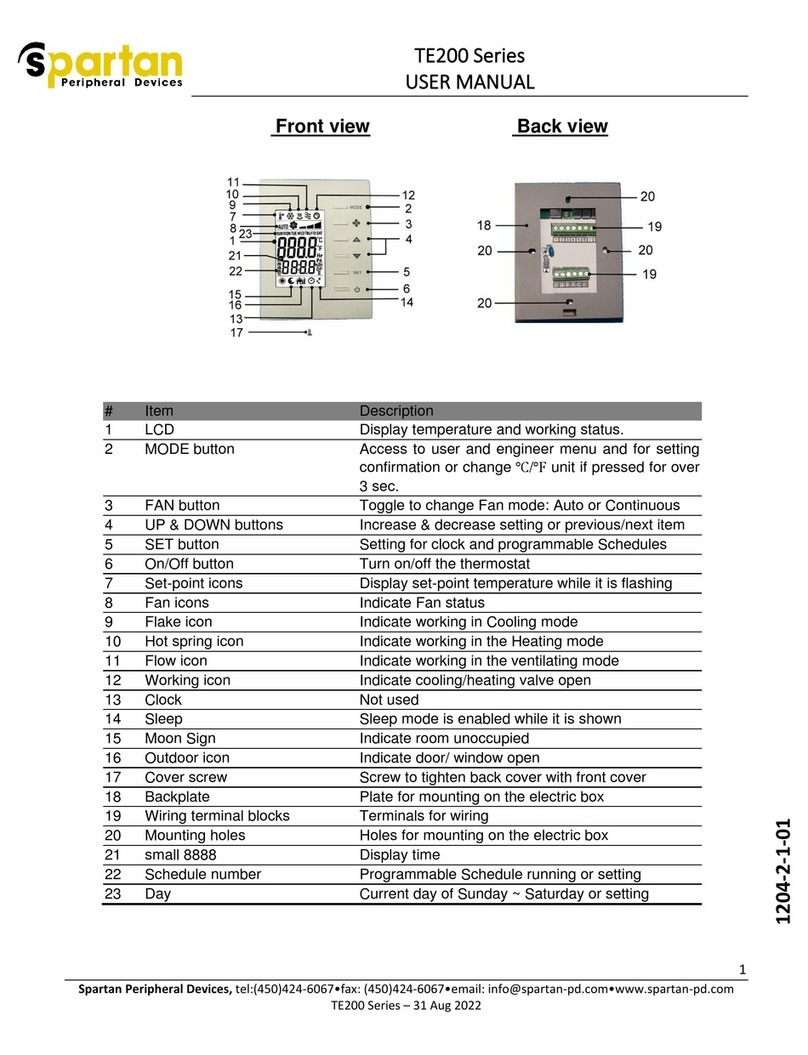

Spartan 87301 User manual

PREFACE

GENERAL COMMENTS

Congratulations on the purchase of your new SPARTAN EQUIPMENT product! This

product was carefully designed and manufactured to give you many years of dependable service.

Only minor maintenance (such as cleaning and lubricating) is required to keep it in top working

condition. Be sure to observe all maintenance procedures and safety precautions in this manual

and on any safety decals located on the product and on any equipment on which the attachment

is mounted.

This manual has been designed to help you do a better, safer job. Read this manual

carefully and become familiar with its contents.

WARNING!

Never let anyone operate this unit without reading the "Safety Precautions"

and "Operating Instructions" sections of this manual.

Always choose hard, level ground to park the vehicle on and set the brake so

the unit cannot roll.

Unless noted otherwise, right and left sides are determined from the operator's control

position when facing the attachment.

NOTE: The illustrations and data used in this manual were current (according to the

information available to us) at the time of printing, however, we reserve the right to redesign

and change the attachment as may be necessary without notification.

BEFORE OPERATION

The primary responsibility for safety with this equipment falls to the operator. Make sure

the equipment is operated only by trained individuals that have read and understand this

manual. If there is any portion of this manual or function you do not understand, contact your

local authorized dealer or the manufacturer.

SAFETY ALERT SYMBOL

This is the "Safety Alert Symbol" used by this industry. This symbol is used to warn

of possible injury. Be sure to read all warnings carefully. They are included for your

safety and for the safety of others working with you.

SERVICE

When servicing your product, remember to use only manufacturer replacement parts.

Substitute parts may not meet the standards required for safe, dependable operation.

To facilitate parts ordering, record the model and serial number of your unit in the space

provided on the cover of this manual. This information may be obtained from the identification

plate located on the product.

The parts department needs this information to insure that you receive the correct parts for

your specific model.

10344 8-20-05

SAFETY STATEMENTS

THIS SYMBOL BY ITSELF OR WITH A WARNING WORD THROUGHOUT THIS MAN-

UAL IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS INVOLVING YOUR

PERSONAL SAFETY OR THE SAFETY OF OTHERS. FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN INJURY OR DEATH.

THIS SIGNAL WORD IS USED WHERE SERIOUS INJURY OR DEATH WILL

RESULT IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

WARNING!

THIS SIGNAL WORD IS USED WHERE SERIOUS INJURY OR DEATH COULD

RESULT IF THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

THIS SIGNAL WORD IS USED WHERE MINOR INJURY COULD RESULT IF

THE INSTRUCTIONS ARE NOT FOLLOWED PROPERLY.

NOTICE INDICATES A PROPERTY DAMAGE MESSAGE.

GENERAL SAFETY PRECAUTIONS

READ MANUAL PRIOR TO INSTALLATION

Improper installation, operation, or maintenance of this equipment could result in serious

injury or death. Operators and maintenance personnel should read this manual, as well

as all manuals related to this equipment and the prime mover thoroughly before

beginning installation, operation, or maintenance. FOLLOW ALL SAFETY

INSTRUCTIONS IN THIS MANUAL AND THE PRIME MOVER'S MANUAL(S).

READ AND UNDERSTAND ALL SAFETY STATEMENTS

Read all safety decals and safety statements in all manuals prior to operating or working

on this equipment. Know and obey all OSHA regulations, local laws, and other

professional guidelines for your operation. Know and follow good work practices when

assembling, maintaining, repairing, mounting, removing, or operating this equipment.

KNOW YOUR EQUIPMENT

Know your equipment's capabilities, dimensions, and operations before operating.

Visually inspect your equipment before you start, and never operate equipment that is

not in proper working order with all safety devices intact. Check all hardware to ensure

it is tight. Make certain that all locking pins, latches, and connection devices are

properly installed and secured. Remove and replace any damaged, fatigued, or

excessively worn parts. Make certain all safety decals are in place and are legible.

Keep decals clean, and replace them if they become worn or hard to read.

10338 8-16-05

DANGER

WARNING

CAUTION

NOTICE

1.

WARNING!

WARNING!

WARNING!

GENERAL SAFETY PRECAUTIONS

PROTECT AGAINST FLYING DEBRIS

Always wear proper safety glasses, goggles, or a face shield when driving pins in or

out, or when any operation causes dust, flying debris, or any other hazardous material.

LOWER OR SUPPORT RAISED EQUIPMENT

Do not work under raised booms without supporting them. Do not use support material

made of concrete blocks, logs, buckets, barrels, or any other material that could

suddenly collapse or shift positions. Make sure support material is solid, not decayed,

warped, twisted, or tapered. Lower booms to ground level or on blocks. Lower booms

and attachments to the ground before leaving the cab or operator's station.

USE CARE WITH HYDRAULIC FLUID PRESSURE

Hydraulic fluid under pressure can penetrate the skin and cause serious injury or

death. Hydraulic leaks under pressure may not be visible. Before connecting or dis-

connecting hydraulic hoses, read your prime mover's operator's manual for detailed

instructions on connecting and disconnecting hydraulic hoses or fittings.

Keep unprotected body parts, such as face, eyes, and arms as far away as

possible from a suspected leak. Flesh injected with hydraulic fluid may develop

gangrene or other permanent disabilities.

If injured by injected fluid, see a doctor at once. If your doctor is not familiar with

this type of injury, ask him to research it immediately to determine proper treat-

ment.

Wear safety glasses, protective clothing, and use a piece of cardboard or wood

when searching for hydraulic leaks. DO NOT USE YOUR HANDS!

SEE ILLUSTRATION.

CARDBOARD

HYDRAULIC HOSE

OR FITTING

MAGNIFYING GLASS

10339 8-16-05

WARNING!

WARNING!

GENERAL SAFETY PRECAUTIONS

DO NOT MODIFY MACHINE OR ATTACHMENTS

Modifications may weaken the integrity of the attachment and may impair the function,

safety, life, and performance of the attachment. When making repairs, use only the

manufacturer's genuine parts, following authorized instructions. Other parts may be

substandard in fit and quality. Never modify any ROPS (Roll Over Protection Structure)

or FOPS (Falling Object Protective Structure) equipment or device. Any modifications

must be authorized in writing by the manufacturer.

SAFELY MAINTAIN AND REPAIR EQUIPMENT

Do not wear loose clothing or any accessories that can catch in moving parts. If you

have long hair, cover or secure it so that it does not become entangled in the

equipment.

Work on a level surface in a well-lit area.

Use properly grounded electrical outlets and tools.

Use the correct tools for the job at hand. Make sure they are in good condition for the

task required.

Wear the protective equipment specified by the tool manufacturer.

SAFELY OPERATE EQUIPMENT

Do not operate equipment until you are completely trained by a qualified operator in

how to use the controls, know its capabilities, dimensions, and all safety requirements.

See your machine's manual for these instructions.

Keep all step plates, grab bars, pedals, and controls free of dirt, grease, debris,

and oil.

Never allow anyone to be around the equipment when it is operating.

Do not allow riders on the attachment or the prime mover.

Do not operate the equipment from anywhere other than the correct operator's

position.

Never leave equipment unattended with the engine running, or with this attach-

ment in a raised position.

Do not alter or remove any safety feature from the prime mover or this attach-

ment.

Know your work site safety rules as well as traffic rules and flow. When in doubt on

any safety issue, contact your supervisor or safety coordinator for an explanation.

10340 8-16-05

INSTALLATION AND OPERATION

GENERAL INFORMATION

The SPARTAN EQUIPMENT tilt attach installs onto the toolbar/quick-attach mechanism of your

skid steer loader and also attaches to your attachment in the same fashion as a universal quick attach.

Due to this arrangement, thorough knowledge of the skid steer controls is necessary for machine

operation. Read and understand your skid steer operator's manual instructions for attaching and

detaching an attachment.

INSTALLATION INSTRUCTIONS

2. Remove the shipping banding from around the tilt attach and skid.

3. Remove any attachments from the front of the loader.

4. Following all standard safety practices and the instructions for installing an attachment in your

skid steer operator's manual, install the tilt attach onto your skid steer.

NOTE: It is important to make sure the locking mechanism on your quick attach is en-

gaged, therefore locking the tilt attach onto the skid steer.

4. Lower the loader arms to the ground and remove the key.

5. Relieve any pressure from the auxiliary hydraulic system and install your hose kit to the elbows

on the top of the tilt attach and to the loader auxiliary hydraulics. If operating an attachment

(such as a bucket) that does not require hydraulics your tilt attach is ready to accept the

attachment.

6. Install the desired attachment to your tilt attach following the attachment manuals rec-

ommendations.

WARNING! ALWAYS CHECK LOCKING MECHANISM (PINS) BEFORE TILTING OR OP-

ERATING ANY ATTACHMENT.

If installing an attachment to your tilt attach that requires auxiliary hydraulics install one of the valve

kit packages.

2.

POSTMASTER VALVE INSTALLATION (Refer to the diagram and parts list in the back of

instructions.)

1. Install valve mounting bracket to the top of the tilt attach using the .38" hardware supplied.

Secure the valve #2243 to the bracket using the .31" hardware supplied and install the hose

loop to the side of the tilt attach by removing one of the .50" X 1.00"

capscrews from the left side and replacing with the 1.25" capscrew supplied.

Install elbows #3430 to the existing elbows on the tilt attach followed by the 45° end of

the 16.5" hose and the 21" hose. Install straight adapters #62208 to the middle ports of

the valve and connect the 90° ends of the hoses coming from the tilt attach.

Install elbows #3283 to the right side ports in the valve and straight adapters #3324 to the left

ports of the valve.

Remove the power and return hoses from the postmaster and install them into the straight

adapters installed in step #8. Route hoses through the hose loop and up to the

auxiliary hydraulics on the loader.

11066

7-24-08-2

3.

4.

INSTALLATION AND OPERATION

5. Install the two 30" hoses to the remaining elbows in the valve followed by the two #3133

elbows. Connect these to the post master in the same location the power and return hoses

were removed. Check all connections for leaks.

PD4800 POST DRIVER VALVE INSTALLATION (Refer to the diagram and parts list in the

back of instructions.)

1. Install valve mounting bracket to the top of the tilt attach using the .38" hardware sup-

plied. Secure the valve #2243 to the bracket using the .31" hardware supplied and install

the hose loop to the side of the tilt attach by removing one of the .50" X 1.00" capscrews

from the left side and replacing with the 1.25" capscrew supplied.

2. Install elbows #3430 to the existing elbows on the tilt attach followed by the 45° end of the

16.5" hose and the 21" hose. Install straight adapters #62208 to the middle ports of the

valve and connect the 90° ends of the hoses coming from the tilt attach.

3. Install straight connectors #30298 and #30289 to the right side ports in the valve followed

by one set of couplers, and straight adapters #3270 to the left ports of the valve.

4. Connect the power and return hoses from the post driver to the couplers installed in Step

#3. Connect the 80" long hoses #35379 to the connectors on the left ports of the valve

followed by the remaining couplers. Route hoses through the hose loop and up to the

auxiliary hydraulics on the loader. Check all connections for leaks.

UNIVERSAL VALVE INSTALLATION (Refer to the diagram and parts list in the back of

instructions.)

1. Install valve mounting bracket to the top of the tilt attach using the .38" hardware sup-

plied. Secure the valve #2243 to the bracket using the .31" hardware supplied and install

the hose loop to the side of the tilt attach by removing one of the .50" X 1.00" capscrews

from the left side and replacing with the 1.25" capscrew supplied.

2. Install the 45° end of the 16.5" hose and the 21" hose to the elbows on the tilt attach. Install

straight adapters #62208 to the middle ports of the valve and connect the 90° ends of the

hoses coming from the tilt attach.

3. Install elbows #3283 to the right side ports in the valve.

4. Connect the electrical wiring on the diverter valve to the auxiliary electrical connector on

the skid steer loader or to the optional Spartan Equipment control box.

NOTE: The hoses going to the attachment will attach to right side ports of the valve. Attach

hoses going to the loader auxiliary hydraulics to the left side ports of the diverter valve.

Work with your local dealer to obtain appropriate hoses necessary to complete the

hydraulic circuit for the desired attachment hook-up.

WARNING! ALWAYS CHECK LOCKING MECHANISM (PINS) BEFORE TILTING OR OP-

ERATING ANY ATTACHMENT.

11067 7 -24-08-2

5.

MAINTENANCE

&

SERVICE

GENERAL INFORMATION

Regular maintenance is the key to long equipment life and safe operation. Maintenance

requirements have been reduced to the absolute minimum. However, it is very important that

these maintenance functions be performed as described below.

DAILY

Check all bolts and nuts for tightness.

Replace any missing bolts or nuts with approved replacement parts.

Check hydraulic system for hydraulic oil leaks. See procedure below.

Visually inspect the machine for worn parts or cracked welds, and repair

as necessary.

EVERY 40 HOURS

Lubricate all grease fittings.

WARNING!

Escaping fluid under pressure can have sufficient force to penetrate the skin,

causing serious personal injury. Fluid escaping from a very small hole can be

almost invisible. Use a piece of cardboard or wood, rather than hands, to

search for suspected leaks.

Keep unprotected body parts, such as face, eyes, and arms as far away as

possible from a suspected leak. Flesh injected with hydraulic fluid may

develop gangrene or other permanent disabilities.

If injured by injected fluid, see a doctor at once. If your doctor is not familiar

with this type of injury, ask him to research it immediately to determine proper

treatment.

CARDBOARD

MAGNIFYING GLASS

HYDRAULIC HOSE

OR FITTING

IMPORTANT: When replacing parts, use only factory approved replacement parts. Manu-

facturer will not claim responsibility for use of unapproved parts or accessories, and/or other

damages as a result of their use.

8921 4-2-07-3-2

6.

7.8.9.

MAINTENANCE AND SERVICE

CYLINDER SEAL REPLACEMENT

The following information is provided to assist you in the event you should need to repair or rebuild a hydraulic

cylinder. When working on hydraulic cylinders, make sure that the work area and tools are clean and free of dirt to

prevent contamination of the hydraulic system and damage to the hydraulic cylinders. Always protect the active part of

the cylinder rod (the chrome section). Nicks or scratches on the surface of the rod could result in cylinder failure. Clean

all parts thoroughly with a cleaning solvent before reassembly.

DISASSEMBLY PROCEDURE

IMPORTANT: Do not contact the active surface of the cylinder rod with the vise. Damage to the rod could

result.

3. Remove the hex nut, piston, flat washer or spacer tube (if so equipped), and gland from the cylinder rod. If the

cylinder rod is rusty, scratched, or bent, it must be replaced.

4. Remove and discard all the old seals.

ASSEMBLY PROCEDURE

IMPORTANT: Replace all seals even if they do not appear to be damaged. Failure to replace all seals may result

in premature cylinder failure. NOTE: Seal kits will service most cylinders of similar bore size and rod diameter.

1. Install the cylinder rod seal in the gland first. Be careful not to damage the seal in the process, as it is

somewhat difficult to install.

NOTE: A special installation tool (Part #65349) is available to help with installing the seal. Simply fit the end of the tool

over the seal so that the large prong of the tool is on the outside of the seal, and the two smaller prongs on the inside.

The lip of the seal should be facing towards the tool. Rotate the handles on the tool around to wrap the seal around the

end of the tool.

1 0356 10-13-05

THREADED TYPE GLAND

1. Rotate the gland with a spanner wrench counterclockwise until the gland is free of the cylinder tube.

2. Pull the cylinder rod from the cylinder tube and inspect the piston and the bore of the cylinder tube for

deep scratches or galling. If damaged, the piston AND the cylinder tube must be replaced.

10.

11.

MAINTENANCE AND SERVICE

Now insert the seal into the gland from the inner end. Position the seal in

its groove, and release and remove the tool. Press the seal into its seat the

rest of the way by hand.

2. Install the new piston ring, rod wiper, O-rings and backup washers, if ap-

plicable, on the piston.

Be careful not to damage the seals. Caution must be used when installing

the piston ring. The ring must be stretched carefully over the piston with a

smooth, round, pointed tool.

3.

After installing the rod seal inside the gland, as shown in step #1, install

the external seal.

NOTE: Threaded glands may have been equipped with a separate O-ring and

backup washer system or a polypak (all in one) type seal. Current seal kits contain a

polypak (all in one) type seal to replace the discarded seal types on ALL

THREADED GLANDS.

4. Slide the gland onto the cylinder rod, being careful not to damage the rod

wiper. Then install the spacer, or flat washer (if so equipped), small o-ring,

piston, and hex nut onto the end of the cylinder rod.

5.

Secure the cylinder rod (mounting end) in a vise with a support at its

center. Torque the nut to the amount shown for the thread diameter of the

cylinder rod (see chart).

IMPORTANT: Do not contact the active surface of the cylinder rod with the

vise. Damage to the rod could result.

6. Apply a lubricant (such as Lubriplate #105) to the piston and teflon ring. Insert the cylinder rod assembly into

the cylinder tube.

IMPORTANT: Ensure that the piston ring fits squarely into the cylinder tube and piston groove, otherwise the

ring may be damaged and a leak will occur.

7. Use a spanner wrench to rotate the gland clockwise into the cylinder. Continue to rotate the gland with the

spanner wrench until it is tight.

WARNING!

Cylinders serviced in the field are to be tested for leakage prior to the attachment being placed

in work. Failure to test rebuilt cylinders could result in damage to the cylinder and/or the

attachment, cause severe personal injury or even death.

10357 10-13-05

BOLT TORQUE

BOLT TORQUE SPECIFICATIONS

GENERAL TORQUE SPECIFICATION TABLE

Use the following torques when special torques are not given. These values apply to fasteners as received

from suppliers, dry, or when lubricated with normal engine oil. They do not apply if special graphited or moly disulphide

greases or other extreme pressure lubricants are used. This applies to both UNF and UNC threads. Remember to

always use grade five or better when replacing bolts.

IMPORTANT: On all PLATED GRADE 8 bolts, reduce torque 15 from listed bolt torque specification.

10360 6-8-95-2

12.

MOUNTING KIT INSTALLATION

HEAVY DUTY TILT ATTACH ASSEMBLY #17446

1

6

41

43

9318 1-14-08-2

13.

7866 1-14-08-3

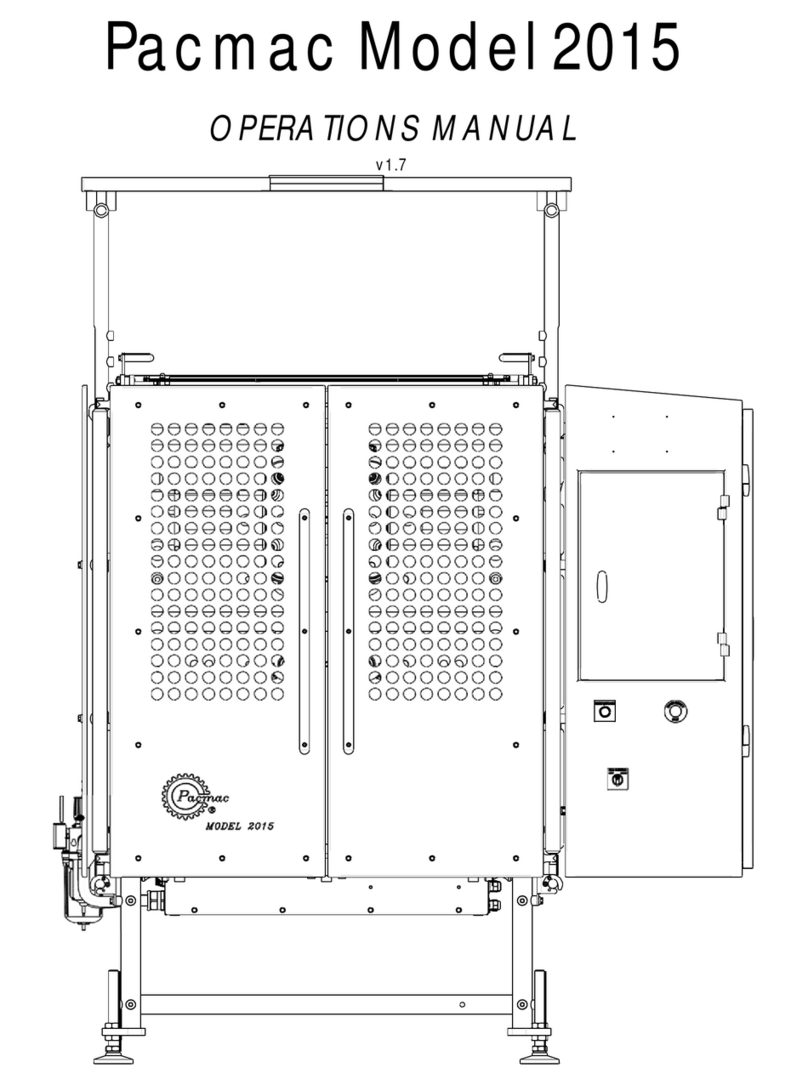

MOUNTING KIT INSTALLATION

TILT ATTACH ASSEMBLY #87301

14.

CYLINDER ASSEMBLY

ASSEMBLY #87332

11064 1-14-08

CYLINDER ASSEMBLY

ASSEMBLY #87332

NOTE: Seal Kit #45617 includes all parts marked with an asterisk (*). Parts are not sold

separately.

11065 1-14-08

This manual suits for next models

4

Table of contents

Other Spartan Industrial Equipment manuals