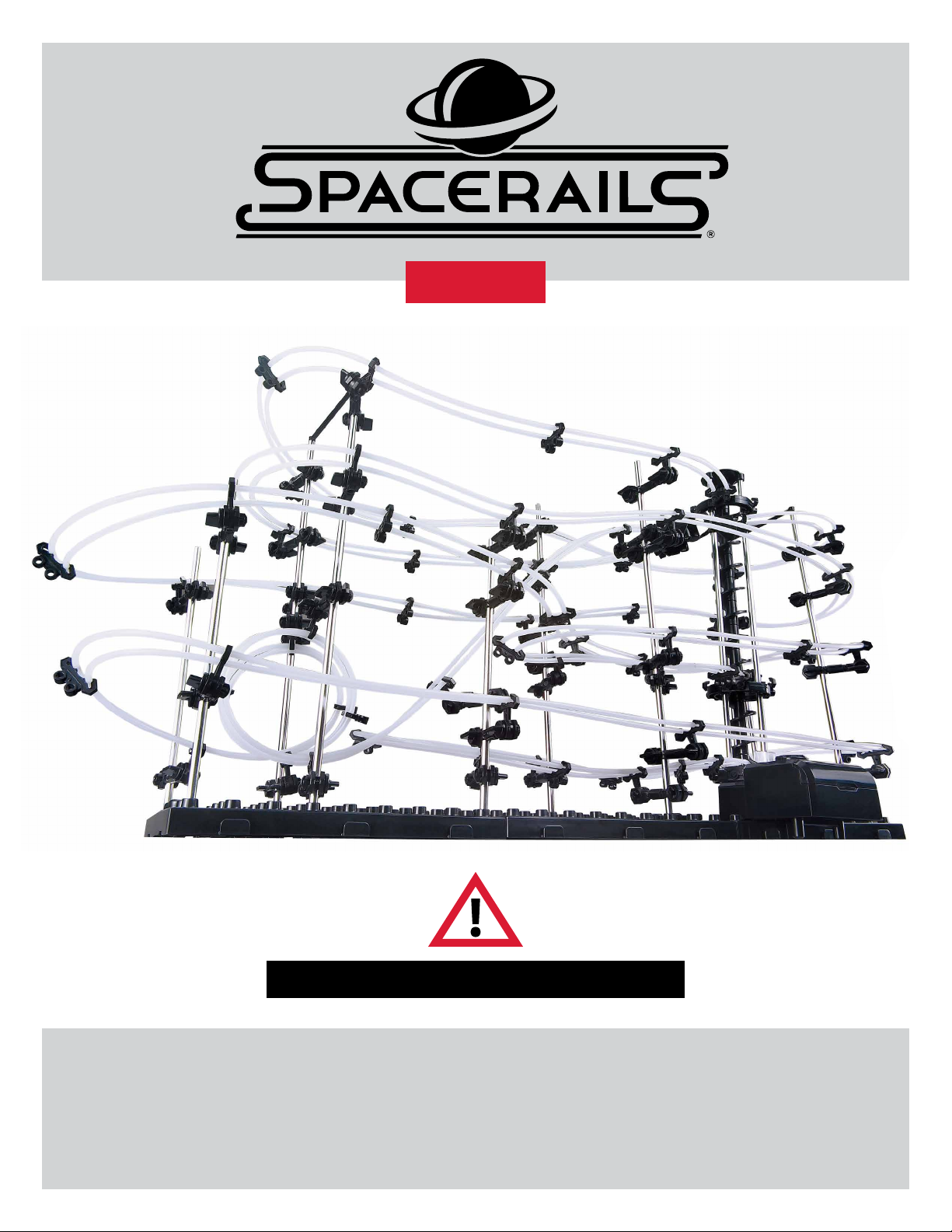

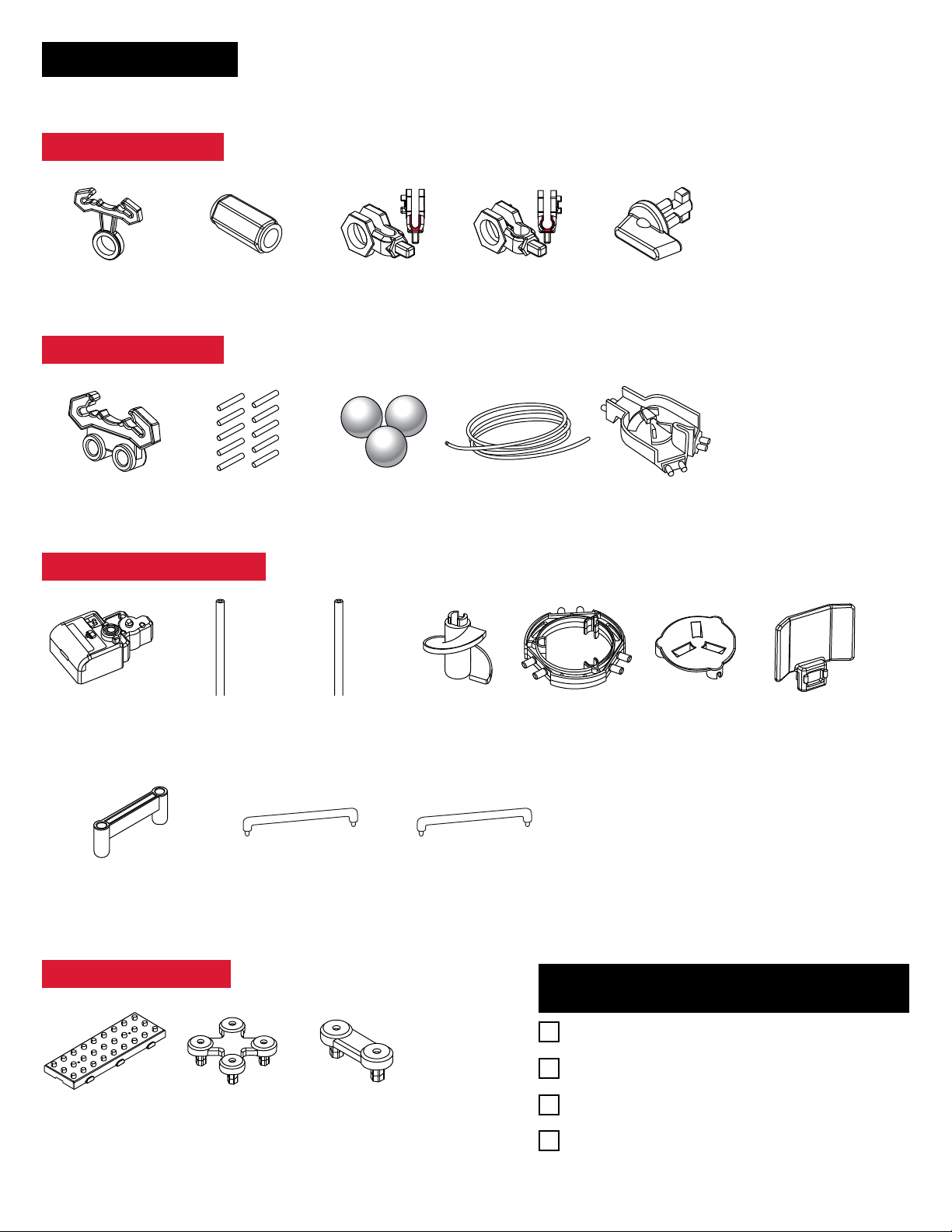

Spacerails Level 3 User manual

Table of contents

Other Spacerails Toy manuals

Spacerails

Spacerails Level 7 User manual

Spacerails

Spacerails Level 8 User manual

Spacerails

Spacerails LEVEL 6 User manual

Spacerails

Spacerails LEVEL 4 User manual

Spacerails

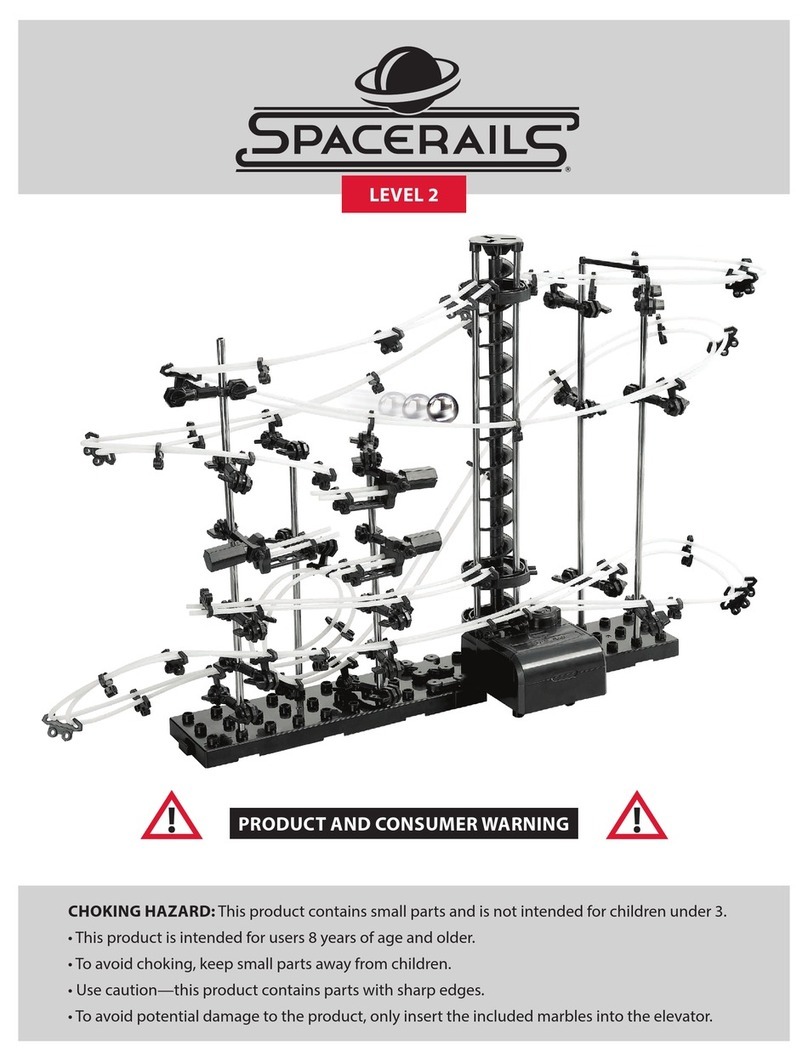

Spacerails Level 2 User manual

Spacerails

Spacerails Level 1 User manual

Spacerails

Spacerails Level 5 User manual

Spacerails

Spacerails Level 9 User manual

Popular Toy manuals by other brands

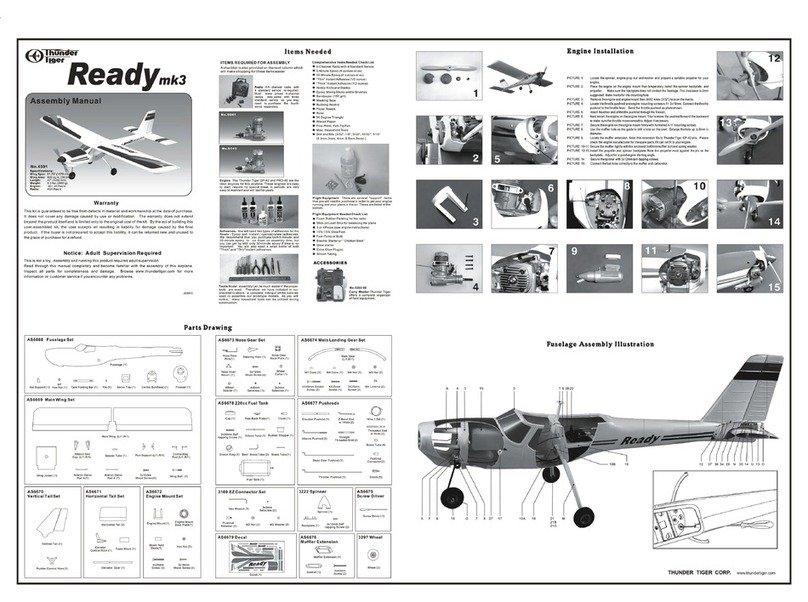

THUNDER TIGER

THUNDER TIGER Ready mk3 Assembly manual

Airigami

Airigami Papier Avion AirBus A320-Neo quick guide

Dynali

Dynali H3 Sport 135 HP Operating handbook

HobbyZone

HobbyZone Aerobird Xtreme instruction manual

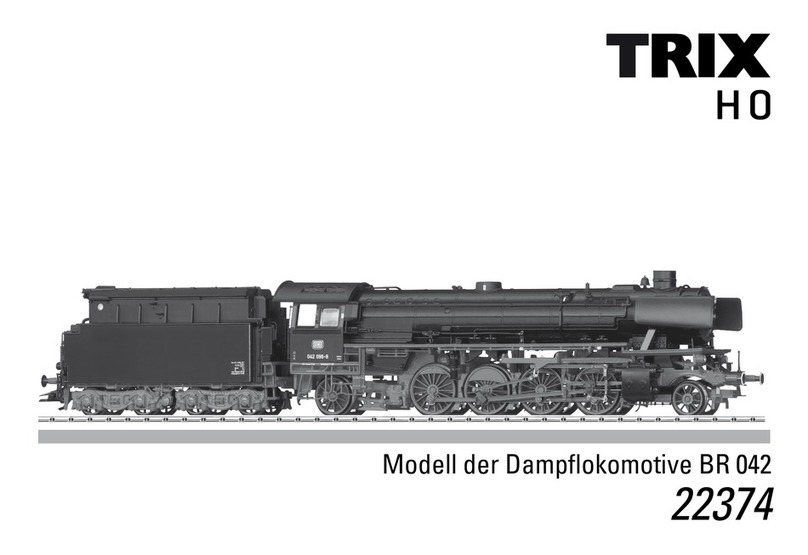

Trix

Trix BR 042 manual

Fisher-Price

Fisher-Price Little People Animal Sounds Farm B8343 manual

Multiplex

Multiplex FunCub Next Generation Assembly instructions

Mega Construx

Mega Construx POKEMON WONDER BUILDERS BULBASAUR GKY72 manual

Eduard

Eduard F-35B quick start guide

Fisher-Price

Fisher-Price Learning Puppy user manual

Phoenix Model

Phoenix Model decathlon - EP instruction manual

Faller

Faller 120159 manual