Sparker TCI-P4 User manual

1

w

w

ww

w

ww

w

w

.

.

.

-

--

-

-

--

-

-

--

-p

pp

p

p

pp

p

p

pp

pr

rr

r

r

rr

r

r

rr

ro

oo

o

o

oo

o

o

oo

o-

--

-

-

--

-

-

--

-m

mm

m

m

mm

m

m

mm

mi

ii

i

i

ii

i

i

ii

il

ll

l

l

ll

l

l

ll

ll

ll

l

l

ll

l

l

ll

le

ee

e

e

ee

e

e

ee

e.

..

.

.

..

.

.

..

.

d

d

de

e

e

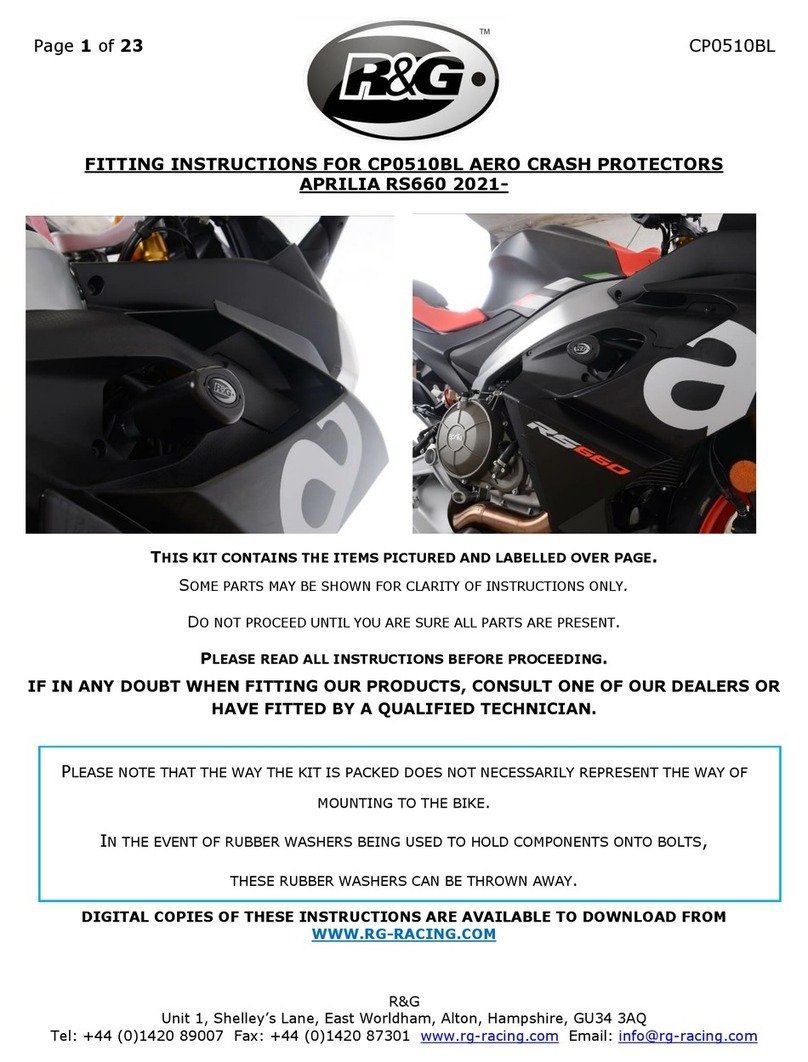

SPARKER TCI-P4

SPARKER TCI-P4 is an inductive ignition unit for road motorcycle. The ignition unit can be set by a computer PC with a

program TCIP4.EXE. Advance (time of ignition) can be set as a function of revolution or as a function of revolution and

TPS (throttle position sensor). Ignition contains outputs for tachometer, fuel pump relay, and servo controller. It contains

also two inputs for blocking of ignition and one for servo controller. It is by the time of programming connected with

computer PC by serial port (COM). The program TCIP4.EXE is included to ignition unit.

HARDWARE

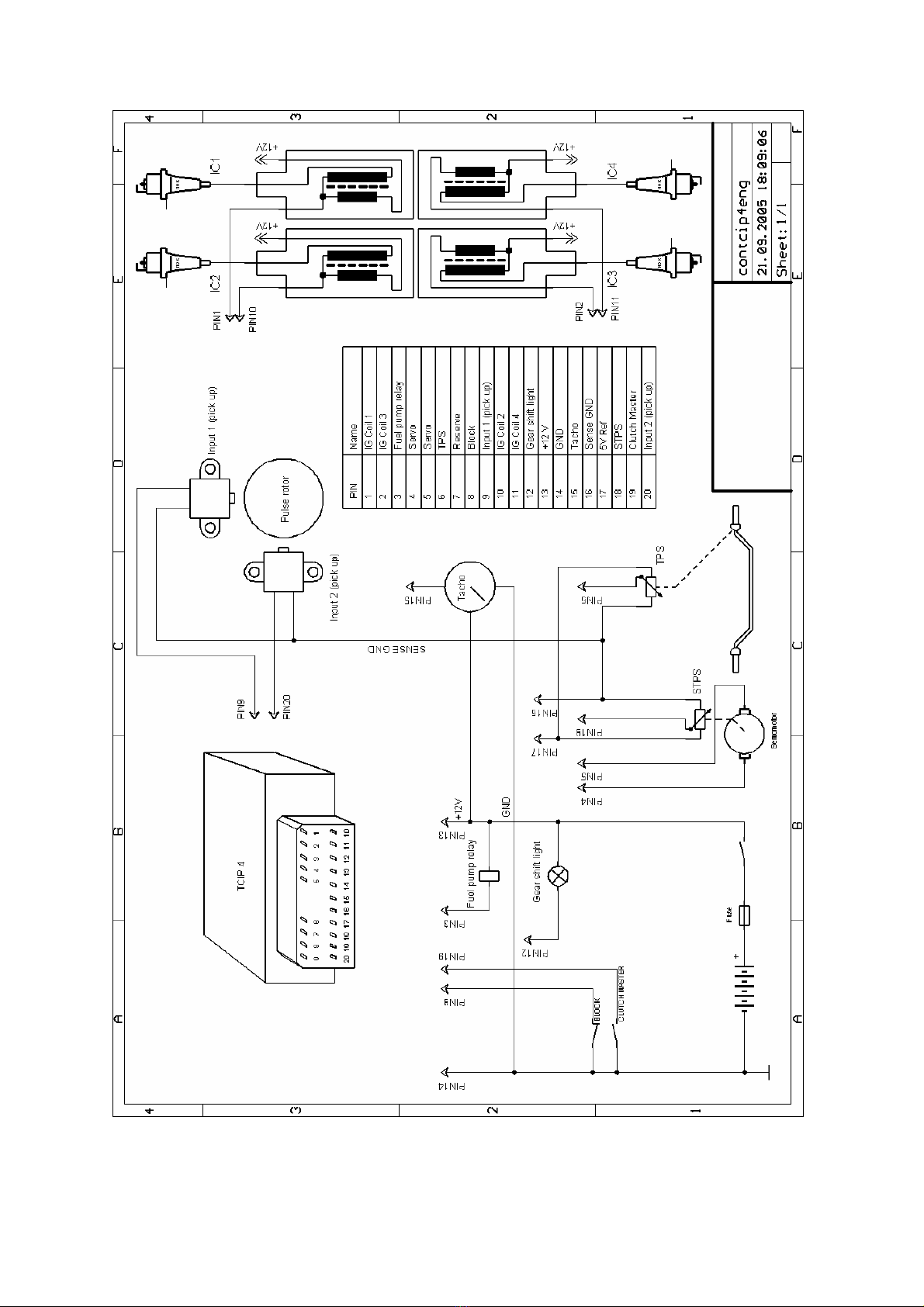

Pick up system.

Ignition can have maximal four channels. Standard version has two channels (four-cylinder engine). Ignition can be

programmed for many pickup systems. Most of them can be choose directly from list in program TCIP4.EXE others can be

set by special procedure (also by program TCIP4.EXE).

Supply voltage +12 V input.

Supply voltage must be within 8 – 18 voltage range. In this range the unit is able to provide optimal control of all the

processes. Supply voltage is connected by positive outlet to +12 V (13) and by negative outlet to GND (14).

Throttle position sensor TPS input.

An input is ready for standard TPS sensors used on motorbikes. It is designed for voltage range 0 - 5 V. Sensor settings for

0 % and 100 % is set by TCIP4.EXE software.

TPS is powered by referential voltage + 5 V (17) and SENSE GND (16). Sensor outlet will be connected to connector (6).

Crankshaft position sensor CKPS input.

An input is ready for standard pickup sensors used on motorbikes as CKPS.

One outlet of the CKPS should be connected to connector (9) and the other one should be connected to SENSE GND (16).

See following the chart. For system with two pick-ups should be one outlet of the second pick-up connected to connector

(20) and the other one should be connected to SENSE GND (16). See following the chart.

Blocking input.

One outlet of blocking switch (for example side stand switch) should be connected to connector (8) and other one should be

connected to SENSE GND (14) or GND (16). If the blocking switch is active the ignition is blocked. Opposite polarity of

blocking input can be set by software TCIP4.EXE.

Induction coils IC 1, IC 2, IC 3, IC 4 outputs

One outlet of induction coil of cylinder 1, 4 should be connected to key switched + 12 V and the other one should be

connected to corresponding connector IC 1, 4 (1). One outlet of induction coil of cylinder 2, 3 should be connected to key

switched + 12 V and the other one should be connected to corresponding connector IC 2, 3 (10).

Excitation (dwell time) of induction coil can be set to short or long by software TCIP4.EXE. Short dwell time is for

induction coil with primary coil resistance less than 2 Ohm. If long time is used for that one coil, coil can be destroyed. If it

is used short time for coil that desire long dwell time, the energy of spark could be small especially in high rpm.

Revolution indicator - TACHO output.

The revolution indicator output is compatible with most of board devices used on motorbikes. Pulse number for one

revolution and corrections is set within TCIP4.EXE software. TACHO output should be connected to connector (15).

FUEL PUMP RELAY output.

Fuel relay is switch on while the motor is running, for about 4 s after the unit is switched on and for about 4 sec. after motor

has stopped. One fuel pump relay outlet should be connected to connector (3) and the other one should be connected to key

switched + 12V. Connect the switched fuel pump relay circuit following the diagram.

2

w

w

ww

w

ww

w

w

.

.

.

-

--

-

-

--

-

-

--

-p

pp

p

p

pp

p

p

pp

pr

rr

r

r

rr

r

r

rr

ro

oo

o

o

oo

o

o

oo

o-

--

-

-

--

-

-

--

-m

mm

m

m

mm

m

m

mm

mi

ii

i

i

ii

i

i

ii

il

ll

l

l

ll

l

l

ll

ll

ll

l

l

ll

l

l

ll

le

ee

e

e

ee

e

e

ee

e.

..

.

.

..

.

.

..

.

d

d

de

e

e

Outputs and input for SERVO.

Outputs and input for servo are compatible with most of servo used on motorbikes (e.g.. Yamaha EXUP). Ignition with

servo is only done on demand.

Output for GEAR SHIFT LIGHT

Maximal current is 5 A (lamp max. 50 W). Revolution for gearshift light is set by software TCIP4.EXE.

One outlet of gearshift light should be connected to connector (12) and other to switched +12 V.

CLUTCH MASTER input.

One outlet of CLUTCH MASTER switch should be connected to connector (19) and the other one should be connected to

SENSE GND (16) or GND (14). If CLUTCH MASTER switch is activated, the unit blocks ignition for a defined period of

time. This provides for higher gearshift without clutch and gas shut-off, thus minimizing the time losses during gear

shifting. Blocking time can be adjusted within TCIP4.EXE software. Reverse polarity of the CLUTCH MASTER switch

can be configured within TCIP4.EXE software.

WIRE COLOUR

pin no.

in connector

NAME DESCRIPTION

orange 1 IC 1 inductive coil 1,4

2 IC 3 not connected in standard

violet 3 FUEL PUMPE RELAY

inductive coil 2,3

green 4 M output for servomotor

green 5 M output for servomotor

grey 6 TPS throttle position sensor

7 not connected

black 8 BLOCK blocking input

yellow 9 CKPS (1) input for pick-up (1)

white 10 IC 2 inductive coil 2,3

11 IC 4 not connected in standard

12 GEAR SHIFT LIGHT output for gear shift light

red 13 + 12 V supply 12 V

blue 14 GND ground

green/yellow 15 TACHO output for tachometer

blue 16 SENSE GND ground for sensors

white/red 17 + 5 V supply for sensors

white/blue 18 STPS servo position sensor

19 CLUTCH MASTER input for gear shift sensor

brown 20 CKPS (2) input for pick-up (2)

3

4

w

w

ww

w

ww

w

w

.

.

.

-

--

-

-

--

-

-

--

-p

pp

p

p

pp

p

p

pp

pr

rr

r

r

rr

r

r

rr

ro

oo

o

o

oo

o

o

oo

o-

--

-

-

--

-

-

--

-m

mm

m

m

mm

m

m

mm

mi

ii

i

i

ii

i

i

ii

il

ll

l

l

ll

l

l

ll

ll

ll

l

l

ll

l

l

ll

le

ee

e

e

ee

e

e

ee

e.

..

.

.

..

.

.

..

.

d

d

de

e

e

SOFTWARE TCIP4.EXE

Pull down menus

File – includes items New - default settings

Open - opens data file

Save - saves data file

Print - prints the current settings

Print all - prints the current settings all tab sheets

Exit - exits the program

Clicking New results in default settings of all parameters. They value for four-stroke engine without TPS.

Port – includes items Com1 to Com10- selection of communication line

For PC without COM (USB only) apply adapter USB/RS232.

Device – includes items Read - reads data from the unit

Verify - compares data in PC with data in the unit

Program - sends data to the unit and conducts verification

Tools –include items of collective settings

Language – language settings: English, German, French and Czech

Help – includes items Help - opens assembly guide (this file)

About the program - data on the software (version, date)

Icons menus

- default settings

Warning!!! Clicking this icon results in automatic default settings of all parameters

- opens data file

- saves data file

- prints the current settings

- see pull down menu Device

Tab sheet Miscellaneous

Limiter - sets revolution of classic starting limiter

Revolutions without ignition - sets number of starting revolution without ignition

Excitation long - sets long excitation of induction coils

Programming after a change - automatic programming settings (after every change)

No reading - reading is not allowed (after programming with this option data cannot be

retrieved from the unit)

Switch activation - input logic settings (if the box is checked the function is activated by switch on input)

5

w

w

ww

w

ww

w

w

.

.

.

-

--

-

-

--

-

-

--

-p

pp

p

p

pp

p

p

pp

pr

rr

r

r

rr

r

r

rr

ro

oo

o

o

oo

o

o

oo

o-

--

-

-

--

-

-

--

-m

mm

m

m

mm

m

m

mm

mi

ii

i

i

ii

i

i

ii

il

ll

l

l

ll

l

l

ll

ll

ll

l

l

ll

l

l

ll

le

ee

e

e

ee

e

e

ee

e.

..

.

.

..

.

.

..

.

d

d

de

e

e

TPS - limit TPS voltage values can be set here [mV]

- measures and sets 0% TPS (supply on, unit connected with PC, no gas)

- measures and sets 100% TPS (supply on, unit connected with PC, full gas)

File: - full path of using file

Tab sheet Motorcycle

Choice of pickup system - Choice of pickup system for certain motorcycle

Pulses per revolution - Setting of tacho output

Correction - Correction of tacho in %

Tab sheet Advance map

Advance map

TP map includes 100 adjustable advance options (in relation revolution and throttle position). Collective setting of the

whole column is possible using the arrows under columns. Collective adjustment of the whole map can be done by

collective change tool (+and –buttons with selection All)

When the motor is running and PC connected with the unit current segment in the fuel map is highlighted. Use of collective

change tool +and –button without selection All - just the current segment will be changed.

TPS - option advance map/advance curve

Base advance - setting of base advance

BASE

ADVANCE

Tab sheet Servo

Servo allowed - software activation of servo controller

10 adjustable options for revolution/required voltage of servo position sensor

Collective adjustment of the whole servo curve can be done by collective change tool (+and –buttons with selection All)

When the motor is running current segment is highlighted in the servo curve. Use of collective change tool +and –button

without selection All - just the current segment will be changed.

Hysteresis – fineness of servo driver steps can be set here

!!!Warning!!! - in case you set too low value there is a risk of servo oscillation

6

w

w

ww

w

ww

w

w

.

.

.

-

--

-

-

--

-

-

--

-p

pp

p

p

pp

p

p

pp

pr

rr

r

r

rr

r

r

rr

ro

oo

o

o

oo

o

o

oo

o-

--

-

-

--

-

-

--

-m

mm

m

m

mm

m

m

mm

mi

ii

i

i

ii

i

i

ii

il

ll

l

l

ll

l

l

ll

ll

ll

l

l

ll

l

l

ll

le

ee

e

e

ee

e

e

ee

e.

..

.

.

..

.

.

..

.

d

d

de

e

e

Monitor

Monitor is located on the right and lower side of the screen – sensor values and motor operational characteristics can be

observed here. Should there be No connection with PC prompt displayed in the upper right corner, the unit is not

connected.

RPM - motor revolution [1/min]

TP - Throttle position [%]

Advance - Ignition advance [°]

Pick up 1 - display whether pick up 1 is running or stopped

Pick up 2 - display whether pick up 2 is running or stopped

U- supply voltage [V]

Servo required - Required value of servo position sensor

Servo measured - Measured value of servo position sensor

Blocking - Blocking activation signal

Number of programming - Number of times the unit has been programmed

1M o t o r - S p o r t – S e r v i c e Stand: 01.10.2005

Markus Schmitt, Am Frankengrund 1, 36093 Künzell

Tel.: 0661-93350031 Mobil: 0173-9438673 FAX 0661-93350032

millemille

mille

Table of contents

Other Sparker Motorcycle Accessories manuals

Popular Motorcycle Accessories manuals by other brands

Bell

Bell FULL FACE user manual

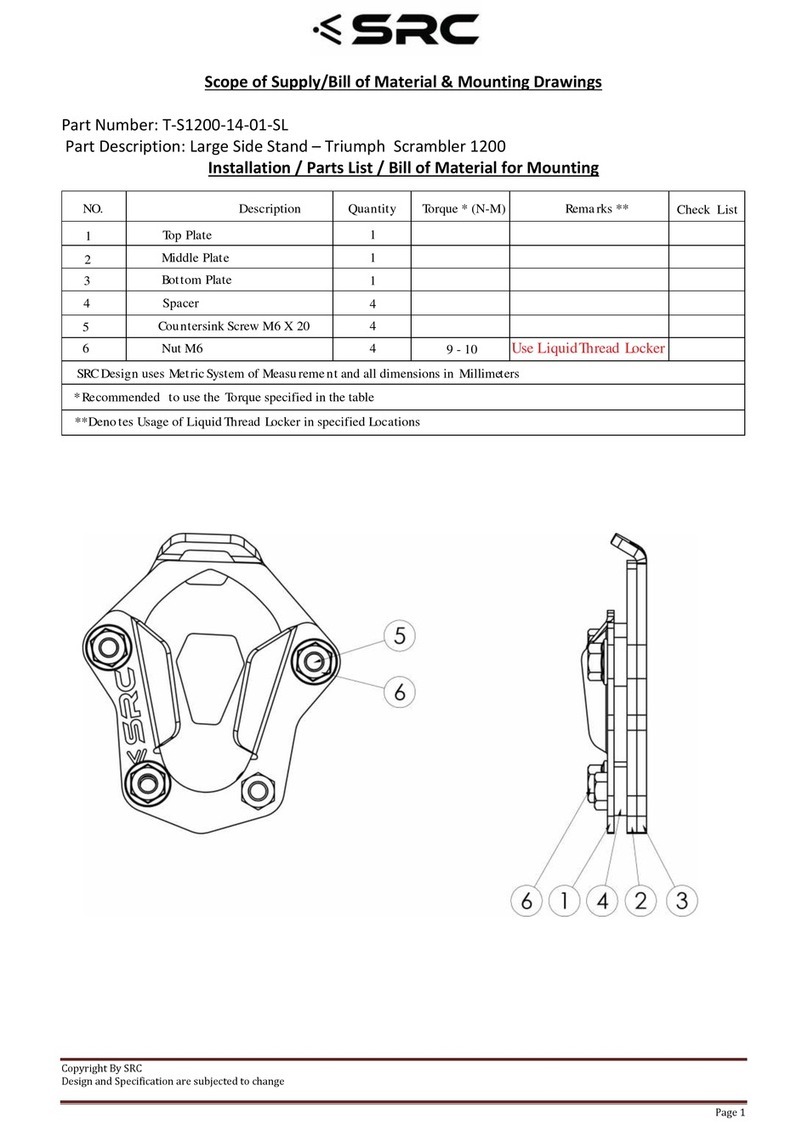

SRC

SRC T-S1200-14-01-SL quick start guide

Vinz

Vinz Laghi instruction manual

Custom Dynamics

Custom Dynamics Street Magic Amber Brightsides Install instructions

Wolfman

Wolfman E-Base B200 Mounting instructions

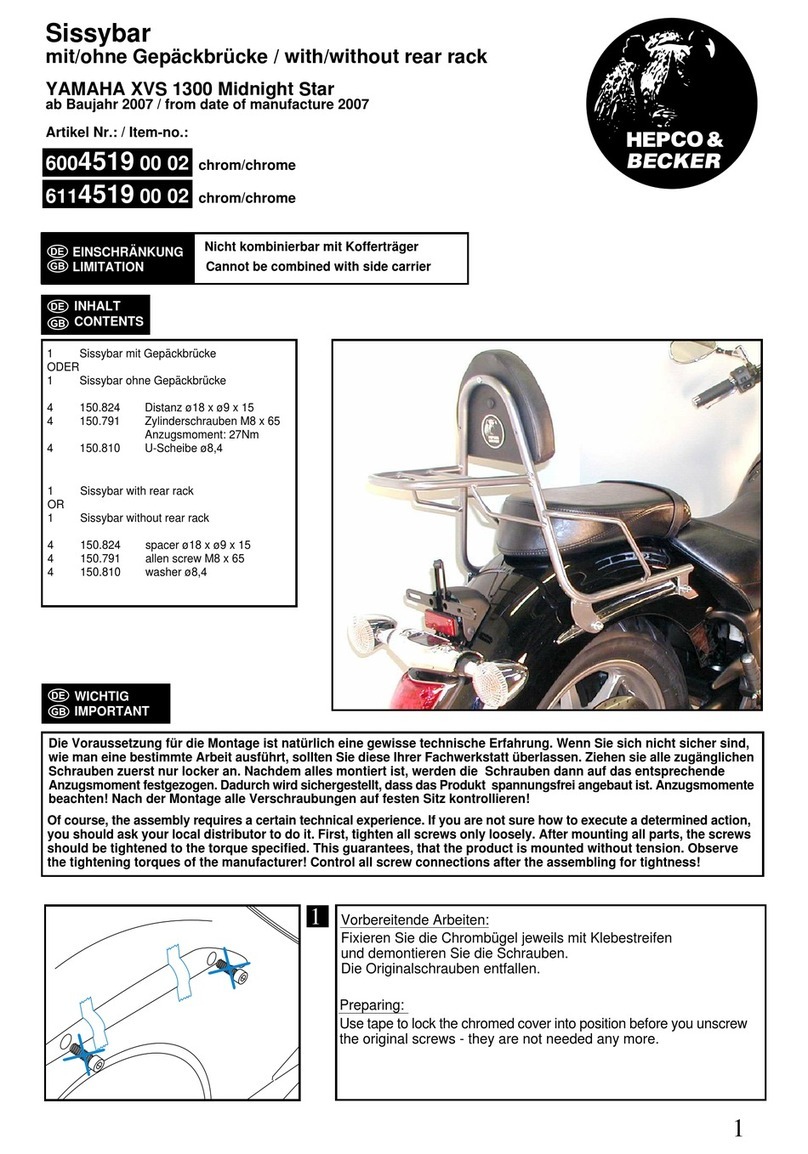

hepco & becker

hepco & becker 6004519 00 02 installation instructions