6

MR98 Series AD2000 Compliant

D-A-CH Region Only

▲ WARNING

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Fisher™ backpressure regulators,

relief and relief valves must be

installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations and

Emerson instructions.

If a leak develops or if the outlet

continually vents gas, service to the

unit may be required. Failure to correct

trouble could result in a hazardous

condition. Only a qualied person shall

install or service the unit.

Installation, operation and maintenance

procedures performed by unqualied

person may result in improper adjustment

and unsafe operation. Either condition

may result in equipment damage or

personal injury. Call a qualied person

when installing, operating and maintaining

the MR98 Series Backpressure Regulators,

Relief and Relief Valves.

Introduction

Scope of the Manual

This manual provides instructions for the installation,

adjustment, maintenance and parts ordering

information of MR98 Series Backpressure Regulators

and Relief Valves. Instructions and parts lists for other

equipment mentioned in this Instruction Manual are

found in separate manuals.

Product Description

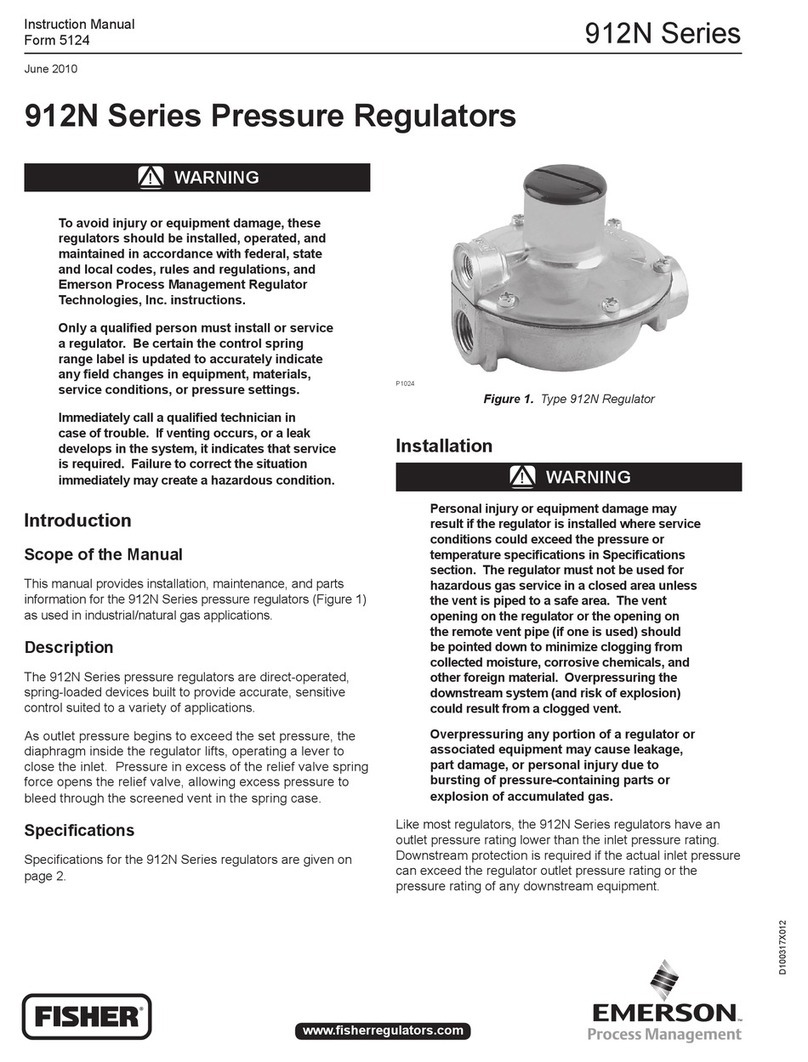

The MR98 Series Backpressure Regulator and Relief

Valves are suitable for multiple uid mediums including

liquid, gas, air and steam services. Typical applications

include use in but not limited to wash tanks, small

heaters, fuel and oil lines, air supply system, test

xtures and sterilizers.

Backpressure Regulator / Pressure Relief Valve—

Types MR98H and MR98HH Regulators are

direct-operated backpressure regulator/relief valve for

pressure control requiring constant outlet pressures

between 2 to 375 psig / 0.14 to 25.9 bar.

See Tables 1 through 4 for detailed breakdown of the

various construction oerings.

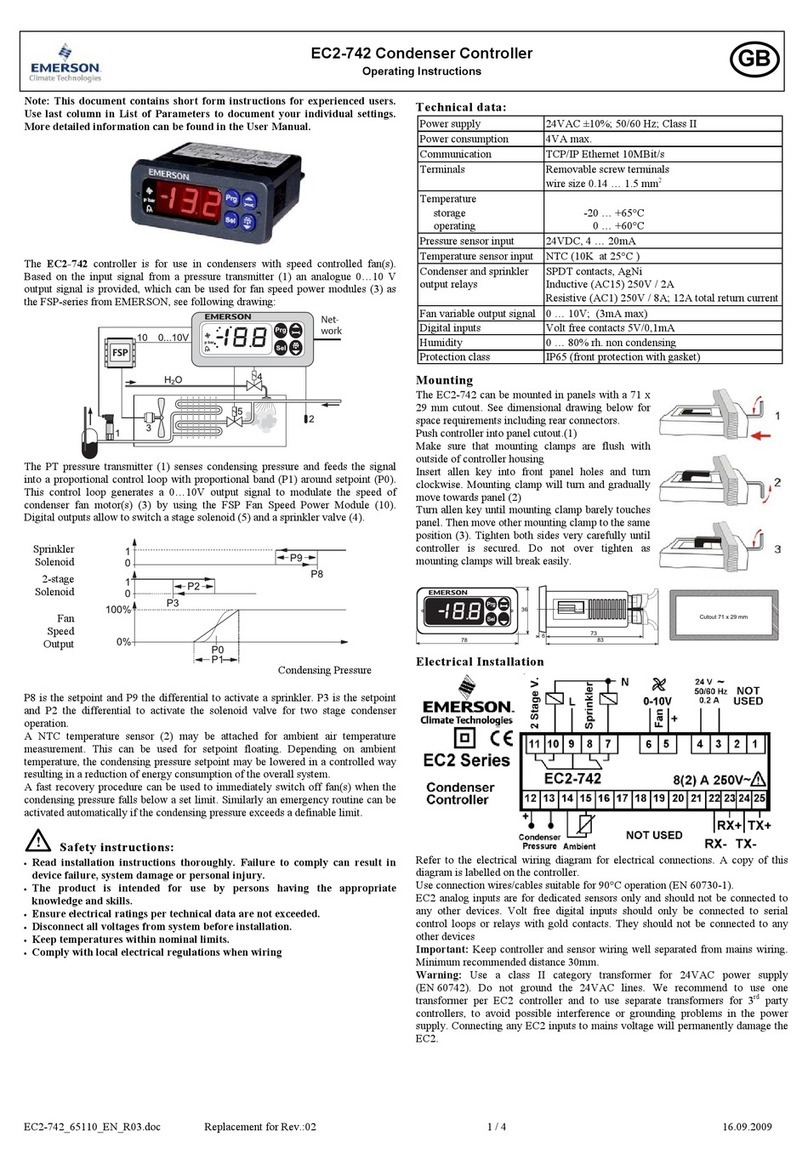

Principle of Operation

Relief or backpressure valves respond to changes in

upstream pressure. Pressure changes register under

the diaphragm (see Figure 2) through a registration hole

in the valve body or through an external control line.

When the pressure increases above the spring setting,

the pressure underneath the diaphragm overcomes the

spring compression. This causes the valve plug to move

away from the orice. The ow path through the valve

is open and excess pressure is vented. When upstream

pressure drops below setpoint, the valve closes.

Installation

▲ WARNING

Personal injury or system damage may

result if this backpressure regulator or

relief valve is installed where service

conditions could exceed the limits given

on the Specications section and/or

regulator nameplate.

Additionally, physical damage to the

backpressure regulator or relief valve

may result in personal injury or property

damage due to escaping of accumulated

gas. To avoid such injury and damage,

install the backpressure regulator or

relief valve in a safe location.

Under enclosed conditions or indoors,

escaping gas may accumulate and be an

explosion hazard. In this case, the vent

should be piped outdoors.

For regulator constructions with a

spring case vent, the vent should be

kept open to permit free ow of gas

to the atmosphere. Protect openings

against entrance of rain, snow, insects

or any other foreign material that may

plug the spring case vent or vent line.