2 3

INSTALLATION

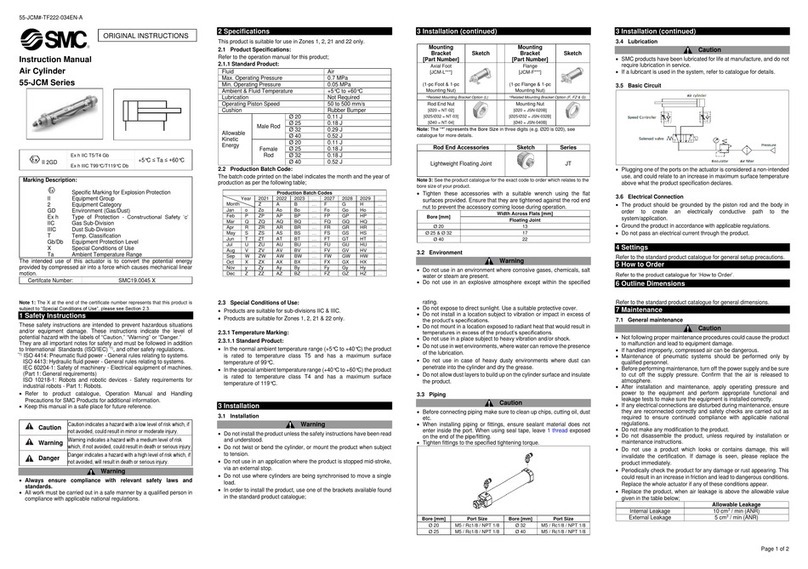

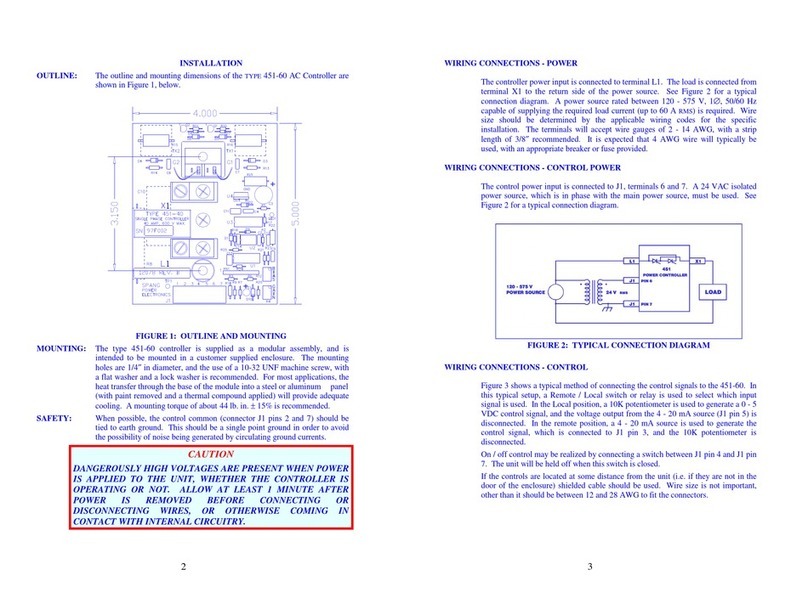

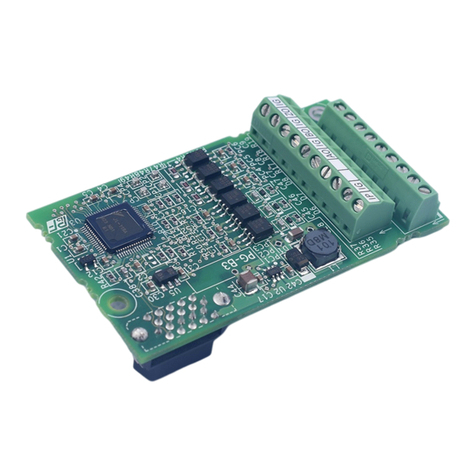

OUTLINE: The outline and mounting dimensions of the

TYPE

451-25 AC Controller

are shown in Figure 1, below.

FIGURE 1: OUTLINE AND MOUNTING

MOUNTING: The type 451-25 controller is supplied as a modular assembly, and is

intended to be mounted in a customer supplied enclosure. The mounting

holes are 1/4″in diameter, and the use of a 10-32 UNF machine screw,

with a flat washer and a lock washer is recommended. For most

applications, the heat transfer through the base of the module into a steel

or aluminum panel (with paint removed and a thermal

compound applied) will provide adequate cooling. A mounting torque

of about

44 lb. in. ±15% is recommended.

SAFETY: When possible, the control common (connector J1 pins 2 and 7) should

be tied to earth ground. This should be a single point ground in order to

avoid the possibility of noise being generated by circulating ground

currents.

CAUTION

DANGEROUSLY HIGH VOLTAGES ARE PRESENT WHEN POWER

IS APPLIED TO THE UNIT, WHETHER THE CONTROLLER IS

OPERATING OR NOT. ALLOW AT LEAST 1 MINUTE AFTER

POWER IS REMOVED BEFORE CONNECTING OR

DISCONNECTING WIRES, OR OTHERWISE COMING IN

CONTACT WITH INTERNAL CIRCUITRY.

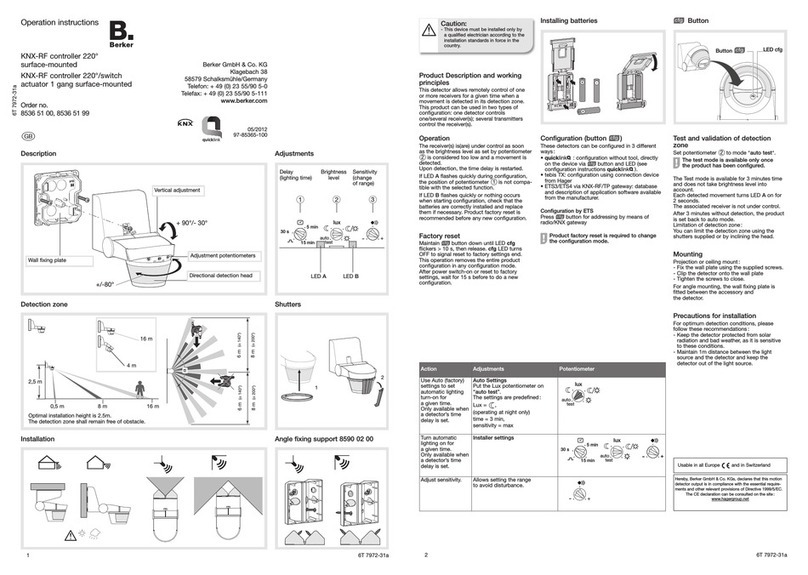

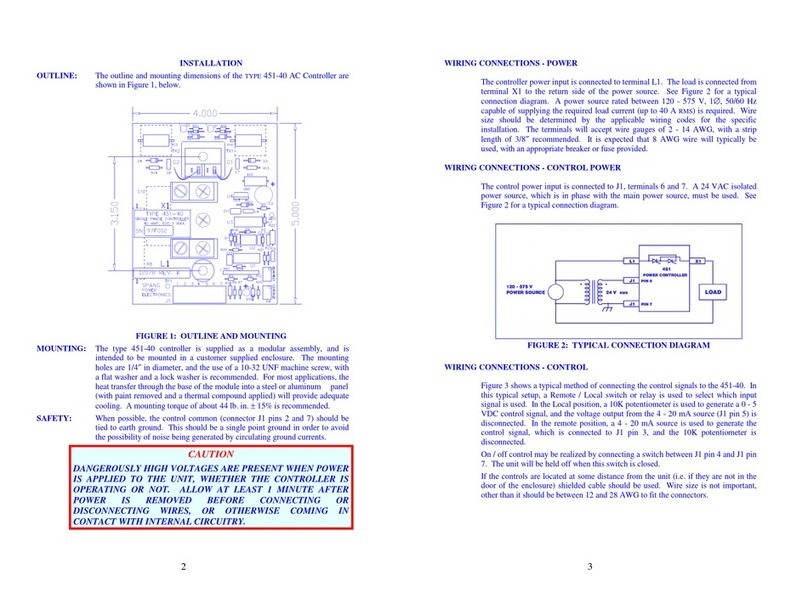

WIRING CONNECTIONS - POWER

The controller power input is connected to terminal L1. The load is connected from

terminal X1 to the return side of the power source. See Figure 2 for a typical

connection diagram. A power source rated between 120 - 575 V, 1∅, 50/60 Hz

capable of supplying the required load current (up to 25 A

RMS

) is required. Wire

size should be determined by the applicable wiring codes for the specific

installation. The terminals will accept wire gauges of 2 - 14 AWG, with a strip

length of 3/8″recommended. It is expected that 12 AWG wire will typically be

used, with an appropriate breaker or fuse provided.

WIRING CONNECTIONS - CONTROL POWER

The control power input is connected to J1, terminals 6 and 7. A 24 VAC isolated

power source, which is in phase with the main power source must be used. See

Figure 2 for a typical connection diagram.

FIGURE 2: TYPICAL CONNECTION DIAGRAM

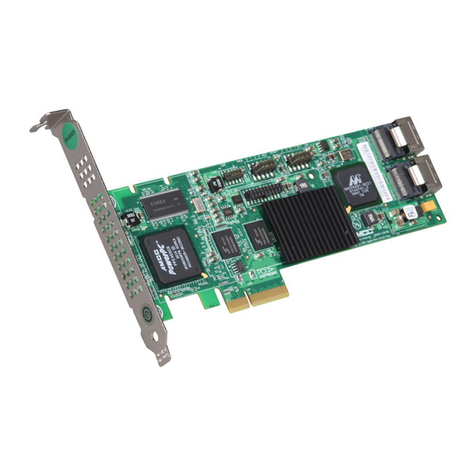

WIRING CONNECTIONS - CONTROL

Figure 3 shows a typical method of connecting the control signals to the 451-25. In

this typical setup, a Remote / Local switch or relay is used to select which input

signal is used. In the Local position, a 10K potentiometer is used to generate a 0 - 5

VDC control signal, and the voltage output from the 4 - 20 mA source (J1 pin 5) is

disconnected. In the remote position, a 4 - 20 mA source is used to generate the

control signal, which is connected to J1 pin 3, and the 10K potentiometer is

disconnected.

On / off control may be realized by connecting a switch between J1 pin 4 and J1

pin 7. The unit will be held off when this switch is closed.

If the controls are located at some distance from the unit (i.e. if they are not in the

door of the enclosure) shielded cable should be used. Wire size is not important,

other than it should be between 12 and 28 AWG to fit the connectors.

G2 G1

G2

11

1 2 3 4 5 6

J1

R1 R9 R7

GAIN

BIAS

R12

R4

U1

GND

INOUT

C1

RN1

1

C3

U3

C4

C5

D1

D2

U2

C2

R2

Q2 Q1R10 R11

D6 D5

C8R14

D4

C5

TX2

R15

R5

D3

R13

TX1

C6

R16

R8

C10

G1

C7

C9

LED1

TYPE 451-25

SPANG

POWER CONTROL

SINGLE PHASE CONTROLLER

4.000

25 AMP, 600 V MAX.

SN

U4

TP1

R17

R18

3.150

5.000

7

R19

R3 R6

R20

R22

R21

POWER SOURCE

120 - 575 V

24 VAC

ISOLATION

TRANSFORMER

L1

J1

J1

X1

451-25

POWER CONTROLLER

LOAD

PIN 6

PIN 7