Sparker DC-CDIP 2 RACE User manual

SPARKER DC-CDIP 2 RACE

SPARKER DC-CDI-P2 RACE is a conductive ignition unit for road motorcycles. T e ignition unit can be programmed via a

computer and it is fully tunable as regards ignition timing. It contains an ignition advance curve/map depending on engine

revolutions and t rottle position. It also contains perip eries suc as: tac ometer output, four multifunction "power outputs",

outputs and input for servo-ex aust-c okes, t ree multifunction inputs and a configurable input for a correction potentiometer.

During programming, t e ignition unit is connected to a computer via a serial port. A setup application " DCCDIP2race.EXE"

is included wit t e ignition unit. Connection is provided via a waterproof connector JAE MX23A 26-NF1.

HARDWARE

Sensing system.

T e ignition unit as two c annels and it can be used wit almost all sensing systems. Selected sensing systems are set up

directly from a drop-down list in t e "DCCDIP2race.EXE" application. Ot er sensing systems can be set up using a special

procedure in t e DCCDIP2race.EXE application.

Supply voltage B+12 V input.

Supply voltage must be wit in t e range from 8 to 18 V. Wit in t is range, t e ignition unit is able to optimally control all

processes. T e ignition unit will be switc ed off if voltage decreases below 8 V or exceeds 18 V. Supply voltage is connected

wit t e positive pole to outlet no. 7 and wit t e negative pole to outlets no. 15 and 16.

Throttle position sensor TPS) input.

T e input is designed for standard t rottle position sensors used in motorcycles. It can accept voltages from 0 to 5 V. Sensor

settings for 0 % and 100 % are included in t e "DCCDIP2race.EXE" application.

TPS is supplied wit reference voltage + 5 V (outlet no. 20) and sensing ground (outlet no. 23). Sensor output is connected to

outlet no. 6.

Crankshaft position sensor CKPS) inputs.

Inputs are prepared for standard pick-up sensors (coil-magnet) used in motorcycles as CKPS. One outlet of t e CKPS is

connected to t e connector (outlet no. 13) and t e second outlet is connected to sensing ground (outlet no. 23). In case of a

two-sensor sensing system, one outlet of t e second sensor is connected to t e connector (outlet no. 26) and t e second outlet is

connected to sensing ground (outlet no. 23).

Multifunction input 1.

One outlet of t e sensor is connected to t e connector (outlet no. 25) and t e second outlet is connected to ground. If you

activate t e switc , a function selected by t e "DCCDIP2race.EXE" application will be executed.

Multifunction input 2.

One outlet of t e switc or sensor is connected to t e connector (outlet no. 24) and t e second outlet is connected to ground. If

you activate t e switc , a function selected by t e "DCCDIP2race.EXE" application will be executed. If "Speed gear" is

selected, a variable resistor (w ic senses t e position of t e engaged speed gear) will be connected to t is input.

Multifunction input 3.

One outlet of t e sensor is connected to t e connector (outlet no. 22) and t e second outlet is connected to ground. If you

activate t e switc , a function selected by t e "DCCDIP2race.EXE" application will be executed. If "Speed" is selected, t e

output of an impulse speed sensor (must be of t e " all" type) will be connected to t is outlet.

POTENTIOMETER input.

T e correction potentiometer wiper will be connected to t is input (outlet no. 12); its front will be connected to sensing ground

(outlet no. 23) and its end to reference voltage + 5 V REF (outlet no. 20) . Use t e "DCCDIP2race.EXE" application to select

w ic value will be corrected by t e potentiometer.

Outputs for induction coils IC 1, IC 2.

One outlet of induction coil IC 1 will be connected to t e connector (outlet no. 14) and t e second outlet will be connected to

ground! One outlet of induction coil IC 2 will be connected to outlet no. 1 and t e second outlet will be connected to ground!

Warning!!! If you connect t e second end of t e induction coil to +12 V instead of t e ground, t e ignition unit will be

destroyed.

Tachometer output.

T e tac ometer output is compatible wit most das board instruments used on motorcycles. T e number of pulses per one

revolution is set in t e "DCCDIP2race.EXE" application.

T e tac ometer is supplied wit +12 V against GND. T e tac ometer input is connected to t e connector (outlet no. 19).

"Power output" 1.

T is is a multifunction output (open-type collector) w ic can be set via t e "DCCDIP2race.EXE" application to execute one

of pre-defined functions. It is outlet no. 2 in t e connector. T e instrument is connected wit one end to outlet no. 2 and wit

t e second end to + 12 V.

Power output 1 is predefined (default) as a fuel pump relay switc .

"Power output" 2.

T is is a multifunction output (open-type collector) w ic can be set via t e "DCCDIP2race.EXE" application to execute one

of pre-defined functions. It is outlet no. 3 in t e connector. T e instrument is connected wit one end to outlet no. 3 and wit

t e second end to + 12 V.

Power output 2 is predefined (default) as a gear-s ift pilot lig t switc .

"Power output" 3.

T is is a multifunction output (open-type collector) w ic can be set via t e "DCCDIP2race.EXE" application to execute one

of pre-defined functions. It is outlet no. 5 in t e connector. T e instrument is connected wit one end to outlet no. 5 and wit

t e second end to + 12 V.

Power output 3 is predefined (default) as a "POWERJET" electromagnetic valve switc .

"Power output" 4.

T is is a multifunction output (open-type collector) w ic can be set via t e "DCCDIP2race.EXE" application to execute one

of pre-defined functions. It is outlet no. 11 in t e connector. T e instrument is connected wit one end to outlet no. 11 and wit

t e second end to + 12 V.

Power output 4 is predefined (default) as a general use switc .

Outputs and input for SERVO.

Outputs and input for servo are compatible wit most brus servomotors used on motorcycles.

T e servo motor is connected to outlets no. 4 and 17. T e wiper of t e servo's sensing potentiometer is connected to outlet no.

8. T e servo's potentiometer is supplied wit reference voltage + 5 V (outlet no. 20) and sensing ground (outlet no. 23).

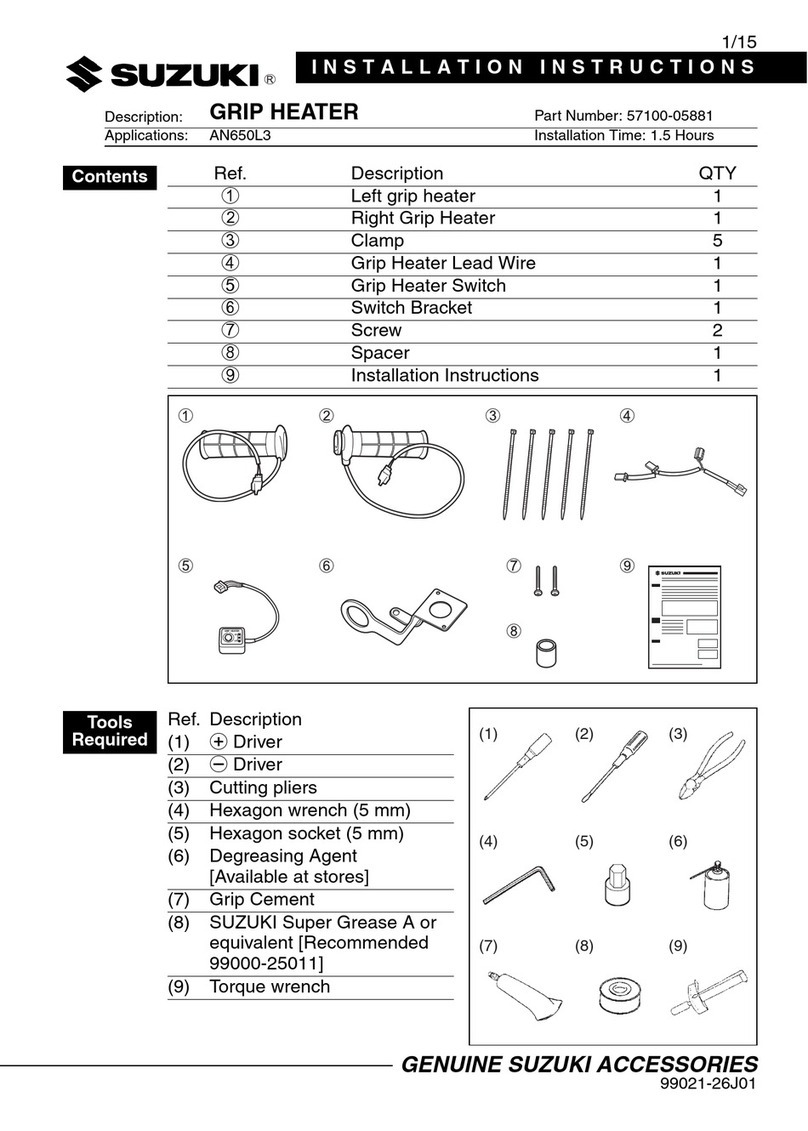

DCCDIP2 race - color, position wires.

color in cable

adapter

pin no. in

connector

name description

w ite 1 IC 2 ignition coil 2

violet 2 POWER OUT 1 Power out 1 (fuel pump relay)

blue/w ite 3 POWER OUT 2 Power out 2 (gear s ift lig t)

green 4 MOTOR+ EXUP output for servomotor

pink 5 POWER OUT 3 Power out 3 (POWER JET Honda)

grey 6 TPS t rottle position sensor input

red 7 SUPPLY +12V supply +12 V

w ite/blue 8 STPS servomotor position sensor input

black 9 RS232 (pin 2 in 9pin connector)

yellow 10 RS232 (pin 3 in 9pin connector)

violet/black 11 POWER OUT 4 Power out 4

w ite/black 12 POT correction potentiometer

yellow 13 PICK-UP 1 pickup 1

orange 14 IC 1 ignition coil 1

blue 15 GND power ground

blue 16 GND ground for RS232 (pin 5 in 9pin connector)

green 17 MOTOR- EXUP output for servomotor

orange 18 RS232 connector (pin 9 in 9pin connector)

green/yellow 19 TACHO OUT tac ometer output

w ite/red 20 V REF +5 V supply +5V for sensors

violet 21 RS232 connector (pin 1 in 9pin connector)

grey/black 22 INPUT 3 multifunction input 3

lig t blue 23 SENSE GND ground for sensors

black 24 INPUT 2 multifunction input 2

grey/red 25 INPUT 1 multifunction input 1

brown 26 PICK-UP 2 pickup 2

DCCDIP2 race - recommended wiring.

3

"DCCDIP2race.EXE" application

Drop-down menus

File - items: New - default data setting

Open - opens a data file

Open from EXE dir - opens a data file from t e location w ere t e program

is installed

Save - saves a data file

Save to EXE dir - saves a data file to t e location w ere t e program is

installed Print - prints t e current setting

of t e current tab

Print all - prints t e current settings all tabs

Exit - exits t e program

New - sets default values for all parameters

T ese correspond approx. to a four-cycle engine wit out

a TPS.

Port - contains items Com1 to Com auto - selection

communication lines, manually or automatically

For PCs w ic only ave a USB port, it is necessary to

use t e adapter USB/RS232.

Ignition - items: Read F7 - reads data from t e unit

Verify F8 - compares data in t e PC and in t e unit

Program F9 - sends data to t e unit and verifies it

Tools - items: Minus F4 - ot key for adding on t e active tab

Plus F5 - ot key for subtracting on t e active tab

Language - contains language setting items: Englis , German,

Frenc and Czec

Help - items: Help - opens t e Assembly instructions (t is file)

About the program - information about t e program (version, date)

Icon menus

- sets default values

Warning!!! Click t is icon to automatically set all parameters to t eir default values.

- opens a data file

- saves a data file

- prints t e current setting

- step back

- step forward

4

- see t e Device drop-down menu

Motorcycle tab

Motorcycle type - selection of a sensing system for a specific motorcycle

Number of revolutions without ignition - sets t e number of revolutions at w ic t ere will be no ignition

Opposite polarity of sensor 1 - allows t e setting of opposite polarity (first negative) on sensor 1

Opposite polarity of sensor 2 - allows t e setting of opposite polarity (first negative) on sensor 2

Synchronization description * - met od of sync ronization (consult wit t e manufacturer)

- c annel 1 - assignment of an ignition position for t e first c annel

- c annel 2 - assignment of an ignition position for t e second

c annel

- setting of t e number of ignitions per one revolution

Correction - percentual correction of t e tac ometer output value

Number of pulses per one revolution - roug setting of t e tac ometer output

Reading ban - if t is field is activated and saved in ignition, it will not be possible

to read t e data saved in ignition

* T e settings in t is menu are only active if a "special" type motorcycle is selected.

Inputs tab

Functions are assigned to multifunction inputs on t is tab.

Input 1 may ave t e following functions *

- Off: T e input as no function.

- Kill switc : If t e input is activated, ignition is not performed.

- Blocking: If t e input is not activated, ignition is not performed.

- Clutc master: After activation, an operation is performed in ignition according to t e "Race" tab.

- Ignition advance reduction: After activation, t e ignition advance decreases – see t e column next.

- Starting limiter: After activation, revolution limiters are reconfigured according to t e "Limiter" column

on t is tab.

- 2nd ignition advance map: After activation, ignition advance will be activated according to t e

"Ignition Advance 2" map.

Input 2 may ave t e following functions *

- Off: T e input as no function.

- Kill switc : If t e input is activated, ignition is not performed.

- Blocking: If t e input is not activated, ignition is not performed.

- Clutc master: After activation, an operation is performed in ignition according to t e "Race" tab.

- Ignition advance reduction: After activation, t e ignition advance decreases – see t e column next.

- Starting limiter: After activation, revolution limiters are reconfigured according to t e "Limiter" column

on t is tab.

- 2nd ignition advance map: After activation, ignition advance will be activated according to t e

"Ignition Advance 2" map.

- Speed gear: Wit t is selection, t e input measures voltage at a resistor sensor of t e engaged speed

gear; t is selection will be performed automatically if "Voltage" is selected in t e "Speed gear

determination" column on t e "Gear" tab. T e setup of individual values for speed gears is performed on

t e "Gear" tab.

Input 3 may ave t e following functions *

- Off: T e input as no function.

- Kill switc : If t e input is activated, ignition is not performed.

- Blocking: If t e input is not activated, ignition is not performed.

5

Table of contents

Other Sparker Motorcycle Accessories manuals