Protech Machinery P300S Product manual

0

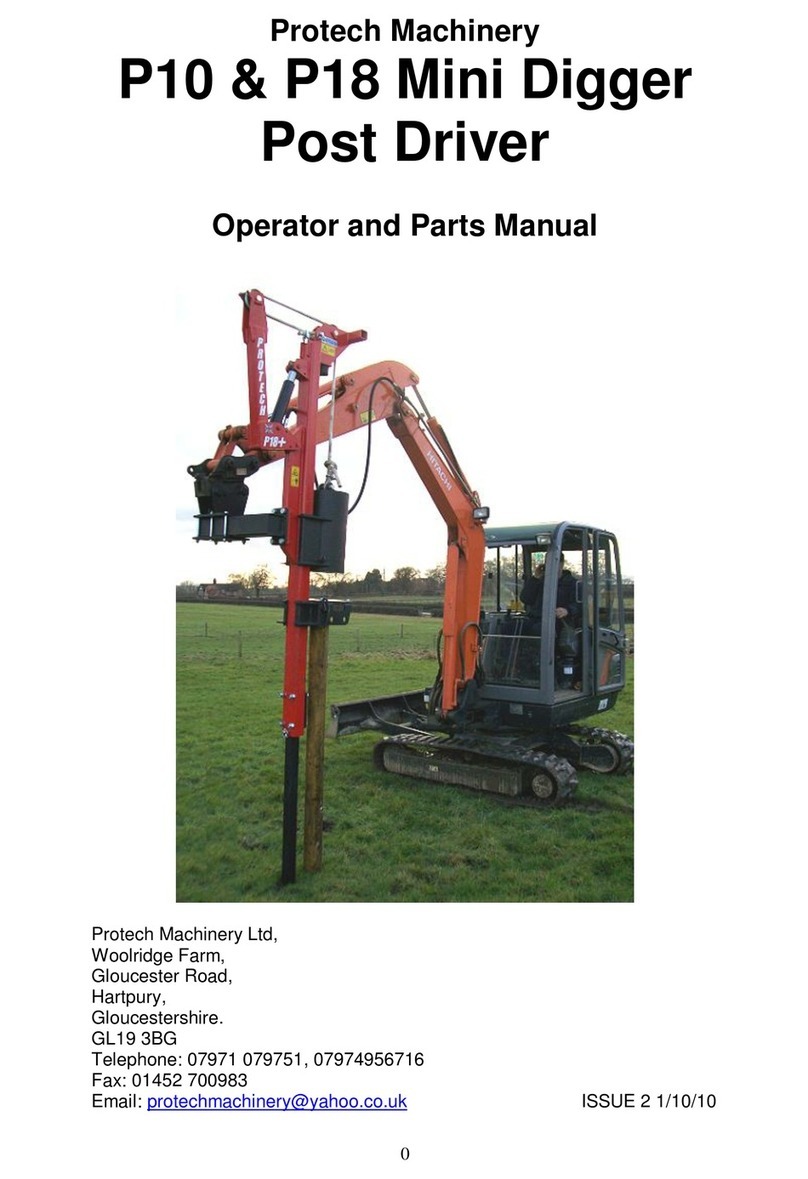

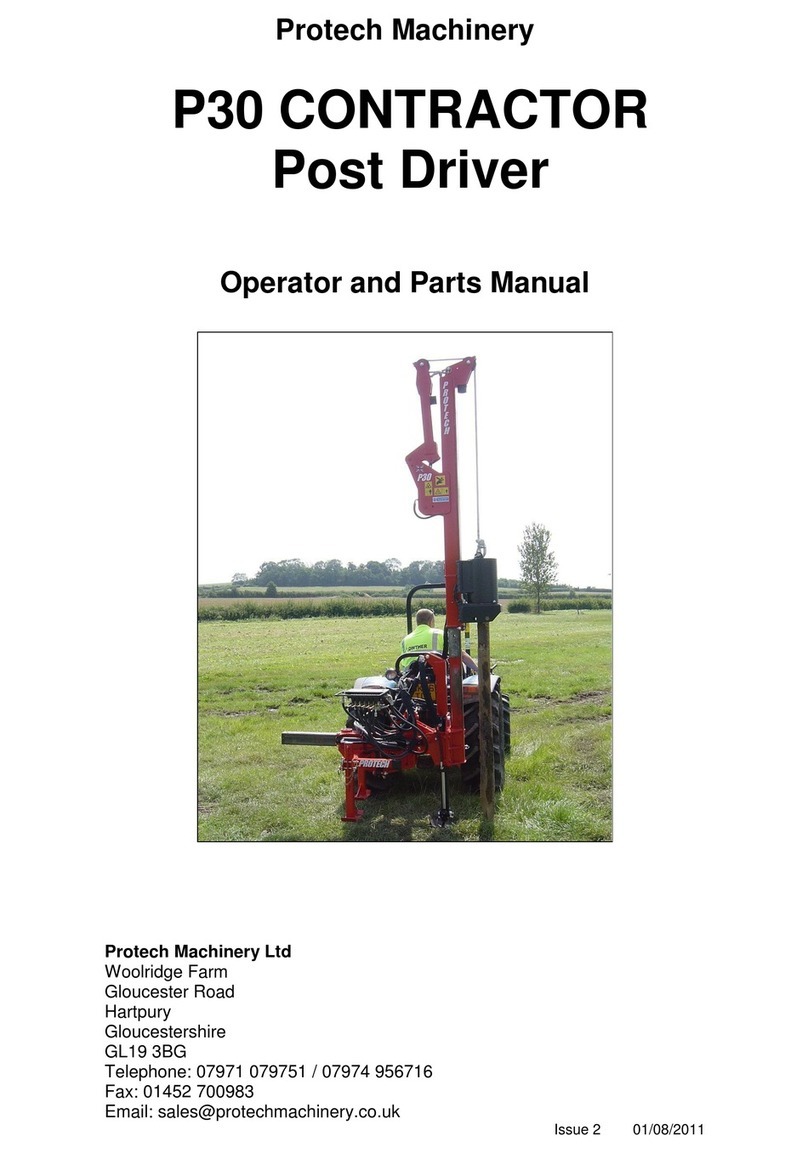

Protech Machinery

P300S P400S

CONTRACTOR

P22 , P200S/T, P250S

Post Driver

Operator and Parts Manual

Protech Machinery Ltd,

Woolridge Farm,

Gloucester Road,

Hartpury,

Gloucestershire.

GL19 3BG Telephone: 07971 079751

1

EC DECLARATION OF CONFORMITY

Conforming to EEC Directive 98/37/EC

We Protech Machinery Ltd

Of Woolridge Farm,

Gloucester Road,

Hartpury,

Gloucestershire.

GL19 3BG

Hereby declare that the product: POSTDRIVER

Product Code P300S, P200S, P22

Serial Number series

Manufactured by the above Company complies with the required provisions of

the Directive 98/37/EC

To effect the correct application of the safety requirements stated in the EEC

Directives, the following standards and/or technical specification have been

used:

BS EN 292-1: 1991 Safety of Machinery – Basic concepts, general principals

for design – Basic terminology, methodology.

BS EN 292–2: 1991 Safety of Machinery – Basic concepts, general principals

for design – Technical principals and specifications.

BS EN 294: 1992 Safety of Machinery – Safety distances to prevent danger

zones being reached by the upper limbs.

BS 5401: 1990 Guide to information content and presentation of operator’s

manuals provided for tractors and machinery for agriculture and forestry.

Signed……………………………………………………………………………..

On behalf of Protech Machinery

Status……………………………………………………………………………….

Date…………………………………………………………………………………

2

Contents

Page number

Introduction 3

P300 Product Specification 4

P300 Part Reference 5

Safety Recommendations 6

Machine Safety Stickers 9

Control Functions of the Post Driver 10

Slew Arm Control 10

Telescopic Slew Arm Control 11

Hydraulic Rear Leg Control 12

Mast Forward Tilt Control 12

Mast Side Tilt Control 13

Driver Weight Control 13

Rock Spike Control 14

Installation Of the post Driver 15

Transportation of the Post Driver 17

Safe use of the Post Driver 17

Safe use of the Rock Spike 18

Storage of the Post Driver 20

Maintenance of the Post Driver 20

Spare Parts List

Spare Parts Illustration

3

IMPORTANT NOTICE

This manual must be read and fully understood before fitting or operating

this machine. Whenever any doubt exists please contact Protech

Machinery for assistance. If the machine is resold the Manual must be

given to the new owner.

Introduction

Dear customer,

Thank you for purchasing a Protech P300 Contractor Post Driver. Protech

machinery Ltd has produced this User Guide to assist and help you get the

most from your post driver.

This manual is line with the relevant Health and Safety regulations to assist you

with operating this machine without harm to yourself.

You should be aware that any person operating this machine with your

permission must be given adequate guidance and information to allow him or

her to use the machine safely.

Where as every effort has been made to ensure the Post Driver conforms to

Protech policy of quality, the machine cannot be expected to withstand abuse

caused by misuse and negligence by the operator.

4

P300 Contractor Product Specification

All dimensions are in millimetres.

Weight

(including rock spike)

1150

kg

Driver weight

30

0

kg

Tractor Horsepower

(minimum)

9

0 hp

Auxiliary oil flow (minimum)

5

0L/MIN

Auxiliar

y oil pressure (minimum)

1

7

0 bar

Please note: the total machine weight will vary depending on driver weight

option.

5

P300 Contractor Part References

The diagram below displays all the P300 parts referred to in this manual.

6

SAFETY INFORMATION

This machine has the potential to be extremely dangerous, in the wrong hands

it can kill. It is therefore imperative that the owner and the operator of this

machine read the following section to ensure that they are both fully aware of

the dangers that do, or may exist, and their responsibilities surrounding its use.

The operator of this machine is responsible not only for their safety but equally

for the safety of others who may come into close proximity of the machine, as

the owner you are responsible for both

POTENTIAL SIGNIFICANT DANGERS ASSOCIATED WITH THE USE OF

THIS MACHINE:

Injuring of feet. No person must be in this area when the Post Driver is raised

or lowered by the tractor or near to the rear leg and foot plate when operating

this control.

Crushing under the falling weight. No person must be near the post when the

weight is falling. Never put a hand on top of the post or rock spike under any

circumstances.

A trapping zone from the forward and side tilting mast, no person must be in

this area.

A trapping zone between the Slew arm and Main frame, no person must be in

this area.

Becoming trapped between tractor and machine when hitching or unhitching.

Machine overbalancing when freestanding (out of use).

Electrocution from Overhead Power Lines (by contact with or ‘flashover from).

Being hit by flying debris such as splinters from wooden posts.

Injection of high pressure oil from damaged couplings or hydraulic hoses.

Beware of low bridges and other overhead obstructions, always measure and

be aware of the maximum height when hitched to the tractor before

transporting.

BEFORE USING THIS MACHINE YOU MUST:

Ensure you read and fully understand all sections of the operator handbook,

Ensure the operator is, or has been properly trained to use this machine.

Ensure the operator has been issued with, reads and fully understands the

operator handbook.

7

The post cap plate must be used to hold posts at all times. Under no

circumstances should the post be held manually while operating the Post

Driver.

Only the operator must control the Post Driver, Spectators must be kept away

from the machine at all times.

Ensure that the tractor meets the minimum weight recommendations of the

machine manufacturer.

Ensure that the tractor is in correct working condition, with correct fluid levels.

Ensure that all safety guards are fitted and in good condition.

Ensure that machine fittings and couplings are in good condition.

Ensure that all warning labels are always visible and not damaged, defaced or

missing

Ensure the operator is protected from noise. Ear defenders should be worn.

Ensure the operator is protected from flying debris. Safety glasses should be

worn.

Always ensure no person is operating or on the tractor while the operator is

near to or using the machine.

Always ensure when you remove your machine from the tractor that it is left in

a safe and stable position using the stands and props provided and secured if

necessary.

Always check for worn hydraulic components.

Always ensure the rope is not damaged. Replacements must be a certified

Protech rope.

When working on sliding ground, it is far safer to drive up and down rather than

across the slopes.

During maintenance or adjustments:

Ensure that the weight is fully down, with the rope relaxed.

Ensure that the hydraulic pressure is released.

Ensure that the Tractor engine is switched off.

During Transport ensure:

That the weight is fully down

That the Post Driver is carried low to the ground and with the mast

crowded back for stability and maximum clearance from overhead

obstructions.

Always drive at a safe speed and in complete control of the vehicle.

8

WHEN NOT TO USE THIS MACHINE:

Never attempt to use this machine if you have not been trained to do so.

Never use a machine until you have read and fully understood the operator

handbook, are familiar with and practiced the controls.

Never use a machine that is poorly maintained

Never use a machine on which the hydraulic system shows signs of wear or

damage.

Never fit, or use a machine on a tractor that does not meet the manufacturers

minimum specification level.

Never start or continue to work a machine if people are nearby or approaching

– stop and wait until they are at a safe distance before continuing.

Never use a machine to perform a task it has not been designed to do.

Never operate the tractor from any other position other than from the driving

seat, especially whilst hitching or unhitching the machine.

Never carry out maintenance of a machine or a tractor whilst the engine is

running – the engine should be switched off, the key removed and pocketed.

Never leave a machine unattended in a raised position – it should be lowered

to the ground on a level firm site.

Never leave a tractor with the key in or the engine running.

Never attempt to detect a hydraulic leak with your hand – use a piece of

cardboard.

Never allow children near to, or play on, a tractor or machine under any

circumstances.

Never move the position of the control panel.

Notes

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

______________________________________________________________

Machine Safety Stickers

9

Standard Triangle to indicate

Alert/Warning

Warning read Product Manual

Warning danger area from tilting

mast

Warning danger of feet being

crushed.

Warning eye protection must be warn

Warning ear protection must be warn

Warning Danger of falling weight

Warning Danger of overhead cables

Lubrication Point

Lifting point

Warning danger of fingers and hands

being crushed

10

Control Functions of the Post Driver

The diagram below displays the layout of the control panel. Moving the control

lever up or down operates the function in the direction displayed of the Post

Driver.

The Post driver controls are positioned to keep the operator at a safe distance

and provide good visibility of the work area. The operator must stay within a

safe working zone (defined later in this manual) around the control panel while

operating the post driver controls.

Slew Arm Control

Operating the slew control lever pivots the slew arm from parallel to the main

frame (transport position) through 120 degrees.

Slew arm

Control lever

Diverter lever pushed away for Rock Spike

Diverter lever Pulled towards for Slew

11

Ensure the Rock Spike diverter lever (if fitted) is in the pulled towards position

otherwise operating the slew control lever will operate the rock spike extractor

function.

As the control is mounted to the slew arm, it will move with operation of the slew

control. The operator must work in the control area of the post driver to avoid

all trapping zones.

Telescopic Slew Arm Control

Operating the Telescopic control lever extends and retracts the inner slew arm

through 800mm.

As the control is mounted to the inner slew arm, it will move with operation of

the telescopic control. The operator must work in the control area of the post

driver to avoid all trapping zones.

Telescopic

12

Hydraulic Rear Leg Control

Operating the Rear Leg control lever extends and retracts the leg and foot plate

which is powered down once the mast in position to stabilise the machine during

the post driving operation. Feet must be kept clear from this crushing zone

during operation of this control.

Mast Forward Tilt Control

Operating the Mast Forward Tilt control lever pitches the mast forward and back

(23 degrees forward and back from mast vertical position). This maintains a

vertical mast while on undulating ground.

Rear leg and

foot plate

Mast forward

tilt

13

Mast Side Tilt Control

Operating the Mast Side Tilt control lever pitches the mast side to side (35

degrees each side from mast vertical position). This maintains a vertical mast

while on undulating ground. Everyone must be kept clear from this trapping

zone during operation of this control.

Driver Weight Control

Operating the Driver Weight control powers the lever arm forward and back

which raises and lowers the weight. Everyone must be kept clear from this

crushing zone during operation of this control.

Rock Spike Control

Mast side Tilt

14

The rock Spike Extractor control is operated through the slew arm control

lever when the diverter lever is in the pushed away position.

15

Installation of the Post Driver.

1. The Post driver is delivered with Slew arm perpendicular to the main frame

and with the Slew lock pin fitted to lock the arm. Ensure the machine is

manoeuvred this position before unhitching from the tractor.

2. With the machine positioned on a firm level site and securely supported,

manoeuvre the tractor squarely up to the machine with the tractors link arms

set to a height level with the machines lower link brackets.

3. Connect the tractors link arms to the machine lower link brackets and retain

in position with the linkage and lynch pins supplied.

4. Connect the tractor top link (not supplied) to the machine and secure with the

linkage and lynch pin supplied. The tractor top link must be category 2 on the

machine end or conversion bush used if category 3.

5. Adjust the Tractor link arm stabilisers to centralise the Post Driver and reduce

excessive lateral sway

6. You must familiarise yourself and understand the controls and their functions;

therefore after studying the previous section practise moving the levers before

connecting any hydraulic hoses the tractor. The diagram shows the safe

working zone the operator must work in while operating the post driver controls.

All dimensions are in millimetres.

16

7. Connect the pressure and return hoses to and from the control valve to the

tractor hydraulic service.

8. Before removing the safety lock plates very carefully move each control lever

forward and back a small distance until each cylinder is able to extend and

retract slightly. Care must be taken as to not damage or strain any fabrication

with the safety lock plates in position. This procedure will prime all cylinders

with oil and remove any air trapped in the hydraulic circuit. Removing the safety

lock plates before doing so could cause the mast to fall if the cylinders are not

charged with oil.

9. Remove the safety lock plates and slew lock pin.

10. Fully operate all controls. Always raise the hydraulic rear leg and foot plate

off the ground before using the slew or telescopic control. Care must be taken

with the weight control, with the weight lifted up the mast operate the control

very carefully to slowly lower the weight. A falling weight down to the bottom of

the mast will cause damage.

11 The Post Driver is now ready for use.

Transporting the Post Driver.

17

To put the Post driver into transport position, operate the slew control to position

the slew arm parallel with the main frame (slew cylinder closed). If the rock

spike option is fitted ensure the diverter lever is pulled towards to operate the

slew function.

Fit the slew lock pin and mast forward tilt and mast side tilt safety lock plates.

Always ensure the telescopic is fully retracted and the mast tilt ram is fully

closed.

Always transport the post driver with the weight fully lower and with the front

legs fully raised so the machine is carried as low as possible on the tractor

linkage without causing obstruction

Always ensure the rock spike (if fitted) is retained with the rock spike lock pin

in the rock spike carrier.

Safe use of the Post Driver.

1. Manually start a post in the desired location so it becomes self supported.

Under no circumstances should the post be held manually while operating the

Post Driver. The Post driver controls are positioned to keep the operator at a

safe distance and provide good visibility of the work area. Under no

circumstances should the control panel position be moved and the operator

must stay within a

2. With the tractor and machine near to the work area remove to slew lock pin

and safety lock plates.

3. Drive the tractor near to the post so it can be reached while operating the

external controls. Lower the machine onto the ground so it stands on its front

legs and firmly apply the tractor handbrake. If working on a sloping ground it is

far safer to drive up and down than across the slope. Engage the auxiliary

service to provide oil flow to the control valve.

4. The operator can now enter the safe working zone. With the driver weight

fully down ensure the post cap lock chain is hooked onto the post cap chain

hook and retained with lynch pin. This connects the driver weight to the post

cap plate.

5. Operate the control to raise the driver weight and post cap plate a short

distance above the post.

6. With the hydraulic rear leg raised off the ground, operate the controls to

position the post cap plate above the post. Ensure the mast is angled to match

the desired angle of the post. With the Post driver in this position, the

operator must never put their hands on top of the post or move the post

manually.

7. Lower the rear leg and foot plate only enough to stabilise the machine. If the

front legs are raised off the ground then the rear leg has been lowered too far.

18

8. Carefully lower the driver weight and post cap plate onto the post.

9. Unhook the post cap lock chain from the post cap plate.

10. Operate the control to raise the driver weight then move the control lever

fully in the down position to drop the weight with maximum impact.

11. Repeat step 10 until the post has been driven into the ground to the desired

depth.

12. With the driver weight and cap plate lowered on top of the post hook the

post cap lock chain onto the post cap chain hook.

13. Operate the driver weight control to raise the weight and post cap plate of

the post.

14. Operate the control to raise the rear leg and foot plate off the ground.

15. Operate the Slew or telescopic control to move the mast away from the

post.

16 Carefully operate the driver weight control to slowly lower the weight and

post cap plate fully to the bottom of the mast.

17. At this position the operator can move away from the safe working zone.

17. Repeat the safe working procedure steps for each post. To transport the

post driver then ensure the transportation procedure is followed.

Safe Use of the Rock Spike.

The rock spike is an optional extra is recommended for use on stony or hard

ground and creates a pilot hole for the post.

1. Follow steps 2, 3 and 4 from the Safe use of Post Driver section.

2. Operate the weight control to carefully raise the weight and post cap plate a

short distance above the rock spike.

3. Ensure the diverter lever is pushed away so when operating the slew control

lever the rock spike ram is activated.

4. Operate the control fully retract the rock spike ram. This should slightly raise

the rock spike above the rock spike carrier.

5. Remove the rock spike lock pin.

19

6. The operator must remain in the safe working zone and push the rock spike

hinge around and underneath the post cap plate. Never push the rock spike

itself and never put hands on top of the rock spike. Pushing the rock spike hinge

keeps the operators hands and arms clear from the suspended weight and post

cap plate.

7. Operate the control to extend to the rock spike ram and lower the rock spike

onto the ground. Continue to extend the rock spike ram until the rock spike

hinge is lowered 500mm below the rock spike collar.

8. Operate the control to slowly lower the weight and post cap plate onto the

rock spike.

9. Unhook the post cap lock chain from the post cap chain hook.

10. Operate the control to fully raise the driver weight then move the control

lever into the fully down position to drop the weight.

11. Repeat step 10 to drive in the rock spike. Ensure the rock spike hinge is

lowered between hits to always ensure the hinge collar is below the rock spike

collar otherwise causing damage to the rock spike ram and fabrication.

12. Once the rock spike has been driven to the desired depth and with the driver

weight and post cap plate lowered on top of the rock spike, hook the post cap

lock chain onto the post cap chain hook and retain with lynch pin.

13. Operate the control to fully retract the rock spike ram.

14. Operate the control to raise the driver weight and post cap plate a short

distance above the rock spike.

15. The operator must remain in the safe working zone and pull the rock spike

hinge (which keeps hands and arm clear from the suspended driver weight and

post cap plate) back into the rock spike carrier and retain with the rock spike

lock pin. Never pull the rock spike itself and never put hands on top of the rock

spike.

16. Carefully operate the control to slowly lower the driver weight and post cap

plate down to the bottom of the mast.

17. At this position the operator can move away from the safe working zone.

Storage of the Post Driver

Where possible, store the Post Driver away from areas that have public access.

This manual suits for next models

4

Table of contents

Other Protech Machinery Construction Equipment manuals

Protech Machinery

Protech Machinery P10 Product manual

Protech Machinery

Protech Machinery P30 Product manual

Protech Machinery

Protech Machinery P230S Post Driver Product manual

Protech Machinery

Protech Machinery P220+ Product manual

Protech Machinery

Protech Machinery P30 Product manual

Protech Machinery

Protech Machinery P240T User manual