Spartus Full face mask 90 User manual

SPARTUS® full face mask 90

USER’S MANUAL

IMPORTANT! Keep these user Instruction for reference.

Before using the SPARTUS® full face mask 90 and the related lters, must carefully read and understand the instruction, and strictly

abide by the relevant content and retention of instruction in use process, please reference. The mask meet the requirement of Re-

gulation (EU) 2016/425 and CE marked accordingly, and have been tested according to EN 136:1998.

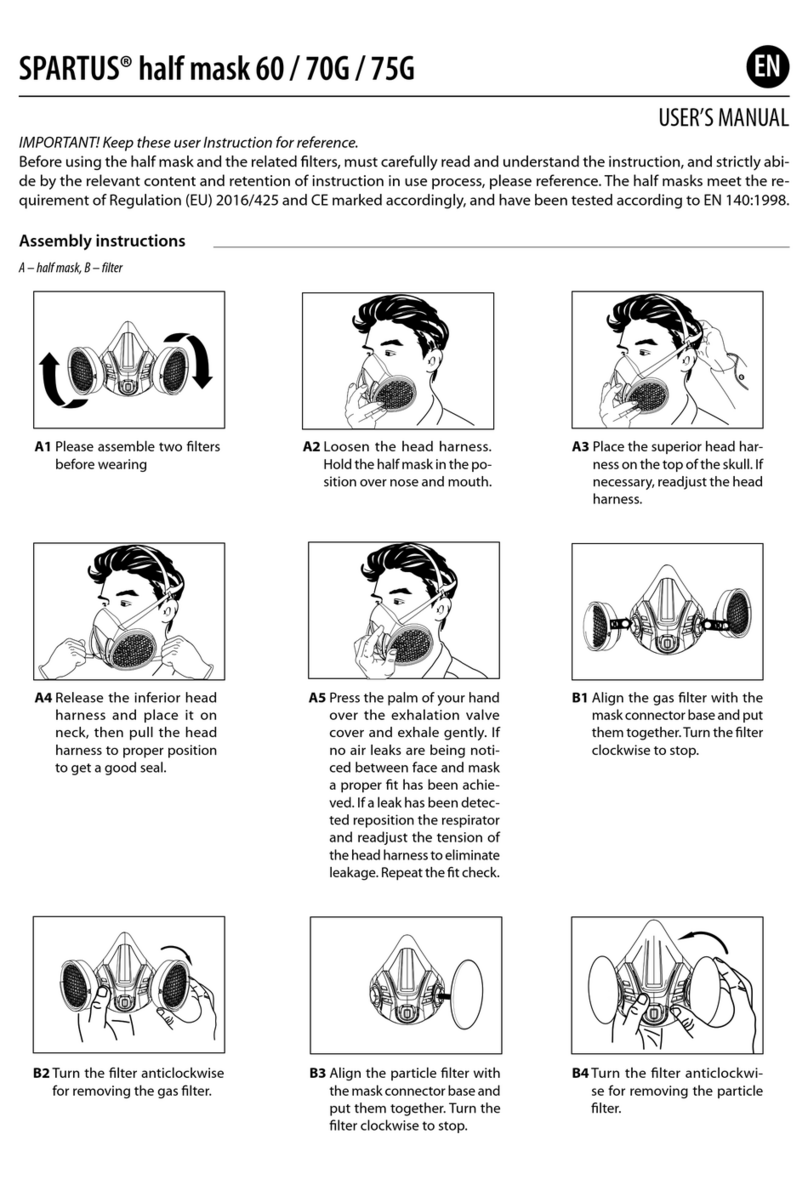

1/ 2/3Assemble or replace gas / particle lter: Align gas/particle lter notch with the bump on facepiece, and push to-

gether. Turn gas/particle lter clockwise to stop. When replacing the gas/particle lter, remove the gas/particle lter by turning it

counterclockwise. 4Mask tting: Hold the head harness and cardle away from your face, place your chin where the facepiece ts

against the chin, and press the respirator against your face so that it ts your face. 5Pull the head harness assembly behind the

head. 6Tighten the lower straps one by one, paying attention to the same tightness on both sides. 7Checking the tightness

of the particule lter: Using hands press or squeeze lter covers toward facepiece and inhale gently. If you feel facepiece collapse

slightly and pull closer to your face with no leaks between the face and facepiece, a proper seal has been obtained. 8Checking

the tightness of the gas lter: Place the palm of hands to cover face of gas lter and inhale gently. If you feel facepiece collapse

slightly and pull closer to your face with no leaks between the face and facepiece, a proper seal has been obtained. 9After wea-

ring this respirator, press the„Positive Fit Check Button” with your nger to the bottom. 10 Exhale slowly, the facepiece will bulge

slightly. If the respirator can maintain a little positive pressure and there is no obvious leakage between the face and the facepiece,

it means that the seal is good. 11 Respirator removal: Pull the buckle of head harness to fully loosen the 6 head harness straps.

12 Replace the exhalation valve: Open the bottom buckle of exhalation valve cover with your nger and remove it. 13 Remove

the exhalation valve from the valve seat by pulling valve stem from valve seat. Replace exhalation valve by inserting stem into hole

and manipulating stem tip until valve seat completely. The valve is at and free to move. 14 Replace the inhalation valve: Remove

the inhalation valve from the valve seat by pulling valve stem from seat. Replace inhalation valve by inserting stem into hole and

manipulating stem tip until valve seat completely. The valve is at and free to move.

Assembly instructions

1

5

9

13 14

10 11 12

6 7 8

234

EN

Use instructions

SPARTUS® full face mask is used two filters to protect people from harmful working environment. And the protection performance

is depend on the filters.

SPARTUS® full face respirator is compatible with the following combined filters:

Filter model Protection against

SPARTUS®50 For use against organic gases and vapors with boiling point > 65°C

SPARTUS®100 / SPARTUS®200 For use against certain organic gases and vapors, certain inorganic gases and vapors,

sulfur dioxide and other acidic gases and vapors, ammonia and organic ammonia derivatives

SPARTUS®10 / SPARTUS®60 For use against protect against solid or liquid substance in the nely divided state

(for use with twin filtering device)

Warning

Leave the contaminated area immediately and replace respirator if:

– the full mask becomes damaged;

– you taste or smell contaminants or an irritation occurs;

– breathing becomes difficult;

– dizziness or other distress occurs.

1. The full face mask does not supply oxygen. Please do not use in atmosphere containing less than 19.5% oxygen.

2. Do not use this mask in oxygen enriched air and explosive atmosphere.

3. It is unlikely that the requirements for leakage will be achieved if facial hair passes under the face seal.

4. Check prior to use, ensure fit of face piece.

5. The mask must be used with two filters.

6. Stay away from the contaminated areas when replacing the filters.

7. If you cannot achieve a proper fit, do not enter the contaminated area.

Inspection procedure

SPARTUS® full face mask must be inspected before use to ensure that it is in good operating condition. The mask should be repla-

ced of upon observation of damaged or defective parts. The following inspection procedure is suggested:

1. Check the mask for any cracks, tears and/or dirt.

2. Check the inhalation valve, exhalation valve, valve seat for deformation, dirt, impurities, cracks or signs of rupture.

3. Make sure that the head straps are intact and have a good elasticity.

4. Examine all plastic and rubber parts for signs of cracking or fatiguing.

5. Check to ensure breathing is smooth and there is no leaking.

6. Examine to ensure that filters are compliant with the working environment.

5. Check the lenses for any damage that may affect the performance or visual eld of the respirator. Make sure the protective film

has been removed.

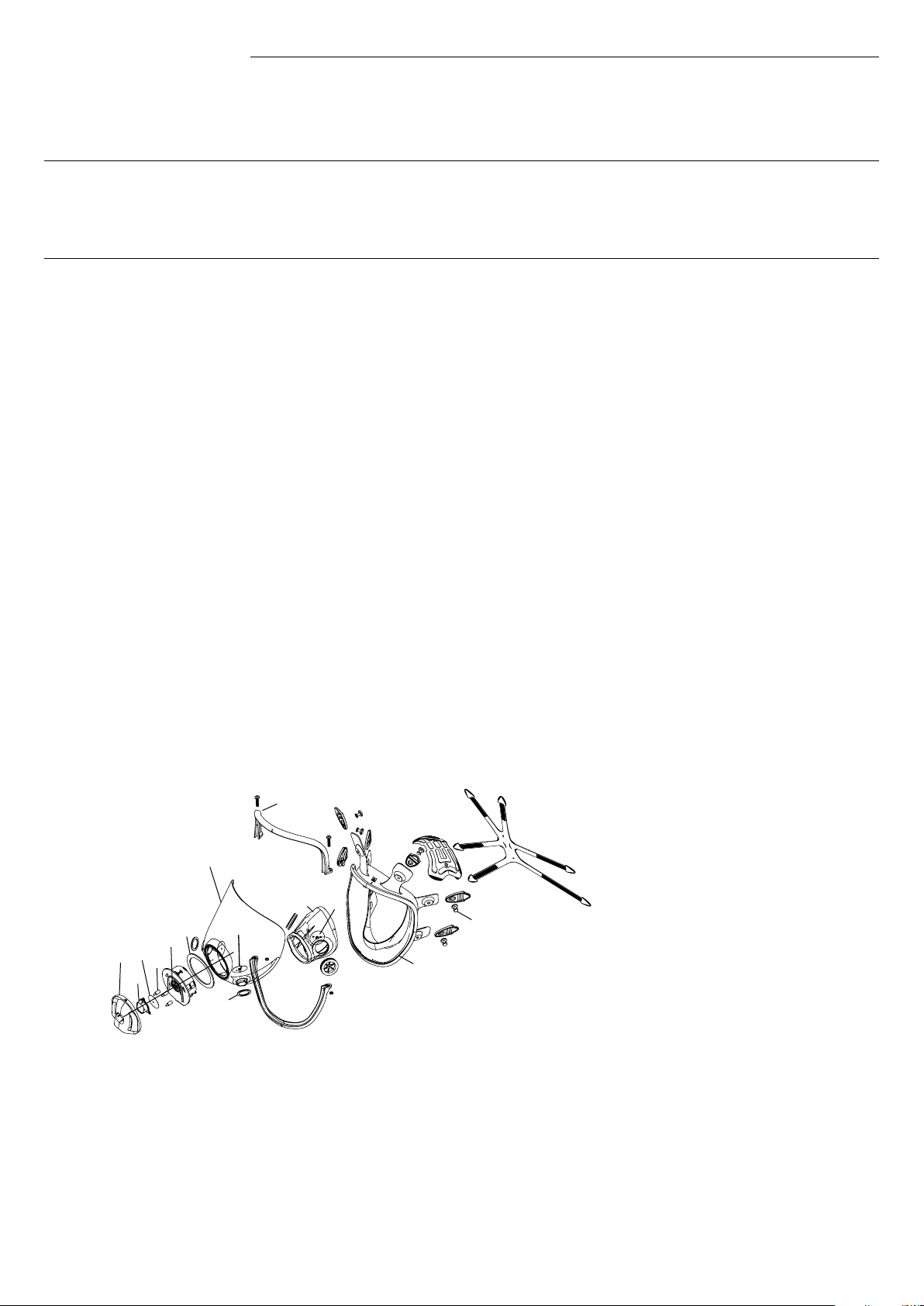

1A Head Harness

1B Head Harness Cradle

1C Head Harness Buckle

2A Nose Cup

2B Inhalation Valve Seat

2C Inhalation Valve

3A Exhalation Valve Seat

3B Exhalation Valve

3C Exhalation Valve Cover

3D Positive Fit Check Button

3E Spring Column

3F Center Adapter Gasket

4A Lens

4B Inhalation Valve

4C Inhalation Gasket

5A Facepiece

5B Head Harness Button

6 Frame Assembly w/ Screws

1A

2A

5A

5B

4A

6

3A

4B

4C

3F

3B

3C

3D

3E 2B

2C

1B

1C

Cleaning and storage instructions

Cleaning is recommended after use:

– remove the filters before cleaning,

– immerse the respirator and its components (excluding filters) in clean warm water at a temperature not exceeding 49°C. Gently

brush with a soft bristle brush. If necessary, add neutral detergent, without lanolin or other oils,

– use broad-spectrum disinfectants for disinfection to prevent the spread of bacteria. Special attention should be paid to the

instructions of the disinfectant manufacturer, such as dilution ratio, temperature and disinfection time,

– to maintain and extend the product in good condition, the cleaned respirator should be stored away in its original packaging or

in a container box from contaminated areas when not in use. Always remember to store away from direct daylight or any source

of heat.

– storage life: 5 years from date of manufacture.

Maintenance

The replacement parts and components must be from the original manufacturer. Otherwise, the protective eect of the respirator

may be aected, and even cause illness or death.

The exhalation valve

1. Open the bottom buckle of exhalation valve cover with your nger and remove it.

2. Remove the exhalation valve from the valve seat by pulling valve stem from valve seat.

3. Check the exhalation valve seat to ensure that it is clean and in good condition.

4. Replace exhalation valve by inserting stem into hole and manipulating stem tip until valve seat completely.

The valve is at and free to move.

5. Replace the exhalation valve cover.

NOTE: Conduct a negative pressure seal check to ensure that the exhalation valve is functioning properly.

The inhalation valve

1. Remove the inhalation valve from the valve seat by pulling valve stem from seat.

2. Check the inhalation valve seat to ensure that it is clean and in good condition.

3. Replace inhalation valve by inserting stem into hole and manipulating stem tip until valve seat completely.

The valve is at and free to move.

NOTE: Conduct a positive pressure seal check to ensure that the inhalation valve is functioning properly.

Product manufacturing date

The parts of the product show markings that bring information of manufacturing date, and its reading

is described as in the example below:

Maintenance

Use only original spare parts. After use the SPARTUS® full face mask 90 must be checked and cleaned.

Replace damaged parts.

Pictogram legend

Date code = 07th month , 2022 year (07.2022)

See manufacturer’s instruction manual

Maximum humidity during storage

Reusable particulate lter

End of storage time

Storage temperature range

SPARTUS® FILTERS

Before using the SPARTUS® lters, please carefully read and understand the instructions, and strictly follow it. Improper use may

cause serious injury, harm to your health or death.

Use instructions

1. Check the lter and package prior to use. Ensure the llter is good condition. Do not use if there are hole, deformation, crack on

the lter.

2. Filter can only be used according to its type and class. See marking on the lter before use. Choose appropriate to use.

3. In case, if you experience increased breathing resistance, you smell contaminants or feel dizziness, headache, irritation or any

other discomfort, you should leave the dangerous area immediately and replace lter.

Warning

1. The lter don’t produce oxygen, use in normal breathing air quality, do not use in hazards of oxygen, deciency of oxygen or

oxygen enriched air.

2. The use of gas or combined respiratory protective devices, specially those which are not directly connected to the face piece during

work with open ames or liquid metal droplets may cause serious risk due to the ignition of the charcoal containing lters which

may generate acute levels of toxic substances.

3. Don’t use in explosive atmosphere.

4. Storage under conditions other than those specied by the manufacturer may aect the shelf life.

5. Follow guidance as to use of lters.

6. Don’t modify and abuse of the product.

SPARTUS® gas lters

The service life of gas lter is aected by the type, volatility and concentration of air pollutants and environmental conditions, such

as temperature, atmospheric pressure and humidity. SPARTUS® gas lters meet the requirement of Regulation (EU) 2016/425 and

CE marked accordingly, and have been tested according to EN 140:1998.

Specication

Marking: Type / Protection against gases and vapours / Filter colour: A-Brown, B-Grey, E-Yellow, K-Green / A – for use against organic

gases and vapors with boiling point > 65°C / B – for use against certain inorganic gases and vapours / E – for use against sulphur dioxide

and other acidic gases and vapours / K – for use against ammonia and organic ammonia derivatives

Type Protection against gases and vapours Colour

A1 ABrown

B1 BGrey

E1 EYellow

K1 KGreen

A1 E1 A EBrown, Green

A1 B1 A BBrown, Grey

A1 B1 E1 A B EBrown, Grey, Green

B1 E1 K1 B E KGrey, Yellow, Green

A1 B1 E1 K1 A B E KBrown, Grey, Yellow, Green

(listed above features for use with twin ltering device)

Marking meaning

Marking Filter class Protection against Colour

A1 1 For use against organic gases and vapors with boiling point > 65°C Brown

B1 1 For use against certain inorganic gases and vapours Grey

E1 1 For use against sulphur dioxide and other acidic gases and vapours Yellow

K1 1 For use against ammonia and organic ammonia derivatives Green

(class 1 is low capacity lters)

SPARTUS® particle lter

The service life of the particle lter is aected by such factors as the concentration of particulate matter in the air, the user’s respiratory

rate, ambient temperature and humidity conditions. If the particulate lter is dirty, damaged or the inhalation resistance increases

signicantly, it must be replaced immediately. SPARTUS® particle lter meet the requirement of Regulation (EU) 2016/425 and CE

marked accordingly, and have been tested according to EN 14387:2004+A1:2008.

Specication

Model Type Protection against

SPARTUS®10 / SPARTUS®60 P3 R For use against protect against solid or liquid

substance in the nely divided state

(particle lter is intended to be used for more than a single shift – mark „R”)

Use limitations

SPARTUS® lters never be used under following conditions:

– oxygen concentration is lower than 19,5%,

– in an oxygen-enriched environment where oxygen concentration 23,5% and increase.

– the type of poison is unknown (the lter is only used according to its type and classication on the marking),

– the concentration of harmful gases not exceeds 0,1%,

– for specic applications, contact the distributor or manufacturer.

Maintenance

Gas lter is not re-usable – do not need cleaning or maintenance. Particle lter is re-usable – take o the particle lter after using

and store it in its original packaging.

Storage conditions

Storage under conditions specied by the manufacturer, otherwise it may aect its classication and shelf life. Particle lter shall be

stored in the dry, clean, low humidity and non-pollution environment. Do not use out of shelf life.

05.2023

Table of contents

Other Spartus Respiratory Product manuals