SPC Thermatile Ten-Twelve User manual

Thermatile Ten-Twelve

Radiant Panels

Installation instructions

2IOM 53, Issue 13 - Thermatile TEN-TWELVE

Contents Page

1|General 3

1.1 |Description 3

1.2 |Receipt and Preparation 3

1.3 |Storage and Handling 4

1.4 |Dimensional Data 4

1.5 |Technical Data 4

2|Installation 5

2.1 |Ceiling Grid 5

2.2 |Free Hanging 5

2.3 |Plasterboard 6

2.4 |Multiple Panels 7

2.5 |Wire/Rod Hanging Requirements 8

2.6 |Non-standard Applications 9

2.7 |Electrical Connections 9

2.8 |Mounting Height 10

3|Operation 11

3.1 |Cooling Applications 11

3.2 |Sensors 11

3.3 |Fault Finding 11

4|Maintenance 11

5|Appendix 12

5.1 |Appendix 1 - Wall-mounted installation 12

5.2 |Appendix 2 - Plastic ball guard 14

5.3 |Appendix 3 - Site Handling 15

5.4 |Appendix 4 - Bracket Positions 16

3IOM 53, Issue 13 - Thermatile TEN-TWELVE

1. General

1.1 Description

The SPC Thermatile TEN-TWELVE panels are

manufactured from a unique aluminium sandwich

panel that is both structurally rigid and an

excellent conductor of heat.

The TEN panel incorporates a bespoke cartridge

element bonded to the back of the panel through

which 10mm copper tubes run; connections are

10mm, the tubes are based on ‘D’ technology with

attened bases for increased contact. The TWELVE

panel uses the same construction but 12mm

copper pipes. The TEN panel is most usually used

for individual panels while the TWELVE is most

usually used on long continuous runs. The TWELVE

panels terminate in specially designed 22mm

manifold pieces.

Panels are suitable for laying in false ceiling grids

between T bars, free hanging or for installation

into plasterboard ceilings. Panels for grids and

plasterboard would normally be supplied with

a pre-installed insulating pad to minimise heat

loss into the void. Panels for such applications

can be supplied without the insulation but it is

recommended that the installer provides their

own insulation in this instance. Panels intended

for installation in plasterboard will be supplied

with edge extrusions for plasterboard xing.

Panels can also be supplied with special brackets

for wall rather than ceiling mounting. Free hanging

panels would normally be supplied without

insulation and may be used for cooling as well

as heating. Such panels can be supplied with

extruded aluminium trim to cover the cut edges

which adds around 10mm to the dimensions

of the panels and makes them unsuitable for

installation in grids.

Panels are supplied with xing brackets for

wire hangers as standard though threaded rod

adaptors are available to order. Panels may be

supplied with suspension kits, control kits and/or

exible connection hoses. The hose for the TEN

panels would normally be 10mm to 15mm push-t

and the TWELVE hoses 22mm to 22mm push-t

and 750mm long (hoses with compression ttings

are also available on request). Shorter hoses for

interconnecting TWELVE panels are supplied with

22mm ttings (push-t by default) on both ends. A

range of dierent hose ttings and lengths may be

supplied.

While bespoke sizes are possible the standard

panel width is 595mm and standard panels

lengths are 590, 1190, 1790, 2390,2990 and

3590mm. Maximum depth over the panel and

pipes is less than 25mm; insulation, if tted, is

additional to this. Connections will extend

beyond 25mm.

1.2 Receipt and Preparation

Panels are supplied suitably packed with an

additional plastic lm applied to the nished

lower surface. This lm should remain on until

such time as the panels are to be tted and then

peeled away. Cleaning of the underside of the

panel can be undertaken using a wet or dry cloth

but abrasives and staining cleaning agents must

not be used. If the protective lm is removed after

hanging care must be taken to prevent damaging

the brackets and anchors.

4IOM 53, Issue 13 - Thermatile TEN-TWELVE

1.3 Storage and Handling

Panels are packed in cardboard cartons

bearing the SPC works order number, model

reference and site references where appropriate.

Installation, operation and maintenance instructs

are also supplied along with any special drawings

or instructions required for the project. On receipt

check that all details are correct to the schedule

and report any damage or missing parts to the

carrier and SPC immediately.

It is recommended that the panels remain in the

packaging until they are required. When handling

panels safety gloves must be worn.

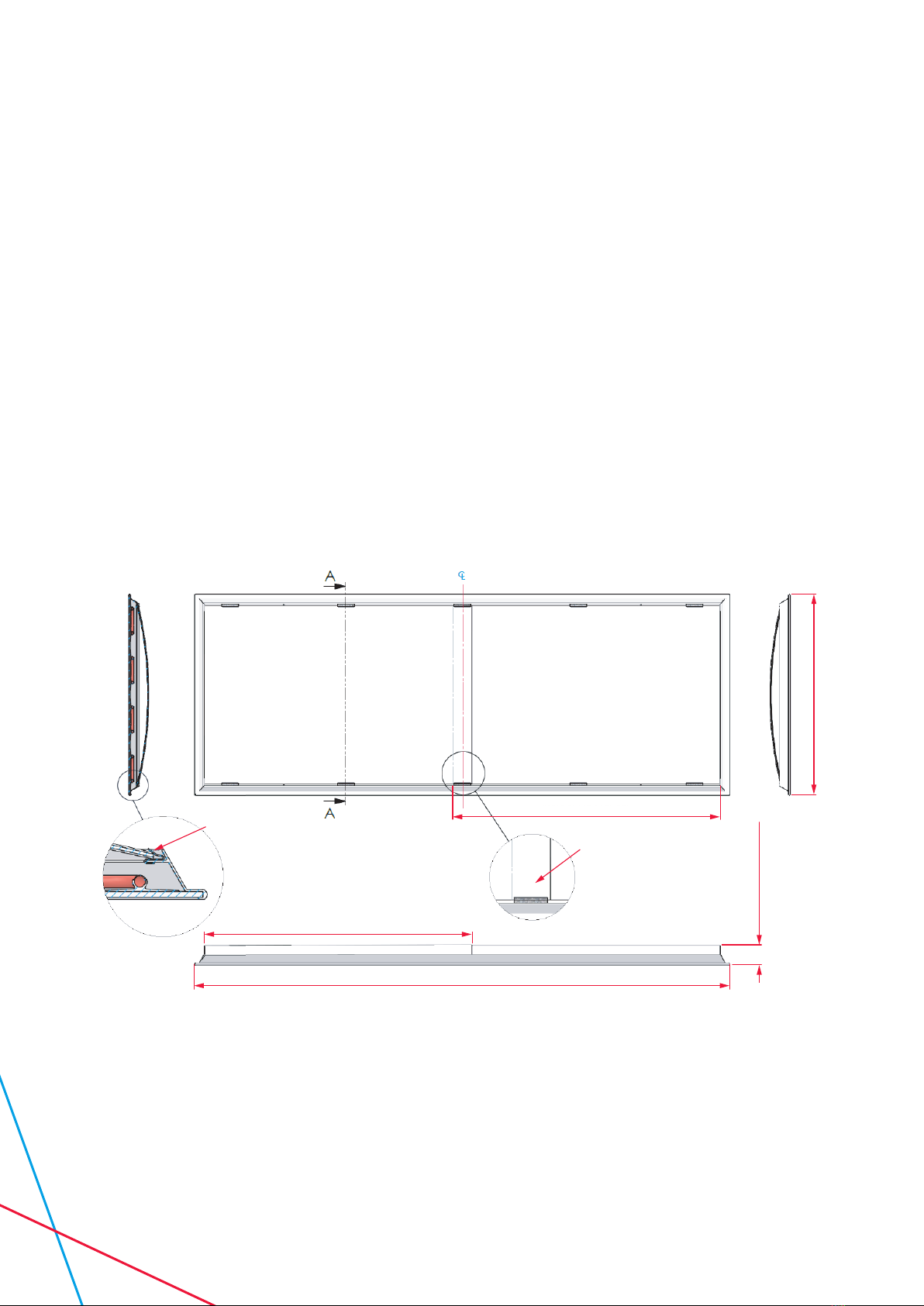

1.4 Dimensional Data

Panels can be supplied in bespoke sizes but the

approximate sizes and weights of standard panels

are as shown in the table below:

Nominal Panel Size 600x600 1200x600 1800x600 2400x600 3000x600 3600x600

Outside dimensions (mm) 590x595 1190x595 1790x595 2390x595 2990x595 3590x595

Approximate dry weight (kg) 3.2 6.4 9.6 12.8 16.0 19.2

Internal volume (l) 0.2 0.3 0.6 0.8 1.0 1.3

Approximate wet weight (kg) 3.4 6.7 10.2 13.6 17.1 20.5

1.5 Technical Data

Panel Type Ten Twelve

Tube O/D (mm) 10.0 12.0

Tube wall thickness (mm) 0.35 0.5

Underside (visible) skin 0.7mm painted aluminium 0.7mm painted aluminium

Upper skin 0.5mm primered aluminium 0.5mm primered aluminium

Core Aluminium (honeycomb or equivalent) Aluminium (honeycomb or equivalent)

Panel thickness 5.0/5.5mm 5.0/5.5mm

Tube holders Cartridge panel Cartridge panel

Maximum working pressure 10 bar 10 bar

Maximum working temperature 85°C 85°C

5IOM 53, Issue 13 - Thermatile TEN-TWELVE

2. Installation

2.1 Ceiling Grid

Single panels are typically placed into a T-bar

type ceiling grid based on a 600mm square grid

pattern. While the panels will rest unsupported

in the grid they must be xed to the ceiling for

safety reasons. Panels will be supplied, by default,

with brackets suitable for wiring hanging, if rod

hanging is preferred then adaptor brackets need

to be ordered, Gripple type wire suspension kits

are recommended. The wires or rods must hang

vertically between the brackets and ceiling as

the brackets/rivets are not suitable for signicant

lateral loads.

Panels may be supplied with connecting hoses

which will be either 15mm or 22mm and either

push-t or compression type. For connecting

panel to panel shorter interconnecting hoses may

be supplied with 10mm to 10mm connections

or 22mm to 22mm connections in push-t or

compression. Push-t connectors rely on a rubber

O ring for sealing and it is important that the ends

of the pipework are rounded and led (deburred)

before the push-t hose is attached to ensure a

damage free seal.

2.2 Free Hanging

Panels must be independently supported from the

ceiling/sot using either wire or rod hangers. The

panels are supplied, as standard, with the requisite

number of standard wire hanging brackets, if rod

hangers are to be used then suitable brackets

would need to be ordered to adapt the standard

wire hanger. Anchors of a suitable type to match

the ceiling fabric must be tted in the ceiling

directly above the brackets attached to the panels.

Connecting and inter-connecting hoses may

be supplied with the panels and their use and

installation should be as above.

Panels may be supplied with extruded aluminium

trim around the perimeter. Such panels are

suitable for hanging via wire systems from the

trim itself rather than via brackets. If insulation

is tted to the back of the panels this will readily

deform to allow tting of the wire hanging hook. If

rod fasteners are used instead of wire fasteners, it

should be stated on the order and larger diameter

holes will be drilled in the trim. If rod fasteners

are not identied at order stage, the trim can be

drilled on site to suit the diameter of the rod.

6IOM 53, Issue 13 - Thermatile TEN-TWELVE

2.3 Plasterboard

Panels are available for plasterboard ceilings and

are supplied with a special frame. The frame is an

extrusion which ts around the perimeter of the

panel. Fixing screws are tightened through the

frame into wooden battens in the ceiling.

The drawing below shows the steps to be taken in

order to properly mount plasterboard panels; the

primary support is via the hanging wires and the

screws into the battens provide additional support

and ensure that the frame sits level. The drawing is

intended to give information regarding the method

of installation; the actual installation will vary in

terms of number and position of xings.

Thermatile Fitting Instruction For Plasterboard Ceiling

Panel Length Ceiling Aperture Width Ceiling Aperture Length

590 605 600

1190 605 1200

1790 605 1800

2390 605 2400

2990 605 3000

3590 605 3600

Stage 1

• Cut aperture in plasterboard (see table

for size).

• Fit suitable wooden batten around perimeter

in ceiling void.

• Attach hanging wires to anchor points above

(by others).

Stage 2

• Attach wires to wire hanging brackets and

connect push t hoses for ow and return.

Stage 3

• Push panel up ush with ceiling and screw

through plasterboard to batten

7IOM 53, Issue 13 - Thermatile TEN-TWELVE

2.4 Multiple Panels

When panels are intended for installation in

continuous runs they may be supplied with

interconnecting hoses. Due to the high owrates

associated with continuous runs they will be from

12mm tube i.e. the TWELVE type panel.

The gure below shows a two panel run with

interconnecting hoses. Runs with greater numbers

of panels will have multiple panels interconnected.

The longer hoses are for connection to the main

ow and return piping.

Note: Interconnecting hoses need to be bent

through 180º as shown so as to connect pairs

of connections facing in the same direction.

No other arrangement of interconnection is

allowed and will be impossible with the hoses

supplied.

Figure 2. Example of multiple panel runs

Figure 1. Plasterboard hanging

SECTION VIEW

Plaster Board

Thermatile

Frame

Wooden Batten

8IOM 53, Issue 13 - Thermatile TEN-TWELVE

2.5 Wire/Rod Hanging Requirements

The panels are supplied as standard with the

necessary quantity of xing brackets fastened to

the rear of the panel. The standard bracket suits

wire hanging but adaptors are available to make

the brackets suitable for hanging via threaded rod.

Irrespective of the hanging type, wire or rod, the

hangers must be vertical and anchored to the

ceiling directly above the bracket. The brackets are

not designed to be suitable for signicant lateral

forces.

When installing panels they must not be hung

from some of the brackets unsupported. All of

the brackets must be properly secured before

the support is released. This support could be a

tter or tters or, if available, a scissor lift or other

mechanical means.

Figure 3. Incorrect and correct hanging method

Figure 4. Panels must be supported on all brackets

(scissor lift etc useful for large panels)

9IOM 53, Issue 13 - Thermatile TEN-TWELVE

V/A = VALVE/ACTUATOR, CAN BE 2 PORT, 3 PORT ON/OFF OR MODULATING

S = SENSOR, POSITIONED IN A REPRESENTATIVE POSITION WITHIN THE ZONE

C = CONTROLLER, REACTS TO SENSED TEMPERATURE TO POWER VALVE ACTUATOR

V/A

C

S

S

ZONE 2

PANELS

ZONE 1

PANELS

C

V/A

RETURN

FLOW

2.6 Non-standard Applications

Panels may be supplied for other than ceiling

mounting. Panels can be tted vertically to walls

or at an angle from the wall at high level. In this

instance the panels will be supplied with the

necessary support struts and hanging brackets.

Such installations are normally bespoke and tting

instructions will be separately supplied or must be

requested from SPC.

2.7 Electrical Connections

There are no electrical connections to the panels

themselves. The arrangement of panels will

normally be in zones and these will be controlled

by valves which will require electrical power and

control wiring. The schematic is an example

of how the panels may be controlled; it is not

representative of the panels themselves.

Figure 5. Control example

10 IOM 53, Issue 13 - Thermatile TEN-TWELVE

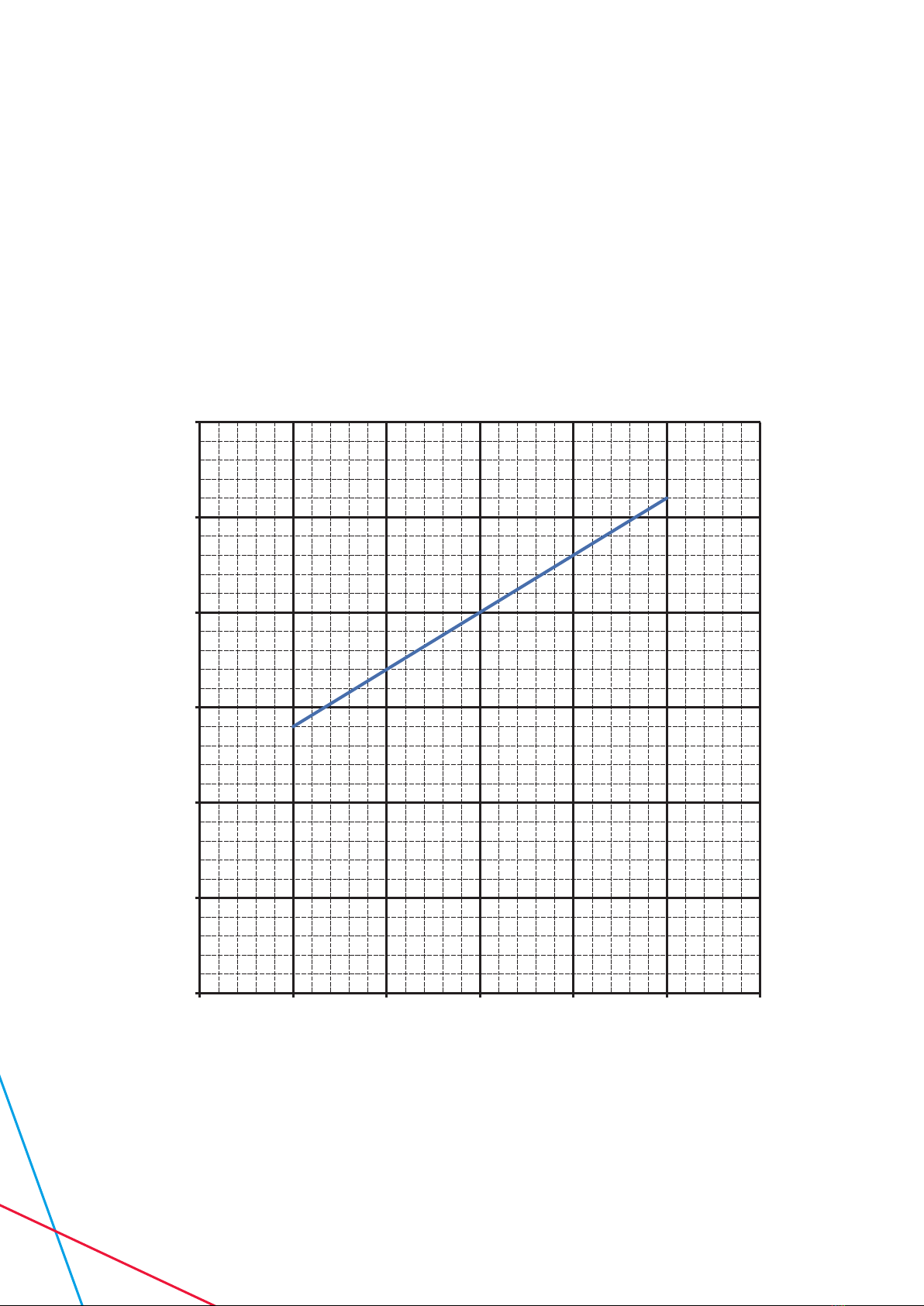

2.8 Mounting height

The chart showing minimum mounting heights

recommends the minimum height that the

panels should be mounted at, from the ground,

as a function of the water temperature in order

to prevent any discomfort occurring as a result

of asymmetric radiation. The chart is for static

occupancy; if occupants are moving around the

space then comfort can be ensured at higher

water temperatures or lower mounting heights.

0

0.5

1

1.5

2

2.5

3

30 40 50 60 70 80 90

Figure 6. Mounting heights

Minimum Mounting Height (m)

Mean Water Temperature (ºC)

Minimum Mounting Height Againt Mean Water

Temperature For Static Occupancy Comfort (ISO 7730)

11IOM 53, Issue 13 - Thermatile TEN-TWELVE

3. Operation

Ensure that the panels are piped together and

into the heating (cooling) system as required

by the application. Manual and or automatic air

vents should be tted at high points in the piping

systems. Ensure that all manual valves are opened

and allow uid to circulate through the heating

system. Open air vents to ensure that there is no

air trapped; close manual vents as soon as water is

released.

Zone valves should open and close in response

to the sensed room or zone temperature and

sensors should be positioned in representative

position within the space to achieve optimum

comfort.

3.1 Cooling Applications

When chilled water is used it is important that its

temperature is not less than the dewpoint of the

air in the space; In this way the panels will not

sweat. The temperature of the chilled water must

be controlled in response to the humidity in the

space and/or condensation sensors must be tted.

Note that the pipework to and from the panels will

also sweat and should be insulated/vapour sealed

wherever possible.

3.2 Sensors

For radiant systems black bulb sensors are

often used as they give a better indication of the

eective temperature in the space. If standard

air temperature sensors are used then allowance

needs to be made for the radiant eect – setpoints

can be a couple of degrees lower in heating mode

and higher in cooling mode.

3.2 Fault Finding

Fault Remedy

Air in system Open vent plug(s)

Low water temperature in heating mode Check operation of boiler and mixing valves

High water temperature in cooling mode Check operation of chiller and mixing valves

Low water ow rate Check operation of pump and diverting valves

Valves closed Check valve settings

4. Maintenance

Radiant panels are largely maintenance free. The

surface of the panel can be cleaned using a dry

cloth or non-abrasive/corrosive detergents; if

unsure rst try cleaning uid on a small area of the

panel.

The waterways consist of copper pipes and exible

hoses will normally be EPDM rubber, any ushing

undertaken or inhibitors used need to be suitable

for use with these materials.

12 IOM 53, Issue 13 - Thermatile TEN-TWELVE

5. Appendix

5.1 Appendix 1 - Wall-mounted installation

Below are examples of typical wall-mounted

applications where the panels are mounted at

an angle from the wall. SPC supply comprises

the panels themselves with special wall-mounted

brackets riveted to the back towards the bottom

of the panel. These brackets are notched at an

angle to suit the corresponding wall brackets also

supplied by SPC.

The installer will need to x unistrut or equivalent

to the walls at the centres indicated and attach

the wall brackets to the unistrut via captive spring

nuts and bolts. For angled panels the top of the

panel incorporates a pivoted arm which is sized

to provide the necessary spacing between the top

of the panel and the wall. This pivot arm should

be screwed into the upper row of unistrut. If the

panels are vertical and not angled then the upper

pivot arms will be replaced by additional upper

brackets.

When installing wall mounted panels it is

important that all the brackets and pivot arms

are located prior to allowing the panel to support

its own weight. Failure to do so or transferring

excessive pressure to the brackets will cause

failure of the rivets.

Angled, wall-mounted panels may be supplied with

guards on the top and end caps on the sides as

shown on the images.

Figure A1 shows details of the xing arrangement

as applied to a 595mm high panel, gure A2 shows

a nished assembly including top ball guard and

side caps.

553 Between Rail Centres

20°

85°

Ball Guard

595 Wide

Radiant

Panel

Wall Bracket

Supplied

Loose

41mm

Unistrut

& Fixings

(Supplied

By Others)

No 6 Self

Tapping Screws

Figure A1.

13IOM 53, Issue 13 - Thermatile TEN-TWELVE

Long Edging

Clips To End

Of Radiant Panel

Top Edging

Fits Under

Ball Guard

Loosley Secure End Cap

Through Hole In Ball

Guard With Tie Wraps

Provided

Figure A2.

14 IOM 53, Issue 13 - Thermatile TEN-TWELVE

5.2 Appendix 2 - Plastic ball guard

If panels are to be suspended at high level in

sports halls they may be supplied with rigid plastic

boards and brackets to be tted over the top

of the panel forming a dome to prevent balls/

shuttlecocks becoming trapped.

The plastic boards will be supplied cut to size to

suit the panel width and the requisite number of

plastic boards and brackets will be shipped with

the panels.

The xing brackets are slid onto the excluded

aluminium frame as shown below. They can be

gently tapped with a hammer to lock them into

position.

When more than one plastic board is required

to cover the length of the run then they should

be overlapped and a xing bracket located at the

point of overlap as shown. Intermediate brackets

should be used so as to ensure the plastic board

is securely held in position and these intermediate

brackets should be tted at approximately 600mm

centres. A bracket should also be tted close to

each of the panel edges.

The plastic boards, when tted correctly, will allow

anything falling onto the topside of the panel to be

thrown o due to the ‘doming’ of the board. The

plastic boards and xing brackets provide a strong

assembly which becomes held tighter in position

as the board is put under load and depressed by

ying sports equipment.

SK5668 - Ball Guard Clip

Panel Height

With Rigid Plastic

NOTE

Ball guard clip spread out evenly

Rigid Plastic Length

Rigid Plastic Boards

Overlap Under

Ball Guard Clip

Rigid Plastic Length

Plastic Width

Panel Length

Figure B1.

15IOM 53, Issue 13 - Thermatile TEN-TWELVE

5.3 Appendix 3 – Site Handling

The radiant panels are likely to have been supplied

with steel hanging brackets. When packed these

brackets are prevented from causing any damage

but once unpacked can cause damage to the

underside of other panels if incorrectly handled.

If unpackaged panels are stacked they must be

stacked as shown in the packaging label below

rather than with the brackets resting on the

painted underside of the panel; damage as shown

on the photograph below can occur otherwise.

Thermatile TEN-TWELVE

Radiant Panels

** WARNING – ONLY STACK PANELS AS SHOWN,WITH THESE LABELS

FACING EACH OTHER. USE POLYSTYRENE BLOCKS TO SUPPORT AND

PROTECT THE EXTERNAL SURFACES FROM DAMAGE **

spc-hvac.co.uk

*INCORRECTLY STACKED PANELS WILL CAUSE DENTS TO THE VISIBLE FACE – PLEASE STACK CORRECTLY*

16 IOM 53, Issue 13 - Thermatile TEN-TWELVE

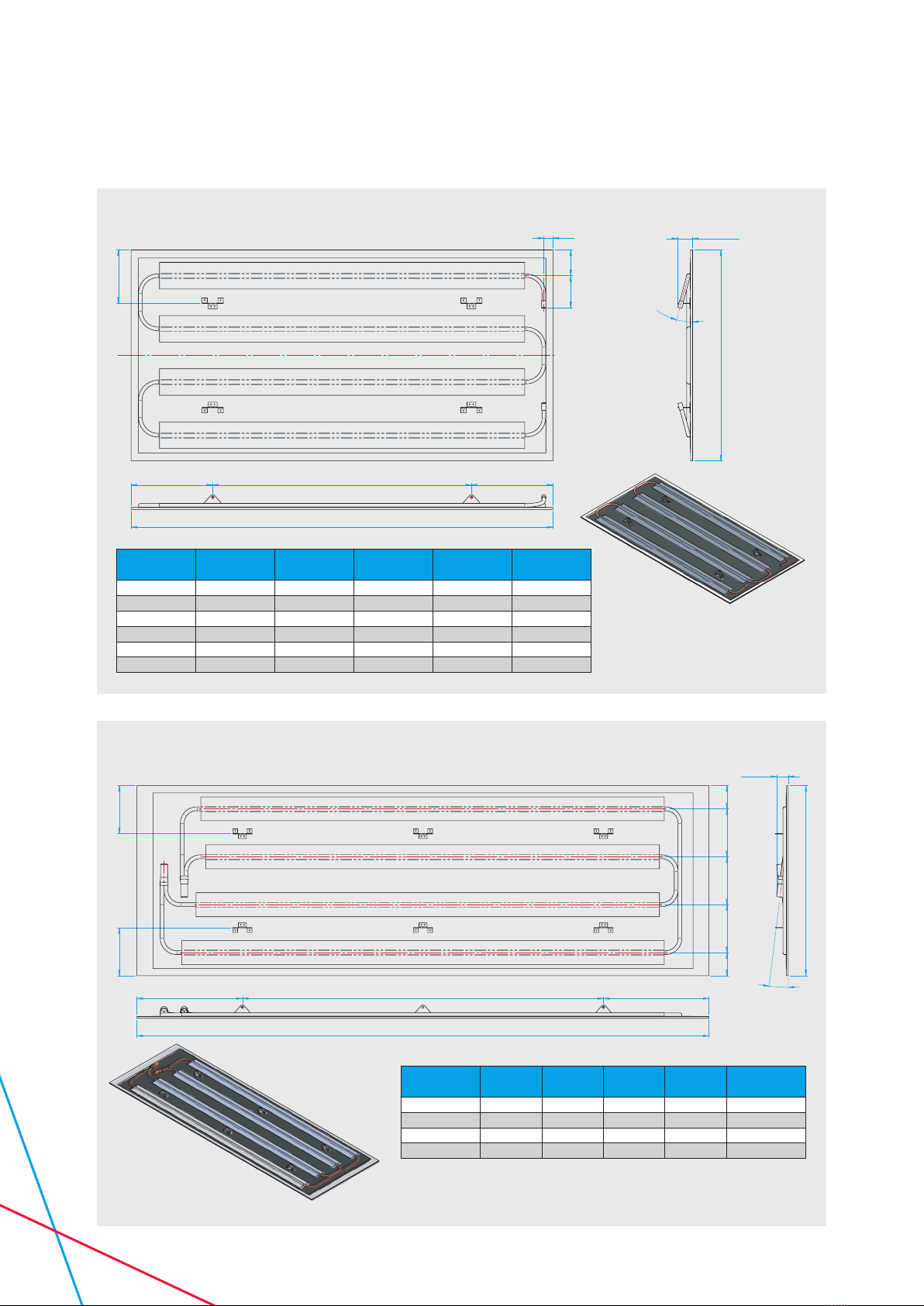

5.4 Bracket Positions

26

72.590.8

150

C

L

595 (600 NOMINAL)

15°

41.6 TYP

"LENGTH"

DIM "A" "B" PITCHES OF "C" DIM "A"

PICTORIAL

ISO VIEW

150

72.572.5 150 150 150

150

595 (600 NOMINAL)

7°

36.6 TYP

"LENGTH"

DIM "A" "B" PITCHES OF "C" DIM "A"

PICTORIAL

ISO VIEW

Nominal

Length Length DIM A DIM B DIM C Hanging

Points

600 590 130 1 330 4

1200 1190 230 1 730 4

1800 1790 330 2 565 6

2400 2390 430 2 765 6

3000 2990 430 2 1065 6

3600 3590 430 3 910 8

Nominal

Length Length DIM A DIM B DIM C Hanging

Points

1800 1790 330 2 565 6

2400 2390 430 2 765 6

3000 2990 430 2 1065 6

3600 3590 430 3 910 8

TWELVE - Standalone Cartridge Panel

TEN - Stand Alone Cartridge Panel

NOTE: 600 X 1800 NOMINAL PANEL SHOWN INSULATION NOT SHOWN IN VIEWS

NOTE: 600 X 1200

NOMINAL PANEL SHOWN

PANELS SYMMETRICAL

AT C

LINSULATION NOT

SHOWN IN VIEWS

17IOM 53, Issue 13 - Thermatile TEN-TWELVE

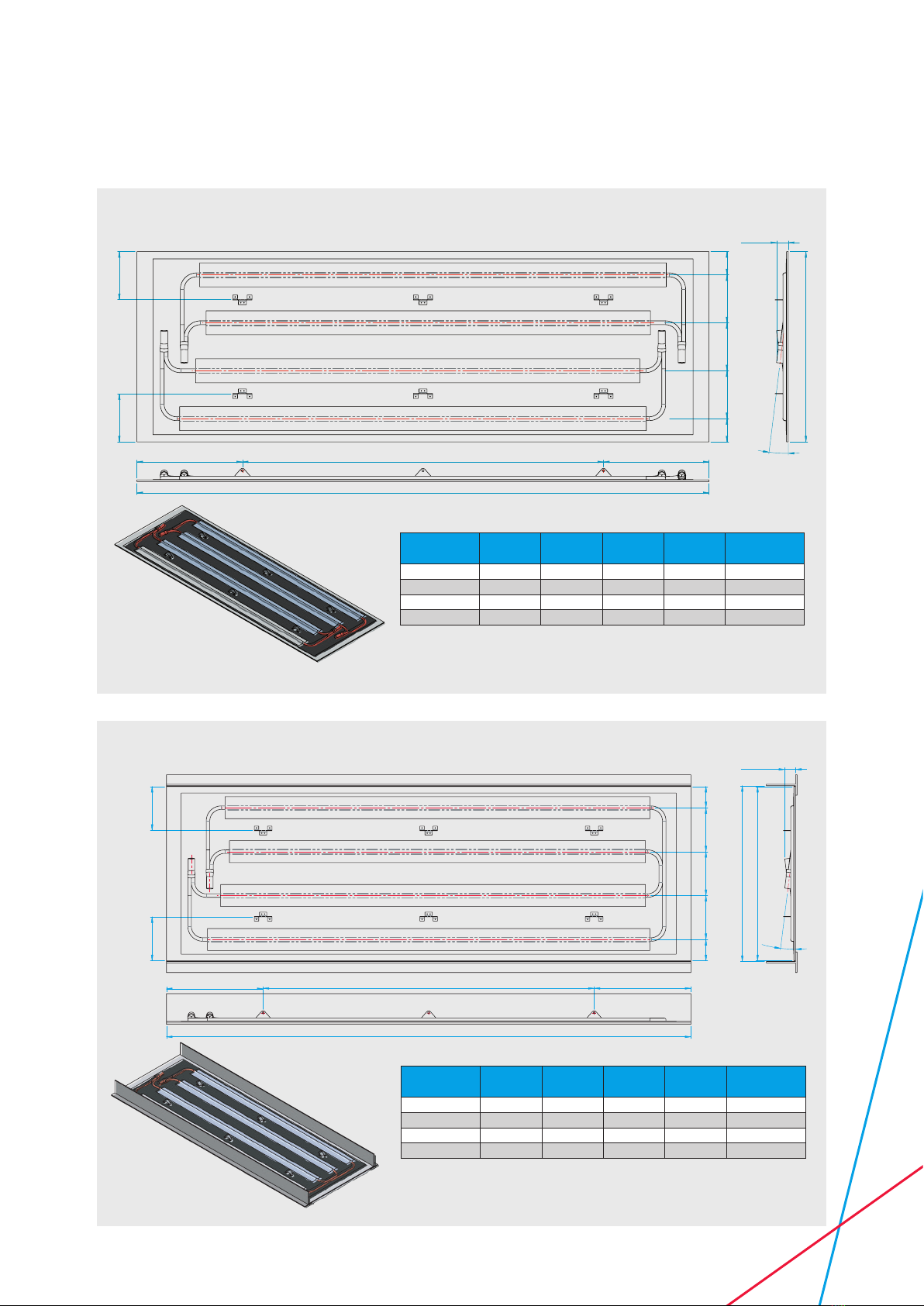

150

72.572.5 150 150 150

150

595 (600 NOMINAL)

7°

36.6 TYP

"LENGTH"

DIM "A" "B" PITCHES OF "C" DIM "A"

PICTORIAL

ISO VIEW

150150

72.5 150 150 150 72.5

NOMINAL WIDTH = 600

PANEL WIDTH = 595

7°

36.6 TYP

"LENGTH"

DIM "A" "B" PITCHES OF "C" DIM "A"

PICTORIAL

ISO VIEW

Nominal

Length Length DIM A DIM B DIM C Hanging

Points

1800 1790 330 2 565 6

2400 2390 430 2 765 6

3000 2990 430 2 1065 6

3600 3590 430 3 910 8

Nominal

Length Length DIM A DIM B DIM C Hanging

Points

1800 1790 330 2 565 6

2400 2390 430 2 765 6

3000 2990 430 2 1065 6

3600 3590 430 3 910 8

TWELVE - Standalone Cartridge Panel = T-Bar

TWELVE - Middle Section Cartridge Panel

NOTE: 600 X 1800 NOMINAL PANEL SHOWN INSULATION NOT SHOWN IN VIEWS

NOTE: 600 X 1800 NOMINAL PANEL SHOWN INSULATION NOT SHOWN IN VIEWS

18 IOM 53, Issue 13 - Thermatile TEN-TWELVE

150150

72.5 150 150 150 72.5

NOMINAL WIDTH = 600

PANEL WIDTH = 595

7°

36.6 TYP

"LENGTH"

DIM "A" "B" PITCHES OF "C" DIM "A"

PICTORIAL

ISO VIEW

155155

77.5 150 150 150 77.5

7°

595 - PANEL WIDTH

605 - CEILING APERTURE

657 - FRAME TO FRAME WIDTH

HOLE

CENTRES

DIM "A" "B" PITCHES OF "C" DIM "A"

PICTORIAL

ISO VIEW

26

11

1

50

2mm

GAP

PANEL FRAME DIMENSIONS

ON DETAIL A

PLASTERBOARD

55

55

"D" PITCHES OF "E"

55

54789

C

L

C

L

HOLES DIMENSIONS ONLY

SYMMETRICAL UPON CENTRELINES

Nominal

Length Length DIM A DIM B DIM C DIM D DIM E Hanging

Points

1800 1790 330 2 565 3 580.67 6

2400 2390 430 2 765 4 585.5 6

3000 2990 430 2 1065 5 588.4 6

3600 3590 430 3 910 6 590.33 8

Nominal

Length Length DIM A DIM B DIM C Hanging

Points

1800 1790 330 2 565 6

2400 2390 430 2 765 6

3000 2990 430 2 1065 6

3600 3590 430 3 910 8

TWELVE - Standalone Cartridge Panel = Plasterboard

TWELVE - Middle Section Cartridge Panel = T-Bar

NOTE: 600 X 1800 NOMINAL PANEL SHOWN

INSULATION NOT SHOWN IN VIEWS

FOR CLARITY HANGING WIRES, HOSES &

INSULATION ARE NOT SHOWN.

CEILING APERTURE DESIGNED TO GIVE

2MM CLEARANCE AROUND PANEL FRAME

NOTE: 600 X 1800 NOMINAL PANEL SHOWN INSULATION NOT SHOWN IN VIEWS

19IOM 53, Issue 13 - Thermatile TEN-TWELVE

155155

"PANEL LENGTH""PANEL LENGTH"

7°

595 - PANEL WIDTH

605 - CEILING APERTURE

657 - FRAME TO FRAME WIDTH

HOLE

CENTRES

DIM "A" "B" PITCHES OF "C" DIM "A""B" PITCHES OF "C"

PICTORIAL

ISO VIEW

26

11

50

2mm

GAP

1

PANEL FRAME DIMENSIONS

ON DETAIL A

PLASTERBOARD

55

55

"D" PITCHES OF "E"

54789

55

55

"D" PITCHES OF "E"

54789

*

C

L

HOLES DIMENSIONS ONLY SYMMETRICAL UPON CENTRELINES

155

155

77.5

150 150 150

77.5

605 - CEILING APERTURE

657 - FRAME TO FRAME WIDTH

15°

595 - PANEL WIDTH

HOLE

CENTRES

DIM "A" DIM "A"

"B" PITCHES OF "C"

PICTORIAL

ISO VIEW

50

2mm

GAP

26

1

11

PANEL FRAME DIMENSIONS

ON DETAIL A

PLASTERBOARD

5554755

55

"D" PITCHES OF "E"

55

HOLES DIMENSIONS ONLY

SYMMETRICAL UPON CENTRELINES

C

L

C

L

Nominal

Length Length DIM A DIM B DIM C DIM D DIM E Hanging

Points

1800 1790 361 2 565 3 571 6

2400 2390 461 2 765 4 578.25 6

3000 2990 461 2 1065 5 582.6 6

3600 3590 461 3 910 6 585.56 8

Nominal

Length Length DIM A DIM B DIM C DIM D DIM E Hanging

Points

1800 1790 330 2 565 3 580.67 6

2400 2390 430 2 765 4 585.5 6

3000 2990 430 2 1065 5 588.4 6

3600 3590 430 3 910 6 590.33 8

TEN - Standalone Cartridge Panel = Plasterboard

TWELVE - Cartridge Panel In Runs = Plasterboard

NOTE: 600 X 1800 NOMINAL PANEL SHOWN

INSULATION NOT SHOWN IN VIEWS

FOR CLARITY HANGING WIRES, HOSES &

INSULATION ARE NOT SHOWN.

CEILING APERTURE DESIGNED TO GIVE

2MM CLEARANCE AROUND PANEL FRAME

NOTE: 600 X 1800 NOMINAL PANEL SHOWN

INSULATION NOT SHOWN IN VIEWS

NOTE: FRAME PANEL SHOWN ON ‘BOTTOM VIEW’ MUSTBE PUSHED UP AGAINST

THE FIRST PANEL SO THAT THE RAMES ARE FLUSH * ANY REMANING GAPS

TOBE FILLED WITH SUITABLE ANTI-PICK MASTIC.

FOR CLARITY HANGING WIRES, HOSES & INSULATION ARE NOT SHOWN.

CEILING APERTURE DESIGNED TO GIVE 2MM CLEARANCE AROUND PANEL FRAME

SPC House

Evington Valley Road

Leicester

LE5 5LU

T: 0116 249 0044

E: spc@spc-hvac.co.uk

spc-hvac.co.uk

IOM 53, Issue 13 - Thermatile TEN-TWELVE

Table of contents

Popular Electric Heater manuals by other brands

Baxi Fires Division

Baxi Fires Division MIRAGE 804 Installer and owner guide

Oceanic

Oceanic OCEAISHT1000W user manual

Helo

Helo SKSM STJ Series product manual

Heatrex

Heatrex Quartzone owner's manual

Trotec

Trotec TEH 70 operating manual

Fired Up Corporation

Fired Up Corporation Sola SPH-15AA instruction manual