Packing List Specifications

Nailer 1

Keys 3

1

Manual 1

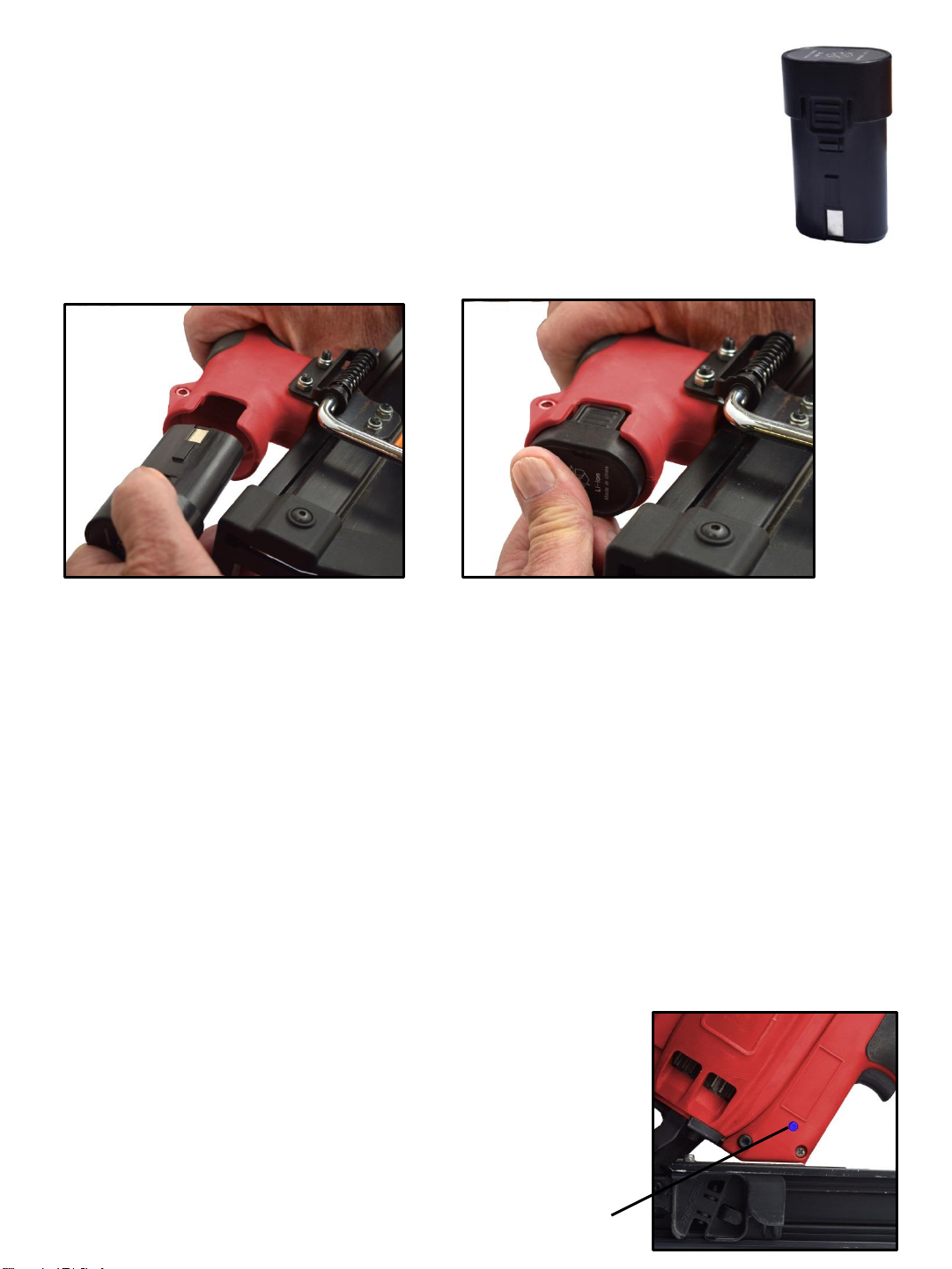

Batteries 2

1

Model SJ-GFKL1

Weight 3.38Kg Dry

Dimensions 410mm L - 430mm W - 115mm H

Cycle Rate

-3 nails

per second. No more than 1200

nails per hour or 5000 nails per day

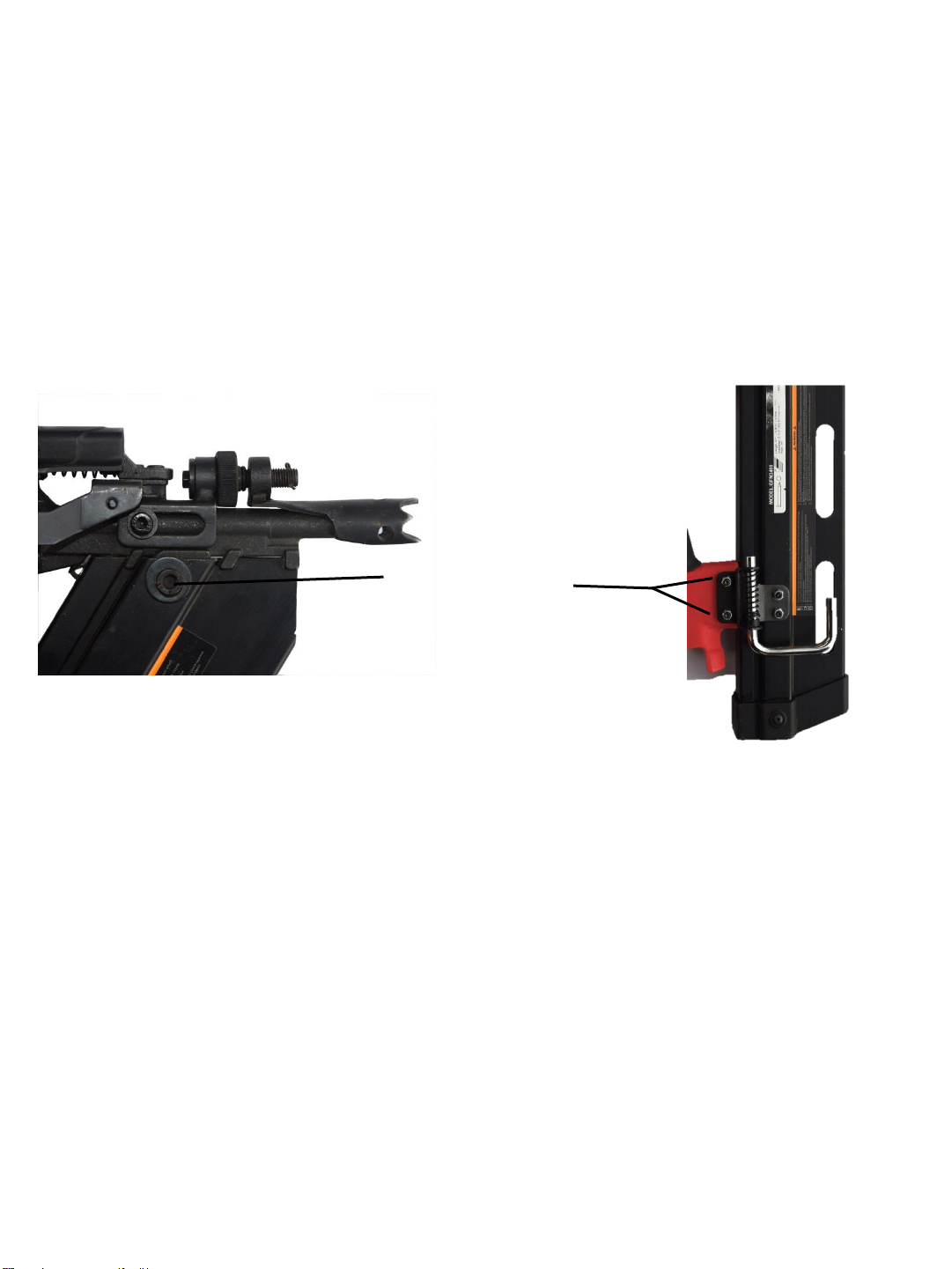

Fasteners 34 Degree clipped head paper collated

nails. 2.87mm to 3.33mm shank diameter.

50 - 90mm in length

80 nails

Fuel cell Recommended: Paslode Impulse

Power+ Fuel Cell (B20543F)

Average nails per fuel cell 1200

Safety Instructions

1. Do not attempt to operate this tool until you have read and understood all safety precautions on

the tool and manual instructions. Failure to follow all safety precautions and instructions may

result in serious personal injury to yourself or others.

2. Eye and Ear protection must be worn and meet the requirements of ANSI Standard Z87.1. Eye

protection should have side shields for increased safety.

3. Operate the tool only in a well-ventilated environment. This nailer is an internal combustion

device and exhausts carbon monoxide. Prolonged exposure to carbon monoxide may cause

dizziness, nausea or unconsciousness.

4. The cordless framing nailer is an internal combustion device. It produces hot exhaust gases that

may ignite flammable materials. This tool must not be used in a combustible environment or in

the presence of combustible materials, such as flammable chemicals, adhesives, gasoline or

solvents.

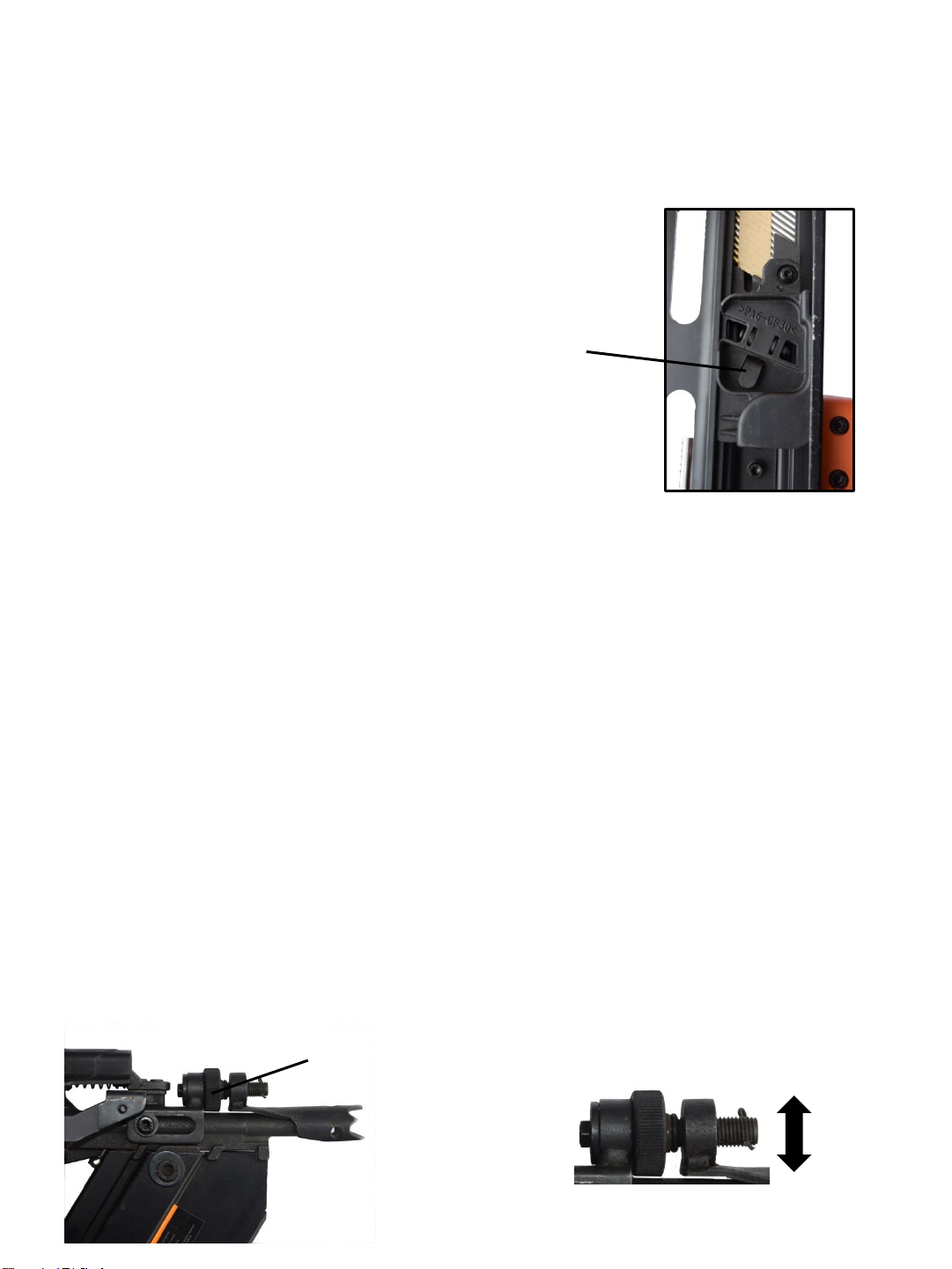

5. If carrying or transporting the nailer, remove the battery. Failure to do so may result in the

accidental discharge of a fastener.

6. Do not operate the tool in temperatures above 45℃.

7. Do not operate the tool in the rain or in wet environments.

8. Do not point the tool at yourself or anyone else. This is dangerous.

9. Do not load fasteners with the trigger and/or work contact element depressed.

10. Remove the fuel cell and the battery before performing any maintenance, cleaning, clearing nail

jams or removing nails from the magazine.

11. Always store the tool in a safe and dry place with the fuel cell, battery and fasteners removed.

3

THOROUGHLY READ THIS BOOKLET BEFORE USING THIS NAILER