Space-Ray LoPro LPBL42-N5 User manual

Form No. 43539500

July 2021 A

LOW PROFILE RADIANT GAS BROODER

MODELS: LPBL42-N5 / LPBL42-L5 with DIRECT SPARK IGNITION

INSTALLATION

AND OPERATION

INSTRUCTIONS

Patent Pending

OWNER/INSTALLER: For your safety this manual must be carefully read before installing, operating or

servicing this brooder. This brooder is intended for use with either Natural Gas or Propane Gas. It must be

installed by a qualified service person or a licensed contractor in accordance with state and local codes. In

the absence of these codes, the installation must conform to the National Fuel Gas Code ANSI Z223.1 (latest

edition) also know a NFPA54 or the CAN/CGA-B149.1/2 Installation Code in Canada.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury, property

damage or death. Refer to this manual. For assistance or additional information, consult a qualified

installer, service agency or the gas supplier.

INSPECT all combustion air openings into the building and, if necessary, clear as they become blocked by

litter, dust, feathers or other matter.

INSPECT and clean the brooder filters on a regular basis to allow proper brooder operation.

FOR YOUR SAFETY: EXHAUST FANS MUST be operating on an appropriate cycle when brooders are

operating to avoid a high concentration of carbon monoxide. When used without fresh air, this brooder may

give off carbon monoxide, an odorless and poisonous gas. CARBON MONOXIDE POISONING MAY LEAD TO

DEATH. Early signs of carbon monoxide poisoning resemble the flu with headaches, dizziness and nausea. If

you experience these signs, GET FRESH AIR IMMEDIATELY! Have the brooders serviced as soon as possible

and check the ventilation in the house.

These brooders are designed for agricultural applications and may operate with the use of either Natural Gas

or Liquid Propane (LP) Gas. Check the brooder’s nameplate to determine the correct gas type before

proceeding with installation.

IF YOU SMELL GAS:

!DO NOT try to light any appliance.

!DO NOT touch any electrical switch; do not use any

telephone in your building.

!IMMEDIATELY call your gas supplier from a neighbor's

telephone. Follow the gas supplier's instructions. If you

cannot reach your gas supplier, call the fire department.

DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

SAVE THIS MANUAL

FOR FUTURE REFERENCE.

FOR YOUR SAFETY

Scan warranty QR code on the right to

register your product.

Form No. 43539500

July 2021 A –1–

TABLE OF CONTENTS

Section

Description Page

1.0)

GENERAL INFORMATION ............................................................................................ 1

2.0)

BROODER SPECIFICATIONS....................................................................................... 2

3.0)

BROODER CONTROL DESCRIPTION.......................................................................... 2

3.1)

BROODER ACCESSORIES .......................................................................................... 3

3.2)

PACKING LIST............................................................................................................... 5

4.0)

BROODER ASSEMBLY................................................................................................. 6

4.1)

GAS VALVE WIRE CONNECTIONS .............................................................................. 10

5.0)

MINIMUM CLEARANCES TO COMBUSTIBLES .......................................................... 12

6.0)

BROODER INSTALLATION........................................................................................... 12

7.0)

GAS CONNECTIONS ..................................................................................................... 13

7.1)

INSTRUCTIONS FOR TESTING OF GAS LEAKS AND PROPER GAS PRESSURE... 16

7.2)

GAS PIPE SIZING EXAMPLE ....................................................................................... 18

8.0)

ELECTRICAL CONNECTIONS ....................................................................................... 19

9.0)

LIGHTING AND SHUTDOWN INSTRUCTIONS............................................................ 22

10.0)

VENTILATION ................................................................................................................ 23

11.0)

CLEANING AND ANNUAL MAINTENANCE................................................................. 23

12.0)

TROUBLESHOOTING .................................................................................................... 26

13.0)

REPLACEMENT PARTS GUIDE.................................................................................... 28

1.0) GENERAL INFORMATION

This brooder is a self-contained infrared radiant brooder for agricultural locations where flammable gases or

vapors are not generally present.

Installation of the brooders must be in accordance with all applicable codes shown in the instructions and/or

the local codes and authorities having jurisdiction. In the absence of local codes, the brooder must be

installed in accordance to the National Fuel Gas Code ANSI Z223.1/NFPA54 in the U.S. or the CAN/CGA-

B149.1/2 Installation Code in Canada. Clearances to combustibles as outlined in the manual should always

be observed.

Inspect all openings and filters regularly and clean as necessary. This is necessary because litter, dust

feathers and other matter can become airborne and clog openings and filters and adversely affect brooder

operation and performance.

Every brooder should be located with respect to building construction and other equipment so as to permit

access to the brooders. Each installer shall use skillful and reliable installation practices when locating the

brooders and must give consideration to service accessibility.

This brooder is for INDOOR INSTALLATION ONLY and is used in an UNVENTED mode. The term Unvented

actually means Indirect Vented. While the products of combustion are expelled into the building, national

codes require ventilation in the building to dilute these products of combustion. This ventilation must be

provided by gravity or mechanical means. Ventilation requirements are addressed further in these

instructions.

This heater complies with IAS U.S. No. 8-94 (Draft No. 2) and CAN-1-2-20-M85.

Copies of the National Fuel Gas Code (ANSI Z223.1-latest edition) are available from the CSA at 8501 E.

Pleasant Valley Rd., Cleveland, OH 44131 or 55 Scarsdale Road, Don Mills, Ontario M3B 2R3. All NFPA

codes are available from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

This product can expose you to chemicals including ceramic fibers,

which are known to the State of California to cause cancer, and carbon

monoxide, which is known to the State of California to cause birth

defects or other reproductive harm. For more information go to

www.p65warnings.ca.gov.

Form No. 43539500

–2–July 2021 A

2.0) BROODER SPECIFICATIONS

INPUT RATING

Propane Gas:

42,000 BTU/h (12.31 kW)

Natural Gas:

42,000 BTU/h (12.31 kW)

Propane/Butane Mix Gas

42,000 BTU/h (12.31 kW)

GAS SUPPLY PRESSURE

Propane Gas:

11” – 14” W.C. (27.4 - 34.8 mbar)

Natural Gas:

5” – 14” W.C. (12.4 - 34.8 mbar)

Propane/Butane Mix Gas

11” – 14” W.C. (27.4 - 34.8 mbar)

MANIFOLD PRESSURE

Propane Gas:

10” W.C. (24.9 mbar)

Natural Gas:

4” W.C. (10.0 mbar)

Propane/Butane Mix Gas

10” W.C. (24.9 mbar)

ORIFICE SIZE

Propane Gas:

5/64” (.0781”)

Natural Gas:

3.1mm (.1220”)

Propane/Butane Mix Gas

1.8mm (.0709”)

MOUNTING HEIGHT

Recommended - 72” (1830mm)

BROODER SPACING

25’ – 40’ (7.6m – 12.2m)

BROODER SIZE

Canopy Diameter:

35” (890mm)

Brooder Height:

13.75” (349mm)

WEIGHT

Assembled Brooder:

21.5 lbs (10 kg)

VENTILATION REQUIRED

Per Brooder:

168 CFM (286 m3/hr)

GAS CONSUMPTION

Propane Gas:

0.46 GPH (1.75 L/hr)

Natural Gas:

0.42 Therm (44.3 MJ/hr)

Propane/Butane Mix Gas

0.46 GPH (1.75 L/hr)

ELECTRICAL SUPPLY

24 VAC, 1 Ph, 60Hz, 0.8A

3.0) BROODER CONTROL DESCRIPTION

Brooder Control No. 5 is designed for single or multi-zone installations using one or more thermostats. A

Zone Control (available as an accessory, Part No.43619050) is required to provide a 24-Volt power supply to

each brooder. The burner is controlled with a Direct Spark Ignition (DSI) switch, which is designed to provide

100 percent gas shut off of the main valve in the event that the main burner flame is not sensed.

Form No. 43539500

July 2021 A –3–

3.1) BROODER ACCESSORIES

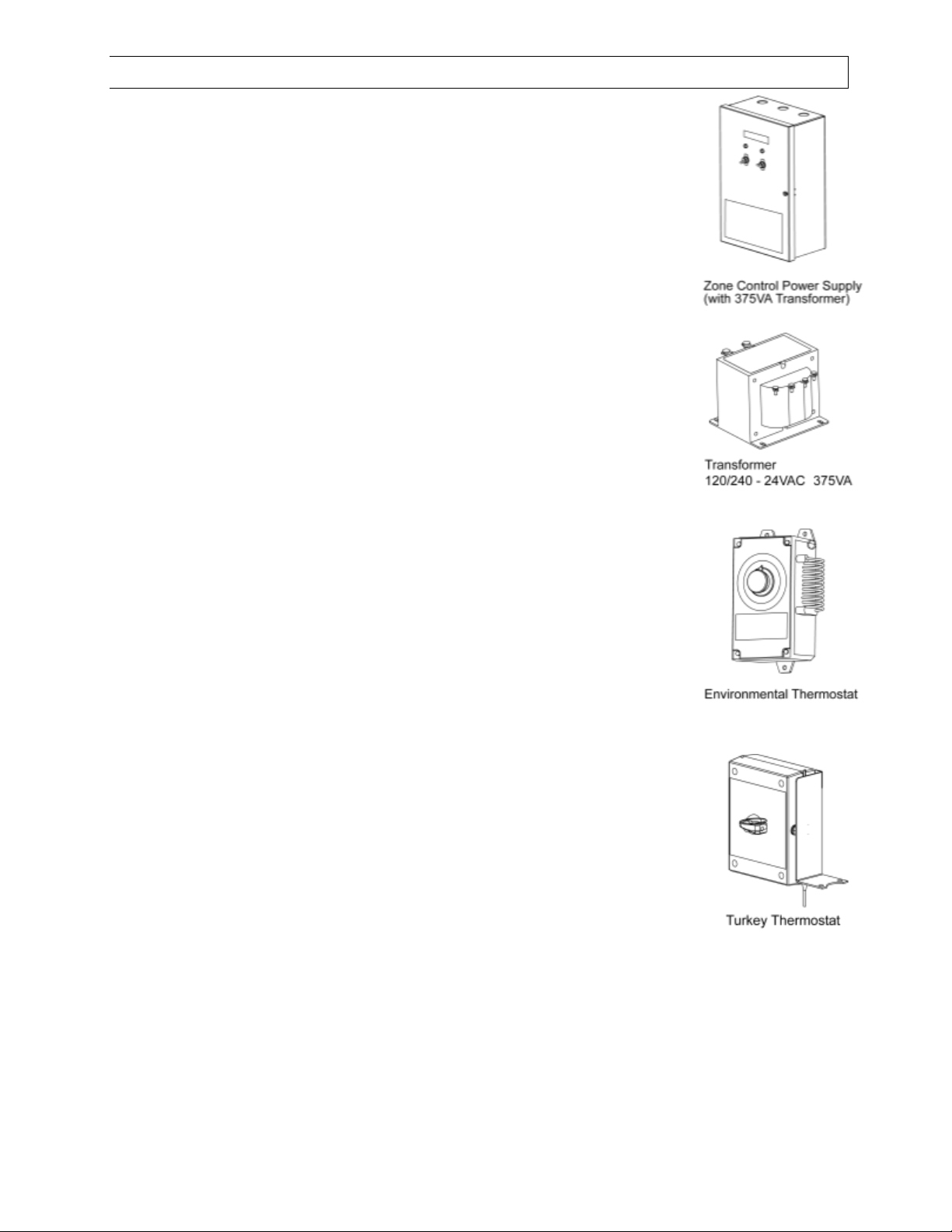

A) Zone Control Panel Model ZCP22, Part No. 43619050

This is a power supply control which utilizes a 375VA transformer to

provide the required 24VAC for single or multiple groups (zones) of

brooders. Refer to electrical section of manual for allowable heater

quantities per transformer.

B) Transformer Replacement –375VA 120/240VAC

24VAC, Part No. 30222070

C) Thermostat –Environmental (EW-4-20), Part No. 30525010

Ratings: SPDT 120/240VAC, 16A Full Load

Temperature range: -40 Deg. F to 104 Deg. F +/- 2.5 Deg.F

Differential

Housing: Watertight ABS plastic meets NEMA 4x and NEC Article 547-

4 requirements for use in harsh environments. Adjustable dial allows

thermostat to be recalibrated.

D) Thermostat –Individual, Part No. 43317060

Temperature range: 58 Deg. F to 122 Deg. F with ten (10)

temperature scale ranges.

The thermostat is used to control individual brooders for Turkey heating

applications. Includes Mears thermostat, plastic enclosure, bracket and

screws to mount to White-Rodgers #25M18 gas valve.

Form No. 43539500

–4–July 2021 A

E) Transformer Kit, Part No. 44195160

This kit has a 120/24VAC 20VA transformer which

provides the required 24VAC for a single brooder. A

moisture proof junction box, cord connectors and wire nuts

are included.

F) Hose Kits - No. 5A Controls:

Part No. 30522060 - 6FT Hose with 3/8” swivel female flare fittings and 6” spring. Ball valve not included.

Part No. 30522100 - 10FT Hose with 3/8” swivel female flare fittings and 6” spring. Ball valve not included.

Part No. 30522069 - 6FT Hose with 3/8” swivel female flare fittings and 6” spring. Includes ball valve.

Part No. 30522109 - 10FT Hose with 3/8” swivel female flare fittings and 6” spring. Includes ball valve.

Kit Components:

Item Number

Part Number

Description

Qty

1

30241010

MALE FTG 45 FLARE 3/8 TUBE x 1/2 MPT (for gas shut-off valve)

1

2

30241000

MALE FTG 45 FLARE 3/8 TUBE x 3/8 MPT (for main gas valve)

1

3

30523060

HOSE, 3/8 ID x 6FT with 3/8" F SWIVEL FITTINGS and 6” Spring

1

4

30523100

HOSE, 3/8 ID x 10 FT with 3/8" F SWIVEL FITTINGS and 6” Spring

1

5

30285000

Manual Gas Shut-Off Ball Valve 1/2 FPT

1

G) Manual Gas Shut-Off Ball Valve –1/2”NPT, Part #30285000

H) Wire Brush –Long, Part #43295020

Wire Brush –Short, Part #43295010

This manual suits for next models

3

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions