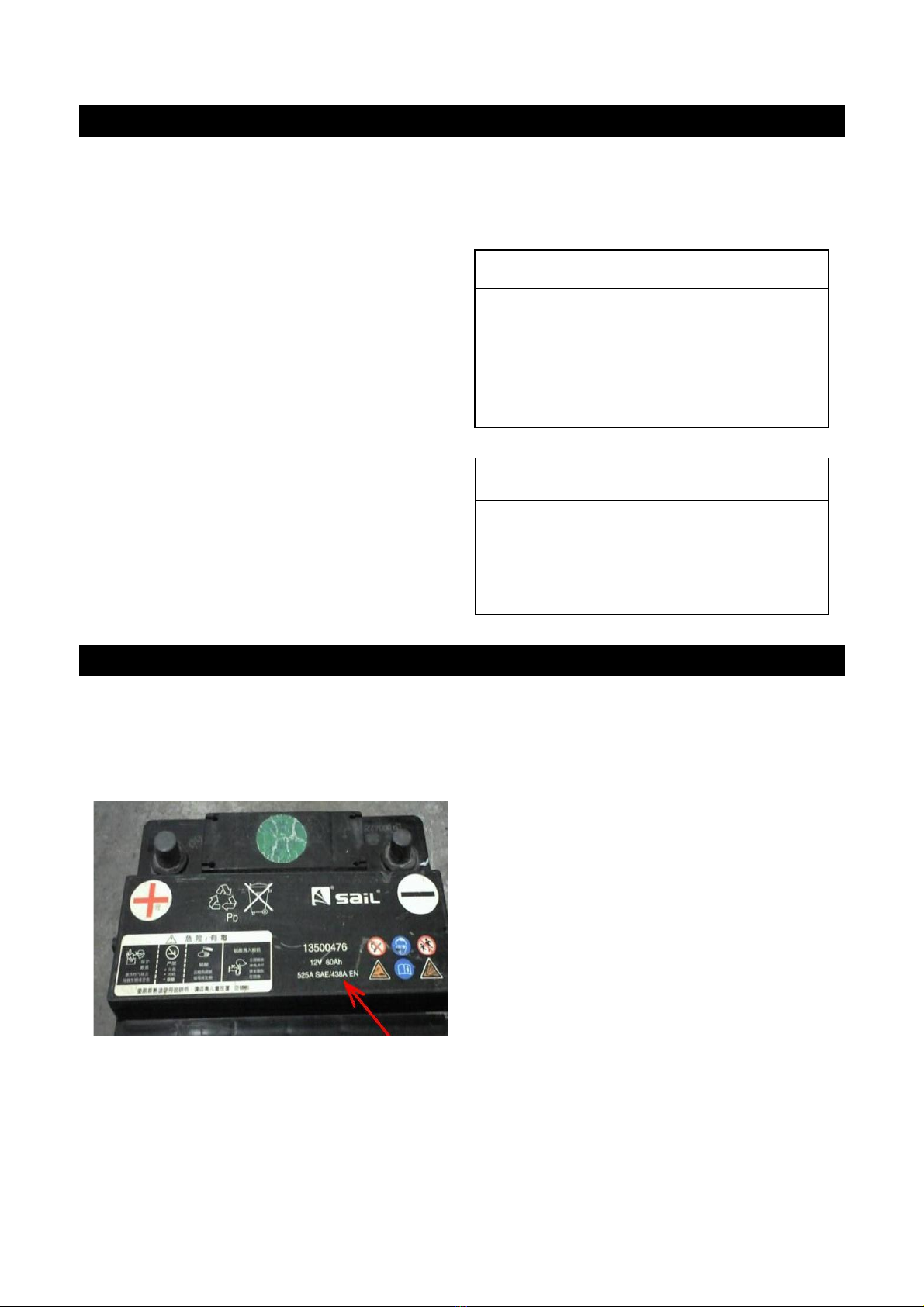

BATTERY SYSTEM STANDARD AND RATING

The SP61062 battery tester will test each battery according to the selected system and rating.

Use UP/DOWN key to select according to the actual system standard and rating marked on the

battery. Use UP/DOWN key to select according to the actual system standard and rating marked

on the battery. See in the below picture, the arrow indicated location.

•CCA: Cold Cranking Amps, specified by SAE&BCI, most frequently used value for starting

battery at 0°F (-18°C).

•BCI: Battery Council International standard

•CA: Cranking Amps standard, effective starting current value at 0°C

•MCA: Marine Cranking Amps standard, effective starting current value at 0°C.

•JIS: Japan Industrial Standard, displayed on the battery as combination of the numbers and

letters, e.g. 55D23,80D26.

•DIN: German Auto Industry Committee Standard

•IEC: Internal Electro technical Commission Standard

•EN: European Automobile Industry Association Standard

•SAE: Society of Automotive Engineers Standard

•GB: China National Standard

1. Regular Flooded

2. AGM Flat Plate

3. AGM Spiral

4. GEL

5. EFB

Battery Type

CCA

Select Input

10

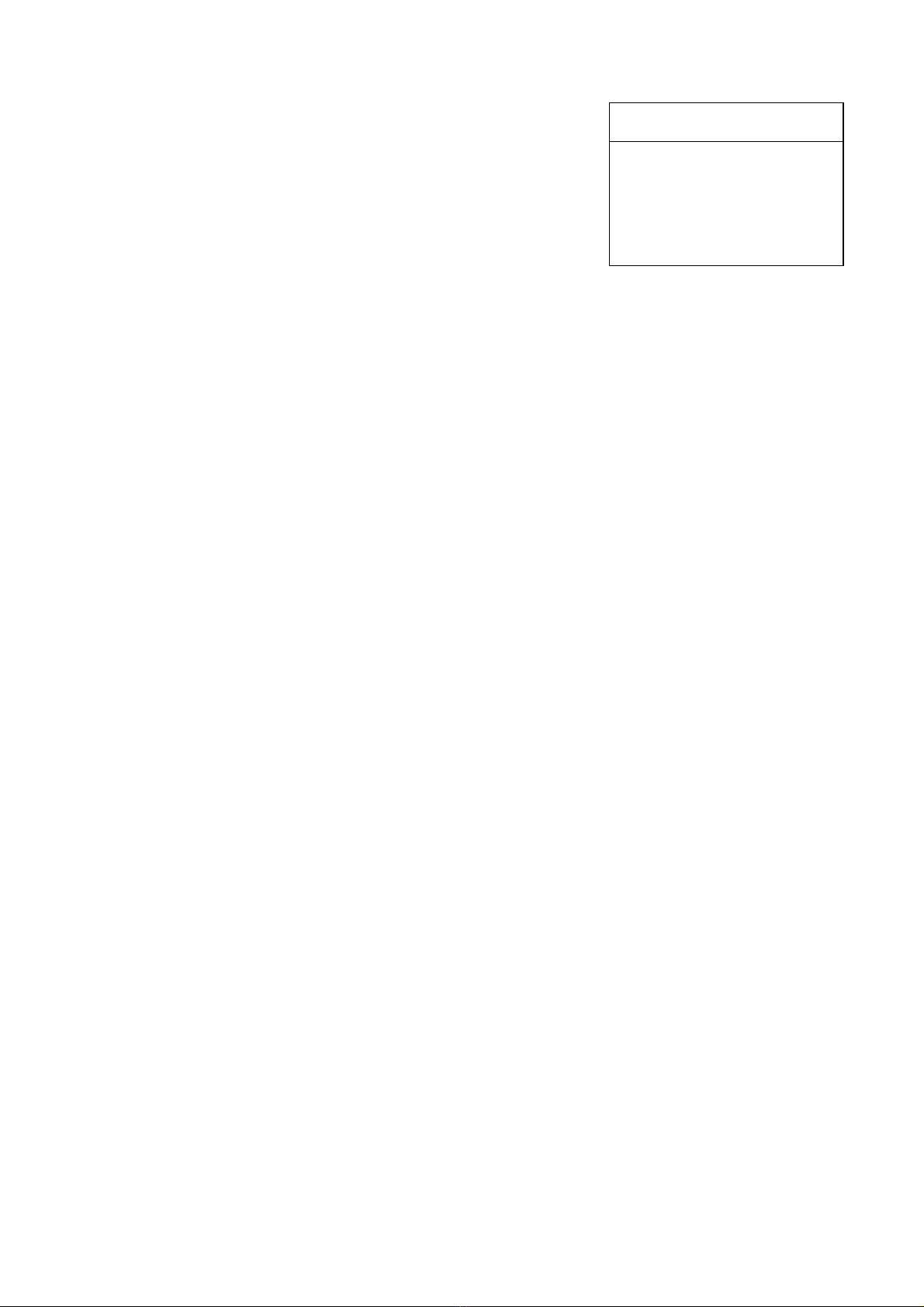

RATING RANGE AS FOLLOWS

Measure Standard

Measure Range

CCA

100-2000

BCI

100-2000

CA

100-2000

MCA

100-2000

JIS

26A17--245H52

DIN

100-1400

IEC

100-1400

EN

100-2000

SAE

100-2000

GB

30Ah-220Ah

Input correct test standard and rating, press ENTER key, tester starts to

test, and dynamic interface "TESTING" prompted. See below:

It takes around 3 seconds to display the battery test result.

BATTERY TEST RESULT

Battery test result includes 5 types as following:

1. GOOD BATTERY

The battery is without fault, good to use.

2. GOOD RECHARGE

Good battery but low current, recharge before using.

500A CCA

Setting Rate

Condition: 96% 12.64V

Charge: 98% 490CCA

Internal R=6.1mΩ

Rated: 500A

GOOD BATTERY

Condition: 78% 12.20V

Charge: 30% 440CCA

Internal R=7.2mΩ

Rated: 500A

GOOD, RECHARGE

11

Start Engine

Cranking Test

3. REPLACE

The battery is near to or already reached the end of the

using life, replace battery.

4. BAD CELL, REPLACE

Battery interior damaged, bad cell or short circuit, replace

battery.

5. CHARGE, RETEST

Unstable battery shall be recharged and retested to avoid

error. If same test result appears after recharge and

retest, the battery is regarded as damaged, replace the

battery. Attention: If "Replace" resulted from IN-VEHICLE

mode, check the cable connections between the

alternator and the battery. If the tester still says to

REPLACE, disconnect and retest the battery under OUT-

OF-VEHICLE before making a decision to replace battery.

NOTE: After testing, if need to Exit, press EXIT key to directly Exit to the start up interface. After

testing: if it's "IN-VEHICLE" test state, press ENTER key will bring to Cranking Test.

CRANKING TEST

Tester prompts as following:

Starting the engine as prompted, tester will automatically

complete the cranking test and display the result.

Normally, cranking voltage value lower than 9.6V is

regarded as abnormal and it is normal if it is higher than

9.6V. Test result of the tester includes actual cranking

voltage and actual cranking time.

Condition: 46% 12.68V

Charge: 80% 490CCA

Internal R=18.1mΩ

Rated: 500A

REPLACE

Condition: 0% 10.64V

Charge: 20% 0CCA Internal

R=45.2mΩ

Rated: 500A

BAD CELL,REPLACE

Condition: 39% 12.08V

Charge:20% 310CCA

Internal R=30.1mΩ

Rated: 500A

CHARGE - RETEST

RPM Detected

Cranking Test

Time 780ms

Cranking Normal

10.13V

Cranking Test

12

When cranking test is abnormal, battery test result will

also be displayed at the same time.

This is for the convenience of the maintenance

personnel to quickly know the whole state of the

starting system according to the data.

After you have finished testing, do not shut down the

engine, press ENTER key to enter Charging Test.

CHARGING SYSTEM AND RECTIFIER DIODE TEST

When doing the charging test, please choose "Charging

Test".

Press ENTER key again to start the charging test.

NOTE: Do not shut down the engine during the test.

All electrical appliance and device are in OFF.

Turn off any electrical appliances in the vehicle during the

test as it will affect the accuracy of the test result.

TESTER WILL DO THE FOLLOWING TESTS IN SEQUENCE:

RIPPLE TEST

For ripple test, tester will display the real time ripple and

meanwhile, shows ripple volt and charging volt values at

the bottom line.

It takes approx. 6 seconds for the ripple test.

CHARGING TEST

After the ripple test, tester will automatically start the

loaded voltage test.

Loaded Volt Test takes approx. 3 seconds, then it hints

"Step on accelerator to increase engine rotation speed"

Operate accordingly to increase the engine rotating speed

to 2500rpm or above, and keep for 5 seconds.

Tester starts the charging volt test after it has detected a

increase in rpm.

Time 1020ms

Cranking Low

10.13V

Cranking Test

1. Battery Test

2. Cranking Test

3. Charging Test

Test In-Vehicle

95mV 14.32V

Ripple Test

Loaded Testing ****

Charging Test

Increasing RPM to

2500 r/min

And keep it 5

seconds.

Press OK to

continue.

Charging Test

13

After the test is finished, the tester displays the effective

charging volts, ripple test result and charging test result.

NOTE: If no increase in rpm is detected, it is the fault of

alternator regulator or the connection with the battery

has failed. Tester will try 3 times to detect, if still failed, it

will skip the increase rpm detect and the test result

displays "No Volt Output". See below:

Check the connection between alternator and battery, then retest.

Charging Test Result:

1. Charging Volt: Normal

Charging system shows the generator output normal, no problem detected.

2. Charging Volt: Low

Charging volt of the charging system is low.

Check drive belt of the alternator to see whether it is slipping or has run off.

Check the connection between alternator and battery.

If both of the drive belt and the connection are in good condition, follow the

manufacturer's suggestion to eliminate alternator fault.

3. Charging Volt: High

Alternator output volt is high.

Since most of the vehicle alternators use a internal regulator, the alternator

assembly has to be replaced.(Some old style cars are using external

regulator, then directly replace the regulator.)

The normal high volt of the voltage regulator is maximum 14.7±0.5V.If

charging volt is too high, it will overcharge the battery. Therefore the battery

life will be shortened and troubles will be caused.

4. No Volt Output:

No alternator volt output is detected. Check the alternator connection cable

and the belt whether they are in a sound condition.

5. Diode Test:

Through the test of charging current ripple, tester will find out whether the

diode is normal or not. When ripple volt is too high, it proves at least one

diode is damaged. Check and replace the faulty diode.

Loaded 14.16V

Unloaded 14.39V

Ripple 15mV

Charging Normal

Cranking Test

14

1. Battery In-Vehicle

2. Out Of-Vehicle

3. Review Data

4. Print Data

5. System Setup

Main Menu

BATTERY OUT-OF-VEHICLE TEST

The SP61062 battery tester activates once the clamps have been correctly connected and

automatically enters the battery test program. It will display the following content in a sequence,

select accordingly.

BATTERY OUT-OF-VEHICLE

Battery OUT-OF-VEHICLE means battery is not

connected to the vehicle at all.

Select UP/DOWN key to select the battery out

of vehicle. Then press the ENTER key to

confirm.

SELECT BATTERY TYPE

The tester will now prompt you to choose a

battery type, i.e. Regular Flooded, AGM Flat

Plate or AGM spiral, Gel and EFB battery.

Press the UP/DOWN key to select a battery

type, and then press the OK key to confirm.

BATTERY SYSTEM STANDARD AND RATING

The SP61062 battery tester will test each battery according to the selected system and rating.

Use UP/DOWN key to select according to the actual system standard and rating marked on the

battery. Use UP/DOWN key to select according to the actual system standard and rating marked

on the battery. See in the below picture, the arrow indicated location.

•CCA: Cold Cranking Amps, specified by SAE&BCI, most frequently used value for starting

battery at 0°F (-18°C).

•BCI: Battery Council International standard

•CA: Cranking Amps standard, effective starting current value at 0°C

•MCA: Marine Cranking Amps standard, effective starting current value at 0°C.

1. Regular Flooded

2. AGM Flat Plate

3. AGM Spiral

4. GEL

5. EFB

Battery Type

15

•JIS: Japan Industrial Standard, displayed on the battery as combination of the numbers and

letters, e.g. 55D23,80D26.

•DIN: German Auto Industry Committee Standard

•IEC: Internal Electro technical Commission Standard

•EN: European Automobile Industry Association Standard

•SAE: Society of Automotive Engineers Standard

•GB: China National Standard

RATING RANGE AS FOLLOWS

Measure Standard

Measure Range

CCA

100-2000

BCI

100-2000

CA

100-2000

MCA

100-2000

JIS

26A17--245H52

DIN

100-1400

IEC

100-1400

EN

100-2000

SAE

100-2000

GB

30Ah-220Ah

Input correct test standard and rating, press ENTER key, tester starts to

test, and dynamic interface "TESTING" prompted. See below:

It takes around 3 seconds to display the battery test result.

CCA

Select Input

500A CCA

Setting Rate

16

BATTERY TEST RESULT

Battery test result includes 5 types as following:

1. GOOD BATTERY

The battery is without fault, good to use.

2. GOOD RECHARGE

Good battery but low current, recharge before using.

3. REPLACE

The battery is near to or already reached the end of the

using life, replace battery.

4. BAD CELL, REPLACE

Battery interior damaged, bad cell or short circuit, replace

battery.

5. CHARGE, RETEST

Unstable battery shall be recharged and retested to avoid

error. If same test result appears after recharge and

retest, the battery is regarded as damaged, replace the

battery.

Condition: 96% 12.64V

Charge: 98% 490CCA

Internal R=6.1mΩ

Rated: 500A

GOOD BATTERY

Condition: 78% 12.20V

Charge: 30% 440CCA

Internal R=7.2mΩ

Rated: 500A

GOOD, RECHARGE

Condition: 46% 12.68V

Charge: 80% 490CCA

Internal R=18.1mΩ

Rated: 500A

REPLACE

Condition: 0% 10.64V

Charge: 20% 0CCA Internal

R=45.2mΩ

Rated: 500A

BAD CELL,REPLACE

Condition: 39% 12.08V

Charge:20% 310CCA

Internal R=30.1mΩ

Rated: 500A

CHARGE - RETEST

17

REVIEW DATA

Select REVIEW DATA in the main menu

Check the history of battery testing result

PRINT DATA

Before choosing the print data function, it is necessary to connect the tool to the computer via

USB cable. Once all are available, please kindly insert the CD to the computer.

Install the USB driver

Then open the Print software

1.Battery in Vehicle

2.Out of Vehicle

3.Review Data

4. Print Data

5.System Setup

Main Menu

Condition: 96% 12.64V

Charge: 98% 490CCA

Internal R=6.1mΩ

Rated: 500A

GOOD BATTERY

18

Choose the COM Port NO.

If there is some history in print software, please clear it.

Choose the function of Print Data in the tool.

Once the data is transferred to the computer,

the print software will show this information.

After transferring the data to the computer, the tool

will automatically return to the main menu.

CLEANING AND MAINTENANCE

•Keep your Battery Analyser dry, clean and free from oil, water and grease.

•Use a mild detergent on a clean cloth to clean the outside of the tool, when necessary.

•Store the unit in a dry dust free environment.

DISPOSAL AND RECYCLING INFORMATION

When the tool reaches its end of life, take it to a collection point designated by local authorities

for E-waste.

The separate collection and recycling of your product at the time of disposal will help conserve

natural resources and ensure that it is recycled in a manner that protects human health and the

environment.

1.Battery in Vehicle

2.Out of Vehicle

3.Review Data

4. Print Data

5. System Setup

Main Menu

Condition: 96% 12.64V

Charge: 98% 490CCA

Internal R=6.1mΩ

Rated: 500A

GOOD BATTERY

19

LIMITED WARRANTY

This Limited Warranty applies only to new products* distributed by SP Tools Pty Ltd (“SP Tools”). It is a condition of this Limited

Warranty Policy that the purchaser read the owner’s manual for the product and only use the product to the extent or for the

purposes stated therein. The purchaser must also ensure that all servicing requirements are completed as listed in the owner’s

manual (said servicing is at the owner’s expense). We recommend that all servicing is completed by an authorised service agent and

that records of said servicing are retained by the purchaser as proof in the event of a warranty claim.

Whilst the owner’s manual, packaging, and/or other documentation supplied with SP Tools’ products may provide details in respect

of a Limited Warranty, the terms set out herein supersede these matters, and this Limited Warranty applies in their place. This

warranty is no less advantageous than otherwise described in such other documentation.

SP Tools agrees, subject to the terms and conditions specified below, to repair or replace at SP Tools’ cost, the product purchased by

you when the product does not perform in accordance with its specifications during the limited warranty period, due to any fault in

manufacturing, materials and/or workmanship. SP Tools is not liable to repair or replace products that the purchaser uses in a

manner that is inconsistent with the owner’s manual or in the circumstances set out in paragraphs 1.1 – 1.7 below.

The benefits to the purchaser under this warranty are in addition to other rights and remedies under the Competition and Consumer

Act 2010 (Cth). The limited warranty period, within which a defect in the product must appear, commences from the date of

purchase and ceases on expiration of the specified term below.

THE LIMITED WARRANTY PERIOD

• SP Speciality Tools –12 Months

THE PURCHASERS ATTENTION IS DRAWN TO THE FOLLOWING

To the extent permitted by law and subject to this Limited Warranty, and as part of the terms of the sale of the equipment or part

thereof: SP Tools shall not be liable for any form of loss, damage, cost, injury or harm of any kind (whether direct, indirect, special

or consequential) howsoever arising from the use or supply of the equipment to the purchaser.

EXCLUSIONS TO LIMITED WARRANTY POILICY

This Limited Warranty will not apply where the equipment or any part thereof:

1.1 Fails due to an accident (including liquid spillage), abuse, misuse, neglect or normal wear and tear;

1.2 Has been used in a manner other than for which it was originally designed;

1.3 Has been tampered with or is otherwise than as supplied by SP Tools;

1.4 Where any damage, malfunction or other failure of the equipment or any part thereof resulted directly or indirectly from

unauthorized persons, adjusting or failing to adjust any part requiring normal maintenance and service (examples include

adjustment of tappets, air filter maintenance, lubrication and tightening of screws nuts and bolts);

1.5 Malfunctions due to the use of defective or incompatible accessories;

1.6 Is damaged by lightning or thunderstorm activity; or

1.7 Has been transported to a country where no authorised Service Agents exist.

CLAIMING WARRANTY

This Limited Warranty may be claimed on in the following manner:

2.1 In order to make a claim under this Limited Warranty, the purchaser must deliver the equipment or any part thereof to an

SP Tools authorised repair agent and pay all costs of transportation and all costs incidental to making a claim under

this Limited Warranty. The purchaser must first contact SP Tools (contact details described above) and request the

delivery address of an SP Tools authorised repair agent.

2.2 The purchaser must deliver to the repair agent written reasons why the purchaser considers that the purchaser has a claim

under this Limited Warranty and must provide all necessary details, including:

•The place, date and from whom the unit or part was purchased.

•The unit or part involved, Model and Serial Number.

•The defect, malfunction or failure in respect of which the claim is being made.

•Proof of service of the unit or part (if applicable)

•Proof of purchase in respect of the unit or part.

2.3 If the Limited Warranty claim is valid, the repair agent will carry out repairs and return the product at no charge to the

purchaser. These repairs are limited to the Limited Warranty fault identified and as such will not include any other faults due to

misuse, abuse, failure to maintain, fair wear and tear or the replacement of serviceable items such as oil, spark plugs, air filters,

fuel etc.

Our goods come with guarantees that cannot be excluded under Consumer Law. You are entitled to a replacement or refund for a

major failure and for compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

Note: Units which are failing to perform in accordance with specifications due to non-warrantable causes will be subject to freight,

repair and or quote charge

Table of contents

Other SP tools Test Equipment manuals

Popular Test Equipment manuals by other brands

DATREND Systems

DATREND Systems vPad-RW operating manual

TESTO

TESTO 549 instruction manual

Q3 Innovations

Q3 Innovations AlcoHAWK PT500 owner's manual

Honeywell

Honeywell Posi 3 Setup guide

Vanguard Instruments

Vanguard Instruments VBT-75P S2 user manual

Brütsch Rüegger

Brütsch Rüegger MITUTOYO SURFTEST SJ 201P manual