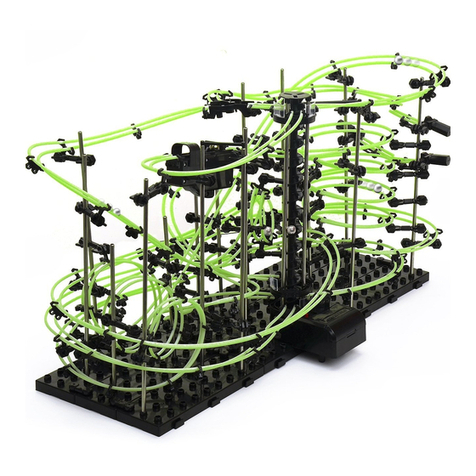

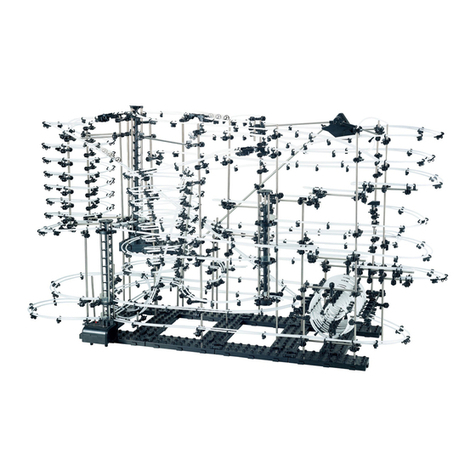

Spacerails Level 8 User manual

LEVEL 8

PRODUCT AND CONSUMER WARNING

CHOKING HAZARD: This product contains small parts and is not intended for children under 3.

• This product is intended for users 8 years of age and older.

• To avoid choking, keep small parts away from children.

• Use caution—this product contains parts with sharp edges.

• To avoid potential damage to the product, only insert the included marbles into the elevator.

Page 2 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

PARTS INCLUDED

Keep parts together to avoid misplacing them.

ARM COMPONENTS

Arm Clip

x80

Arm Sheath

x75

Arm Holder A

x70

Arm Holder B

x90

Arm Lock

x170

SPLIT AND CAPTURE COMPONENTS

Rail Splitter

x2

Capsule Ring

x1

Capsule

x1

BASE COMPONENTS

Base Base Holder A Base Holder B

x12 x10 x8

RAIL COMPONENTS

Rail Clip

x150

Rail Coupling

x10

Marble

x10

Rail

40,000 mm

RECOMMENDED TOOLS & ITEMS (NOT INCLUDED)

Wire Cutters or Utility Scissors

Pen or Marker

3 AA Batteries (newer models) or 1 C Battery

Ruler (in centimeters)

ELEVATOR COMPONENTS

Power Box

x1

Elevator Helix

x25

Elevator Ring

x5

Elevator Cover

x1

Elevator Guard

x8

Power Box Stand

x1

SHAFT COMPONENTS

Shaft (600mm)

x9

Shaft (391mm)

x5

Shaft (300mm)

x8

Shaft (200mm)

x2

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 3

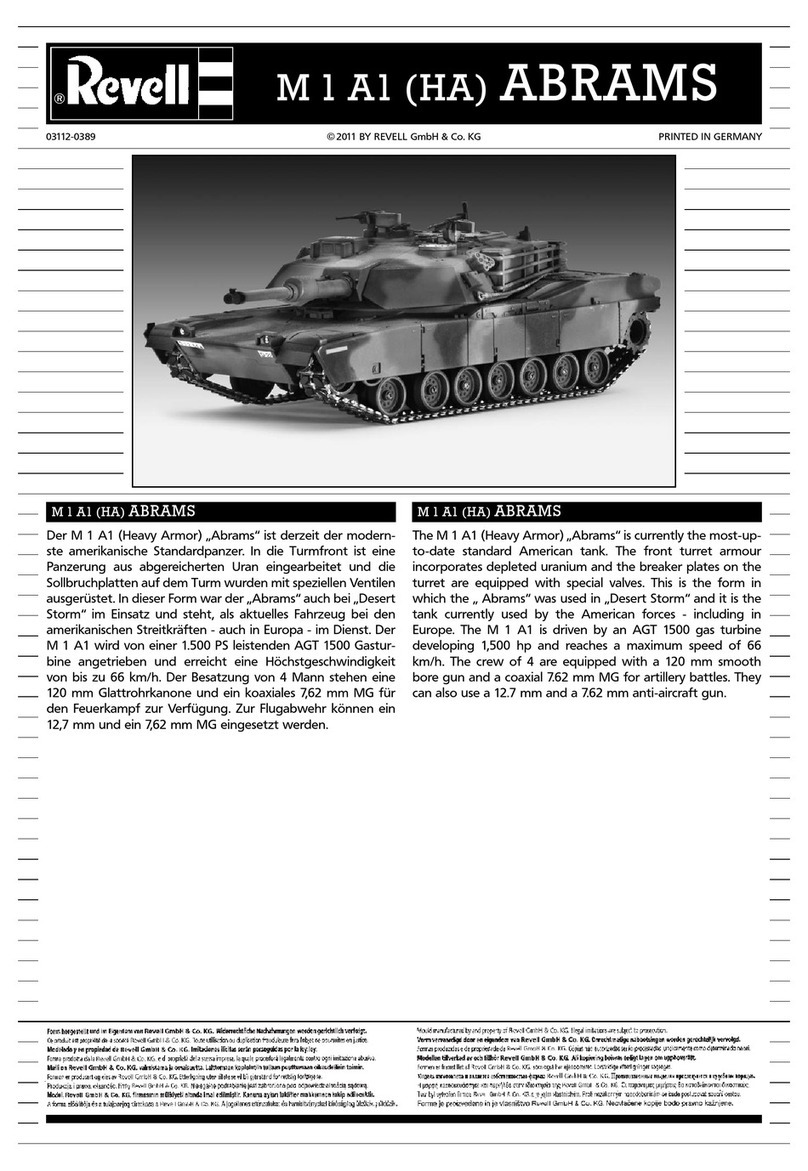

1PREPARE ARMS AND RAIL SPLITTER

Attach one Arm Holder B on each side

of the Arm Sheath.

BARM B QTY: 4

RAIL SPLITTERS

Step 1: Attach one Rail Clip on each

of the Rail Splitter posts.

AARM A QTY: 66

Slide Arm holder B onto shaft. Insert Arm Lock through Arm

Holder B and Rail Clip. Turn the Arm Lock counter-clockwise to

secure the Rail Clip in place. (These will be assembled during the

shaft assembly step.)

ARM C QTY: 10

Step 1: Attach one Arm Holder A and one

Arm Holder B with one Arm Sheath. Insert

one Arm Clip into Arm Holder A.

Step 3: Turn the Arm Lock

counter-clockwise to secure

the Arm Clip in place.

Step 2: Insert Arm Lock through

Arm Holder A and Arm Clip.

To avoid damaging parts, do not move or adjust the Rail Clip while locked in the arm. To move the Rail Clip, release

Arm Lock by turning clockwise, position Rail Clip as desired, then secure Arm Lock again.

C

D

Page 4 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

Step 1: Interlock all

base block tabs as

shown above.

Step 2: Press Base Holder A and

Base Holder B pieces into the base

blocks for a more secure hold.

This is how the arm types are

referenced on the shaft drawings.

Illustration of base with tabs

locked and Base Holders installed.

Approximately 18% of actual size.

Step 1: Slide Arm Holder B of each arm on to a shaft and lock in

place with Arm Lock. Refer to the next page for orientation and

location of each arm.

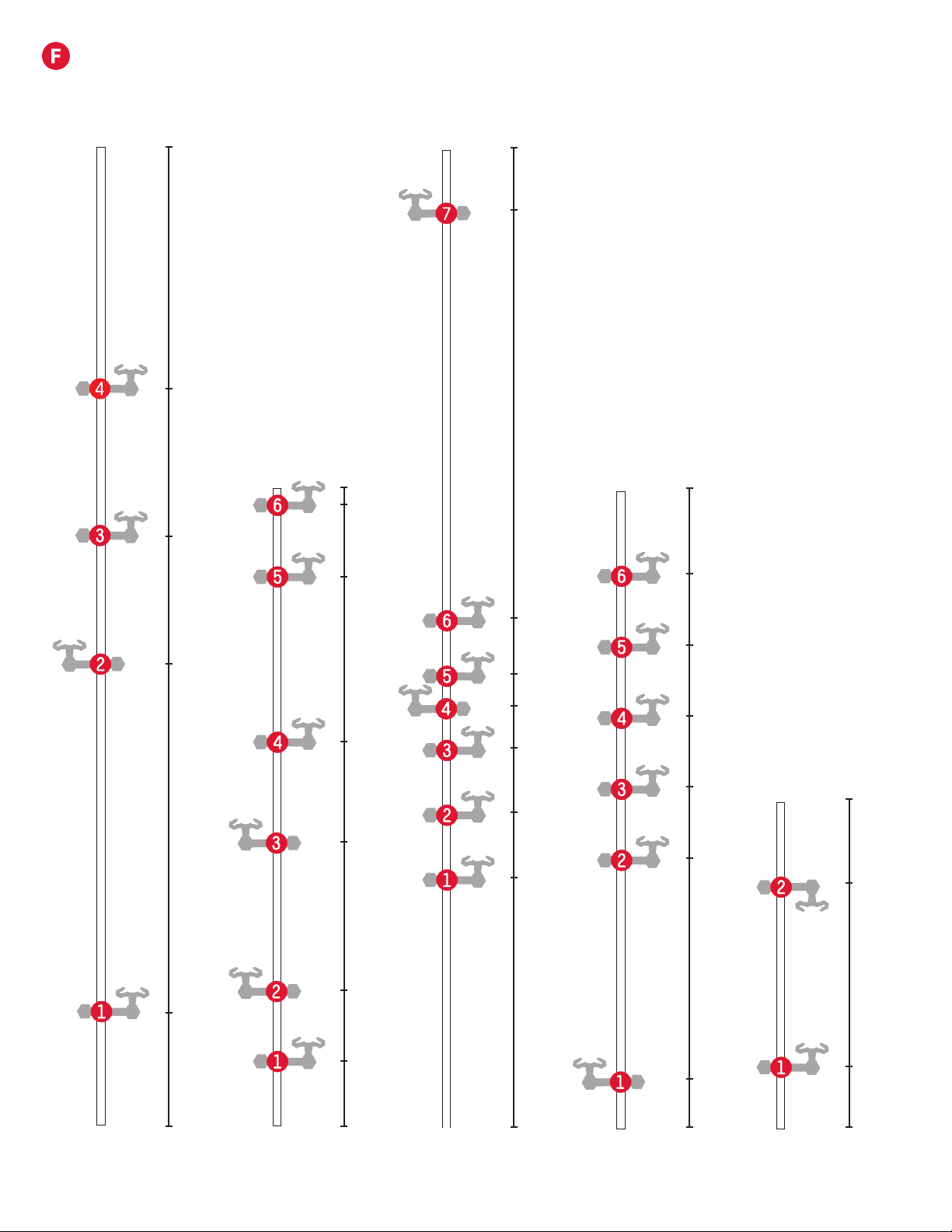

SHAFT ASSEMBLY

NOTE:

Please see the included full size drawings for the next several steps.

This will simplify the positioning of base, arms, shafts, and the rail

cut lengths.

BASE ASSEMBLY

Arm A

Arm B

Arm C

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 5

600

550

508

442

380

62

Shaft A

600

578

80

116

Shaft B

157

227

300

Shaft C

391

365

210

128

Shaft D

TOP

BASE

BACK

OF BASE

FRONT

OF BASE

SHAFT TO BASE ORIENTATION

Step 2: Attach each arm as shown in step 1 with the orientation and location shown here. In later steps the letter of each

shaft and number of each arm will guide in the installation of the rails. For example arm A-3 below is 442 mm from the

base. Illustration is approximately 37% of actual size. All shaft measurements are in Millimeters.

391

49

65

98

140

160

183

223

254

Shaft E

Page 6 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

Shaft I

391

28

163

206

250

293

337

Shaft J

200

37

148

SHAFT ASSEMBLY CONTINUED

600

151

191

230

256

270

310

560

Shaft H

600

281

448

360

68

379

391

335

234

173

82

38

Shaft F Shaft G

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 7

Shaft K

300

35

83

214

254

Shaft L

300

235

TOP

BASE

BACK

OF BASE

FRONT

OF BASE

SHAFT TO BASE ORIENTATION

SHAFT ASSEMBLY CONTINUED

Shaft O

300

144

235

Shaft NShaft M

300

38

103

168

235

247

391

235

247

328

Page 8 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

Shaft Q

Shaft T

153

Shaft R

589

180

330

475

519

Shaft S

43

90

125

160

195

230

253

300

Attach

arm L-1

Attach

arm M-4

43

76

111

147

182

217

253

Attach

arm O-2

Attach

arm P-3

300

Shaft S and shaft T are suspended above

the base using Arm B connections From

shafts L, M, O, and P.

Shaft P

300

105

187

235

SHAFT ASSEMBLY CONTINUED

TOP

BASE

BACK

OF BASE

FRONT

OF BASE

SHAFT TO BASE ORIENTATION

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 9

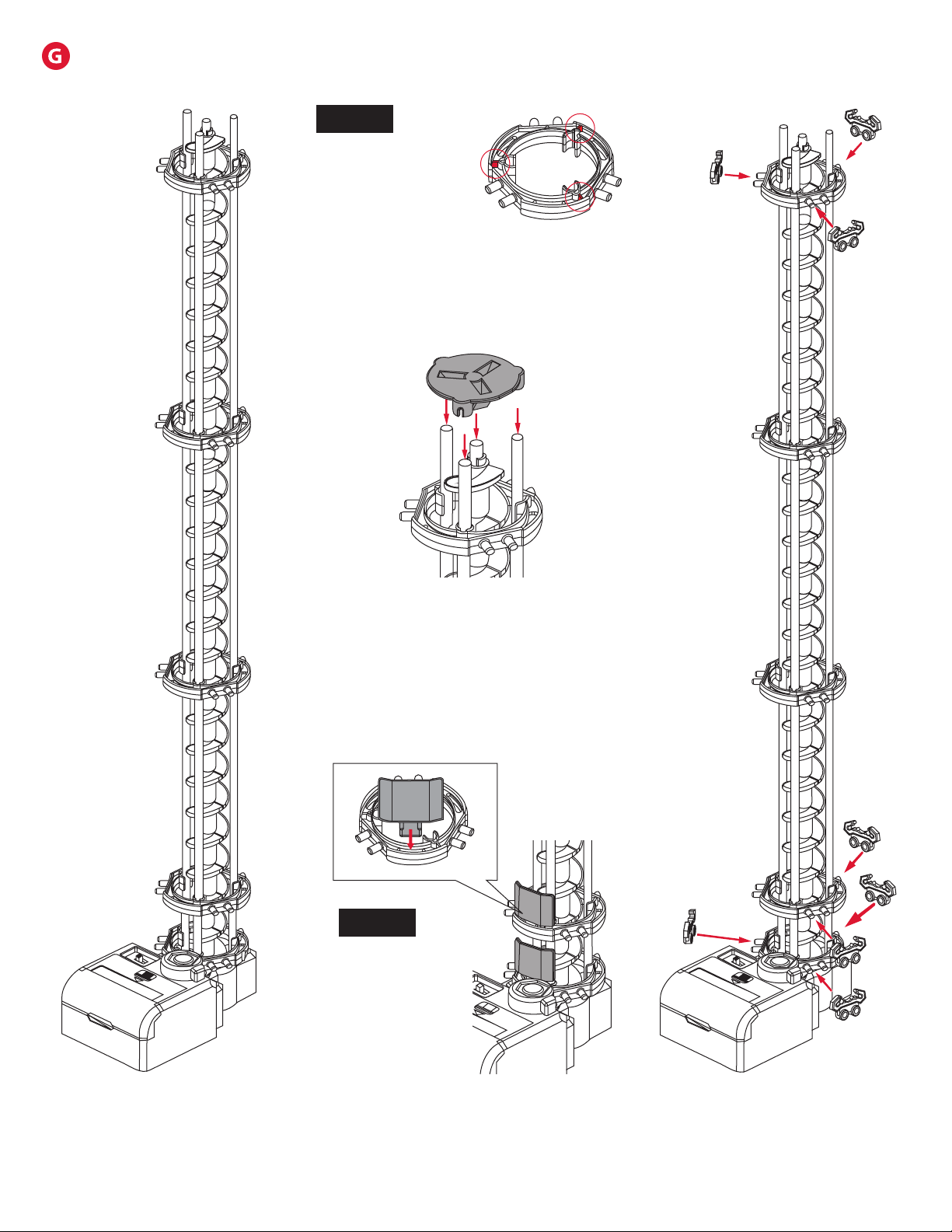

Step 3: Once the corkscrew is

built, attach three support shafts

to the Power Box.

Step 1: Place a 600 mm shaft in

the white hole on the Power Box.

ELEVATOR ASSEMBLY

Illustrations are approximately 33% of actual size.

Step 2: Connect Elevator Helix

pieces together with the male part

facing up to ll the shaft.

NOTE:

Install the rst

Elevator Helix

piece male side up

and rotate it until

it slides in place

and engages with

driver at the base

of Power Box.

Page 10 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

NOTE:

The Marble may

fall out of the

elevator if it

enters too fast.

Step 7: Attach Rail Clips to each

Elevator Ring as shown.

Step 4: Slide each Elevator Ring

into position on the support

shafts right-side up.

Step 6: Insert three Elevator Guards each in

the bottom two Elevator Rings.

Step 5: Place the Elevator Cover onto the

top of the elevator assembly.

NOTE:

Elevator Rings are

right side up when

tabs in red are

on the top.

550 mm

385 mm

200 mm

30 mm

0 mm

ELEVATOR ASSEMBLY CONTINUED

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 11

CUT THE RAIL TO SIZE

15 cm

a

b

22 cm

c

28 cm

d

78 cm

e

90 cm

f

150 cm

g

310 cm

h

360 cm

i

365 cm

j

435 cm

Step 1: Measure each section and mark the cutting point with a pen. Rail measurements

are in Centimeters.

Step 2: Cut each section according to your measurement. Make sure to cut at a 90° angle.

Tip: To help avoid do-overs and using too much rail, cut generously (slightly longer than

required) to begin with. You can always cut a long rail shorter.

NOTES:

Illustration of rail lengths is 4% of actual size.

Please see the included full size drawings. This will simplify the

positioning of base, arms, shafts, and the rail cut lengths.

H

Page 12 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

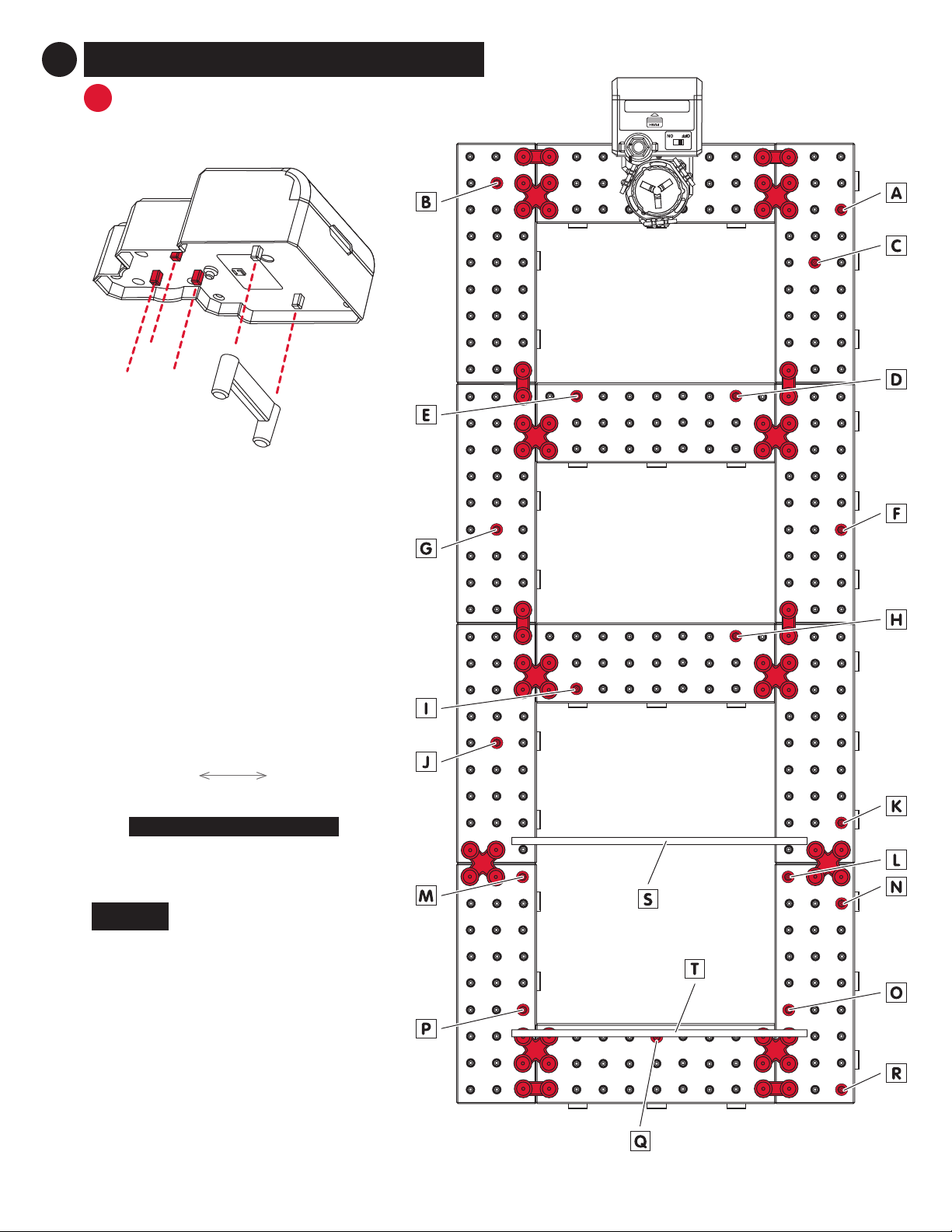

INSTALL ELEVATOR AND SHAFTS TO BASE

Illustrations are approximately 28% of actual size.

Step 1: Attach Power Box Stand to the

Power Box.

Step 2: Firmly seat the posts from the

Power Box in the holes on the base.

Step 3: Use diagram on the left for

location of each shaft. Push shaft into

holes on base until sturdy. Refer to

drawings on pages 5 through 7 for

orientation to install shafts.

FRONT

OF BASE

BACK

OF BASE

Posts attach

to base

2CONSTRUCTING THE ROLLER COASTER

A

NOTE:

Shaft S and shaft T are suspended above

the base using Arm B connections from

shafts L, M, O, and P.

BACK

OF BASE

FRONT

OF BASE

SHAFT TO BASE ORIENTATION

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 13

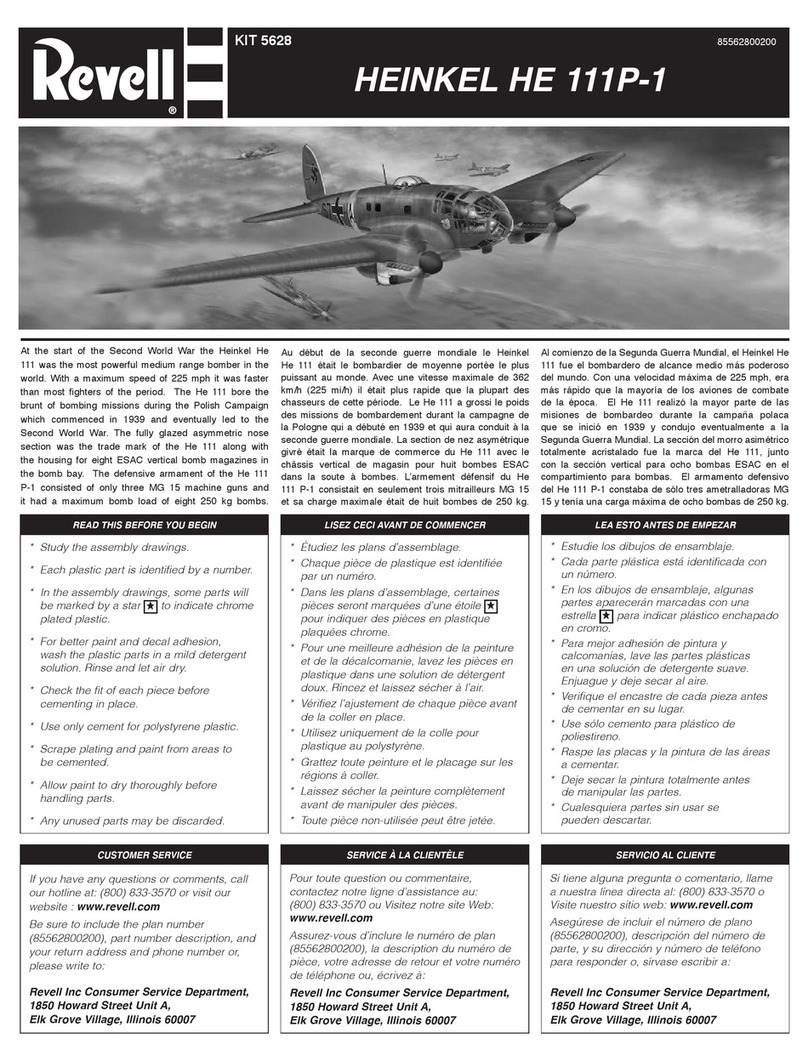

BINSTALLING RAILS

Connecting rails to arms: To install the rails, press them into the arm as

shown. You should hear a click when the rail is locked in place.

When building a curved Rail Clips and Arm Clips

can be adjusted to create a banked curve. Plenty

of Rail Clips are included so that they can be

applied liberally.

Attach Rail Clips every 8-10 cm along rail

to maintain stability and keep rails parallel.

Keeping rails uniform maintains speed and

avoids throwing the Marble o course.

Rails should extend into the elevator

enough to catch the Marble.

Rail Couplings are provided but not needed. If

more length is needed for a rail, insert the coupling

into the end of both rails being joined.

Keep incline as smooth as possible to avoid

losing speed or contact with rails.

Page 14 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

BINSTALLING RAIL

Rail Section 1:

Step1: Install one side of a rail at a time. Starting at the

top center Elevator Ring connect rail D (78 cm) to rail

Clip. Keeping rail tight connect to arm H-7 and Finish rail

at arm R-4. Repeat step for second rail. Attach Rail Clips

every 8-10 cm along rail to maintain stability and keep

rails parallel.

Step2: Starting at arm R-5 connect rail E (90 cm). Loop

rail under and connect to arm R-3. Keeping rail tight

connect to arm F-4 and Finish rail at arm A-3. Repeat step

for second rail. Attach rail Clips every 8-10 cm along rail

to maintain stability and keep rails parallel.

Step 3: Starting at arm A-4 connect rail B (22 cm). Loop

rail under and connect to arm A-2. Finish by attaching

the rail to the Rail Clip on single side of the Rail Splitter.

Fine Tune: Once each rail section is completed run a

Marble down your course and make sure it travels well.

Make any adjustments as needed. Do not worry about

adjusting the splitter until all rails have been connected.

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 15

Step1: Start by attaching rail A (15 cm) to Rail Clip of rst

splitter facing the front of the base. Connect rail through

arm D-3 and nish by attaching rail to the Rail Clip on

the single side of the second Rail Splitter. Repeat step for

second rail.

Step2: Connect rail G (310 cm) to Rail Clip on second

splitter facing the back of the base. Create an nested loop

where each successive loop is slightly smaller than the

one above it. Starting with the inside rail connect arms

I-6, H-6, I-5, H-4, I-4, H-3, I-3, H-2, I-2, H-1, across to arm

E-4 and arm B-2. Finish at Rail Clip on Elevator Ring 2

facing the front of the base. Repeat step for the outside

rail. At least one rail will need to be trimmed at Elevator

Ring. Attach Rail Clips to keep rails consistently spaced,

supported, and create banked corners as needed.

BINSTALLING RAIL

Rail Section 2:

NOTE:

If length of rail is longer or shorter than

expected try adjusting the size of the nested

loops to better utilize the rails.

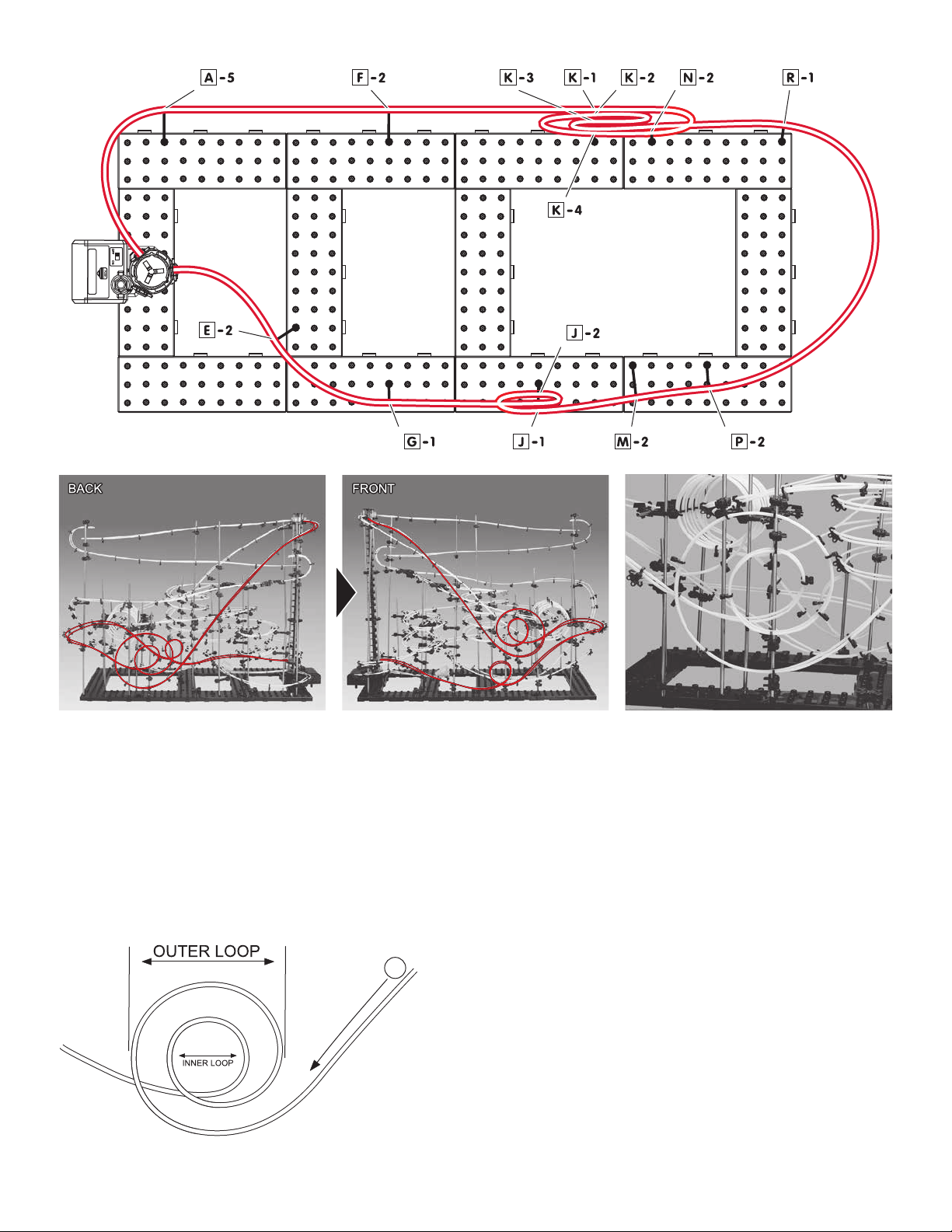

This top view of the nested loop section shows how each successive loop

is slightly smaller than the one above it. Start with a loop of about 20 cm

and work down to about 17 cm on the bottom loop. These numbers are

intended to be a guide only. Test your loops with the Marble. Adjust until

you get good consistent speed throughout this section.

Page 16 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

Rail Section 3:

Step1: Starting at the top Elevator Ring facing the back

of the base connect rail H (360 cm) to inner side of Rail

Clip. Keeping rail tight connect to arm A-5 then arm F-2

and K-1. Loop rail up to arm N-2 and K-4. Loop down to

K-2 and up to K-3 to create the inner loop. The inner loop

will shift inside the outer loop and pass right next to

shaft K and shaft N.

Step2: Create a banked rail through arm R-1 and arm

P-2. Continue rail through arm M-2 and arm J-1. Loop up

to arm J-2 and shift loop inside and up through arm G-1.

Finish by passing through arm E-2 and into the Rail Clip

on the bottom Elevator Ring in the center position.

Step3: Repeat Step 1 and Step 2 for the outer rail. Attach

Rail Clips to keep rails consistently spaced, supported,

and create a banked corner as needed.

For the double loop a good starting point for size is 20

cm for the outer loop and 10 cm for the inner loop.

For the single loop on the front try starting with a

10cmloop.

These numbers are intended to be a guide only. Test

your loops with the Marble. Adjust until you get good

consistent speed throughout this section.

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 17

Rail Section 4:

Step1: Starting at the top Elevator Ring facing the front

of the base connect rail J (435 cm) to inner side of Rail

Clip. Keeping rail tight connect to arm B-3 then arm

G-6 and M-3. Loop rail up to arm T-1 and down through

S-1. Create a nested loop where each successive loop is

slightly smaller than the one before it by looping through

arms T-2, S-2, T-3, S-3, T-4, S-4, T-5, S-5.

Step2: Create a banked rail through arm O-1 and arm

P-1. Continue rail through arm G-2, arm F-1, and arm A-1.

Finish at Rail Clip on Elevator Ring 1 facing the back of the

base.

Step3: Repeat Step 1 and Step 2 for the outer rail. Attach

Rail Clips to keep rails consistently spaced, supported,

and create a banked corner as needed.

NOTE:

This image shows a close up

of the horizontal loops and

how rail Section 6 will pass

through them.

NOTE:

Start with a loop of about 13 cm on the front and work

down to about 9 cm on the back loop. These numbers

are intended to be a guide only. Test your loops with

the Marble. Adjust until you get good consistent speed

throughout this section.

Page 18 Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com

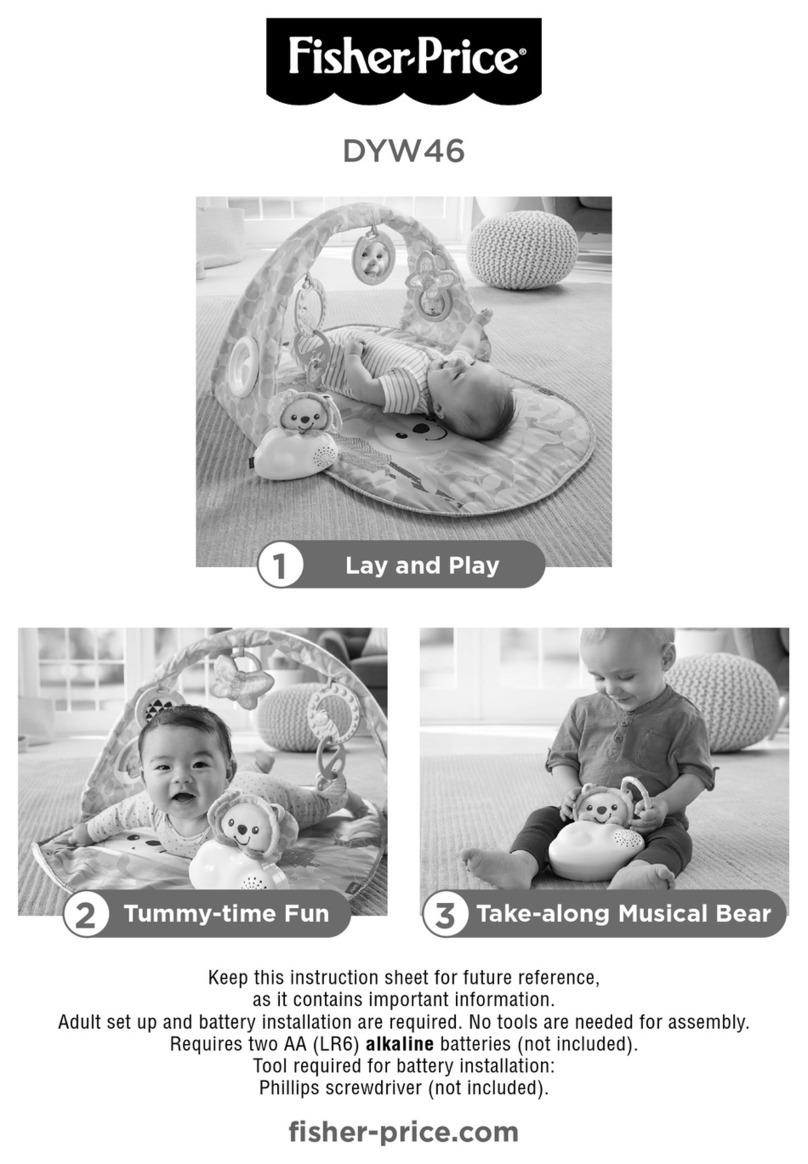

Rail Section 5:

Step1: Start by attaching rail F (150 cm) to Rail Clip of

rst splitter facing the back of the base. Connect rail

through arms F-3, N-3, R-2, Q1, M-1, and I-1 creating a

ramp to jump the Marble. Repeat step for second rail. Do

not trim excess rail until the ramp has been ne tuned.

Adjust the speed and angle of the ramp for the jump and

catch to be successful.

Step2: Attach rail C (28 cm) to arm E-1 and nish at the

Rail Clip on Elevator Ring 2 in the center position.

Step3: Attach the Capsule Ring and Capsule to rail C as

shown below.

Arm E-1 Arm E-1 Rail Clip

Seaich Corporation, LLC. All rights reserved. www.seaich.com |Spacerails, LLC. www.spacerails.com Page 19

Rail Section 6:

Step1: Start by attaching rail I (365 cm) to the inside

Rail Clip of second splitter facing the front of the base.

Connect rail through arms G-5 and arm M-5. Pass rail

through horizontal loop section and attach arm N-1 and

then arm H-4.

Step2: Pass rail I between shaft D and shaft E and attach

to arm E-8. To create the Figure 8 section the arms on

shaft D and shaft E will need to be rotated around the

shaft. Continue creating the gure 8 section with arms

G-4, E-7, C-2, D-2, E-6, G-3, E-5, C-1, and E-3. Finish by

passing through arm B-1 and into the Rail Clip on the

bottom Elevator Ring facing the front of the base.

Step3: Repeat Step 1 and Step 2 for the outer rail. Attach

Rail Clips to keep rails consistently spaced, supported,

and create a banked corners as needed.

NOTE:

Congratulations on completing Spacerails Level 8! Fine

tune the rails and see how many marbles you can get

going at the same time. If the marbles are coming into

the elevator too quickly it may knock other marbles

already in the tower out. Create a dip or nd other ways

to slow marbles to just the right speed at entrance.

Seaich Corporation

1910 West 1040 South

Salt Lake City, UT 84104

(833) 732-4242

Spacerails LLC

Spacerail © 2021

www.spacerails.com

Table of contents

Other Spacerails Toy manuals

Spacerails

Spacerails Level 3 User manual

Spacerails

Spacerails Level 7 User manual

Spacerails

Spacerails Level 1 User manual

Spacerails

Spacerails Level 2 User manual

Spacerails

Spacerails Level 5 User manual

Spacerails

Spacerails LEVEL 6 User manual

Spacerails

Spacerails LEVEL 4 User manual

Spacerails

Spacerails Level 9 User manual