Spanco A Series Quick guide

ISO 9001:2015 Registered

Manual 103-0008

Assembly and Maintenance Instruction Manual

Effective October 2022

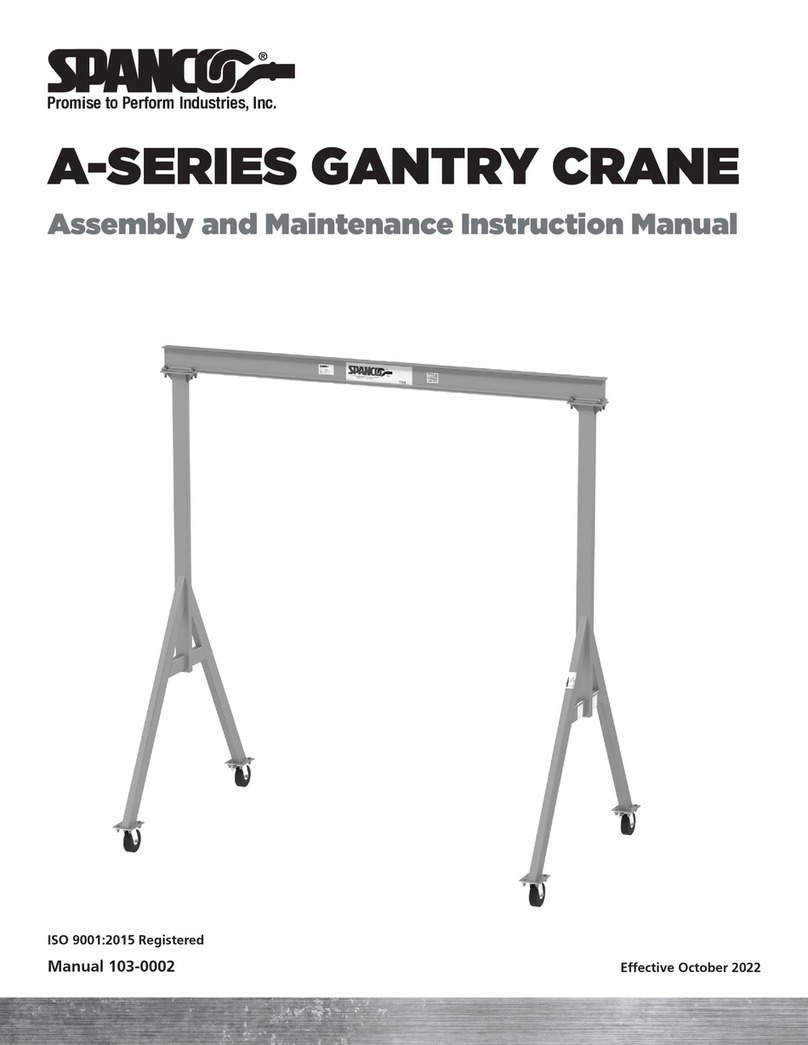

A-SERIES ALUMINUM

GANTRY CRANE

Promise to Perform Industries, Inc.

i Rigid Lifelines®Traveling Bridge Anchor Track™System | 1-800-869-2080 1-800-869-2080 | Rigid Lifelines®Traveling Bridge Anchor Track™System ii

i Spanco®A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

SPANCO GANTRY CRANE CONDITIONS OF USE AND WARNINGS STATEMENT

1. Read, understand, and follow the manual, assembly drawings, and warnings provided with your system before

beginning installation, use, or disassembly. Follow all instructions carefully.

2. This manual, and any other instructions, must be provided to the user(s) of this equipment. The user(s) must understand

the equipment’s proper use and limitations.

3. This crane is engineered to accommodate a standard hoist and a standard hoist weight. The standard hoist weight is

calculated at 15 percent of the crane’s rated capacity. Please inform Spanco if hoist weight exceeds 15 percent of the

crane’s rated capacity, or if the lifting speed exceeds 50 FPM.

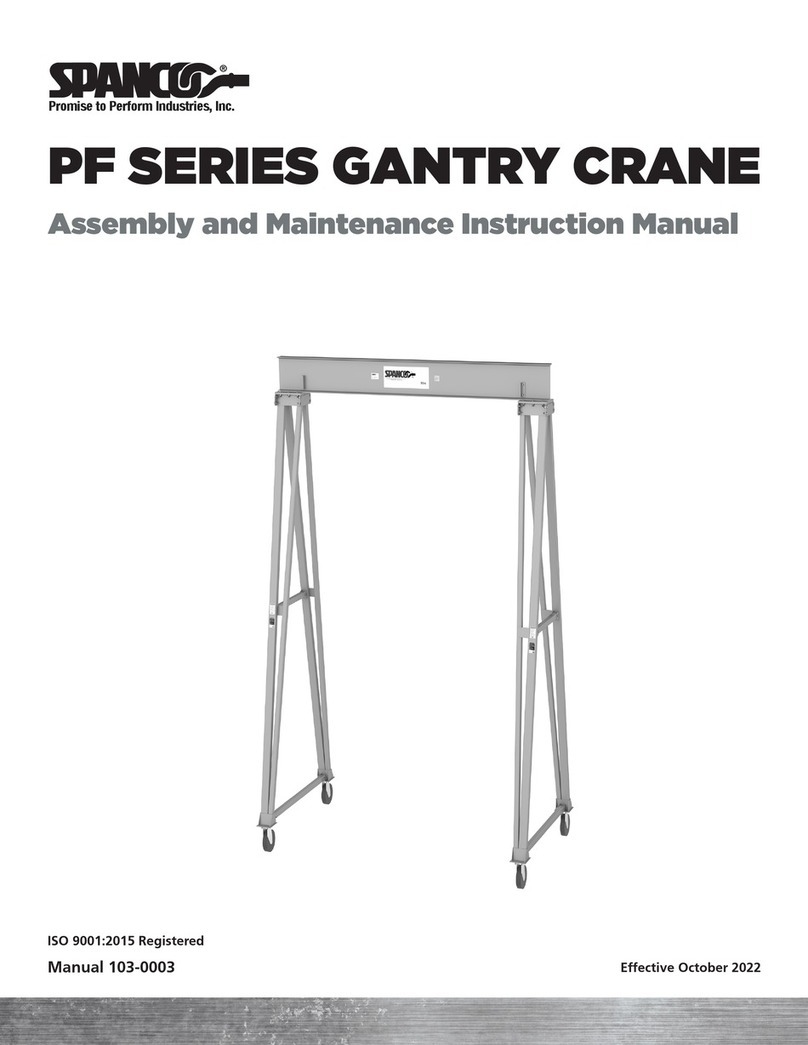

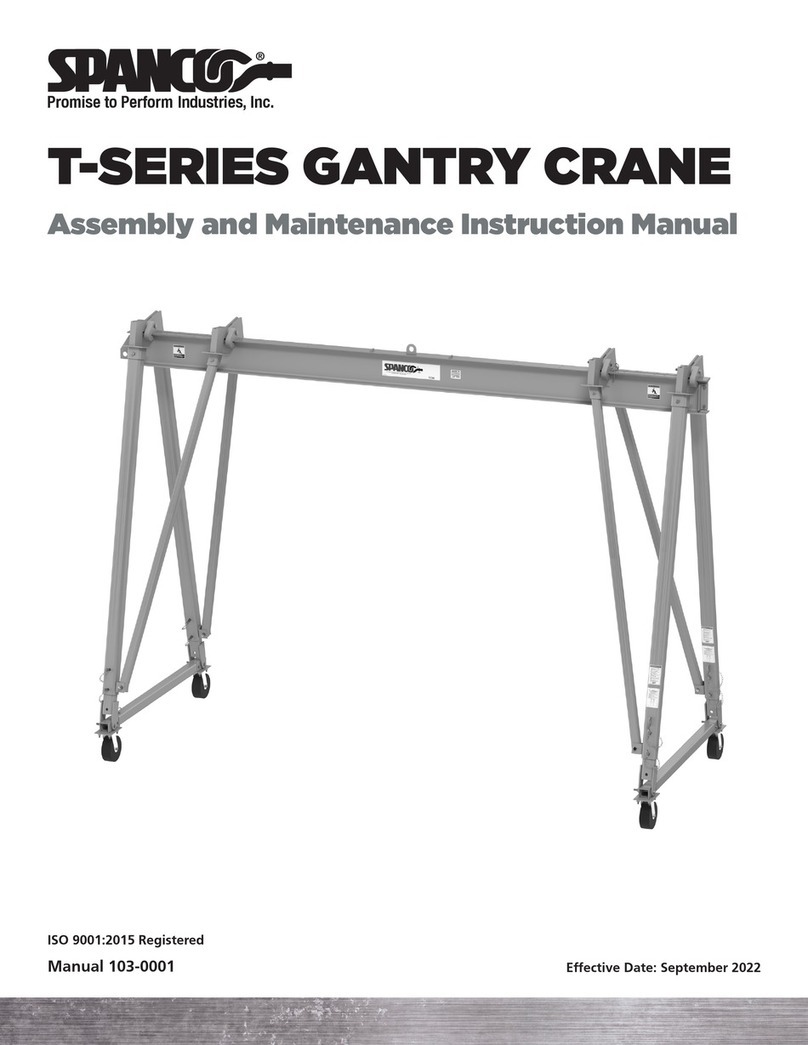

4. Motorized trolley travel is available for PF-Series and T-Series Gantry Cranes.

5. ”Sidewinder” hoists or low headroom hoists with motors that are parallel to the beam can potentially impart large

torques (twisting moments) to the beam that can cause beam twisting and oscillations. Hoist inverter controls are heavily

recommended for all “sidewinder” hoists or low headroom hoists with motors that are parallel to the beam installed on

beam lengths over 12 feet.

NOTE: To eliminate any form of beam oscillation, use only an inverter controlled hoist of this type.

6. Power Drive options for motorized gantry travel are available for PF-Series Gantry Cranes only. Review Power Drive

installation instructions in the separate Power Drive instruction manual.

7. Each component and system must be employed and maintained in accordance with all OSHA and ANSI standards.

8. Use a hoist with the same or lower capacity rating as the gantry crane. Do not lift more than the rated crane capacity.

9. The rated capacity is displayed on a label on the Spanco system. Exceeding the capacities displayed on this label can

result in serious injury or death.

10. There should never be any type of loading past the end stops for any reason.

11. Never apply an off-plumb load to the system.

12. Always check for overhead hazards, such as power lines, trees, equipment, overhead structures, or walls, before using or

moving a portable system.

13. Never use this system as fall protection or for lifting, hoisting, or carrying personnel.

14. When moving the gantry under load, keep the load in the center of the beam and as close to the ground as possible.

15. Before moving the gantry under load, remove any obstacles and ensure that the load is not attached to the floor.

16. Spanco Gantry Cranes are desgined to be moved manually. Do not push or pull the gantry with a lift truck or other

vehicle.

17. When moving a gantry crane under load, push the gantry; do not push or pull the suspended load.

18. Never exceed two people pushing an Aluminum gantry crane.

19. Do not disassemble the gantry or adjust the height, span, or caster frame spread (if applicable) when the gantry is under

load.

i Rigid Lifelines®Traveling Bridge Anchor Track™System | 1-800-869-2080 1-800-869-2080 | Rigid Lifelines®Traveling Bridge Anchor Track™System ii

Spanco.com • 1-800-869-2080 • Spanco®A-Series Aluminum Gantry Crane ii

SPANCO GANTRY CRANE CONDITIONS OF USE AND WARNINGS STATEMENT

20. Do not stand under the gantry when it is being adjusted in height, span, or caster frame spread.

21. Do not stand or walk under a suspended load.

22. Caster frame spread must be a minimum of 40 percent of the overall height (T-Series only).

23. Adjustments and repairs must be made in an area that does not interfere with operation.

24. Do not load the gantry on an incline or move a loaded gantry onto an inclined surface.

25. Do not allow the load to swing or roll against the gantry support members.

26. Do not allow the hoist trolley to strike the end stops or gantry supports at any time.

27. The system must be tied down if exposed to winds exceeding 30 miles per hour. Spanco considers it an unsafe practice

to operate cranes in winds over 15 miles per hour. Although the drive may work in speeds exceeding 15 miles per

hour, Spanco does not recommend using any crane in winds over 15 miles per hour for safety reasons. If quoted

for a pre-defined wind speed, the drive components have been designed for an approximate wind speed. It is the

responsibility of others to generate a risk assessment of wind conditions and part stability, and to generate a lifting plan

that accounts for the sail effect of the part being lifted and the length of the cable the part is suspended on. Notify

Spanco if the system will be subjected to constant buffeting winds.

28. Although Spanco may provide components that are intended for service in a specific environment, it is the customer’s

responsibility to confirm that the provided Spanco system and components will work in and are acceptable for their

specific application and environment.

29. Before each use, inspect the system for bent, broken, cracked, or missing components.

30. Thoroughly inspect the system annually per OSHA law.

31. Per OSHA law, load testing must be performed before the system can be placed into service.

32. Engineering of any attachment points must be done by others.

33. Component appearances and dimensions shown are approximate and subject to change without notice. All literature

dimensions are developed using standard components for the spans and capacities. Substitution of optional trolleys or

other components will affect certain dimensions.

34. Never deviate from the above unless you have written permission and authorization from Spanco.

iii Rigid Lifelines®Traveling Bridge Anchor Track™System | 1-800-869-2080 1-800-869-2080 | Rigid Lifelines®Traveling Bridge Anchor Track™System 1

iii Spanco®A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

SYSTEM APPLICATIONS

The Spanco System is used for material handling applications. This material handling system is labeled with a maximum rated

capacity and is designated for Class C service as defined by the CMAA; follow all limitations as noted on system labels.

STANDARDS AND COMPLIANCE

Please refer to local, state, and federal (OSHA) requirements governing occupational safety for additional information

regarding material handling. The Spanco system meets or exceeds the requirements set forth in OSHA 1910.179, ANSI

B30.11, and MMA MH27.2 or CMAA 70.

REQUIRED TRAINING

This system is intended to be used by people who are trained in its correct application and use. It is the responsibility of the

users and the users’ management to ensure that they are familiar with OSHA law and these instructions, and that they are

trained in the correct use and care of this equipment. Authorized users must also be aware of the operating characteristics,

application limits, and the consequences of improper use, which can result in serious injury or death. All users must read and

understand CMAA 79 Crane Operator’s Manual.

Every material handling application must be OSHA compliant. Safety and training measures may include, but are not limited

to:

• Operator certification training

• Operator evaluation program

• Hand signal protocols if required

• Lock-out/Tag-out training

The above list is not a comprehensive list. Specific applications may need to include additional protocols. For more information

on how to create a comprehensive lift plan within your facility, follow CMAA 79

Crane Operator’s Manual.

Follow the Inspection Checklists in this manual: review the Before Each Use Inspection Checklist on page 17 before each

use and review the Annual Inspection Checklist on page 18 annually.

iii Rigid Lifelines®Traveling Bridge Anchor Track™System | 1-800-869-2080 1-800-869-2080 | Rigid Lifelines®Traveling Bridge Anchor Track™System 1

Spanco.com • 1-800-869-2080 • Spanco®A-Series Aluminum Gantry Crane 1

TABLE OF CONTENTS

CONDITIONS OF USE AND WARNINGS STATEMENT .................................................................................................i-iii

SYSTEM APPLICATIONS ................................................................................................................................................... iii

STANDARDS AND COMPLIANCE .................................................................................................................................... iii

REQUIRED TRAINING........................................................................................................................................................ iii

ASSEMBLY INSTRUCTIONS ................................................................................................................................................2

1. Equipment Needed for Assembly................................................................................................................................2

2. Inventory....................................................................................................................................................................2

3. Attaching the Swivel Locks to the Caster Assemblies ..................................................................................................3

4. A-Frame Assembly......................................................................................................................................................3

5. Attaching the Caster Assemblies to the A-Frame Assemblies .................................................................................. 3-4

6. Beam Assembly...................................................................................................................................................... 4-5

FINAL ASSEMBLY ................................................................................................................................................................6

ADJUSTING THE GANTRY HEIGHT ....................................................................................................................................6

ADJUSTING THE GANTRY SPAN........................................................................................................................................7

MINIMUM CLEAR SPAN CHART ........................................................................................................................................8

OPTIONAL ACCESSORIES...................................................................................................................................................9

1. Tagline Assembly..................................................................................................................................................9-10

2. Top Lock Wheel Brake Assembly.........................................................................................................................10-11

3. V-Groove Track Installation .................................................................................................................................11-12

MAINTENANCE................................................................................................................................................................. 13

LOAD TEST......................................................................................................................................................................... 13

DESIGN FACTORS ............................................................................................................................................................. 13

SERVICE FACTOR .............................................................................................................................................................. 13

DISASSEMBLY..............................................................................................................................................................14-15

LABELING .......................................................................................................................................................................... 16

INSPECTION CHECKLISTS................................................................................................................................................ 17

Before Each Use Inspection Checklist............................................................................................................................ 17

Annual Inspection Checklist.......................................................................................................................................... 18

PRODUCT WARRANTY COVERAGE................................................................................................................................ 19

ABOUT SPANCO ............................................................................................................................................. BACK COVER

Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

2 Spanco® A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

ASSEMBLY INSTRUCTIONS

1. Equipment Needed for Assembly

a ) This manual

b ) Applicable safety equipment for workers’ use during assembly, such as hard hats, safety shoes, etc.

c ) Measuring tape

d ) Torque wrench

e ) Long carpenter’s level or laser level

f ) Wrench/socket sets up to 7/8 inches.

g ) A spacious, level area for assembly (e.g., parking lot)

h ) A way to mark locations, such as a permanent marker

i )

A-SERIES-ALU-ASSEMBLY SHEET 1 OF 2,

hereafter referred to as

A-Series Aluminum Gantry Crane Assembly

Drawing

, included as a separate document.

j )

A-SERIES-ALU-ASSEMBLY SHEET 2 OF 2,

hereafter referred to as

A-Series Aluminum Gantry Crane Label Placement

Drawing

, included as a separate document.

2. Inventory

a ) Open all bundles and confirm that all components are accounted for: see

Building Materials Description

located

in the top right corner of the A-Series Aluminum Gantry Crane Assembly Drawing. Note that the quantity of

components in an assembly are multiplied by the number of the assemblies.

b ) Check for damage to components that may have occurred during shipping.

c ) Your A-Series Gantry Crane consists of the following components:

1 ) One Beam

2 ) One Beam Hardware Kit

3 ) Two A-Frame Assemblies

4 ) Two Upright Tubes

5 ) Two Top Plate Assemblies

6 ) Four Casters

7 ) One Caster Mounting Hardware Kit

NOTE: Your system may also include optional accessories, such as a Height Adjustment Kit, extension tubes, wheel

brakes, and other optional components.

NOTE: One half-and one-ton models are manufactured with with square edge tubing. Two- and three-ton models

are manufactured with rounded edge aluminum tubing.

Two- and three-ton model

tubing profile.

One half- and one-ton model

tubing profile.

Spanco.com • 1-800-869-2080 • Spanco® A-Series Aluminum Gantry Crane 3

Promise to Perform Industries, Inc.

3. Attaching the Swivel Locks to the Caster Assemblies

Refer to A-Series Aluminum Gantry Crane Assembly Drawing for Steps A Through F

a ) The swivel lock ships zip tied to the caster assembly for polyurethane casters.

b ) Insert the pin on the swivel lock into the groove beneath the caster plate on the caster assembly.

c ) Open the pin on the swivel lock by pulling and spinning the ring to fit into the groove at the end of the swivel lock.

d ) Using two bolts, washers, and nuts, bolt the swivel lock to the caster plate.

e ) Using a wrench and a socket and ratchet, tighten the swivel lock bolts to 257 foot-pounds.

f ) Repeat steps b) through e) to install the remaining swivel locks.

4. A-Frame Assembly

Refer to A-Series Aluminum Gantry Crane Assembly Drawing for Steps A Through C

WARNING: Crane parts are heavy. Exercise caution when handling all parts during assembly, adjustment, and

disassembly processes.

a ) Select an area under an overhead hoist, or where a lift truck can be used to raise the beam. Be sure there is no

machinery or clutter nearby that will obstruct free movement. All personnel should be wearing applicable safety

gear, such as hard hats, steel toe shoes, and safety glasses.

b ) Lay both A-frames (3) flat on the floor. Slide an upright tube (2) into the top of the center tube of each A-frame.

c ) Engage the load pin to secure each upright tube in its lowest position. Ensure that the load pin is fully engaged.

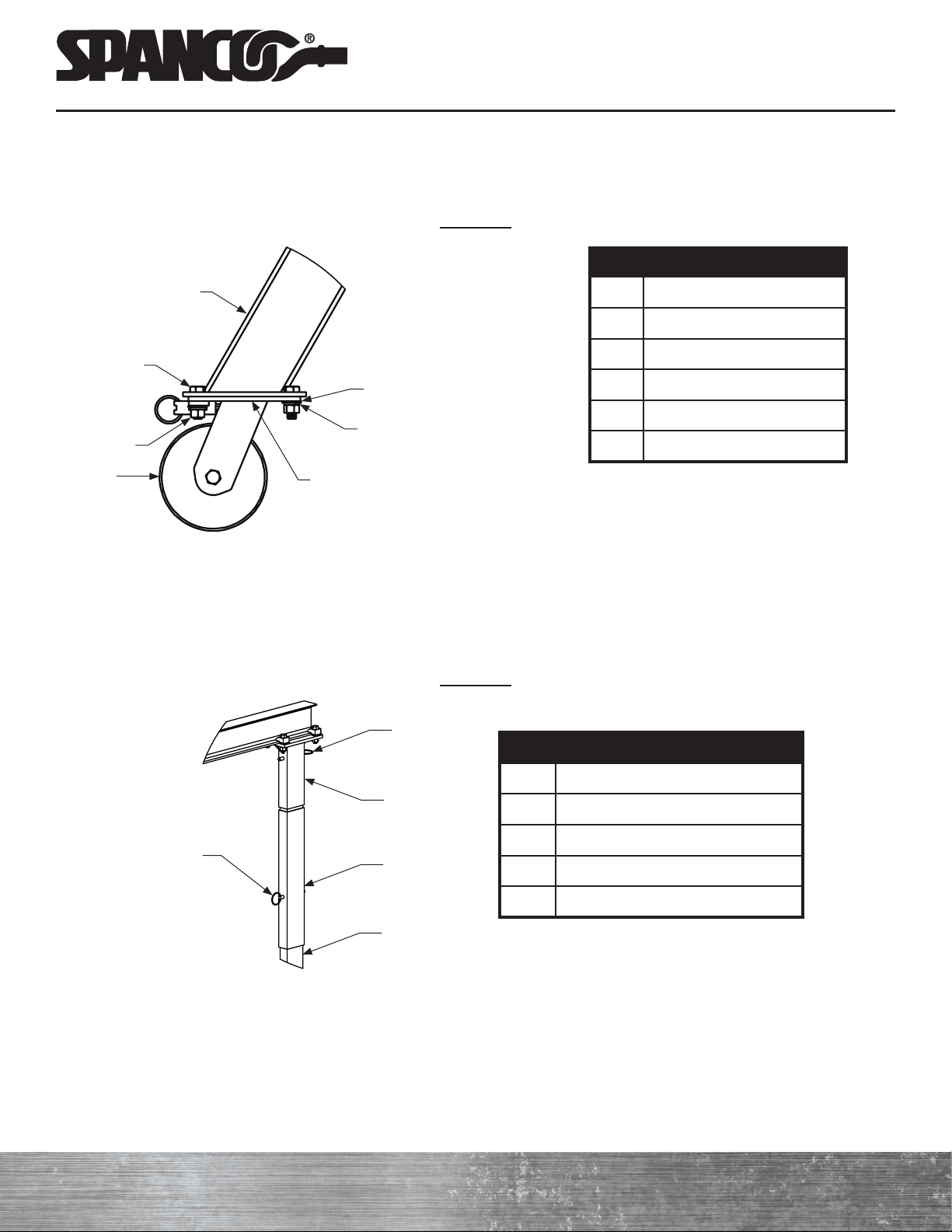

Detail “A”

ITEM DESCRIPTION

2 Upright Tube

3 A-Frame

2

3

Load Pin

5. Attaching the Caster Assemblies to the A-Frame Assemblies

Refer to A-Series Aluminum Gantry Crane Assembly Drawing for steps A through F

a ) Align the holes in the A-frame assembly with the holes in the caster assembly’s top plate.

b ) Per Detail “B,” insert a bolt (10) through the aligned holes in the A-frame and the caster assembly so that the bolts

(10) extend from the A-frame through the caster assembly’s top plate.

c ) Per Detail “B,” place a flat washer (8), lock washer (7), and hex nut (9) on each bolt (10) so that the lock washer (7)

is between the flat washer (8) and hex nut (9). Torque all nuts (9) to 23 foot-pounds.

d ) Repeat steps e) through g) to attach the remaining caster assemblies to the caster frame assemblies.

Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

4 Spanco® A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

ITEM DESCRIPTION

3 A-Frame

6 Caster

7 Lock Washer

8 Flat Washer

9 Hex Nut

10 Hex Bolt

NOTE: Torque all wheel stud nuts to

23 foot-pounds only.

e ) Test the caster brakes and swivel locks to ensure they function properly.

f ) Lock the caster wheels in position parallel to the A-frame to prevent the frame assembly from rolling away when

lifted to the upright position.

Detail “B”

Caster Assembly's

Top Plate

10

9

8

7

6

3

6. Beam Assembly

Refer to A-Series Aluminum Gantry Crane Assembly Drawing for Steps A Through K

a ) Per Detail “E,” place the optional two-foot extensions (16) onto the upright tubes (2), if required, and secure with

one pair of hitch pins (5).

Detail “E”

ITEM DESCRIPTION

2 Upright Tube

3 A-Frame

4 Top Plate

5 Hitch Pin

16 Optional Two-Foot Extension

b ) Per Detail “D,” place one top plate (4) onto each upright tube (2) or two-foot extension (16). Secure each top plate

with a hitch pin (5).

c ) Lift the beam to the gantry’s minimum height. Light aluminum beams may be raised by hand. Use appropriate

lifting equipment and secure rigging to lift larger, heavier beams. Be sure that the holes in the beam flange are on

the bottom, and that the capacity label is right-side-up and legible.

5

5

4

2

16

Spanco.com • 1-800-869-2080 • Spanco® A-Series Aluminum Gantry Crane 5

Promise to Perform Industries, Inc.

ITEM DESCRIPTION

1 Beam

2 Upright Tube

4 Top Plate

5 Hitch Pin

d ) Install the hoist trolley according to the manufacturer’s recommendations onto the lower flange of the beam and

secure it in the middle of the span.

e ) Lift one A-frame assembly (3) into position under one end of the beam, ensuring that the lifting lug is on the

outside of the A-frame, not facing the beam.

Detail “D”

NOTE: Torque 5/8-inch bolts to 108

foot-pounds. Torque 3/4-inch bolts to

210 foot-pounds.

2

4

1

5

f ) Per Detail “C,”

insert a bolt (11) through a beam clamp (15) and a clipped washer (14)

. Ensure that the flat edge of

the clipped washer (14) will face away from the beam.

g ) Per Detail “C,” insert the bolt (11) with the attached beam clamp (15) and clipped washer (14) through the holes in

the top plate (4) and position the beam clamp so it holds onto the lower flange of the beam (1).

h ) Per Detail “C,” securely tighten a lock washer (12) and a hex nut (13) onto the hex bolt (11).

i ) Repeat steps f) through h) for all four holes in the top plate (4). Adjust the beam clamps (15) as needed by tightening

or loosening the nuts (13) until the beam clamps sit properly on the lower flange of the beam (1).

j ) Repeat steps e) through i) to attach the second top plate (4).

k ) Ensure that all beam clamps (15) are installed horizontally and level within plus or minus five degrees. Tighten all

hex nuts (13) to the correct torque value.

Detail “C”

ITEM DESCRIPTION

1 Beam

4 Top Plate

11 Hex Bolt

12 Lock Washer

13 Hex Nut

14 Clipped Washer

15 Beam Clamp

11

13

12

14

15

NOTE: Item 14 quantity varies with

gantry model.

4

1

Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

6 Spanco® A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

FINAL ASSEMBLY

a ) Ensure that the beam is secured properly to the support legs, and that the caster assemblies are secured properly to

the support legs.

b ) Confirm that all of the caster nuts (9) and bolts (10) and the beam clamp nuts (13) and bolts (11) are torqued to the

required specifications prior to removing support rigging.

ADJUSTING THE GANTRY HEIGHT

WARNING: Crane parts are heavy. Exercise caution when handling all parts during assembly, adjustment,

and disassembly processes. Never stand under the system when adjusting the system height or span or while

disassembling the system. Never adjust the gantry height while it is supporting a load.

a ) Secure the trolley and hoist in the center of the beam span.

b ) Slightly lift the beam to relieve the weight from the spring-loaded load pin using the optional Lug-All winch kit (if

included) or any other type of come along with sufficient lifting capacity attached to the lifting lug at the top of

the A-frame and the bottom of the upright tube on both legs, or an existing overhead crane or lift truck and lifting

straps.

NOTE: Make sure that the “winch hoist” or “come-along” has a combined capacity rating equal to the weight of

the beam and any hoist trolley that is suspended from the beam.

c ) Pull back the load pin and secure it in the lockout position.

d ) Operate the Lug-All hoist, other come along, overhead crane, or lift truck to raise or lower the height of the gantry.

NOTE: Both ends must be raised or lowered at the same time.

e ) When the gantry reaches the desired height, release the load pin. The load pin will self locate the hole in the

upright. Be sure the load pin is in the full lock-in position.

f ) Ensure that each support leg has the same number of holes visible in the upright tube.

g ) After you have secured the load pin and have ensured that each support leg has the same number of holes visible in

the upright tube, you can lower the beam and remove the crane or lift truck and lifting straps.

NOTE: Before removing the Lug-All hoist or other lifting equipment, ensure that the load pin is fully engaged.

Spanco.com • 1-800-869-2080 • Spanco® A-Series Aluminum Gantry Crane 7

Promise to Perform Industries, Inc.

Lug-All Winch Kit with Adapter Lug

Leg support removed for clarity

Winch kit with adapter lug for all A-Series Aluminum ALU

Gantry Cranes:

03-015-.5-ALU 1/2 Ton

03-015-1SHORT-ALU* 1 Ton

03-015-1TALL-ALU** 1 Ton

03-015-2-ALU 2 Ton

03-015-3-ALU 3 Ton

*Maximum height under boom of eight feet.

**Maximum height under boom greater

than eight feet.

Lug-All winch

03-015

Correct Incorrect

ADJUSTING THE GANTRY SPAN

a ) Adjust the gantry to its lowest position. The beam is clamped in place at each end with four beam clamps (15).

Using an overhead hoist or lift truck, attach lifting straps to the beam to support the crane. Loosen the bolts which

hold the clamps and move the legs to the desired position.

b ) Do not move the legs (A-frames) inward more than the minimum clear span. The minimum clear span is equal to

the distance between the casters (tread width) or one-half the overall beam length—whichever dimension is greater.

See the minimum clear span chart on page eight for the minimum clear span dimensions for standard Spanco

Aluminum Gantry Crane models.

c ) After adjusting the span as desired, re-tighten all eight bolts (11) securely. Move both legs when adjusting the span

so one end of the beam does not hang over more than the other end. Do not suspend a trolley or load from the

cantilevered ends of the beam.

Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

8 Spanco® A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

Capacity Overall

Span Model Number Minimum Clear

Span (Feet)

Maximum Clear

Span (Feet)

0.5

TON

8 ft. 0.5ALU0809 4' 2" 6' 11"

0.5ALU0811 4' 2" 6' 11"

10 ft. 0.5ALU1009 5' 0" 8' 11"

0.5ALU1011 5' 0" 8' 11"

12 ft. 0.5ALU1209 6' 0" 10' 11"

0.5ALU1211 6' 0" 10' 11"

15 ft. 0.5ALU1509 7' 6" 13' 11"

0.5ALU1511 7' 6" 13' 11"

1 TON

8 ft.

1ALU0808 4' 6" 6' 10"

1ALU0810 4' 6" 6' 10"

1ALU0812 4' 6" 6' 10"

10 ft.

1ALU1008 5' 0" 8' 10"

1ALU1010 5' 0" 8' 10"

1ALU1012 5' 0" 8' 10"

12 ft.

1ALU1208 6' 0" 10' 10"

1ALU1210 6' 0" 10' 10"

1ALU1212 6' 0" 10' 10"

15 ft.

1ALU1508 7' 6" 13' 10"

1ALU1510 7' 6" 13' 10"

1ALU1512 7' 6" 13' 10"

18 ft.

1ALU1808 8' 0" 16' 9"

1ALU1810 8' 0" 16' 9"

1ALU1812 8' 0" 16' 9"

20 ft.

1ALU2008 10' 0" 18' 9"

1ALU2010 10' 0" 18' 9"

1ALU2012 10' 0" 18' 9"

2 TON

8 ft.

2ALU0808 4' 4" 6' 9"

2ALU0810 4' 4" 6' 9"

2ALU0812 4' 4" 6' 9"

10 ft.

2ALU1008 5' 0" 8' 9"

2ALU1010 5' 0" 8' 9"

2ALU1012 5' 0" 8' 9"

12 ft.

2ALU1208 6' 0" 10' 9"

2ALU1210 6' 0" 10' 9"

2ALU1212 6' 0" 10' 9"

15 ft.

2ALU1508 7' 6" 13' 9"

2ALU1510 7' 6" 13' 9"

2ALU1512 7' 6" 13' 9"

3 TON

8 ft.

3ALU0808 4' 8" 6' 8"

3ALU0810 4' 8" 6' 8"

3ALU0812 4' 8" 6' 8"

10 ft.

3ALU1008 5' 0" 8' 8"

3ALU1010 5' 0" 8' 8"

3ALU1012 5' 0" 8' 8"

12 ft.

3ALU1208 6' 0" 10' 8"

3ALU1210 6' 0" 10' 8"

3ALU1212 6' 0" 10' 8"

15 ft.

3ALU1508 7' 6" 13' 8"

3ALU1510 7' 6" 13' 8"

3ALU1512 7' 6" 13' 8"

Spanco.com • 1-800-869-2080 • Spanco® A-Series Aluminum Gantry Crane 9

Promise to Perform Industries, Inc.

OPTIONAL ACCESSORIES

1. Tagline Assembly

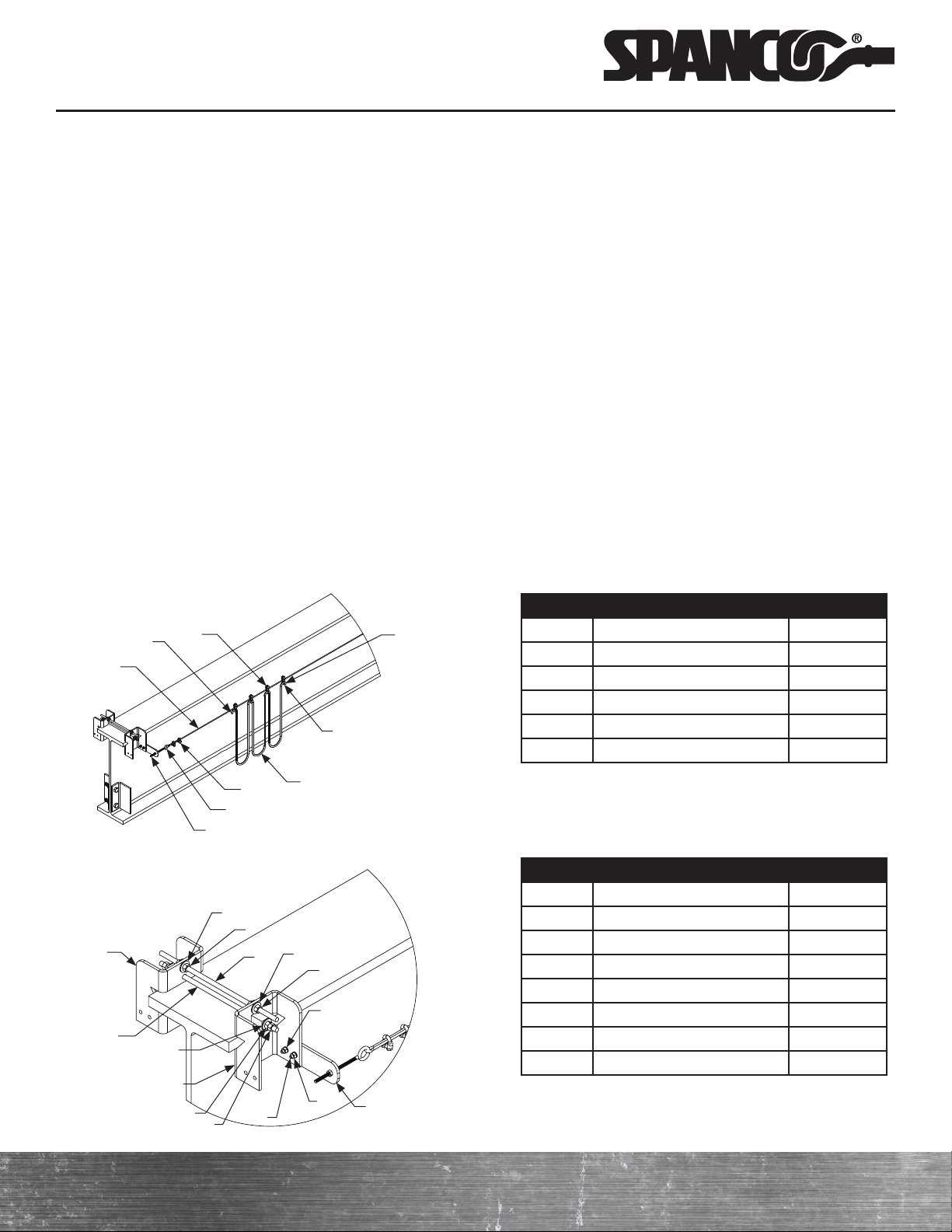

Spanco clamp-on tagline assemblies are designed for universal installation. Clamp-on tagline assemblies include universal

weldments, applicable hardware, tagline cable, cable clamps, eyebolts, and pulleys with cable ties. One pulley and cable

tie is provided for every five feet of tagline length. Power conductor is supplied by others.

Installation

a ) Trim excess rod length to fit socket (if desired).

NOTE: Align each rod so only one end requires trimming.

b ) Torque the inner lower rod nuts (9) to 33 foot-pounds. Adjust the inner upper rod nuts (9) to keep the weldments

plumb.

c ) Holding the inner lower rod nuts in place with a wrench, torque the outer lower rod nuts (9) to 33 foot-pounds.

d ) Holding the inner upper rod nuts in place with a wrench, torque the outer upper rod nuts (9) to 33 foot-pounds.

e ) Align the correct holes in the arm plate (11) with the holes in the tagline weldment (7) and insert two hex head bolts

(13) through the holes. Align the arm plate to keep the tagline approximately 10 inches from the face of the beam.

f ) Place a lock washer (12) and nut (14) on each bolt (13). Torque the nuts (14) to 10 foot-pounds.

ITEM DESCRIPTION QUANTITY

1 Cable Clamp 2

2 Tagline Cable 1

3 Eye Bolt 2

4 1/4-Inch Hex Nut 4

5 Pulley X

6 Cable Tie X

1

2

3

4

5

6

Power Conductor

Figure 1

From Supply To Equipment

ITEM DESCRIPTION QUANTITY

7 Tagline Weldment 2

8 3/8-Inch Threaded Rod 2

9 3/8-Inch Hex Nut 8

10 3/8-Inch Flat Washer 6

11 Arm Plate 1

12 1/4-Inch Lock Washer 2

13 1/4-Inch Hex Head Bolt 2

14 1/4-Inch Hex Nut 2

Note: Only one end of the beam is shown. Total

quantities are doubled.

Figure 2

7

7

8

8

9

10

9

10

10

911

12

13

14

9

Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

10 Spanco® A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

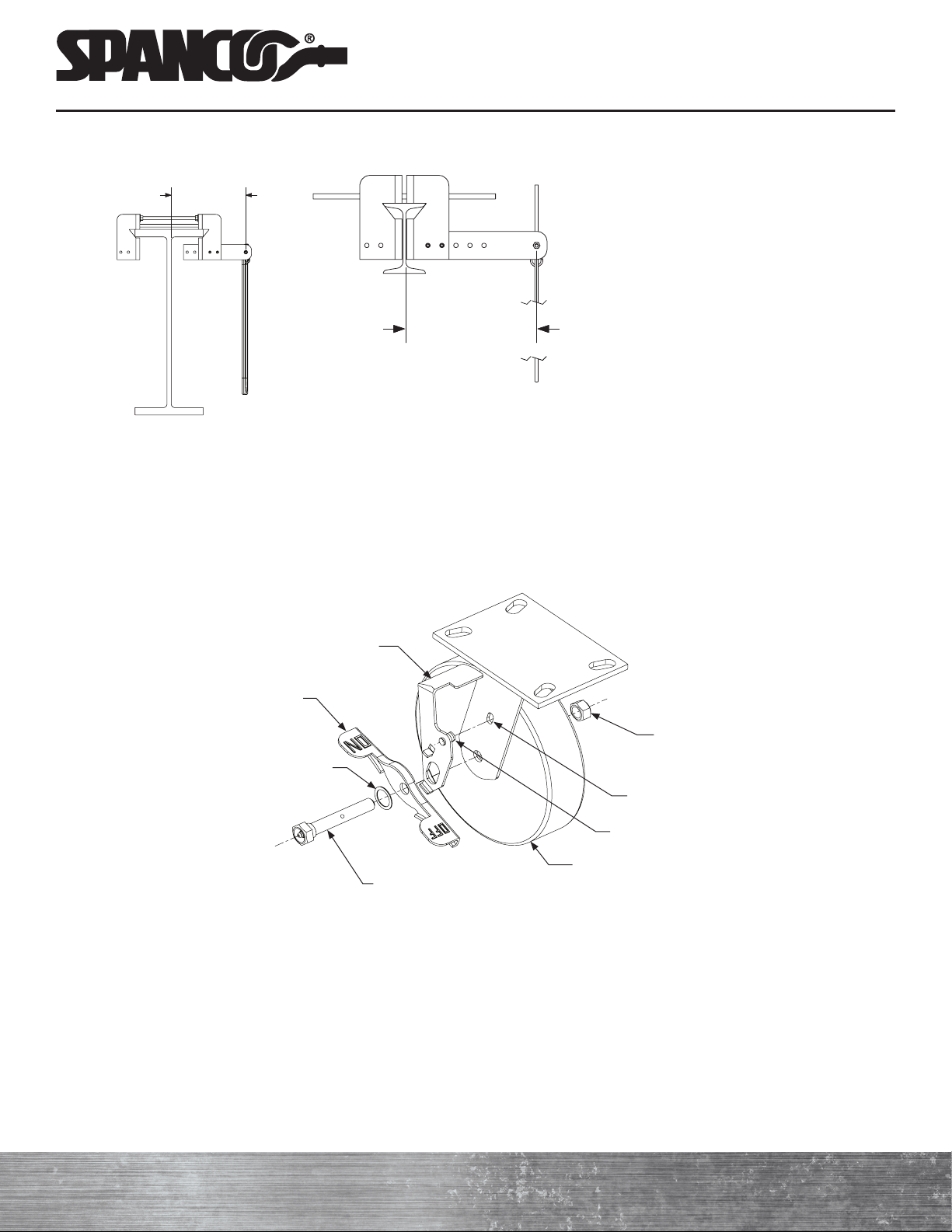

Brake shoe (leg)

Brake pedal

Cup spring washer

Shouldered axle bolt

Wheel

Shoe guide pin

Brake slot

Hex nut

2. Top-Lock Wheel Brake Assembly

Some polyurethane casters ship with their wheel brakes already attached. If your wheel brakes were shipped loose,

follow steps a) through h) to attach the wheel brakes.

Refer to the Wheel Brake Assembly Drawing for Steps A Through H

Wheel Brake Assembly Drawing

a ) Using a 3/4-inch wrench and 3/4-inch socket and ratchet, unbolt the caster stud and remove the nut, bolt, washer,

and caster.

NOTE: If the spacers fall out of the caster, reinsert them into the caster holes.

b ) With the top of the brake shoe facing towards the caster assembly, insert the guide pin on the brake shoe into the

brake slot on the caster assembly.

c ) Using a screwdriver, slightly bend the brake shoe tab so that the brake shoe guide pin and brake shoe tab fit

properly.

d ) With the brake pedal tabs pointed away from the caster assembly, line up the hole on the brake pedal with the hole

on the brake shoe. “On” and “Off” on the brake pedal tabs should be visible when the caster is mounted to the

system.

approx. 10

inches

approx. 10

inches

NOTE: Position the Arm Plate so that

the tagline is approximately 10 inches

from the face of the beam.

Figure 3

Spanco.com • 1-800-869-2080 • Spanco® A-Series Aluminum Gantry Crane 11

Promise to Perform Industries, Inc.

e ) Line up the caster holes with the brake shoe hole and brake pedal hole.

f ) With the washer on the bolt-side of the caster assembly, reinsert the longer axle bolt through the brake pedal,

brake shoe, and caster. Reapply the axle nut at this time.

g ) Using a 3/4-inch wrench and 3/4-inch socket and ratchet, securely tighten the caster nut.

h ) Repeat steps a) through g) to install the remaining caster brakes.

3. V-Groove Track Installation

a ) The exact span of the crane may vary from the design span. Install the full length of the track on one side, making

sure that the track is straight and level. Fasten V-groove track to the floor using 3/8-inch lag bolts and suitable

anchors. (For track supplied by Spanco, use a bolt in each hole. Otherwise, space bolts approximately three feet

apart on each side of the track in a staggered arrangement.) Use shims or grouting as required to keep the track

level and alignment pins at joints to keep the track true. End stops are required at each end of both tracks.

b ) Lay one or two sections of the opposite side of the track at the design span, assemble the crane on the tracks

following the assembly instructions, and operate the crane back and forth a few times, being careful not to run the

crane off the tracks. The loose sections of track will float and set the track to the exact crane span.

c ) After the operating span is determined, attach all the other sections of track to the floor making sure the track is

straight, level, parallel, and at the same elevation as the first track. The end stops should be set square with a 3-4-5

right triangle. The sides and the hypotenuse can be multiplied by any convenient number, such as three, used in the

example.

d ) Set one end stop at point A and measure along the runway track nine feet from point A to point B. With point B

as a center and fifteen feet as a radius, draw a circular arc on the floor. With point A as a center and 12 feet as a

radius, draw a circular arc on the floor intersecting the other arc at point C. A line running through points A and C

is perpendicular, or square, with the runway track.

e ) Extend this line to the other runway track to locate the end stop on that runway. Repeat the process at the other

end of the runway, or measure along each runway the same distance from these end stops for locating the stops at

the other end of the runways.

A

9 RUNWAY TRACK

END STOPS

RUNWAY TRACK

12’15’

C

B

Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

12 Spanco® A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

RUNWAY ALIGNMENT TOLERANCE FOR V-GROOVE TRACK

Span

(2 Runway)

A=3/16” in any

support span

Nom. Span

(L)

Max. Span

(L+A)

Min. Span

(L-A)

Rail to Rail

Elevation

E=1/4” between

adjacent rails

Nom. Tread Line

+E

-E

Straightness C=1/4” in any

support span

+C

-C

Elevation D=1/4” in any

support span

+D

-D

Spanco.com • 1-800-869-2080 • Spanco® A-Series Aluminum Gantry Crane 13

Promise to Perform Industries, Inc.

MAINTENANCE

1. A system inspection should be performed 30 days after installation. All nuts, bolts, and screws should be checked for

tightness. All end stops, cotter pins, and hoist trolleys should be checked for abnormal wear or breakage.

2. A complete inspection of all fasteners and connections should be performed annually or every two thousand (2,000)

hours. Heavy conditions of use may require more frequent inspections.

3. Operators should visually inspect the system before each use to note any unusual or abnormal system operations.

4. If the system fails ANY inspection point on any of the inspection checklists, immediately remove the system

from service and call Spanco at 800-869-2080 for instructions.

5. Download and print additional blank inspection checklists from the literature tab at Spanco.com.

LOAD TEST

After the A-Series Aluminum Gantry Crane has been installed, OSHA requires a load test before operating and after any

modifications. This equipment is designed and manufactured to the rated capacity marked on the equipment with due

allowances for safety factors. Prior to initial use of the Gantry Crane, a person appointed by the owner, under the direction

of a qualified technical person, must perform a load test at 125 percent of the rated capacity using certified test weights. See

CMAA 78 for periodic load testing requirements. Under no conditions shall the rated capacity be exceeded during regular use

or during annual or semi-annual load tests.

DESIGN FACTORS

Nameplate capacities represent the rated load on the hoist hook. The load rating of a hoist shall not exceed the nameplate

capacity. Spanco’s design includes an allowance of 15 percent of nameplate capacity for trolley and hoist deadweight and

25 percent of the nameplate capacity for impact. This design provides a margin to allow for variations in material properties,

operating conditions, and design assumptions. No crane should ever be loaded beyond its rated capacity.

SERVICE FACTOR

All Spanco gantry cranes are designed for moderate usage (Class C Normal/Industrial service) as defined by CMAA 70:

• System or equipment is used where lifted loads average 50 percent of the rated capacity with five to 10 lifts per hour,

averaging 15 feet, not over 50 percent of the lifts at rated capacity.

Applications involving vacuums, magnets, or other high-impact lifters are considered severe usage and require special design

considerations. Contact Spanco for special design pricing.

Consult Spanco for usage other than moderate and all instances of high cycle rates or high-impact applications, such as high-

speed air or electric hoists, vacuum lifters, or magnets.

Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

14 Spanco® A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

DISASSEMBLY

1. Disassembling the Beam

Refer to A-Series Aluminum Gantry Crane Assembly Drawing for Steps A Through K

WARNING: Crane parts are heavy. Exercise caution when handling all parts during assembly, adjustment, and

disassembly processes.

a ) Move the assembled A-Series Aluminum Gantry Crane to an area under an overhead hoist, or where a lift truck

can be used to raise the beam. Be sure there is no machinery or clutter nearby that will hamper free movement. All

personnel should be wearing applicable safety gear, such as hard hats, steel toe shoes, and safety glasses.

b ) Adjust the gantry height to its lowest position.

c ) Secure the hoist trolley in the center of the beam

d ) Ensure that the load pin on each A-frame assembly is fully engaged and secure.

e ) Using an overhead hoist or lift truck, attach the lifting straps to the beam to support the crane during disassembly.

f ) Lock the caster wheels in position parallel to the A-frame to prevent the frame assembly from rolling during

disassembly. Secure the gantry legs to prevent falling.

g ) Using a wrench and socket, remove the hex nuts (13) and lock washers (12) from the hex bolts (11) that secure the

beam from one A-frame assembly.

h ) Remove the hex bolts (11) with the attached beam clamps (15) and clipped washers (14).

i ) Remove the A-frame assembly and carefully lower it to the ground.

j ) Repeat steps g) through i) to remove the second A-frame assembly.

k ) Clear the area below the beam, then safely lower the beam to the ground and remove the lifting straps.

Detail “D”

ITEM DESCRIPTION

1 Beam

2 Upright Tube

4 Top Plate

5 Hitch Pin

11 Hex Bolt

12 Lock Washer

13 Hex Nut

14 Clipped Washer

15 Beam Clamp

2

4

1

5

13

12

11

15

14

Spanco.com • 1-800-869-2080 • Spanco® A-Series Aluminum Gantry Crane 15

Promise to Perform Industries, Inc.

ITEM DESCRIPTION

3 A-Frame Assembly

4 Caster

7 Lock Washer

8 Flat Washer

9 Hex Nut

10 Hex Bolt

3. Removing the Caster Assemblies from the A-Frame Assemblies

Refer to Detail “B” for Steps A Through C

a ) The casters may be removed from the A-frames if desired. To remove the casters, lay each A-frame on the ground.

b ) Remove the hex nut (9), lock washer (7), and flat washer (8) from each bolt (10) and remove the bolts from the

caster assembly’s top plate and the aligned holes in the A-frame assembly.

Detail “B”

2. A-Frame Disassembly

Refer to A-Series Gantry Crane Assembly Drawing Steps A through B

a ) Disengage the load pin in the A-frame assembly from the upright tube of each A-frame.

b ) Slide the upright tube out of the center tube of each A-frame.

Detail “A”

Caster Assembly's

Top Plate

10

9

8

7

4

3

ITEM DESCRIPTION

2 Upright Tube

3 A-Frame

2

3

Load Pin

Promise to Perform Industries, Inc.

A-SERIES ALUMINUM GANTRY CRANE MANUAL

16 Spanco® A-Series Aluminum Gantry Crane • 1-800-869-2080 • Spanco.com

Notes on Label Placement Drawing

• Label 53-0001 “A” should be centered on both sides of the beam.

• Label “B” should be placed on Label “A” and is P/N 53-0009 for one-half-ton capacity systems, 53-0010 for one-ton

capacity systems, 53-0011 for two-ton capacity systems, and 53-0012 for three-ton capacity systems.

• Label 53-0039 “C” should be placed on both upright tubes above the lowest hole.

• Label 53-0003 “D” should be placed on both support legs.

• Label 53-0004 “E” should be placed on both support legs.

• Label 53-0589 “F” should be placed on both A-frames or upright tubes at eye level (approximately 62 inches from the

ground).

• Label “G” should be placed on each A-frame and on label “A” inside the outlined area.

“A”

P/N 53-0001

LABEL # 53-0001

TON

SPANCO.COM | (800) 869-2080

PROUDLY MADE IN THE USA

P/N 53-0039

“C”

DO NOT ADJUST HEIGHT

BEYOND THIS POINT.

EXCEEDING LAST HOLE

ALIGNMENT COULD

RESULT IN INJURY OR

DEATH.

P/N 53-0039

“D”

SAFETY INSTRUCTIONS

READ BEFORE OPERATING

1. Inspect gantry for damaged or missing parts.

2. Not to be used for lifting or supporting

humans.

3. Do not lift more than rated capacity.

4. Never adjust height or disassemble crane

when gantry is under load.

5. Do not load gantry on an incline.

6. Do not push or pull gantry with forklift or other

vehicle.

7. Do not allow load to swing or roll against

support members.

8. Push the gantry, not the load.

9. When moving loaded gantry, keep load close

to the floor.

10. Be certain that load is directly beneath beam

before load is lifted. Do not pull sideways on

crane.

11. Do not anchor legs to the floor.

12. Never stand under gantry when adjusting

height or disassembling crane.

13. Do not lift gantry fully assembled.

LABEL # 53-0003 Spanco.com

P/N 53-0003

“E”

SAFETY INSTRUCTIONS

LABEL # 53-0004

BEFORE ADJUSTING GANTRY HEIGHT

FOLLOW INSTRUCTIONS BELOW:

Spanco.com

1. Never adjust height or disassemble

crane when gantry is under load.

2. Secure trolley and hoist in center of

I-beam.

3. To adjust height: use forklift,

overhead hoist, or attached winch

hoist (if included).

4. Raise center post slightly, pull out

load pin, and secure in lock position.

5. Do not raise or lower one end more

than one foot at a time.

6. Adjust height to required position and

release load pin to full lock position

7. Never stand under gantry when

adjusting height or disassembling crane.

P/N 53-0004

LABELING

The letters correspond to the accompanying labels. All labeling must be legible and attached to the system. If at any time these

labels are lost, stolen, removed, or become illegible, contact Spanco. Labels can be ordered by part number as listed below.

If the system is shipped unpainted or without properly secured labels, proper label placement is the sole responsibility of the

end user. Spanco cannot be held liable for any damage or injury resulting from omitted or improper label placement.

Serial #: 123456-789

Model #: X12XXXX34.5678.90

MFG Date: 00/0000

Promise to Perform Industries, Inc.

“G”“F”

P/N 53-0589

You must read and

understand the manual

before you assemble,

operate, or disassemble

this equipment.

Failure to do so may

result in serious injury

or death.

To download a

replacement manual,

visit Spanco.com or

scan the QR code.

P/N: 53-0589

P/N 53-0010

“B”

Other manuals for A Series

1

This manual suits for next models

50

Table of contents

Other Spanco Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Manitowoc

Manitowoc 2250 MAX-ER 2000 Operator's manual

Protech Machinery

Protech Machinery P300S Operator and parts manual

Innovatech

Innovatech TERMINATOR-2000e Operation and maintenance manual

stellar labs

stellar labs 17000 owner's manual

HIAB

HIAB 322 HiPro CD Operator's manual

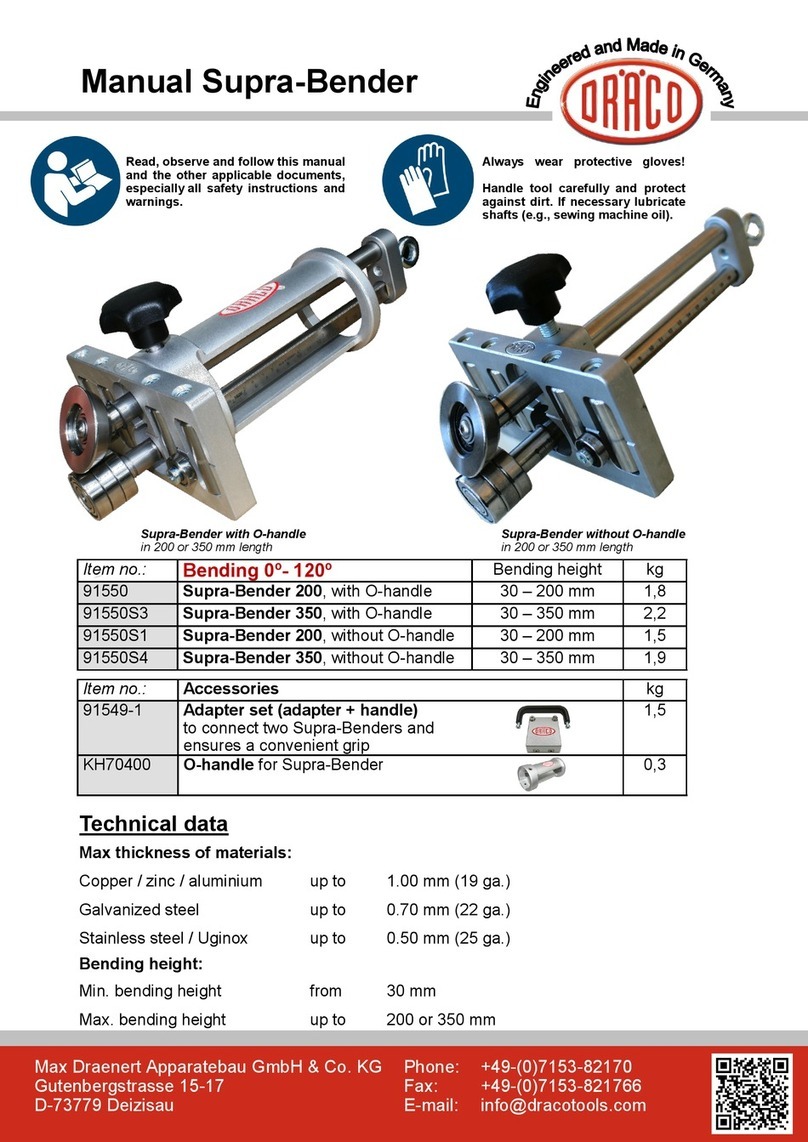

Draco

Draco Supra-Bender 200 manual