Spearhead Quadsaw 1602 User manual

Spearhead QUADSAW 1602/2002/2402

1

QUADSAW

1602/2002/2402

Edition 1.1 –October 2017

Part No. 8999106

Spearhead QUADSAW 1602/2002/2402

2

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with Spearhead Machinery Limited

before delivery to the end user –failure to do so may affect the validity of the machine warranty.

To register machines go to the Spearhead Machinery Limited web site at

www.spearheadmachinery.com, log onto ‘Dealer Inside’ and select the ‘Machine Registration

button’which can be found in the Service Section of the site. Confirm to the customer that the

machine has been registered in the section below.

Should you experience any problems registering a machine in this manner please contact the

Spearhead Service Department on 01789 491867.

Registration Verification

Dealer Name:

Dealer Address:

Customer Name:

Date of Warranty

Registration:

/ /

Dealer Signature:

NOTE TO CUSTOMER / OWNER

Please ensure that the above section has been completed and signed by the selling dealer to

verify that your machine has been registered with Spearhead Machinery Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s

responsibility to regularly inspect all nuts, bolts and hose connections for tightness and re-

tighten if required. New hydraulic connections occasionally weep small amounts of oil as the

seals and joints settle in –where this occurs it can be cured by re-tightening the connection –

refer to torque settings chart below. The tasks stated above should be performed on an hourly

basis during the first day of work and at least daily thereafter as part of the machines general

maintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS

PORT ADAPTORS WITH BONDED SEALS

BSP

Setting

Metric

BSP

Setting

Metric

1/4”

18 Nm

19 mm

1/4”

34 Nm

19 mm

3/8”

31 Nm

22 mm

3/8”

47 Nm

22 mm

1/2”

49 Nm

27 mm

1/2”

102 Nm

27 mm

5/8”

60 Nm

30 mm

5/8”

122 Nm

30 mm

3/4”

80 Nm

32 mm

3/4”

149 Nm

32 mm

1”

125 Nm

41 mm

1”

203 Nm

41 mm

1.1/4”

190 Nm

50 mm

1.1/4”

305 Nm

50 mm

1.1/2”

250 Nm

55 mm

1.1/2”

305 Nm

55 mm

2”

420 Nm

70 mm

2”

400 Nm

70 mm

Spearhead QUADSAW 1602/2002/2402

3

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with Spearhead Machinery Ltd, before delivery

to the end user. On receipt of the goods it is the buyer’s responsibility to check that the Verification of

Warranty Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All machines supplied by Spearhead Machinery Limited are warranted to be free from defects in material

and workmanship from the date of sale to the original purchaser for a period of 12 months, unless a

different period is specified.

1.02. All spare parts supplied by Spearhead Machinery Limited are warranted to be free from defects in

material and workmanship from the date of sale to the original purchaser for a period of 6 months.

1.03. The manufacturer will replace or repair for the purchaser any part or parts found, upon examination at its

factory, to be defective under normal use and service due to defects in material or workmanship.

Returned parts must be complete and unexamined.

1.04. This warranty does not apply to any part of the goods, which has been subjected to improper or abnormal

use, negligence, alteration, modification, fitment of non-genuine parts, accident damage, or damage

resulting from contact with overhead power lines, damage caused by foreign objects (e.g. stones, iron,

material other than vegetation), failure due to lack of maintenance, use of incorrect oil or lubricants,

contamination of the oil, or which has served its normal life. This warranty does not apply to any

expendable items such as blades, flails, bushes, belts, flap kits, skids, shields, guards, wear pads or

pneumatic tyres.

1.05. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are specifically

excluded from the warranty.

1.06. Warranty on hoses is limited to 12 months and does not include hoses which have suffered external

damage. Only complete hoses may be returned under warranty, any which have been cut or repaired will

be rejected.

1.07. Machines must be repaired immediately a problem arises. Continued use of the machine after a problem

has occurred can result in further component failures, for which Spearhead Machinery Ltd cannot be held

liable, and may have safety implications.

1.08. Except as provided herein, no employee, agent, dealer or other person is authorised to give any

warranties of any nature on behalf of Spearhead Machinery Ltd.

1.09. For machine warranty periods in excess of 12 months the following additional exclusions shall apply:

1.09.1. Hoses, external seals, exposed pipes and hydraulic tank breathers.

1.09.2. Filters

1.09.3. Rubber mountings

1.09.4. External electric wiring.

1.09.5. Labour and mileage costs.

1.10. All service work, particularly filter changes, must be carried out in accordance with the manufacturer’s

service schedule. Failure to comply will invalidate the warranty. In the event of a claim, proof of the

service work being carried out may be required.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of non-genuine

parts may seriously affect the machine’s performance and safety. Spearhead Machinery Ltd cannot be

held responsible for any failures or safety implications that arise due to the use of non-genuine parts.

Spearhead QUADSAW 1602/2002/2402

4

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the Spearhead

Machinery web site and confirms the registration to the purchaser by completing the confirmation form in

the operator’s manual.

2.02. Any fault must be reported to an authorised Spearhead Machinery dealer as soon as it occurs. Continued

use of a machine, after a fault has occurred, can result in further component failure for which Spearhead

Machinery Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs undertaken

more than 2 weeks after a failure has occurred, or 2 days after the parts were supplied will be rejected,

unless the delay has been authorised by Spearhead Machinery Ltd.

2.04. All claims must be submitted, by an authorised Spearhead Machinery Service Dealer, within 30 days of

the date of repair.

2.05. Following examination of the claim and parts the manufacturer will pay, at their discretion, for any valid

claim the cost of any parts and an appropriate labour allowance if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by Spearhead Machinery Ltd is final.

3. LIMITATION OF LIABILITY

3.01. The manufacturer disclaims any express (except as set forth herein) and implied warranties with respect

to the goods including, but not limited to, merchantability and fitness for a particular purpose.

3.02. The manufacturer makes no warranty as to the design, capability, capacity or suitability for use of the

goods.

3.03. Except as provided herein, the manufacturer shall have no liability or responsibility to the purchaser or

any other person or entity with respect to any liability, loss, or damage caused or alleged to be caused

directly or indirectly by the goods including, but not limited to, any indirect, special, consequential, or

incidental damages resulting from the use or operation of the goods or any breach of this warranty.

Notwithstanding the above limitations and warranties, the manufacturer’s liability hereunder for damages

incurred by the purchaser or others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this warranty may be

brought more than one (1) year after the cause of the action has occurred.

4. MISCELLANEOUS

4.01. The manufacturer may waive compliance with any of the terms of this limited warranty, but no waiver of

any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be unenforceable,

then the invalidity of such provision shall not invalidate any other provisions herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided herein.

Spearhead QUADSAW 1602/2002/2402

5

This machine is produced by Greentec A/S on behalf

of Spearhead Machinery Limited.

CE Declaration of Conformity,

Conforming to EU Machinery Directives

2006/42/EF

We, GreenTec A/S, Merkurvej 25, DK-6000 Kolding hereby declare

that:

Product

……………………………………………..…………………………

Product Code

……………………………………………..…………………………

Serial No

……………………………………………..……..………………….

Type

……………………………………………..…………………………

Manufactured by: GreenTec A/S, Merkurvej 25, DK-6000 Kolding

In terms of its design, method of construction and execution thereof, the item of

machinery described above complies with the basic health and safety regulations

of the respective EU Directives. The Machinery Directive is supported by the

following harmonized standards:

DS/EN ISO 12100 3rd edition 2011. Safety of Machinery –General principles

for design –Risk assessment and risk reduction.

DS/EN 953+A1 4th edition 2010. Safety of Machinery –Guards –General

requirements for the design and construction of fixed of moveable guards.

DS/EN ISO 4413 1st edition 2010. Hydraulic fluid power –General rules and

safety requirements for systems and their components

The EC Declaration only applies if the machine stated above is used in accordance

with the operating instructions.

Signed

(On behalf of GreenTec A/S)

Status

Sales Director

Date

………………………………………………

Spearhead QUADSAW 1602/2002/2402

6

CONTENTS

Spearhead Warranty 2

Introduction 8

General Information 9

Vehicle/Tractor Preparation 10

Safety For Maintenance & Operator 12

Safety and Instructional Decals Identification 13

Additional Safety Advice 14

Components Identification 16

Features & Specification 17

Safety Around The Machine 18

Before Starting Work 21

Mounting/Dismounting The Machine 23

Hose Connections 24

Blade Cutting Direction 26

Transporting The Quadsaw 28

Work Position With The Quadsaw 29

Field Of Application 32

Driving Directions For Using The Quadsaw 34

First Time Operation 35

Safety Distances Vertically 36

Operating The Machine 37

Maintenance 39

Routine Maintenance Schedule 41

Lubrication 42

Belts 45

Correct Belt Tension 46

Belt Diagrams 47

Hose Connections 48

Pump And Motor Failure 49

Storage 50

Correct Lifting Of The Quadsaw 51

Noise Measuring 52

Supplier Information & CE Declaration 53

Warning, Bans & Directions 54

Disassembling 55

Problem Solving 56

Ordering Parts 57

Main Frame –1602 58

Main Frame –2002 60

Main Frame GT–2402 62

Main Frame PL–2402 64

Spearhead QUADSAW 1602/2002/2402

7

Motor –1602 66

Motor –2002 68

Motor –2402 69

Blade Shaft –1602 70

Blade Shaft –2002 71

Blade Shaft –2402 72

Primary Tensioning System –1602 73

Primary Tensioning System –2002 74

Primary Tensioning System –2402 75

Secondary Tensioning System –1602 76

Secondary Tensioning System –2002 77

Secondary Tensioning System –2402 78

S180020.101 –Spearhead Machinery Safety & Marketing Decals 79

Piston Motor Information 80

Spearhead QUADSAW 1602/2002/2402

8

INTRODUCTION

The Spearhead Quadsaw blade

saw is a professional attachment

designed specifically for the

cutting of trees and branches and

developed for the discerning

customer with a focus on cutting

performance, efficiency and

output and working environment.

Available in width of 1.6 m (1602),

2.0 m (2002) and 2.4 m (2402)

the attachment is equipped with

either 400 mm(1602), 500 mm

(2002) or 600 mm(2402) ‘belt-

driven’ blades which have the

ability to cut multiple branches up

to a maximum diameter of 70mm (1602), 80mm (2002) and up to 120mm (2402). For

single branches passing through the Quadsaw at any one time these sizes can be

increased to 100 mm (1602), 120 mm (2002) and 160 mm (2402).

Important Note

The information contained in this manual is correct at the time of publication. However,

in the course of constant development, changes in specification are inevitable. Should

you find the information given in this book different to the machine it relates to please

contact the “After Sales Department” for advice.

Please ensure that this manual is handed to the operator before using the

machine for the first time. The operator must fully understand the contents of this

manual before using this machine.

If the machine is resold the Manual must be given to the new operator

Spearhead QUADSAW 1602/2002/2402

9

GENERAL INFORMATION

Read this manual before fitting or operating the machine or accessory. Whenever any

doubt exists contact your local dealer or the Spearhead Machinery Service

Department for assistance.

Only use ‘Genuine Spearhead Parts’ on Spearhead Machinery and equipment.

DEFINITIONS: The following definitions apply throughout this manual;

DANGER: Alerts to a hazardous situation which will result in death or

serious injury if not observed carefully.

WARNING: Alerts to a hazardous situation which will result in death

or serious injury if not observed carefully.

CAUTION: Alerts to a hazardous situation which could result in

damage to the machine and/equipment if not observed correctly.

NOTICE: Specific or general information considered important or

useful to emphasise.

LEFT HAND (LH) & RIGHT HAND (RH): These terms are applicable to the machine

when fitted to the tractor and viewed from the rear; these terms also apply to the

tractor references.

SERIAL PLATE

All machines are equipped with a serial plate containing important information relating

to the machine including a unique serial number used for identification purposes.

Note: Images in this manual are provided for instruction and information purposes

only and may not show components in their entirety. In certain instances images may

appear different to the actual machine; when this occurs the general procedure will be

basically the same.

Spearhead QUADSAW 1602/2002/2402

10

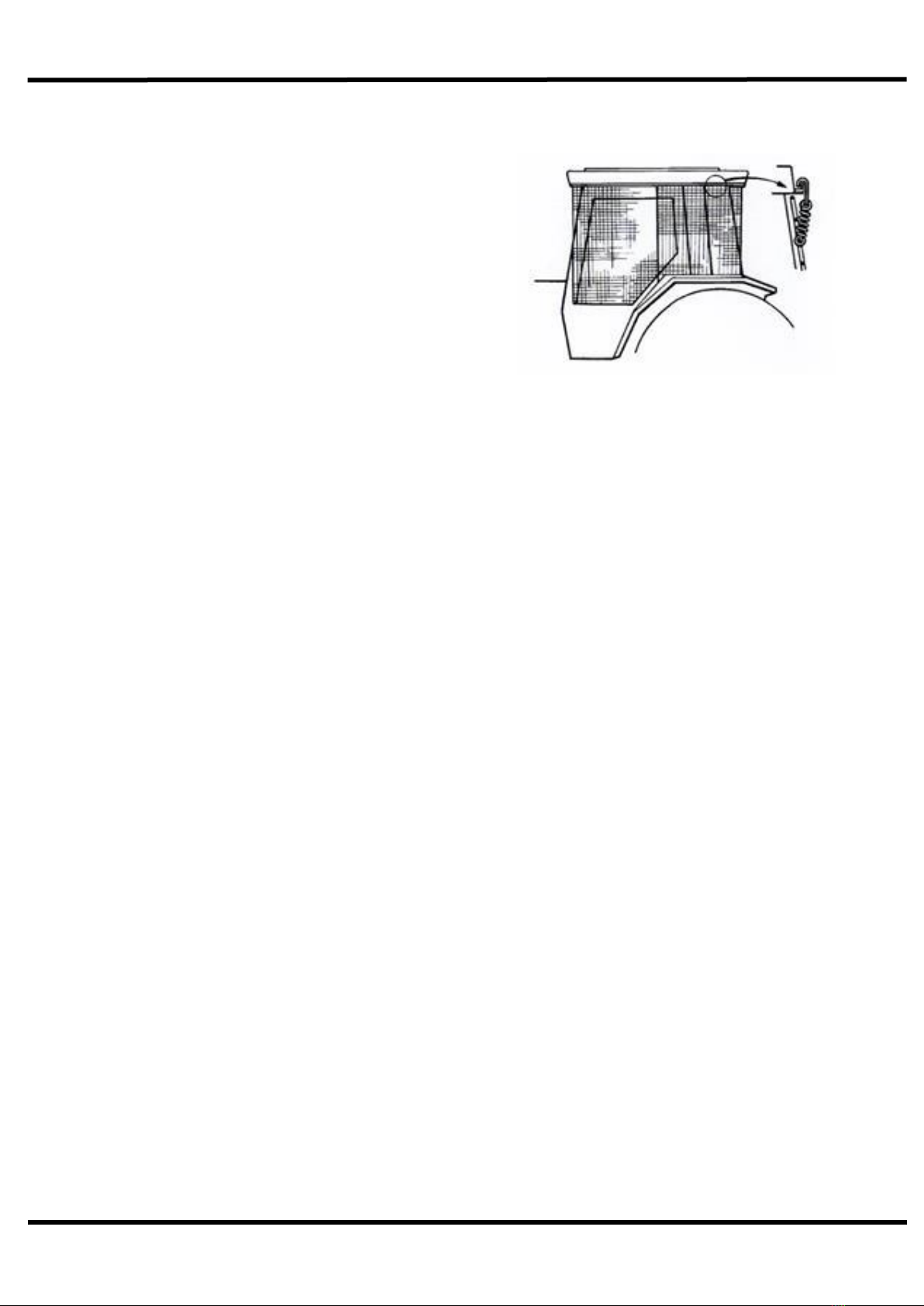

VEHICLE/TRACTOR PREPARATION

We recommend vehicles are fitted with cabs

using ‘safety glass’ windows and protective

guarding when used with our machines. Fit an

Operator Guard such as Spearheads’ available

guard kit (part number OPT0603) and using the

hooks provided fit it to the vehicle. Shape the

mesh to cover all vulnerable areas. The driver

must be looking through mesh and/or

polycarbonate glazing when viewing the

complete working machine in any working

position –unless the vehicle/cab manufacturer can demonstrate that the penetration

resistance is equivalent to, or higher than, that provided by mesh/polycarbonate

glazing. If the tractor has a roll bar only, a frame must be made to carry both mesh and

polycarbonate glazing. The operator should also use personal protection equipment

(PPE) to reduce the risk of serious injury such as; eye protection (mesh visor to

EN1731 or safety glasses to EN166), hearing protection to EN352, safety helmet

EN297, gloves and high visibility clothing.

Vehicle Ballast

It is imperative when attaching ‘third-party’ equipment to a vehicle that the maximum

possible stability can be accomplished by the utilisation of ‘ballast’ in order to counter-

balance the additional equipment added. Quadsaw Branch Cutters have been tested

on the following reach arm systems: Spearhead Twiga MID, PRO & FLEX with tractors

from 4400kg, wheelbase of 250 cm and a track width of 200 cm measured from/to the

outer edge of the tyre till tractors of 5500kg, wheelbase of 280cm and a track width of

250cm measured from/to the outer edge of the tyre. Because there are different types

of tractor structures and differences in weight distribution you must view this as a

“guideline”. Is it possible, then choose wide tyres as possible to increase the stability

of the vehicle.

Front Weights

May be required for rear mounted machines to place 15% of total outfit weight on the

front axle for stable transport on the road and to reduce ‘crabbing’ due to the drag of

the cutting unit when working on the ground.

Rear Weights

May be required to maintain a reasonable amount of rear axle load on the Opposite

wheel from the arms when in work; for normal off-ground work i.e. hedge cutting this

should be 20% of rear axle weight or more for adequate control, and for ground work

i.e. verge mowing with experienced operators, this can be reduced to 10%. All factors

must be addressed in order to match the type and nature of the equipment added to

the circumstances under which it will be used –in the instance of reach arm hedge

cutters it must be remembered that the machines centre of gravity during work will be

constantly moving and will differ from that during transport mode, therefore balance

becomes critical.

Spearhead QUADSAW 1602/2002/2402

11

Factors That Affect Stability

Centre of gravity of the tractor/machine combination.

Geometric condition e.g. position of the cutting head and ballast.

Weight, track width and wheelbase of the tractor.

Acceleration, braking, turning and the relative position of the cutting head during

these operations.

Ground conditions, e.g. slope, grip, load capability of the soil/surface.

Rigidity of implement mounting.

Suggestions To Increase Stability

Increasing wheel track; a vehicle with a wider wheel track is more stable.

Ballasting the wheel; it is preferable to use external weights but liquid can be

added to around 75% of the tyre volume –water with anti-freeze or the heavier

Calcium Chloride alternative can be used.

Addition of weights –care should be taken in selecting the location of the

weights to ensure they are added to a position that offers the greatest

advantage.

Front axle locking (check with tractor manufacturer).

NOTE: The advice above is offered as a guide for stability only and is not a

guide to vehicle strength. It is recommended that you consult your vehicle

manufacturer or local dealer to obtain specific advice on this subject,

additionally advice should be sought from a tyre specialist with regard to tyre

pressures and ratings suitable for the type and nature of the machine you intend

to fit.

Spearhead QUADSAW 1602/2002/2402

12

SAFETY FOR MAINTENANCE & OPERATOR

The safety advice in this manual, the present national emergency preventing precepts

and existing in-house work, operation and safety precepts must be complied with.

Additionally the safety precepts of the vehicle manufacturer must be complied with. If

the machine is used on public roads, the existing laws apply.

Safety Advice For Maintenance And Inspection:

The head of operations must see it that all maintenance, inspections and fittings

are carried out by authorized personnel who have read and understood the

contents of this manual.

Maintenance must only be carried out when the machine is at standstill. This

procedure as described in Spearheads’manual must be carefully observed.

When maintaining a Quadsaw and/or a machine that is lifted, always secure

with suitable support units.

When replacing blades and the like always check the hydraulic system for

remaining pressure; always reduce the pressure to zero.

Only use suitable tools and always wear work gloves, safety shoes and goggles.

Dispose of oil and grease according to regulation.

Immediately after finishing work, all safety and protection units must be installed

and activated again.

Before any use, the sections “Putting Into Operation” by the manufacturer of the

tractor/vehicle must be carefully followed.

Safety Advice For The Head Of Operation/User:

It is of the most utmost importance to be familiar with the equipment and the

operational units before starting work. Afterwards it is too late.

Work wear must be tight fitted. Avoid loose fitted clothes. Check surroundings

before work (children or obstacles such as rocks, fence posts, wire etc.). Always

make sure there is a sufficient view. Safety distance for a tool in work is stated

in the manual.

Riding the Quadsaw or machine when transported or in work is not permitted.

Never leave the driver’s seat when driving.

Staying in the work area is forbidden. Safety distance for the Quadsaw is stated

in the manual.

Take extra precautions when working underneath power lines. Always keep a

safe distance to power lines.

Before leaving the vehicle, always lower machine/Quadsaw to the ground,

remove the ignition key and secure the vehicle from inadvertent activation and

rolling!

Spearhead QUADSAW 1602/2002/2402

13

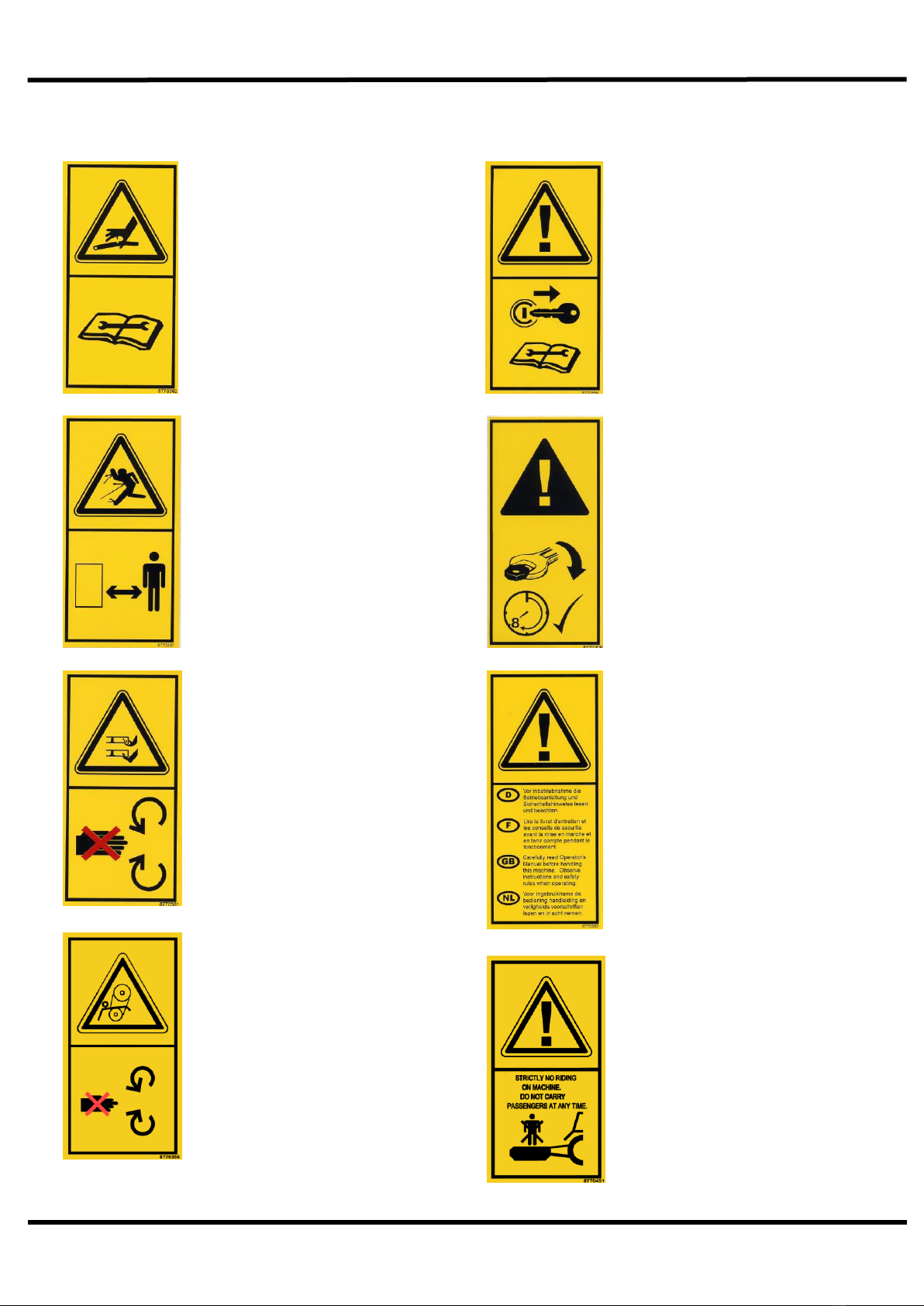

SAFETY AND INSTRUCTIONAL DECALS IDENTIFICATION

Warning

Avoid fluid escaping under

pressure. Consult technical

manual for service

procedures.

Warning

Danger –flying objects.

Keep safe distance from the

machine as the engine is

running.

Warning

Stay clear of rotating saw

blades.

Warning

Do not remove/open guard

when parts are rotating.

Warning

Stop engine and remove key

before performing

maintenance or repair work.

Warning

Check all nuts and bolts are

tight every 8 hours –

retighten if required.

Warning

Carefully read operators

manual before handling this

machine. Observe

instructions and safety rules

when operating.

Warning

Do not stand and ride on the

machine at any time.

Spearhead QUADSAW 1602/2002/2402

14

ADDITIONAL SAFETY ADVICE

Training

Operators need to be competent and fully capable of operating this machine in a safe

efficient way prior to attempting to use it in any public place. We advise therefore that

the prospective operator make use of relevant training courses available such as

those run by the Agricultural Training Board, Agricultural Colleges, Dealers and

Spearhead.

Working In Public Places

When working in public places such as roadsides, consideration should be paid to

others in the vicinity. Stop the machine immediately when pedestrians, cyclists and

horses etc. pass. Restart only when they are at a distance that causes no risk to their

safety.

Warning Signs

It is advisable that any working area be covered by suitable warning signs and

statutory in public places. Signs should be highly visible and well placed in order to

give clear advanced warning of the hazard. Contact the Department of Transport of

your Local Highway Authority to obtain detailed information on the subject. The latter

should be contacted prior to working on the public highway advising them of the time

and location of the intended work asking what is required by the way of signs and

procedure –‘Non-authorised placement of road signs may create offences under the

Highways Act’.

Suggested Warning Signs Required

The reach arm machine must be fitted with a white on blue, 600mm diameter ‘Keep

Left’ (*) direction arrow. A white with red border ‘Hedge Cutting’ warning triangle of at

least 750mm tall must be placed at no greater distance than 500m from the tractor at

any time. These hedge cutting signs should also be placed at key restricted view

areas such as bridges and sharp bends.

*NOTE –this applies to UK Market machines where traffic passes to the right of

a machine working in the same direction as the traffic flow. The direction, use

and colour of the arrow depend on the country of use and the Local Highway

Authorities regulations in the locality.

Use of Warning Signs

On two-way roads, one set of signs is required to be facing in

each direction.

Work should be carried out within 500m of the signs. The signs

will then be required to be moved.

Work only when visibility is good and at times of flow e.g. NOT

during ‘rush-hour’.

Vehicles should have at least one 360° visible amber flashing

beacon (preferably two) or a light bar comprising at least two

Spearhead QUADSAW 1602/2002/2402

15

independent light sources which are clean.

Ideally, vehicles should be conspicuously coloured and have high visibility rear

markings which are clean

Debris should be removed from the road and path as soon as practicable, and

at regular intervals, wearing high visibility clothing and before removing the

hazard warning signs.

Collect all road signs promptly when the job is complete.

Safety Gear

It is recommended that the following personal protective equipment is worn when the

operating and/or maintaining this machine; coveralls, safety boots, safety glasses,

hearing protection, safety helmet, protective gloves.

Although the information stated here covers a wide range of safety subjects it is

impossible to predict every eventuality that can occur under different

circumstances whilst operating this machine. No advice given here can replace

‘good common sense’ and ‘total awareness’ at all times, but will go a long way

towards the safe use of your Spearhead machine.

Maximum Distance

Behind

500m

Maximum Distance

In Front

500m

Warning Sign

Warning Sign

Spearhead QUADSAW 1602/2002/2402

16

COMPONENTS IDENTIFICATION

a) Main Body

b) Motor

c) Skid

d) Guard

e) LH Motor Mount

Position

Please note the machine shown above is in Right-hand configuration. Left-hand

machine builds will have item B at relocated to item E.

Blade Unit Components

a) Saw Blade

b) Mounting Plate

c) Blade Bolt

d) Cover

A

B

C

D

E

A

B

C

D

A

B

C

D

Spearhead QUADSAW 1602/2002/2402

17

FEATURES

Quadsaw for mounting on hydraulic hedge cutters.

Frame with 4 shaft.

Working width approximately 1.6 m (1602), 2.0m (2002) and 2.4m (2402)

540 RPM operating speed

110 kg (1602), 198 kg (2002) and 239 kg (2402) weight.

Four blade HM precision hardened steel saw cutting system.

Each shaft is driven by vee belts, and the whole unit is hydraulic motor driven.

The Quadsaw is supplied with a special bracket enabling mounting on various

vehicles and carriers.

SPECIFICATION

Specification/Model

1602

2002

2402

Working Width

1.6m

2.0m

2.4m

Blade Diameter

400mm

500mm

600mm

Teeth Per Blade

60

72

78

Blade Material

Hardened Steel

Hardened Steel

Hardened Steel

Blade Speed

2600-2700rpm

3000-3200rpm

2700-2800rpm

Oil Flow Rate

40 l/min

50 l/min

45 l/min

Cutting

Performance

Multiple Branch

Up to 70mm

Up to 80mm

Up to 120mm

Single Branch

Up to 100mm

Up to 120mm

Up to 160mm

Main Application

Vertical Cutting

Vertical Cutting

Vertical Cutting

Weight

110Kg

198kg

239kg

Spearhead QUADSAW 1602/2002/2402

18

SAFETY AROUND THE MACHINE

Beware of the following Potential Dangers:

Becoming trapped when hitching or unhitching.

Tractor overbalancing when arm is extended.

Electrocution due to hitting overhead power lines.

Getting caught on rotating take off (PTO).

Being hit or caught by any moving part, e.g. belts, pulleys, arms, cutting head.

Being hit by flying debris or machine parts due to machine damage.

Machine overbalancing when not in use.

Injection of high pressure oil from damaged couplings or hydraulic hoses.

Accidents due to collision with other machines, or debris left on road.

Always

Ensure the operator has read this handbook and has been trained to use the

machine.

Ensure all cab safety guards are in place and all tractor windows closed.

Before leaving the tractor cab always ensure the Quadsaw is firmly on the

ground, no weight is on the machines’ hydraulics and the rotor has stopped

spinning.

Check that all guards are properly fitted and they’re not damaged or have loose

parts. Particular attention should be given to the blades to ensure they are not

damaged, cracked or missing.

Inspect work area for wire, steel posts, large stones and other dangerous

materials and remove before starting work.

Beware of the danger of overhead power cables. The operator must be aware of

the maximum height and reach of the machine when working under power

cables. The minimum height for 11,000 and 22,000-volt cables is 5.2 metres

from the ground. When fully extended, the machine may well exceed this height

so extreme caution should be practised. For more information contact the

Health and Safety Executive or your local power company.

Ensure that all warning labels are always visible and that they are not damaged,

defaced or missing.

Lower the head to the ground when parking up. No weight is on the tractors

hydraulics. The blades have stopped spinning, before leaving the tractor.

Fit locking pins to slew and height before transport and before unhitching when

applicable.

Wear ear defenders if operating without a quiet cab or with cab windows open.

Ensure tractor guards are fitted correctly and are undamaged.

Work at a safe speed, taking into account terrain, passing vehicles and

obstacles.

Ensure that the tractor meets the minimum weight recommendations of the

machine manufacturer and that ballast is used if necessary.

Check that machine fittings and couplings are in good condition.

Spearhead QUADSAW 1602/2002/2402

19

Follow the manufacturer’s instructions for attachment and removal of the

machine from the tractor.

Use clear warning signs to alert others to the type of machine working in the

vicinity. Signs should be placed at both ends of the work site and should be in

accordance with the Department of Transport recommendations.

Ensure cutting blades are of the type recommended by the manufacturer, are

securely fitted and are undamaged.

Ensure hydraulic pipes are correctly routed to avoid damage from chafing,

stretching, pinching or kinking.

Disengage the machine, stop the engine and remove the key before leaving the

tractor cab for any reason.

Clean up any debris left at the work site.

Ensure that when you remove the machine from the tractor it is secured in a

safe position using stands provided.

Operate the blades at a speed give under in the Machine Specification

Section.

Never

Never operate the machine with other people present, as it is possible for

debris, including stones, to be discharged from the front and rear of the head.

WARNING: Some cutting heads may continue to ‘freewheel’ for up to 20

seconds or more after being stopped.

Never operate the machine until you have read and understood the relevant

handbook and are familiar with the controls.

Never use a machine that is poorly maintained or has guards damaged or

missing.

Never allow an inexperienced person to operate the machine without

supervision.

Never use or fit a machine onto a tractor if it doesn’t meet manufacturer

specification.

Never use a machine if the hydraulic system shows signs of damage.

Never allow children to play on or around the machine at any time.

Never attempt any maintenance or adjustment without first disengaging the

PTO, lowering the head to the ground, stopping the tractor engine and applying

the tractor parking brake.

Never leave the cab without removing the ignition key.

Never operate the tractor or controls from any position than the driving seat.

Never stop the engine with the PTO engaged.

Never operate with the sawblades missing.

Never operate PTO above recommended speed, 540 RPM.

Never operate with wire around any rotor. Stop immediately.

Never use the head at any angle, which may throw debris towards the cab.

Never attempt to use the machine for any purpose which it wasn’t designed for.

Never transport with PTO engaged.

Never enter the working area of the machine (risk of injury!).

Spearhead QUADSAW 1602/2002/2402

20

Never transport with the controls live, always turn off the isolator switch (red)

and disconnect supply.

Transport the machine without the blade protection guards mounted.

Attempt to detect a hydraulic leak with your hand; use a piece of card.

Exceed maximum oil pressure of 250 bar in the hydraulic hoses.

This manual suits for next models

2

Table of contents

Other Spearhead Saw manuals