Spa SPEEDO User manual

SPA DESIGN

MICROPROCESSOR

SPEEDO MANUAL

SPA DESIGN MICROPROCESSOR SPEEDO

INSTALLATION AND OPERATING MANUAL

CONTENTS

PAGE 2 ....INSTRUMENT FEATURES.

PAGE 3 ....INSTALLATION DETAILS.

PAGE 4 ....OPERATING INSTRUCTIONS.

PAGE 5 ....MENU SYSTEM.

PAGE 10....SPECIFICATIONS.

PAGE 11....WIRING SCHEMATIC.

PAGE 12....MOUNTING DATA

1

2

INSTRUMENT FEATURES

qCALIBRATES TO ANY TYRE CIRCUMFERENCE

qMAXIMUM SPEED RECALL

qACCELERATION TIMER

qBUILT IN ODOMETER

qRECORD MODE FOR TAKING SNAPSHOTS OF SPEED

qBACKLIT LCD DISPLAY

qLOW BATTERY WARNING

qTRIGGERS OF ANY TARGET OR NUMBER OF TRIGGER POINTS

qCOMPATIBLE WITH MOST TYPES OF SENSORS, OPTO/HALL

qAUTO MODE FOR SELF CALIBRATION OVER STANDARD 1/4 MILE

qREADOUT SELECTABLE FOR MPH OR KMH

MENU SYSTEM FOR :-

qSETTING THE CIRCUMFERENCE 0.1 - 4.00 METRES

qSETTING THE NUMBER OF TRIGGER POINTS 1 - 40

qSETTING THE READOUT TO MPH OR KMH

qSETTING THE SPEED FOR ACCELERATION TIME

qREPLAYING STORED SNAPSHOTS 1 - 60

qRECORD MODE ON/OFF

qRESET RECORD NUMBER

qRESET STORED MAXIMUM SPEED

qRECALL STORED MAXIMUM

qRECALL STORED DISTANCE (MILES OR KM)

qRECALL OR MEASURE ACCELERATION TIME

qTEST / SETUP MODE

qAUTO CALIBRATION MODE

qBACKLIGHT ON/OFF

3

INSTALLATION DETAILS

INSTRUMENT INSTALLATION DOS AND DONTS

DO not allow any stress on the

mounting feet on the case.

DO ensure that the instrument is slightly below the

drivers head for the clearest view.

DO ensure that the back of the instrument is pro-

tected from any water spray that may occur.

CABLE INSTALLATION, DOS & DONTS

DO ensure that the black screened cables do not run

next to power cables, especially if they are ignition

power cables. Ideally, run all screened cables next to

the chassis (earth).

DO ensure that any exposed plugs that are likely to

get water spray are protected with rubber boots.

DO NOT allow cables to run through sharp edged

apertures without protection.

DO NOT fix the cables next to or onto any surface

likely to exceed 80 degrees Centigrade.

SENSOR INSTALLATION DOS AND DONTS

DO ensure that the sensor is pointing toward the

south pole of the magnet (see page 12).

DO ensure that the sensor is aligned with the end of

the magnet when the suspension is under normal

load (car not jacked up).

DO NOT mount the magnet on the mounting flange

of a shaft coupling, mount the magnet on either the

shaft, or the main body of a CV joint.

4

OPERATING INSTRUCTIONS

The SPA Microprocessor Speedo is factory set to standard pa-

rameters, but may be adjusted to your requirements using a

menu system which will be explained further on. all settings and

maximums are stored in EEPROM memory, which will store them

for many years without any power needed.

As supplied the Circumference is set to 1.800 Metres, using 1

trigger points for use with the trigger magnets supplied as stand-

ard. Speed measurements are taken for one revolution of the

wheel and then displayed on the LCD. The speedo display and

the distance total is always updated every 0.36 Sec (totals meas-

ured in speedo mode only), but the maximum speed and snap-

shot recordings are always measured and stored at a much higher

rate (typically 40 times a second) thus storing true values.

When the instrument is first switched you will see SPA displayed

momentarily before speed measurements are displayed.

Also an MPH or KMH logo will appear on the bottom right of

the LCD display to indicate that MPH or KMH is being displayed.

Pressing the red button after this will recall any stored maximum

speed on the display.

If you have set the instrument to RECORD mode you will mo-

mentarily see a record number displayed as r followed by a

two digit number in the range 1-60 after the SPA. This is to

remind you of the record number for the next snapshot to be

used. The RECORD mode is also indicated by an REC symbol

on the top right of the LCD display.

Pressing the red button in this mode causes the instrument to

take a snapshot of the currently measured speed and store it

with the record number displayed while holding down the but-

ton.

If the supply voltage to the instrument drops to below 8.00

Volts, a small BATTERY symbol will displayed on the left of the

LCD display indicating that battery volts are low. The speedo will

still function normally at this voltage, but if the voltage drops

down to 7.00 volts, the instrument will reset itself.

5

To access the menu, hold down the red button and then switch on the

instrument. On the display you will see bon indicating that the

backlight is on (unless you have switched it off previously), you now

release the button. If you now press the red button momentarily again

you will see it increment to the next menu option, keep doing this to

familiarise yourself with them. The sequence of displays and there

meaning is shown below:-

tot =Total distance recall recorded on odometer.

bon =Backlight on or, b-- = Backlight off.

rtP =ResetPeak, IE reset stored maximum speed to zero.

tr = set TRigger points routine.

CAL = set CALibration to tyre circumference routine.

rcP =Recall Peaks, IE recall stored maximum speed, this

will be needed while in RECORD mode.

rEC =RECord mode on or, r-- = Record mode off.

rEP =REPlay of stored snapshots routine.

rtr =ReseTRecord number, IE sets record number back to 1.

tSt =TeST mode, used to set up and test wheel sensors.

AUt =Auto calibrate mode, used to set the calibration of

the speedo by driving over a standard 1/4 mile.

rEA = set REAdout to KMH or MPH, indicated by KPH or

MPH on the bottom right of the LCD display.

SSP = set Start SPeed for the acceleration and mid range

timer.

FSP = set Finish SPeed for the acceleration and mid range

timer.

ACC= routine for displaying and measuring acceleration

time.

The display then scrolls back round to backlight on/off.

To activate any option or routine, press and hold down the red

button, the display will change after 2 seconds.

A more detailed breakdown of each menu option is detailed on

the following pages.

MENU SYSTEM

6

tot (TOTAL DISTANCE RECALL):- Press and hold down the red

button, after 2 seconds the highest part (thousands) of the cur-

rent distance will be displayed. Press and hold down the red

button again, after 2 seconds the lower part (units) of the cur-

rent distance will be displayed (indicated by a decimal point to the

left of the 3 digits). The distance will be in miles or KM according

to the current readout selected. To return to menu at any point

momentarily press the red button and the next menu item will

appear.

bon (BACK LIGHT ON/OFF):- Press and hold down the red but-

ton, after 2 seconds the display changes to the desired option.

rtP (RESET PEAKS):- Press and hold down the red button, after

2 seconds the display increments to the next menu item. The

stored maximums are now reset to zero. This should be done

before any new maximums are to be stored.

tr (SET TRIGGER POINTS):- Use this routine to enter the number

of points that are to pass the speed sensor for one revolution of

the wheel (or shaft).

Press and hold down the red button, after 2 seconds the display

changes to t and a two digit number, indicating the current

number of trigger points the instrument is set to.

To change the number, press the red button momentarily to

increment it one at a time, or press and hold, and the display will

count up quickly. When the display reaches 40 it will scroll back

round to 01 .To exit the routine simply switch off the instru-

ment.

CAL (SET CALIBRATION of tyre circumference):- This routine is

used to enter the rolling circumference of the tyre being used.

Since the whole accuracy of the speedo hinges in the accuracy of

this data it is important to learn how to use it.

It can also be used to Trim the speedo to take into account

external errors and to cater for differential ratios when measur-

ing from prop shafts.

Alternatively use the Auto calibration system described further

on could be used. PLEASE NOTE: If the speedo is not calibrated

and the sensor not set correctly, the speedo may record

incorrect distance on the odometer. Correct operation is

important since the odometer cannot be reset.

1) General calibration procedure:- Measure the exact circumfer-

ence of the tyre at its centre. This circumference is now

entered in two parts, set metres and set millimetres.

Press and hold down the red button, after 2 seconds the current

circumference will be displayed in metres. To change the number,

press the red button momentarily only to increment it 0.1 at a time.

7

When the display reaches 4.0 it will scroll back round to 0.1 .When

this has been set correctly, press and hold down the red button.

The decimal point will now shift to the left and display the remain-

ing millimetres of circumference.

To change the number, press the red button momentarily to incre-

ment it one at a time, or press and hold and the display will count

up quickly. When the display reaches .099 it will scroll back round

to .000 To exit the routine simply switch off the instrument.

2) Special calibration:- If you require to trigger off a target with 10

teeth, then set the trigger points number to 10 in the SET TRIGGER

POINTS menu.

If the target is running at wheel RPM then simply enter the tyre

circumference as described above. However if the target is driving

a differential, then using a calculator, divide the circumference of

the tyre by the ratio of the differential, and enter this value as the

circumference, as described at the beginning of this section.

If you require to trim the accuracy of the speedo because for

example the differential ratio is not accurately known, and you

have determined that the speedo is reading say 2% high, then

using a calculator, subtract 2% off the currently stored circumfer-

ence value and enter this new value as described in the at the

beginning of this section. The speedo will then read 2% lower than

previously.

Alternatively, if you have access to an accurate 1/4 mile marked

road, use the Auto calibration mode described further on.

rcP (RECALL PEAKS):- If you are in record mode, then you need

this option to gain access to stored maximums, as the red button

during speed measurements is used to store snapshots. Simply

press and hold down the red button to view stored maximum, and

release the button to return to the menu.

rEC (RECORD MODE on/off):- Press and hold down the red button,

after 2 seconds the display changes to the desired option.

When this mode is on a small REC symbol will displayed in the

top left of the speedo display, and pressing the red button during

speed measurements will cause the instrument to take a snap-

shot of your current speed instead of recalling the stored maxi-

mum speed IE it will store the current speed at the instant that you

pressed the button, into the instruments memory.

Up to 52 snapshots can be taken on the standard speedo and each

one is given a Record number. These numbers are displayed while

pressing the button to take a snapshot as r followed by the record

number. After you have taken a snapshot the record number will

increment to the next one. When you have reached 52 it will return

back to 01 and overwrite the previous data.

Each time you switch on the instrument in the record mode , it will

8

show you the record number that will be used, next time you press

the button. If you wish to start again from record number 1 and

overwrite old data, then use the RESET RECORD NUMBER option

described further on.

rEP (REPLAY ROUTINE):- This routine is used for replaying or view-

ing your stored snapshots. The routine always starts from record

number 1, but can be quickly scrolled through the whole range. Press

and hold down the red button, after 2 seconds the display will change

to r01 indicating that it will display the snapshot for record number

1, release the button to view the snapshot.

Press the button again and the record number 2 will be displayed,

release the button and the snapshot for record number 2 will be

displayed etc. If you wish to scroll up the record number quickly,

press and hold the button and they scroll up quickly to 60 and back

around to 01.

rtr (RESET RECORD NUMBER):- Press and hold down the red button,

after 2 seconds the display increments to the next menu item. The

record number is now reset to one. This should be done if you want

to overwrite old data, instead of recording sequentially from the

previous record number.

tSt (TEST MODE):- This mode is used for setting up the mechanical

position of the wheel speed sensor, to check that it is triggering

properly. The display counts up every time a trigger pulse is received

from the sensor so you can see it working.

To use this mode, press and hold down the red button, after 2

seconds the display change to t00. The speedo is now ready to

receive trigger pulses. To exit this routine, press the red button and

you will return to the menu.

AUt (AUTO CALIBRATION MODE):- This mode is used for calibrating

the speedo by using a 1/4 mile of road as a standard. You do not need

to enter any circumference data, only the correct number of trigger

points being used, before you use this mode. The car is then driven

over an accurate 1/4 mile stretch, and the speedo then calibrates itself

by working out the exact effective circumference of the tyre. It will

also calibrate out any errors due to differential ratios, IE if you are

triggering of a drive shaft that does not rotate at wheel RPM.

To use this mode, press and hold down the red button, after 2

seconds the display will change to Str which means start

indicating that the program is now ready for a start signal by

pressing the red button. Do not do this until you are ready.

Unless you are using hall effect or opto sensors, it will be neces-

sary for car to be moving fast enough for the sensors to operate

as you pass your start mark on the road. This should be deter-

mined before you use this mode.

9

Start driving the car slowly, but fast enough for the sensors to

work, toward the start mark on the road.

As you pass the start mark, press and release the red button

firmly and the display will change to c00 and start counting up

quickly in response to wheel sensor pulses, this display is only

for reference, to show you that everything working. You may

increase your speed now as long as you dont cause any wheel

slip, but you must slow down again before you approach the 1/

4 mile mark.

As you pass the 1/4 mile mark, travelling at the same speed as

you started (fast enough for the sensors to work), press and

release the red button firmly again and the display will return to

the menu showing AUt. This indicates that calibration is com-

plete and you can verify this by toggling the button through the

menu to CAL and entering the routine to view your effective

circumference.

rEA (SET READOUT):- Use this option to change the readout to

MPH or KMH. Press and hold down the red button, after 2 sec-

onds the display changes to the desired option, as indicated by

KPH or MPH on the bottom right of the LCD display.

SSP (START SPEED):- Use this routine to enter the start speed

that you wish to measure the acceleration for. EG set to 0 for a

0-60 MPH timing.

Press and hold down the red button, after 2 seconds the display

indicates the current acceleration start speed the instrument is

set to. To change the number, press the red button momentarily

to increment it one at a time. When the display reaches 150 it will

scroll back round to 000 .To exit the routine, either press and

hold down the red button, and after 2 seconds the display will

return to SSP, or simply switch off the instrument.

FSP (FINISH SPEED):- Use this routine to enter the finish speed

that you wish to measure the acceleration for. EG set to 60 for a

0-60 MPH timing.

Press and hold down the red button, after 2 seconds the display

indicates the current acceleration finish speed the instrument is

set to. To change the number, press the red button momentarily

to increment it one at a time. When the display reaches 150 it will

scroll back round to 010.To exit the routine, either press and

hold down the red button, and after 2 seconds the display will

return to FSP, or simply switch off the instrument.

ACC (ACCELERATION TIME):- This routine is used to display the

current stored acceleration time, and to measure and store new

acceleration times. To access this routine, press and hold down

the red button, after 2 seconds the display will show the cur-

rently stored acceleration time.

10

To start a new acceleration measurement, press and hold down

the red button, after 2 seconds the display changes to ---

indicating it is ready.

Now accelerate the car. If you are measuring acceleration from a

standing start, then as soon as the wheels begin moving, the

speedo will start the acceleration timer, and your road speed will

be displayed along with the REC symbol on the top right of the

display. If you measuring a mid range time (EG 30-70 MPH), then

you see your road speed indicated, but the REC symbol will not

appear until your car has reached your start speed, at which

point the timer is started.

When your car has reached the programmed finish speed, the

REC symbol will go out, and your new acceleration time will be

displayed. To return to the menu at any point in this routine,

press the red button momentarily and the display will change

back to ACC.

SPECIFICATIONS

MOUNTING DATA

INPUT VOLTAGE 8.0-16 VOLTS (working)

CONSUMPTION 10 mA @ 12 VOLTS (42 mA BACKLIT)

ACCURACY:- 0.05% TYPICAL

ACCELERATION TIMER 0.1 SEC +/- 0.03%

CALIBRATION:- DIGITAL

DATA STORAGE:- EEPROM

WEIGHT:- 190gINCLUDING SENSORS,CABLES,ETC

SIZE:- 50mm x 30mm x 25mm DEEP

PLUS 10mm EACH SIDE FOR MOUNTING FEET

SENSOR FIXING DIA:- 10mm

CABLE LENGTHS:- WHEEL SPEED SENSOR - 120"

POWER SUPPLY - 12"

SWITCH LEAD - 24"

ABSOLUTE MAXIMUM RATINGS:-

INPUT VOLTAGE - 18 VOLTS

SPEED 999 MPH/KMH

ODOMETER 999,999 MILES/KM

INSTRUMENT TEMPERATURE 0 - 50OC

11

WIRING SCHEMATIC

Connector Pins:

1 & 2 - Switch Button

3 - Ground (Black)

4 - +12v (Red)

5 - Sensor (Red)

6 - Sensor (Blue)

7 - Sensor (Green)

12

WIRING SCHEMATIC

SPA DESIGN LTD.

THE BOAT HOUSE,

LICHFIELD STREET,

FAZELEY, TAMWORTH,

STAFFS. U.K. B78 3QN

TEL: 01827 288328

FAX: 01827 260528

e-mail: [email protected]

www.spa-uk.co.uk

Table of contents

Popular Computer Hardware manuals by other brands

TDK

TDK DEA Series Specifications

prophecy

prophecy gofanco PRO-VideoWallv2 user guide

FabiaTech

FabiaTech Low Power FB2503 user manual

ekwb

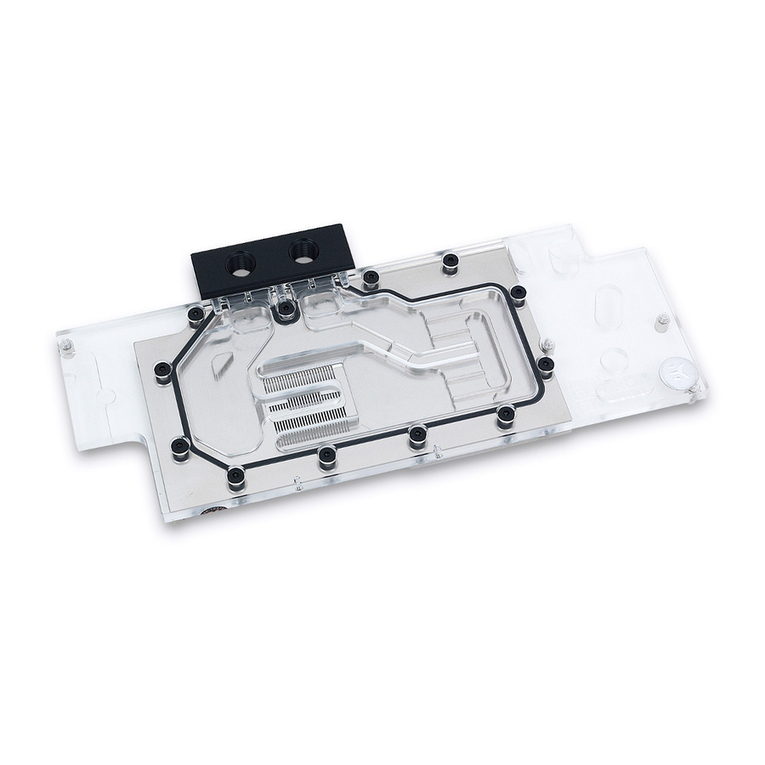

ekwb EK-FC R9-290X INSTALLATION AND MOUNTING MANUAL

Antares

Antares Portable Public Address Speaker System... owner's manual

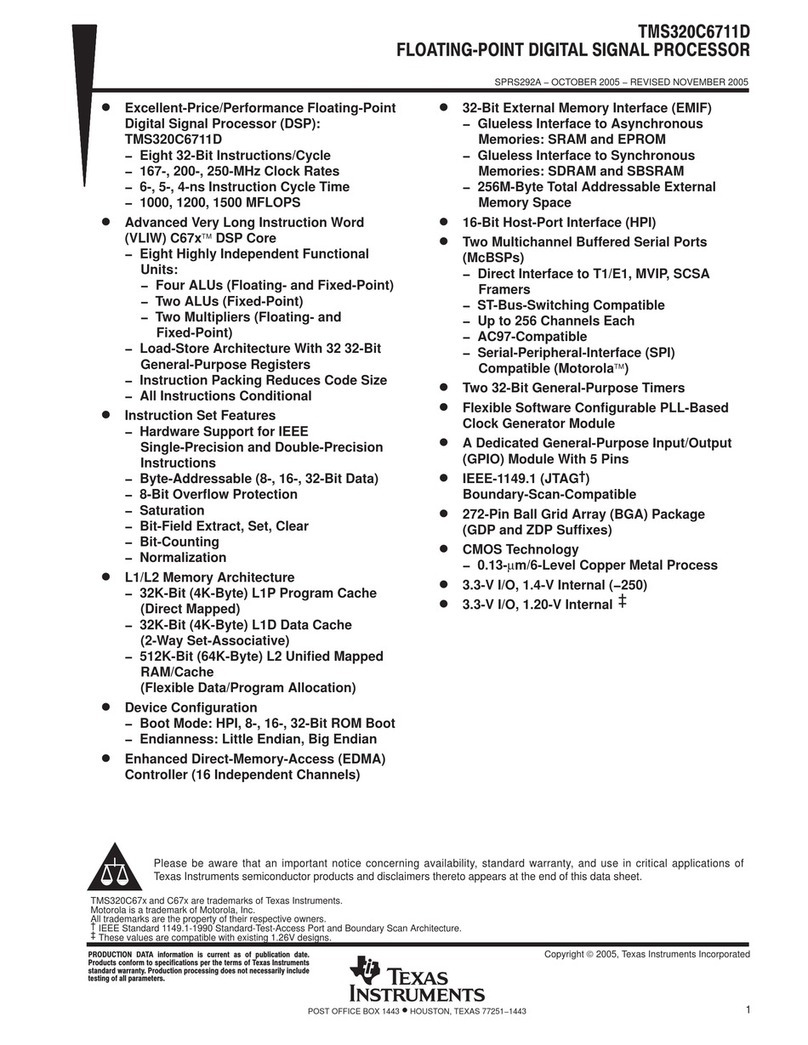

Texas Instruments

Texas Instruments TMS320C6711D user manual