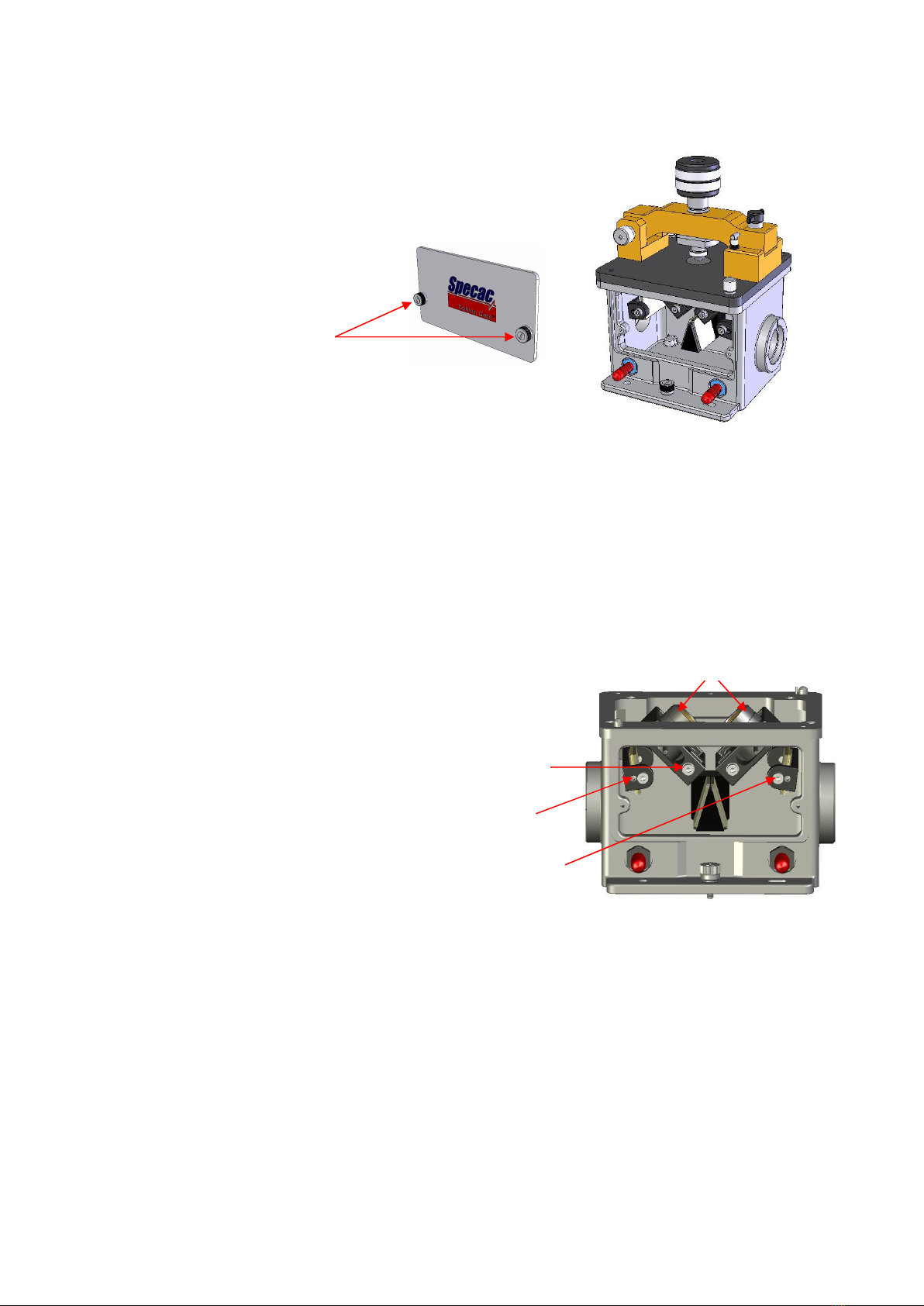

Step 4 – Remove the Front Cover of the Optical Unit

Undo the two captive screws on the front

cover plate of the Optical Unit and pull the

cover plate clear to gain access to the mirrors

and lens optical components for alignment.

Step 5 – Alignment Procedure

With the spectrometer in its energy monitoring mode, use the 3.0mm all driver (for rotation) and 2.0mm Allen key

(for tilt) tools supplied to adjust the alignment screws of the mirrors and lens assem lies in the Optical Unit. It is

important to know the source to detector eam direction of the spectrometer eing used - left to right or right to left –

as it passes through the sample compartment. This determines the input mirror and lens to the sample area and

output mirror and lens from the sample area to adjust.

For alignment start with the output adjusta le mirror for its rotate and then tilt position y turning of the respective

adjustment screws. O tain a maximum energy reading with a rotational adjustment of the mirror efore moving to the

tilt adjustment and then o tain a maximum reading from the tilt adjustment. Then adjust the focus position of the

output lens. The lens arrel locking screw is loosened y the 3.0mm all driver and the lens assem ly is slid in its

mount for focus holding the little tiller ar. When a maximum throughput is o tained from the output lens focal point

lock the screw again.

Repeat the rotate, tilt and focal point adjustment settings ut for the input

mirror and lens components to try and maximise the throughput. If the

energy has increased significantly after these adjustments for the input

mirror and lens components then repeat them again in the same order ut

for the output components once again only. This will ensure that the

accessory is at its optimum alignment settings.

Remem er, this alignment process only has to e

done once when first setting up the accessory in

the spectrometer – so it is worth spending a small

amount of time now in order to get the est

performance from it in the future.

Step 6 – Replace the Front Cover

Once aligned, the front cover can e replaced to maintain a sta le environment inside the accessory. To fit the purge

ellows or a dry air supply to purge the accessory, refer to page 23 of the Golden Gate™ ATR Accessory instruction

manual provided.

Step 7 – t’s Ready to Use!

For safety information and detailed instructions on getting the est from your Golden Gate™ ATR accessory please

refer to the Golden Gate ™ ATR Accessory instruction manual 2I-10500-17 supplied.

Specac Ltd

River House, 97 Cray Avenue,

Orpington

Kent BR5 4HE

Tel: +44 (0) 1689 873134

Fax: +44 (0) 1689 878527

www.specac.com

QS-10500-3

Grub Screw