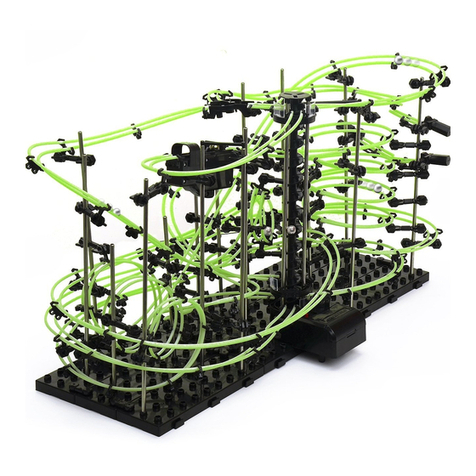

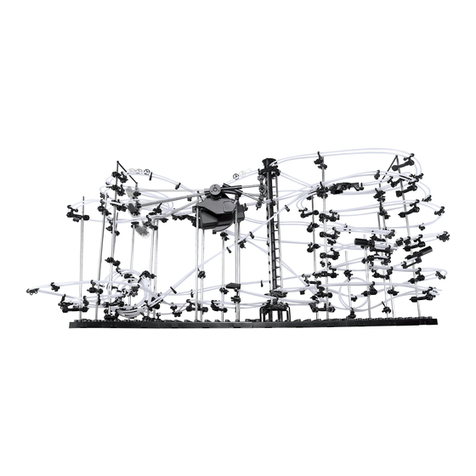

Spacerails Level 9 User manual

LEVEL 9

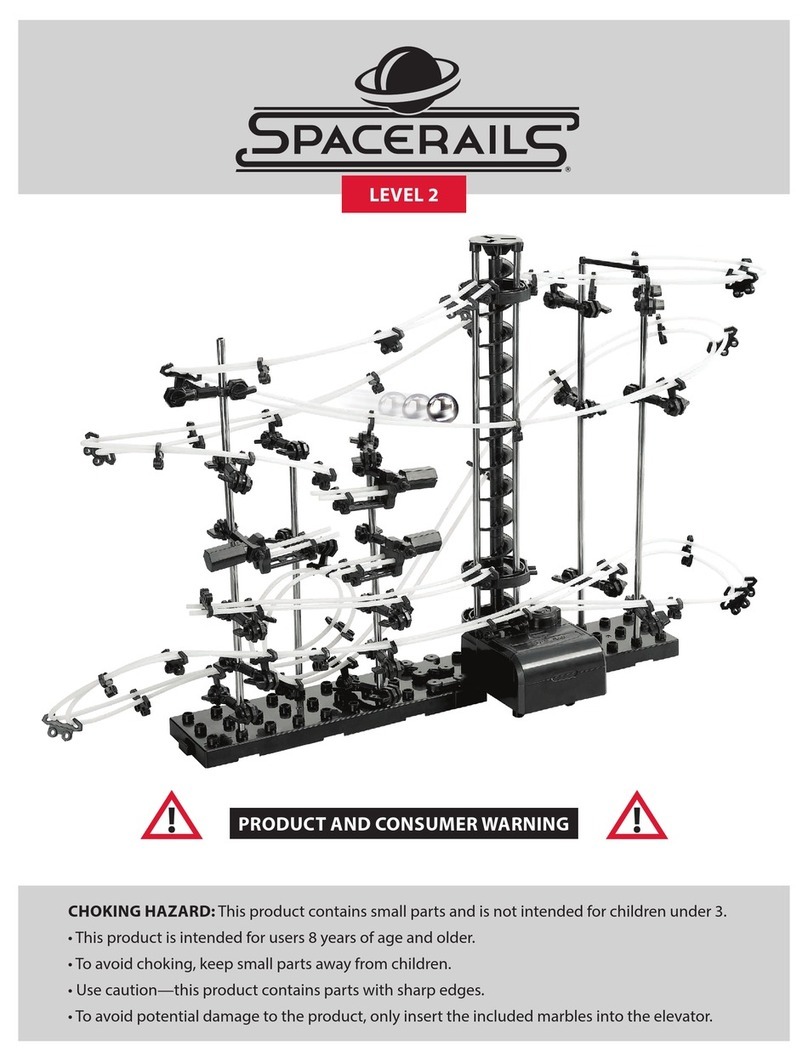

PRODUCT AND CONSUMER WARNING

CHOKING HAZARD: This product contains small parts and is not intended for children under 3.

• This product is intended for users 8 years of age and older.

• To avoid choking, keep small parts away from children.

• Use caution—this product contains parts with sharp edges.

• To avoid potential damage to the product, only insert the included marbles into the elevator.

Page 2 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

PARTS INCLUDED

RECOMMENDED ITEMS (NOT INCLUDED)

Wire Cutters or Utility Scissors

Pen or Marker

6 AA Batteries (newer models) or 2 C Batteries

Ruler (in Centimeters)

ELEVATOR COMPONENTS

Power Box

x 2

Elevator Helix

x 38

Elevator Ring

x 9

Elevator Cover

x 4

Elevator Guard

x 11

Power Box Stand

x 2

Shaft Clip

x 1

Pendulum

x 1

Marble Catch

x 1

Counterweight

x 1

Pendulum Tray

x 1

Rail Splitter

x 3

STUNT COMPONENTS

SHAFT COMPONENTS

600mm

x 9

391mm

x 8

300mm

x 20

200mm

x 7

159mm

x 19

65mm

x 8

Shaft Cap

x 2

ARM COMPONENTS

Arm Clip

x 147

Arm Sheath

x 168

Arm Holder A

x108

Arm Holder B

x 265

Arm Lock

x 375

See-Saw Arm

x 2

Rail Coupling

x 15

Rail

76,000 mm

Rail Clip

x 300

Marble

x 12

RAIL COMPONENTS

BASE COMPONENTS

Base

x 13

Double Sided Base

x 1

Base Holder A

x 13

Base Holder B

x 10

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 3

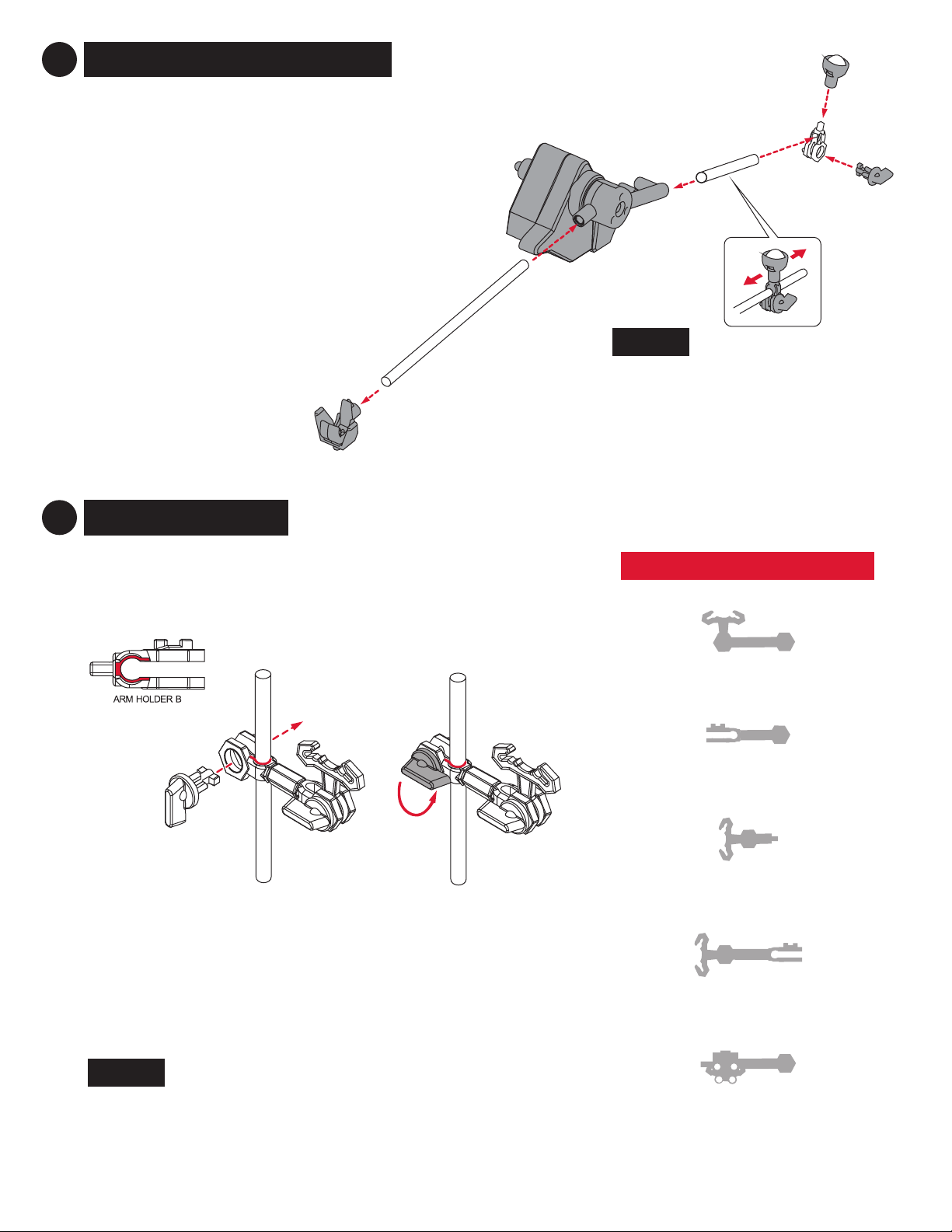

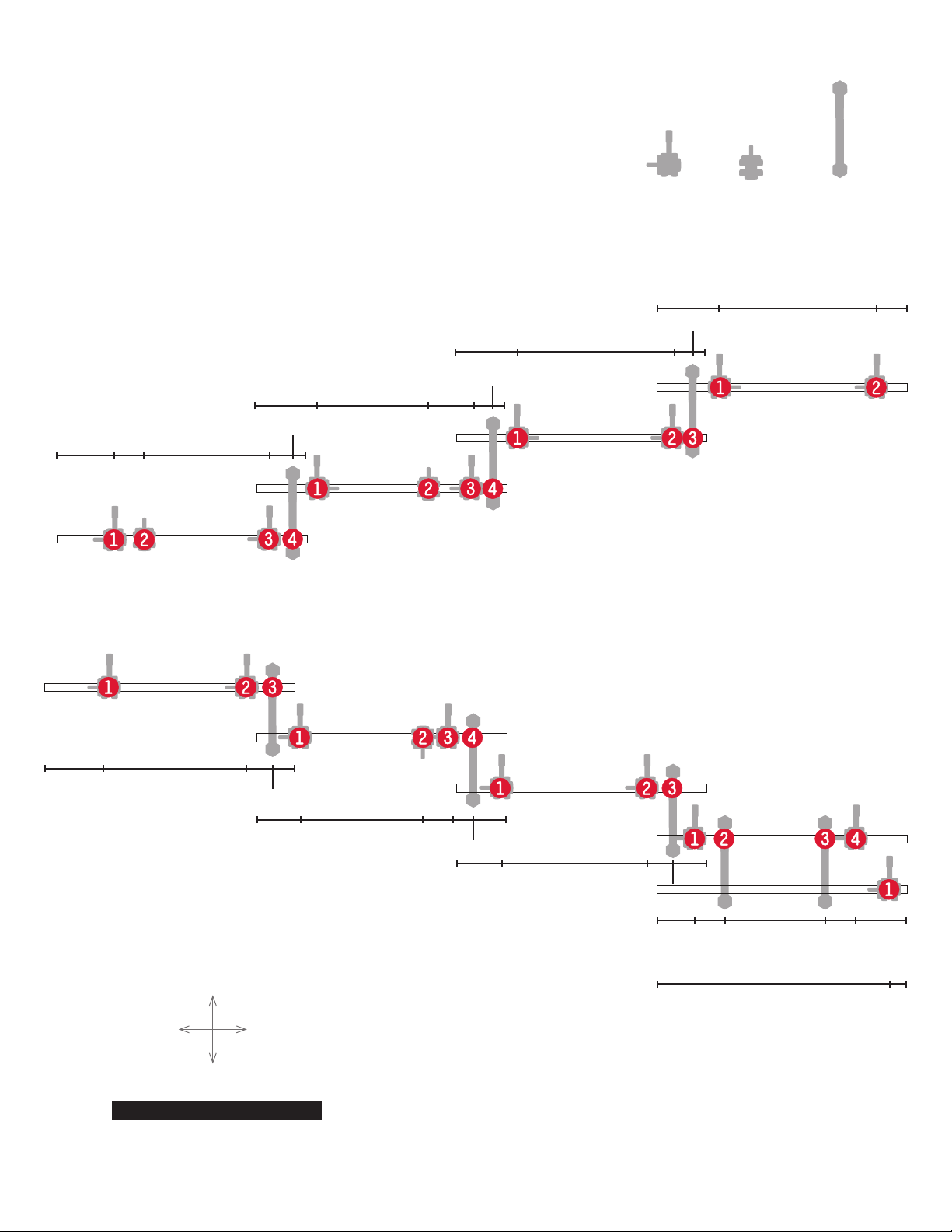

1PREPARE ARMS

Attach one Arm Holder B on each side

of the Arm Sheath.

Attach one Arm Holder B on each side

of the Arm Sheath. When assembling

shafts F, BC, and BD, slide one

ArmHolder B on shaft and insert one

ArmClip and add the Arm Lock.

BARM B QTY: 56

ARM D QTY: 3

AARM A QTY: 107

Slide Arm Holder B onto

shaft. Insert Arm Lock

through ArmHolder B and

Rail Clip. Turn the Arm Lock

counter-clockwise to secure

the Rail Clip in place. These will

be assembled during the shaft

assembly step to shafts D, E, F,

G, BC and BD.

ARM C QTY: 36

Step 1: Attach one Arm Holder A and one

Arm Holder B with one Arm Sheath. Insert

one Arm Clip into Arm Holder A.

Step 3: Turn the Arm Lock

counter-clockwise to secure

the Arm Clip in place.

Step 2: Insert Arm Lock through

Arm Holder A and Arm Clip.

To avoid damaging parts, do not move or adjust the Rail Clip while locked in the arm. To move the Rail Clip, release

Arm Lock by turning clockwise, position Rail Clip as desired, then secure Arm Lock again.

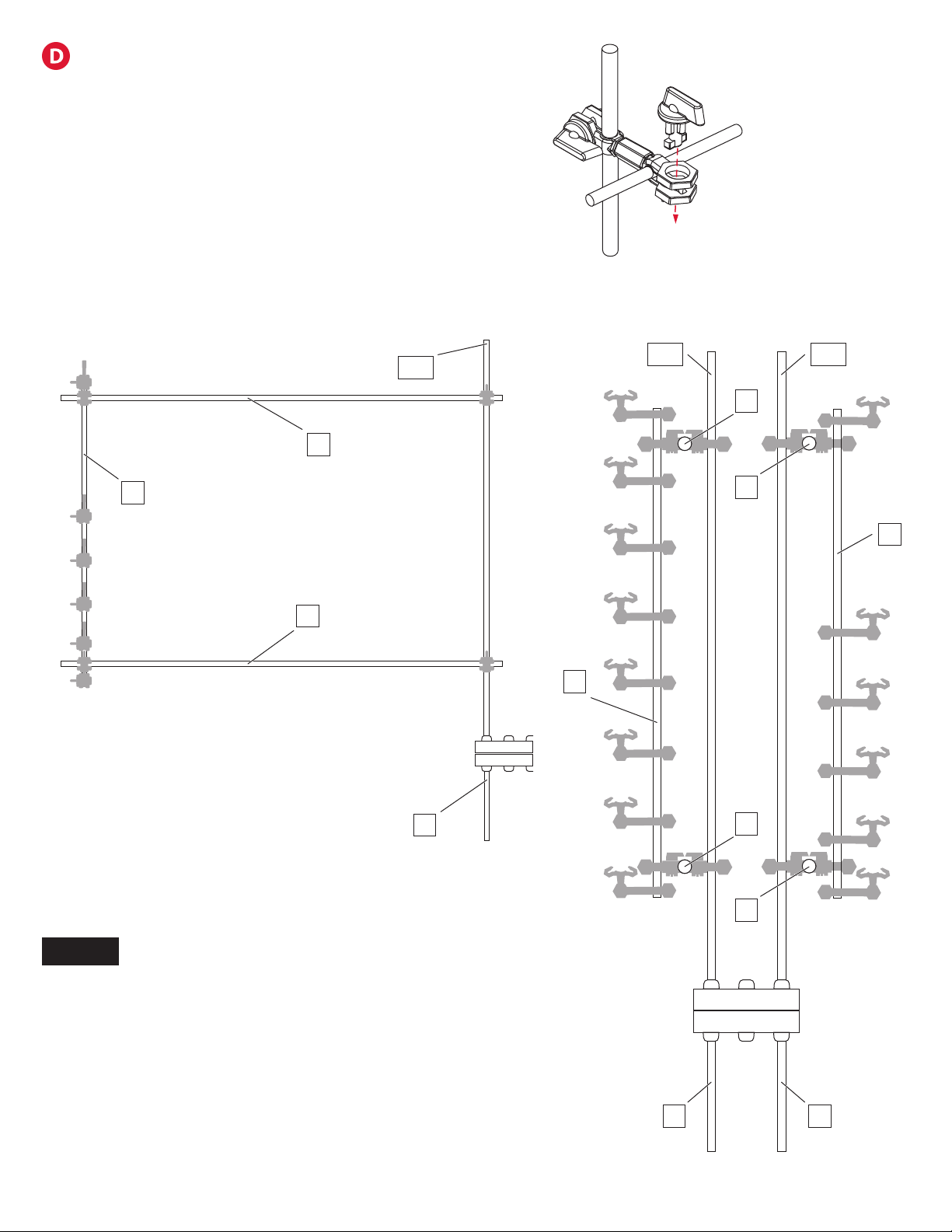

C

D

Cut two 7.5 cm lengths of rail and insert

into See-Saw as shown using a Rail Clip

to support the ends of the rail.

Attach Arm Holder B to the square receiver side of Arm Sheath

to create the arm. Attach the arm to the shaft and the shaft

to the base prior to attaching the round receiver side of the

ArmSheath to the See-Saw Arm.

SEE-SAW ARM QTY: 1 LEFT & 1 RIGHT

Page 4 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

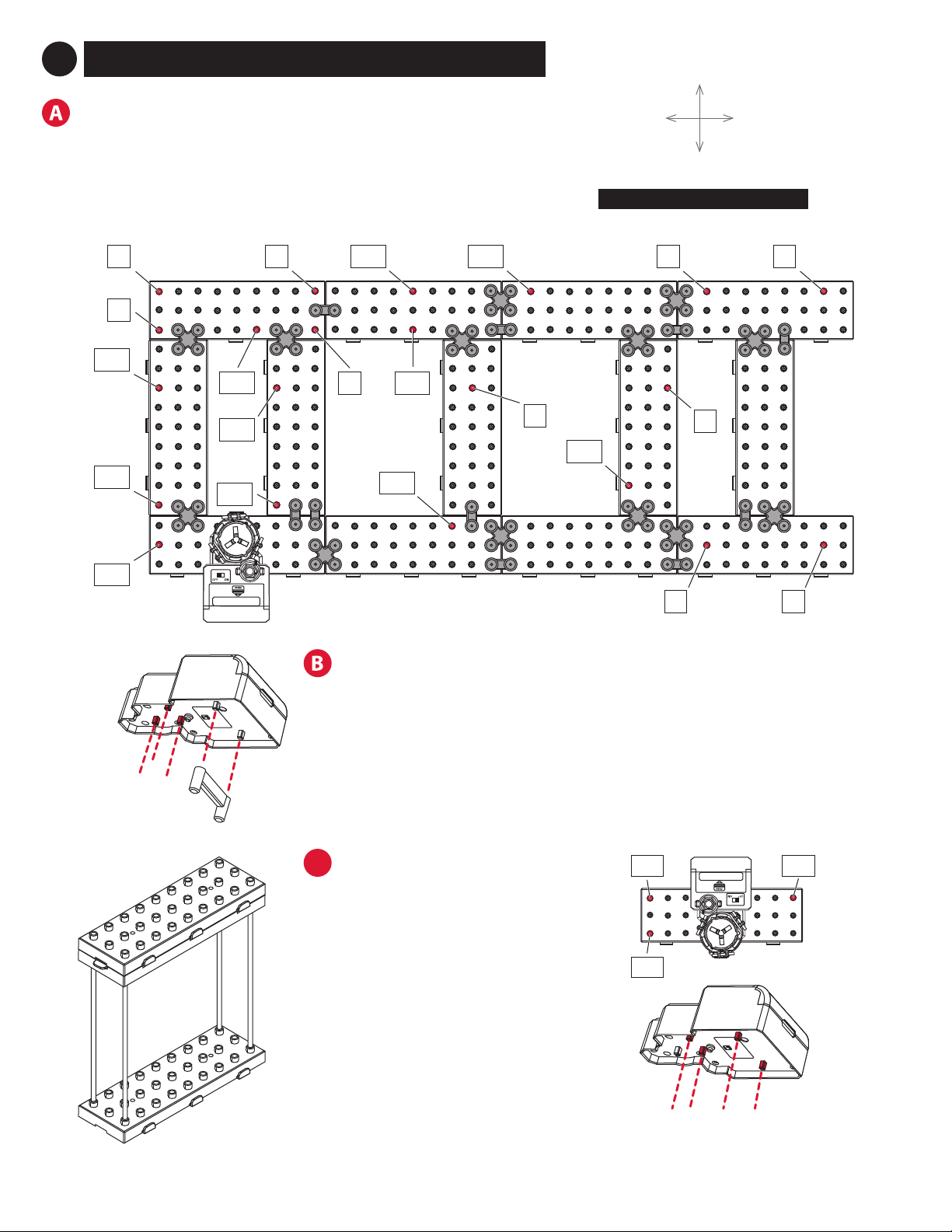

Step 1: Interlock all

Base block tabs as

shown above.

Step 2: Press Base Holder A and

Base Holder B pieces into the Base

blocks for a more secure hold.

NOTE:

Please see the included

full size drawings for the

next several steps. This will

simplify the positioning of

base, arms, shafts, and the

rail cut lengths.

Step 3: Assemble base blocks as shown in the

Illustration of completed base with all tabs

locked and Base Holders installed. Approximately

20% of actual size.

BASE ORIENTATION

BACK OF BASE

FRONT OF BASE

LEFT

OF BASE

RIGHT

OF BASE

2BASE ASSEMBLY

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 5

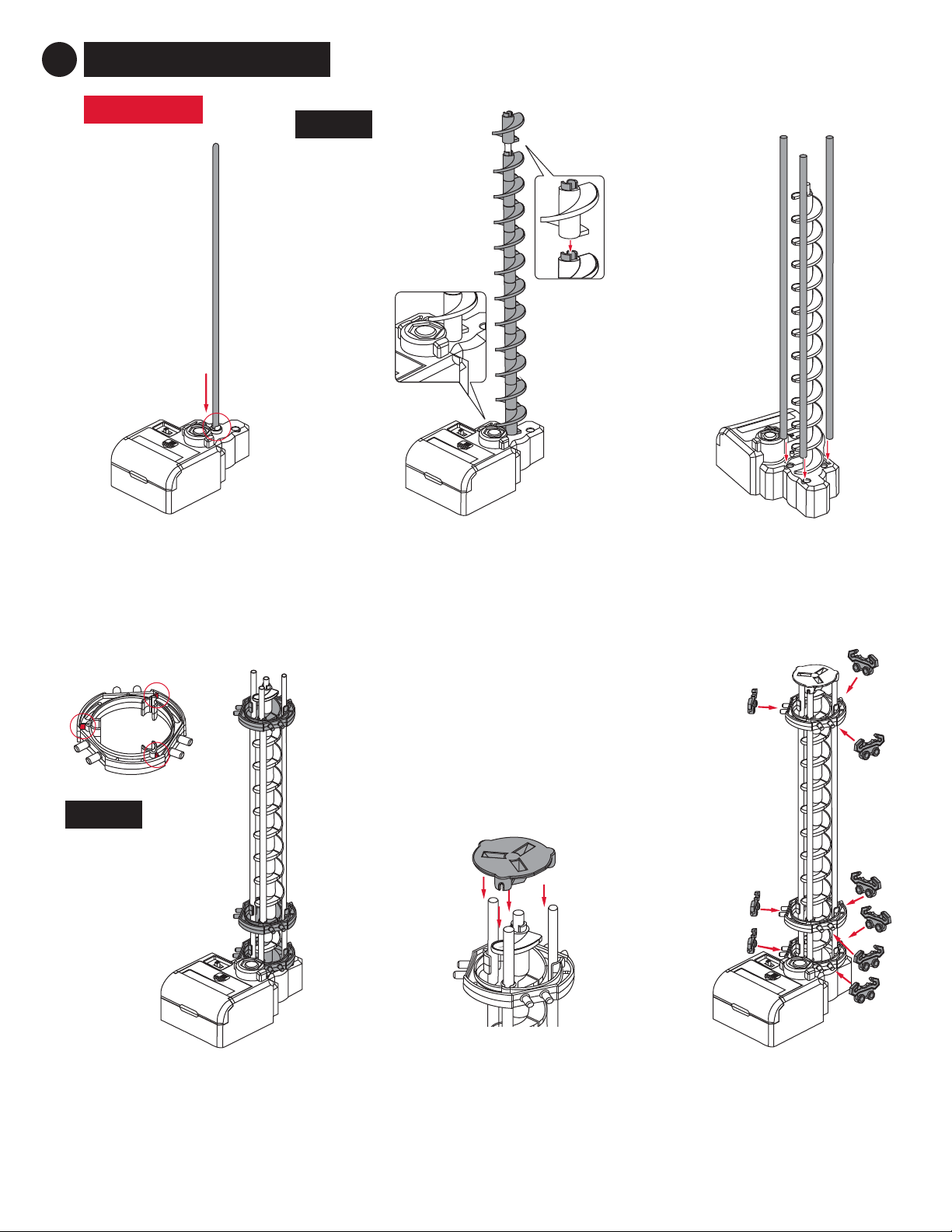

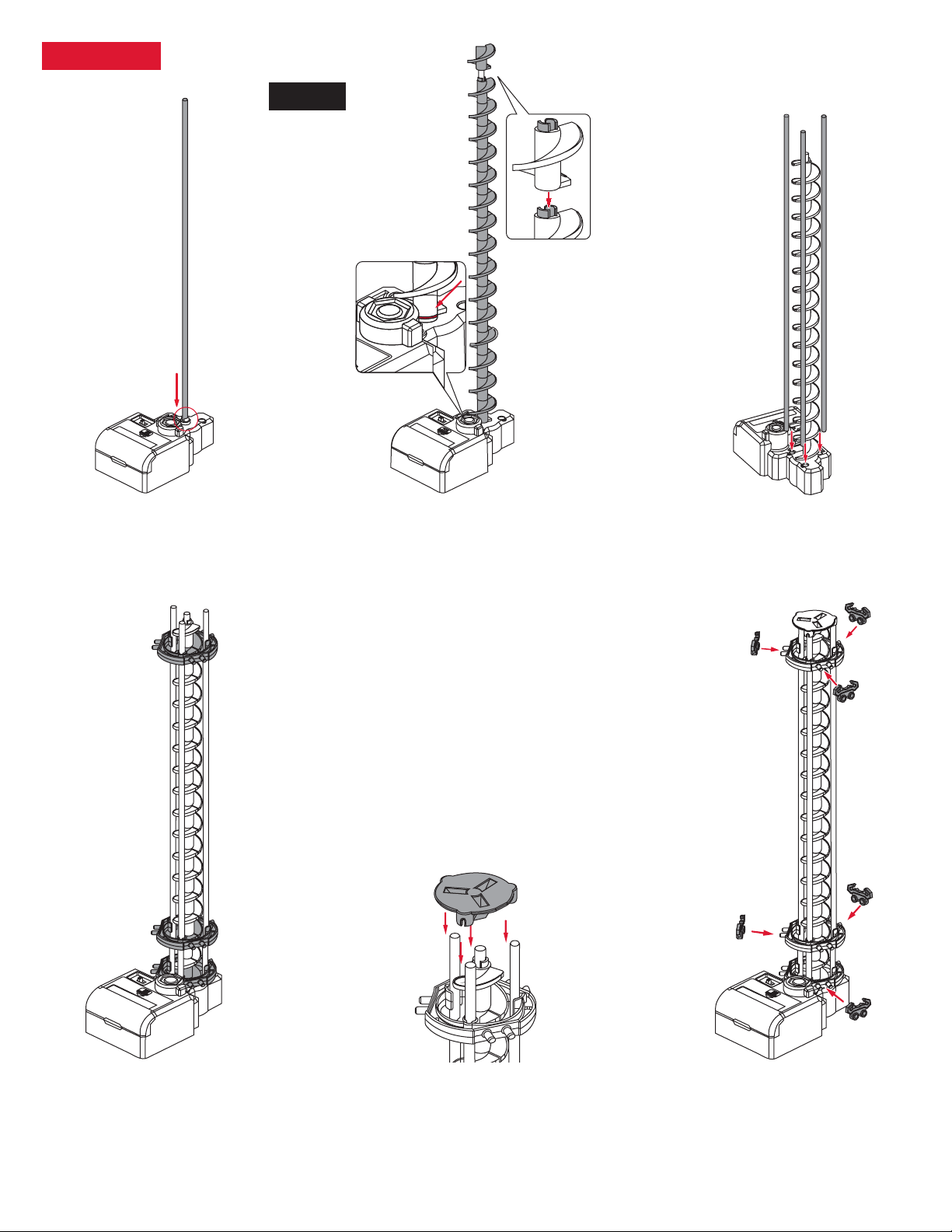

ELEVATOR A

Step 3: Once the corkscrew

is built, attach three 300 mm

support shafts to the Power Box.

Step 1: Place a 300 mm shaft in

the white hole on the Power Box.

Step 2: Connect Elevator Helix

pieces together with the male part

facing up to ll the shaft.

NOTE:

Install the rst Elevator

Helix piece male side

up and rotate it until

it slides in place and

engages with driver at

the base of Power Box.

Step 6: Attach Rail Clips to

each Elevator Ring as shown.

Step 4: Slide each Elevator Ring

into position on the support

shafts right-side up.

Step 5: Place the Elevator

Cover onto the top of the

elevator assembly.

NOTE:

Elevator Rings are

right side up when

tabs in red are on

the top.

240 mm

40 mm

0 mm

3ELEVATOR ASSEMBLY

Page 6 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

ELEVATOR B

Step 3: Once the corkscrew

is built, attach three 391 mm

support shafts to the Power Box.

Step 1: Place a 391 mm shaft in

the white hole on the Power Box.

Step 2: Connect Elevator Helix

pieces together with the male part

facing up to ll the shaft.

NOTE:

Install the rst Elevator

Helix piece male side

up and rotate it until

it slides in place and

engages with driver at

the base of Power Box.

Step 6: Attach Rail Clips to

each Elevator Ring as shown.

Step 5: Place the Elevator Cover

onto the top of the elevator

assembly.

Step 4: Slide each Elevator Ring

into position on the support

shafts right-side up.

335 mm

30 mm

0 mm

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 7

ELEVATOR C

Step 3: Once the

corkscrew is built,

attach three 300 mm

support shafts to the

Elevator Cover.

Step 1: Insert a 300 mm

shaft rst into a Shaft Cap

and then into the center

hole of an Elevator Cover.

Add the Shaft Clip 2 cm up

from the base.

Step 2: Connect

Elevator Helix pieces

together with the

male part facing up

to ll the shaft.

Step 6: Attach Rail

Clips to each Elevator

Ring as shown.

Step 5: Place the Elevator

Cover onto the top of the

elevator assembly.

2 cm

Step 4: Slide each

Elevator Ring into

position on the

support shafts

right-side up.

NOTE:

The Marble may

fall out of the

elevator if it

enters too fast.

Add Elevator Guards to the right of each

Rail Clip installed to the bottom two

Elevator Rings.

ADDING GUARDS: Repeat this step for all

three elevators that have been built.

75 mm

185 mm

0 mm

Page 8 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

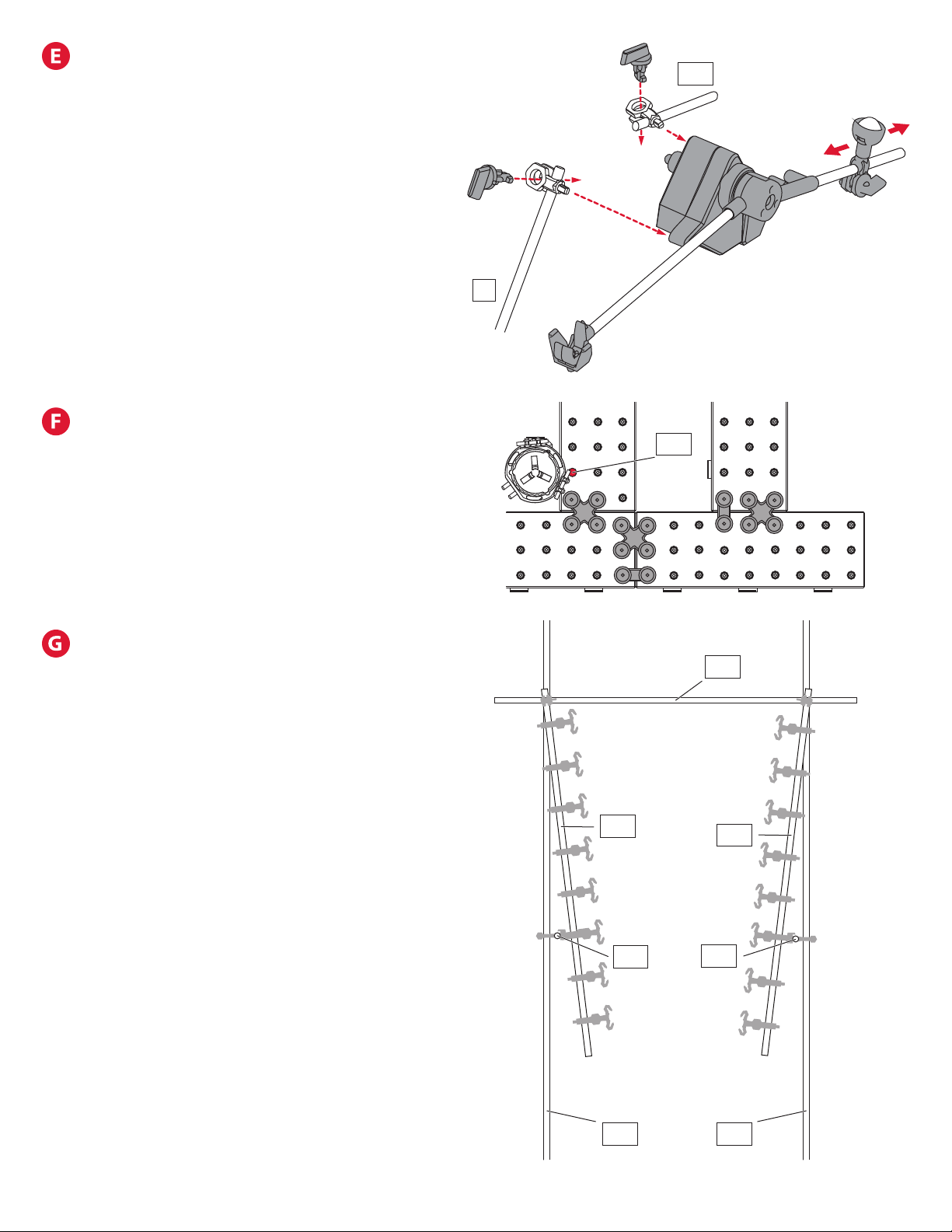

4PREPARE PENDULUM STUNT

Attach the Marble Catch to a 200 mm shaft. Insert

other end of shaft to the left side of the Pendulum.

Next attach an Arm Holder B to a 65 mm shaft with

an Arm Lock and add the Counterweight to the post

of Arm Holder B. Finally, attach the 65 mm shaft to

the right hand side of the Pendulum.

NOTE:

The Counterweight is adjustable, if the

pendulum stunt is not working, try

moving the weight to dierent positions.

NOTE:

The shafts listed below contain no arms and are not included in the drawings.

Shafts: I, J, L, M, N, O, W, X, Y, Z, AX, AY, and AZ

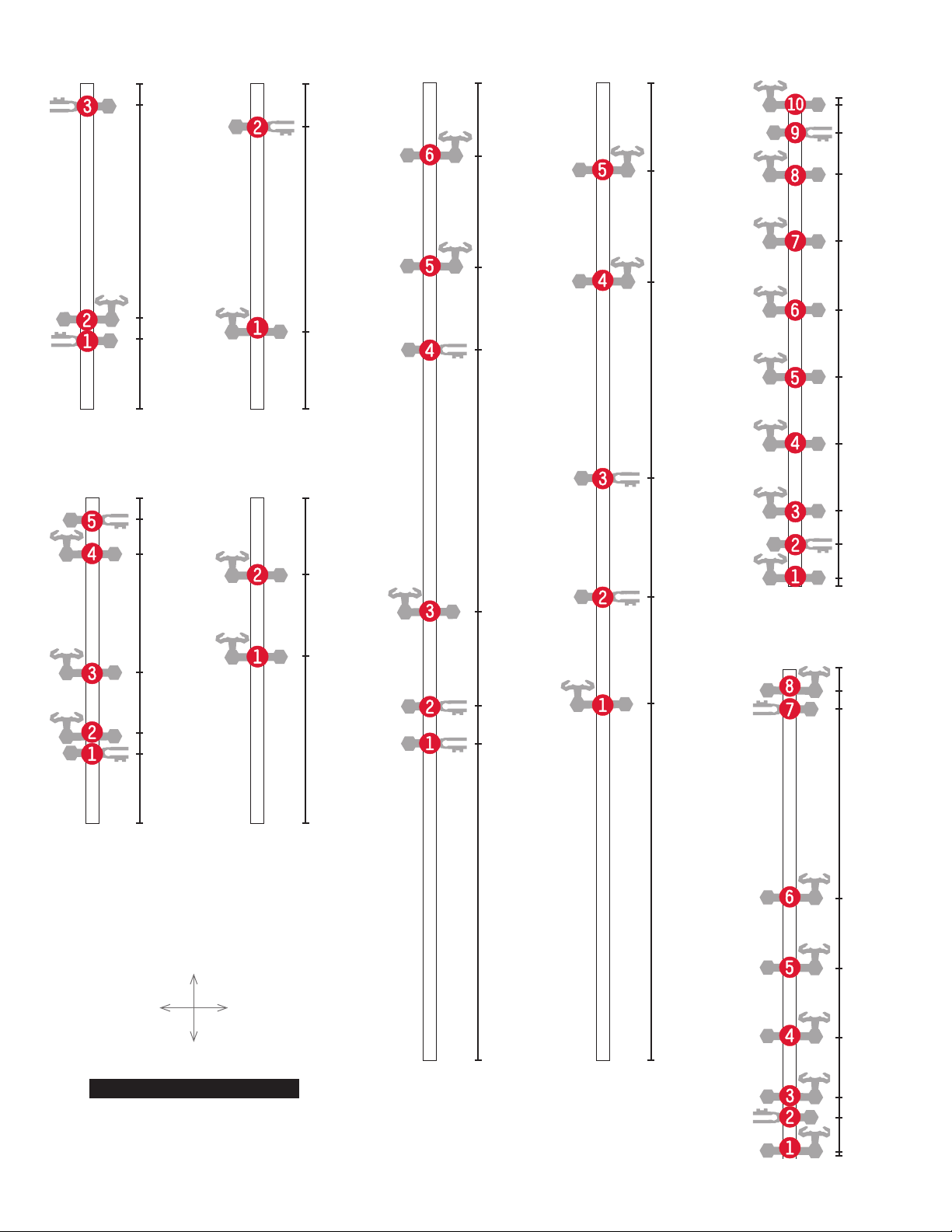

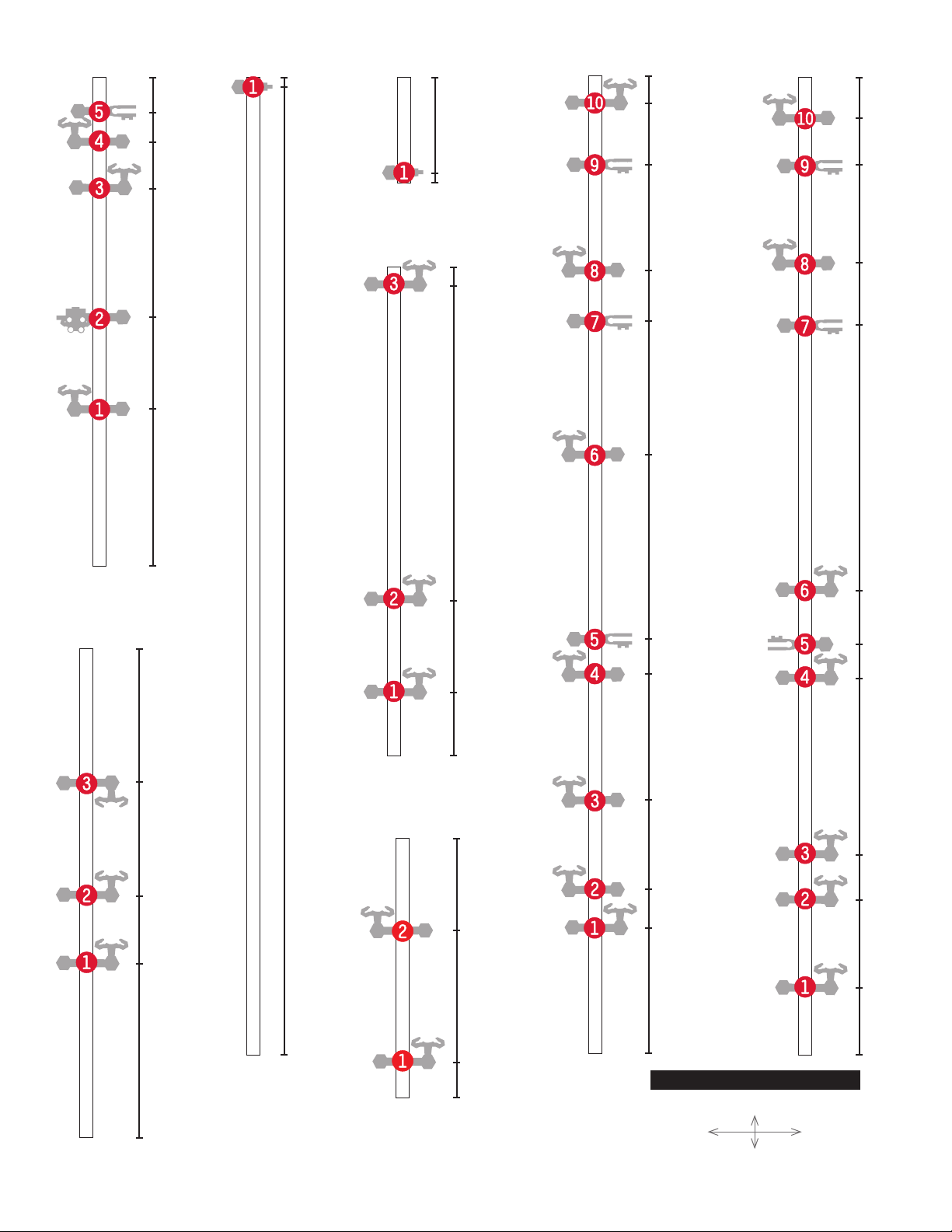

Step 1: Slide Arm Holder B of each arm on to a shaft and lock in

place with Arm Lock. Refer to the next pages for orientation and

location of each arm.

Step 2: Attach each arm as shown in step 1 with the orientation

and location shown on the following pages. In later steps the letter

of each shaft and number of each arm will guide in the installation

of the rails. For example Arm A-3 is 104 mm from the base.

Shaft illustrations are approximately 37% of actual size. All shaft

measurements are in Millimeters.

Arm A

Arm B

Arm C

Arm D

See-Saw Arm

ARM TYPE REFERENCE

5SHAFT ASSEMBLY

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 9

Shaft A Shaft C Shaft D Shaft F

10

600

44

54

104

168

185

242

267

315

335

448

500

563

578

310

355

Shaft B

600

44

54

185

340

524

595

300

46

100

129

158

187

216

245

286

Shaft E

300

46

112

141

170

198

228

257

286

300

100

40

130

160

190

224

291

10

Shaft G

300

105

135

165

195

225

291

285

TOP

BASE

FRONT

OF BASE

BACK

OF BASE

SHAFT TO BASE ORIENTATION

Page 10 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

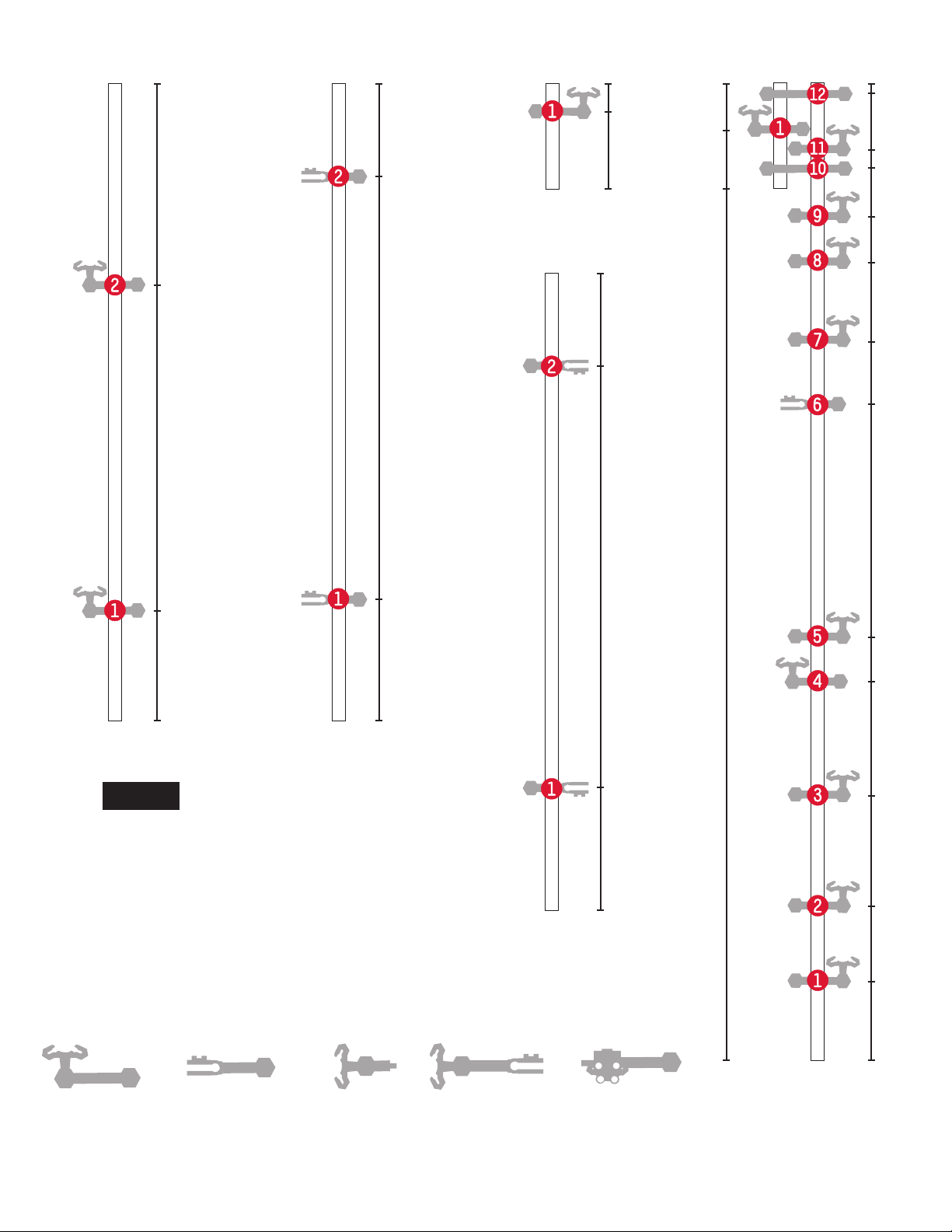

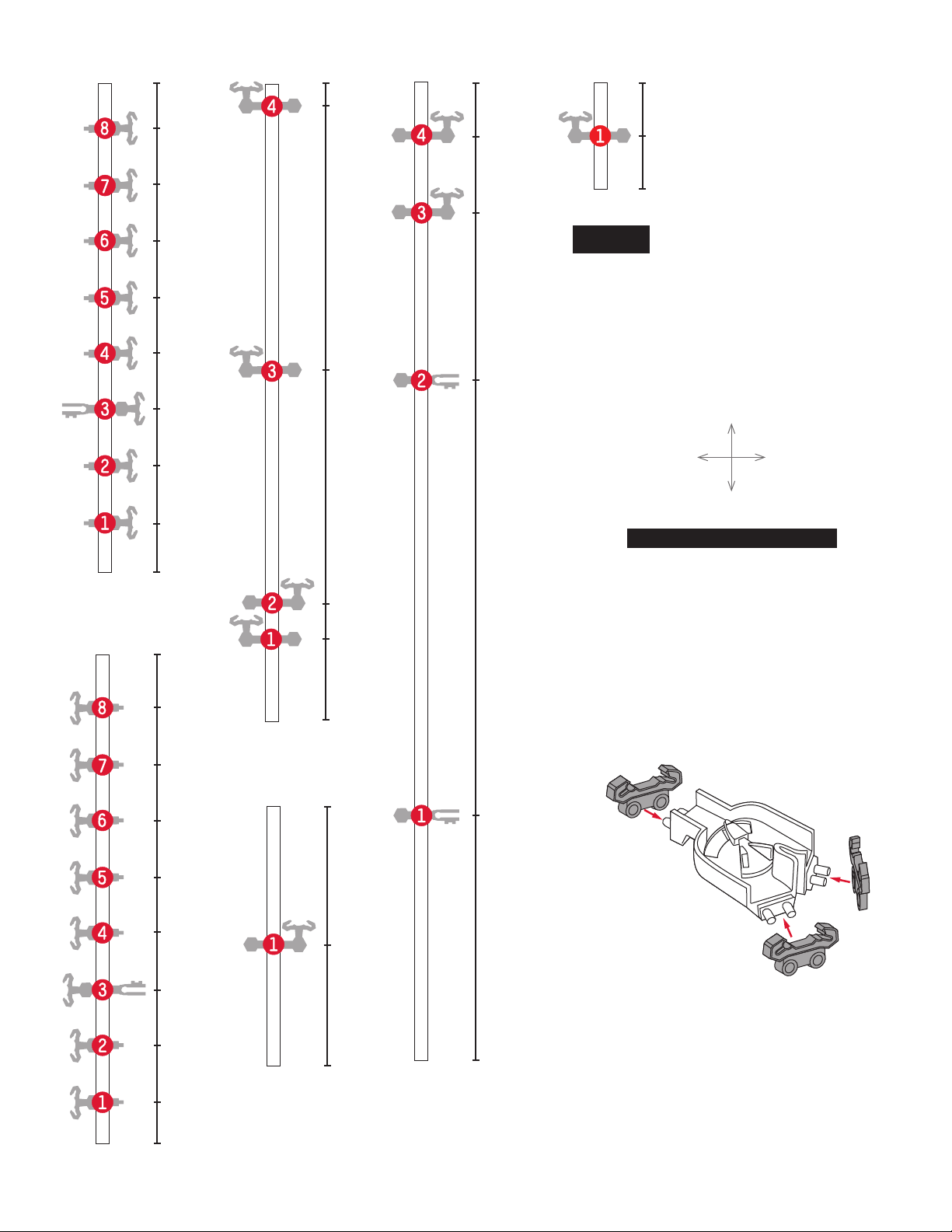

Shaft H

44

54

186

200

Shaft K

44

55

95

186

168

200

Shaft P

50

173

200

Shaft Q

105

155

200

TOP

BASE

FRONT

OF BASE

BACK

OF BASE

SHAFT TO BASE ORIENTATION

Shaft R Shaft S

600 600

194

217 222

278 284

357

436

480

490

558 550

Shaft T

Shaft U

300

3

3

17

18

36

46

78

88

119

131

163

172

214

279

290

300

278

255

295

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 11

Arm A Arm B Arm C Arm D See-Saw Arm

Shaft V

70

270

391

Shaft AB

75

335

391 600

51

98

166

235

262

402

445

493

520

550

562

593

535

576

600

Shaft AE & AF

75

335

391

Shaft AD

65

49

Shaft AC

NOTE:

If you want to jump ahead you can start

adding the arms to the base at any time. Keep

in mind that some arms like H and K utilize

the Arm B connectors to attach to other

shafts and are suspended above the base.

Page 12 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

STAIR STUNT ARMS

The arms for this stunt are connected to each other and will build a

suspended stair stunt. For now just build the arms as shown here.

Some of the arms on this page are shown from the narrowest side.

For example: the arm AG-1 is seen from the end with the Rail Clip

above the arm. The Arm Lock is also visible on the side. Arm AG-4 is

an Arm B and is shown connecting shafts AG and AH together. Arm BArm A Arm B

Shaft AG

Shaft AK

Shaft AL

Shaft AO

Shaft AM

Stair Stunt A

Stair Stunt B

Shaft AH

Shaft AI

Shaft AJ

SHAFT ORIENTATION STAIRS

UP

DOWN

LEFT SIDE

OF BASE

RIGHT SIDE

OF BASE

40

40

40 110

140

140

140

150

150

40

40

20

20

20

50 140

130

110 120

120

40 100 120

145

150

150

140

140

Shaft AN

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 13

Shaft AP

Shaft AQ

300

99

152

235

279

263

110

151

215

300

Shaft AR Shaft AV Shaft AW

600

594

Shaft AT

Shaft AU

99

42

300

292

600

80

103

158

235

254

370

449

483

545

586

600

44

98

126

236

250

288

447

488

545

577

105

25

159

Shaft AS

65

4

TOP

BASE

FRONT

OF BASE

BACK

OF BASE

SHAFT TO BASE ORIENTATION

Page 14 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

Shaft BC

300

30

65

100

135

168

203

237

272

Shaft BD

25

60

94

129

163

198

232

267

300 57

67

218

391

Shaft BE

380

Shaft BF

77

159

Shaft BG

600

150

417

523

570

Shaft BH

65

35

NOTE:

Please see the included full size drawings.

This will simplify the positioning of base,

arms, shafts, and the rail cut lengths.

TOP

BASE

FRONT

OF BASE

BACK

OF BASE

SHAFT TO BASE ORIENTATION

RAIL SPLITTERS

Step 1: Attach one Rail Clip on each

of the Rail Splitter posts.

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 15

ATTACH ELEVATOR TO BASE

Step 1: Attach Power Box Stand

to the Power Box.

Step 2: Firmly seat the posts

from the Power Box in the holes

on the base.

ADDING THE UPPER FLOOR

Step 1: Add the Double Sided Base

over the back left base block using

shafts N, O, P, and Q.

Step 2: Add the shafts in the

diagram to the upper oor.

Step 3: Firmly seat the posts from

the Power Box in the holes on the

Upper Base. Do not attach a Power

Box Stand. This elevator is pushed

forward and attaches with

dierent posts.

Attach posts

to base

Use diagram below for location of each shaft. Push

shaft into holes on base until sturdy. Refer to drawings

on pages 9-14 for orientation of shaft to the base.

SHAFT ORIENTATION STAIRS

BACK OF BASE

FRONT OF BASE

LEFT SIDE

OF BASE

RIGHT SIDE

OF BASE

AC

AV

BH AW

BG

AQ

AP AE

AU

BF

AT

N

O

P

Q

S

K A

HC

V

AB

AD

BE

Attach posts to

the upper base

6ADDING SHAFTS AND ELEVATORS TO BASE

C

Page 16 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

ROUND ABOUT STUNT SUSPENDED SHAFTS

Step 1: Attach shafts W and X (159 mm) to the arms on shaft

AB so that they extend to the left of the base. Add Arm Locks

as needed.

Step 2: Attach shafts Y and Z (159 mm) to the arms on shaft

AD so that they extend to the left of the base.

Step 3: Attach shaft T to shaft W and X. The arms of shaft T

should face the back of the base.

Step 4: Attach shaft U to shaft Y and Z. The arms of shaft U

should face the front of the base.

Illustration shows how

to suspend an arm using

arm type B.

AB AD

W

T

U

Y

X

Z

N O

Completed view from left of base.Completed view from front of base.

AD

U

Y

Z

O

NOTE:

Remember to insert Arm Locks for all arms as they are

connected. This will help keep things from shifting

around unintentionally. If you need to move an arm

do not force it. Release the Arm Lock reposition arm

and return Arm Lock to the locked position.

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 17

ADDING PENDULUM TO STRUCTURE

Step 1: Attach shaft R at about a 45° angle

above the base with the bottom of the shaft

connecting at arm P-2, AP-5, and AE-6. The

shaft should sit just in front of the back row of

shafts and angle up and to the right.

Step 2: Attach shaft AS at arm A-13. Shaft AS

should angle down and to the left side

of the base.

Step 3: With the pendulum facing the front of

the base insert the post of arm AR-1 into the

hole on the back left side of the pendulum.

Step 4: Finish by inserting arm AS-1 into the

hole on the back of the pendulum on

the right side.

ADDING ELEVATOR C

Attach elevator C on the left side to arm BG-1

and arm BG-2. The bottom of elevator C should

be approximately 125 cm above the base and

the center shaft of elevator C should line up

with arm BG when observed from the right side

of the base. Fine tuning will be required

as rails are attached to keep everything

running smoothly.

VERTICAL FUNNEL SUSPENDED SHAFTS

Step 1: Connect shaft AZ (300 mm) at arms

AV-9 and AW-9. This will give added support

to the stunt and keep the top of these shafts

evenly spaced.

Step 2: Next attach shaft AX at arm AV-5

parallel to the base. Then attach shaft AY at arm

AW-5 parallel to the base.

Step 3: Now the funnel shape will be created

starting at the bottom by attaching shaft BC

from arm BC-3 to shaft AX and shaft BD from

arm BD-3 to shaft AY.

Step 4: For the top of the funnel shape connect

shaft BC to arm AV-7 and shaft BD at arm AW-7.

Target a distance of 15 cm at the bottom of the

funnel and 23.5 cm at the top with the bottom

approximately 14.5 cm from the base.

AS

R

BG

AV

AZ

BC

AX AY

BD

AW

Page 18 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

DOUBLE LOOP STUNT SUSPENDED SHAFTS

Step 1: Attach shaft I to the arms H-3 and C-3. Attach shaft

J to the arms H-1 and C-1. This creates a box shape when

observing from the front of the base.

Step 2: Attach shaft L to the arms A-5 and K-5. Attach shaft

M to the arms A-1 and K-1. This creates a box shape when

observing from the back of the base.

Step 3: Attach shaft E centered between shafts L and I using

arms E-1 and E-8. The arms of shaft E should face down.

Step 4: Attach shaft D centered between shafts J and M using

arms D-1 and D-8. The arms of shaft D should face up.

Step 5: Attach shaft F between shafts H and K 100 cm above

the base using arms F-1 and F-8. The arms of shaft F should

face to the right. Attach F-2 to shaft V for additional support.

Step 6: Attach shaft G between shafts A and C 100 cm above

the base using arms G-1 and G-8. The arms of shaft G should

face to the left.

Step 7: Attach shaft R to arm G-3 and rest on working surface.

Shaft R is not over the base.

STAIR STUNT SUSPENDED ARMS

Step 1: Take stair stunt part A and slide into position so that it can connect

to arms S-3, V-3 and R-4. This is the upper portion of the stair stunt.

Step 2: Take stair stunt part B and move into position so that it can connect

to arms S-1, V-3, R-2 and R-1. This is the lower portion of the stair stunt.

S

V

R

Stair Stunt A

Stair Stunt B

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 19

C

7 cm (qty: 3)

D

7.5 cm (qty: 4)

E

16 cm (qty: 2)

F

21 cm (qty: 4)

G

34 cm (qty: 6)

H

43.5 cm (qty: 1)

I

46 cm (qty: 2)

J

54 cm (qty: 2)

K

55 cm (qty: 2)

L

66 cm (qty: 2)

M

71 cm (qty: 2)

N

75 cm (qty: 2)

O

86 cm (qty: 2)

P

90 cm (qty: 2)

Q

93 cm (qty: 2)

R

100 cm (qty: 2)

S

175 cm (qty: 2)

T

188 cm (qty: 2)

U

194 cm (qty: 2)

V

475 cm: (qty 2)

W

550 cm (qty: 2)

X

560 cm (qty: 2)

Y

670 cm

(qty: 2)

A

5 cm (qty: 1)

B

5.5 cm (qty: 2)

7CUT THE RAIL

Step 1: Measure each section and mark the cutting point with a pen.

Step 2: Cut each section according to your measurement. Make sure

to cut at a 90° angle.

Tip: To help avoid do-overs and using too much rail, cut generously (slightly

longer than required) to begin with. You can always cut a long rail shorter.

NOTE:

Illustration of rail lengths is 2.6% of actual size.

Please see the included full size drawings. This will

simplify the positioning of base, arms, shafts, and

the rail cut lengths.

Page 20 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

Connecting rails to arms: To install the rails, press them into the arm as

shown. You should hear a click when the rail is locked in place.

When building a curve, Rail Clips and Arm Clips

can be adjusted to create a banked curve. Plenty

of Rail Clips are included so that they can be

applied liberally.

Attach Rail Clips every 8-10 cm along rail to

maintain stability and keep rails parallel. Keeping

rails uniform maintains speed and avoids throwing

the Marble o course.

Rails should extend into the elevator

enough to catch the Marble.

Rail Couplings are provided but not needed.

If more length is needed for a rail, insert the

coupling into the end of both rails being joined.

Keep incline as smooth as possible to avoid

losing speed or contact with rails.

8INSTALLING RAILS

Add the Catch Tray to the pendulum drop

stunt to make it easier to catch the marbles.

Table of contents

Other Spacerails Toy manuals

Spacerails

Spacerails LEVEL 4 User manual

Spacerails

Spacerails Level 5 User manual

Spacerails

Spacerails Level 3 User manual

Spacerails

Spacerails Level 2 User manual

Spacerails

Spacerails Level 1 User manual

Spacerails

Spacerails LEVEL 6 User manual

Spacerails

Spacerails Level 8 User manual

Spacerails

Spacerails Level 7 User manual