Specac Golden Gate User manual

Low Temperature

Golden GateTM Diamond ATR System

User Manual

2I-10590 Issue 10

2

List of Safety Symbols

Safety Symbol

ISO 7000 symbol m

eaning

CAUTION!

WARNING – Hot Surface

(Reference ISO 7010-W017)

For indoor use only

(Reference IEC 60417-5957)

WARNING – Low Temperature/Freezing

conditions

(Reference ISO 7010-W010)

CAUTION! Only use the configured temperature controller

supplied with this accessory.

CAUTION! This user instruction manual should be read in

conjunction with the temperature controller and Golden

Gatetm manuals provided separately with the respective

Specac accessory.

3

Low Temperature

Golden Gate™ Diamond ATR

User Manual

2I-10590 Issue 10

User Manual

4

Low Temperature Golden Gate™ Diamond ATR

Models GS10590 / GS10592

USER MANUAL

1. INTRODUCTION 5

2. PACKING AND CHECKLIST 5

3. SAFETY OF USE 6

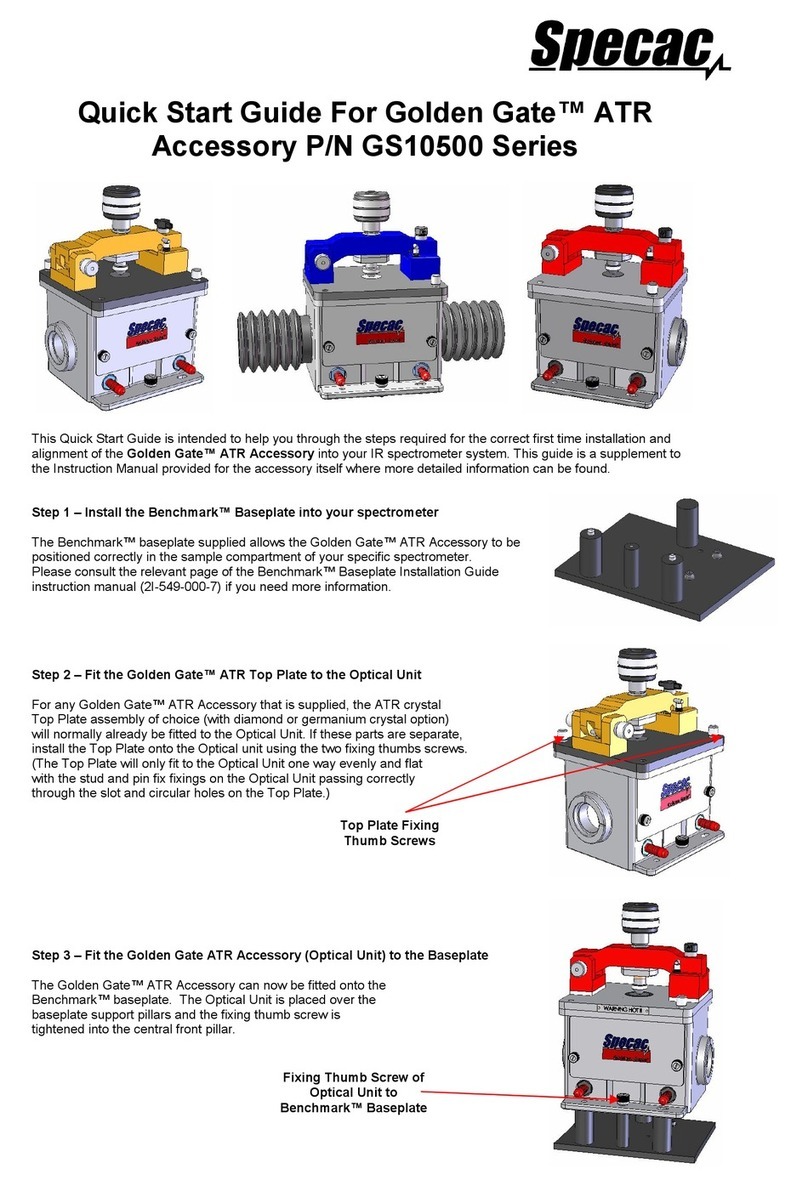

4. INSTALLATION 7

FIXING OF P/N GS10590 TOP PLATE 8

5. OPERATION OF THE LOW TEMPERATURE GOLDEN GATE™

ATR TOP PLATE 11

IMPORTANT NOTE FOR OPERATION 11

DEWAR CAP (10) NITROGEN PURGE CONNECTION 11

REFRIGERANTS TO USE 13

PREPARATION FOR USE AND GENERAL OPERATION 14

PROCEDURE USING A HIGH THERMAL TRANSFER GASKET 15

OTHER EXAMPLES OF OPERATION 18

1) USE OF LIQUID NITROGEN TO -80°C 18

LIQUID SAMPLES 19

SOLID SAMPLES 23

2) USE OF CARDICE (DRY CO2) AND ACETONE AS

REFRIGERANT AT -30°C 24

6. OPERATING PARAMETERS FOR THE LOW TEMPERATURE

GOLDEN GATE™ ATR TOP PLATE 25

7. LEGEND - PART IDENTIFICATION OF LOW TEMPERATURE

GOLDEN GATE™ TOP PLATE 27

8. SPARE PARTS FOR LOW TEMPERATURE GOLDEN GATE

TOP PLATE 28

© April 2016 Specac Ltd. All rights reserved.

Golden Gate™ and Brilliant Spectroscopy™ are trademarks of

Specac Ltd. Other product names mentioned herein may be

trademarks of their respective owners.

Low Temperature Golden Gate™ ATR

5

1. Introduction

Thank you for purchasing a Specac Product.

The Low Temperature Golden Gate™ single reflection diamond ATR

top plate is designed for use on the Golden Gate™ ATR optical base

unit. It is used to study liquid or solid samples at temperatures from

minus 150C to +80C. Liquid samples are analyzed by simply

covering the diamond ATR crystal, and the standard Golden Gate

clamp bridge is used to provide pressure for solid samples, providing

excellent sample contact.

Fig 1. Sectional Front View of Low Temperature ATR

2 6

4

5

3

1

4

User Manual

6

Golden Gate™ Top Plate

The analysis area of the top plate is a heatable diamond crystal

bonded into a tungsten carbide support disk (1), surrounded by a

cooling jacket dewar assembly (2). The dewar assembly is clamped to

the heated diamond ATR top plate (3) by four clamping screws (4).

There is a heat transfer gasket (5) between the diamond/ tungsten

carbide disk (1) and the centre part of the dewar (2). (Please see Figs

1 and 2.)

Fig 2. Diamond/Tungsten Carbide Puck and Gasket detail area of

Low Temperature Golden Gate™ Top Plate

Using liquid nitrogen as an example refrigerant in the dewar chamber

(6) and from control of power to the heaters, temperatures below

ambient can be achieved. For temperatures above ambient, no

refrigerant is required and the heaters for the diamond crystal are used

alone. Power to the heaters is provided by a dedicated 4000 Series

Temperature Controller. A separate instruction manual is provided for

operation of the Temperature Controller with the Low Temperature

Golden Gate™ ATR top plate.

2 5

3

1

Low Temperature Golden Gate™ ATR

7

2. Packing and Checklist

On receipt of your Low Temperature Golden Gate™ ATR accessory

please check that the following have been provided.

Low Temperature Golden Gate™ single reflection diamond ATR

top-plate (P/N GS10590).

Golden Gate Optical unit with choice of ZnSe or KRS-5 lenses and

appropriate Benchmark baseplate (if ordered as a complete

Golden Gate system (P/N GS10592)).

4000 Series Temperature Controller, instruction manual and power

cables.

Flat “transfer load” anvil to sapphire tipped rod assembly.

Sapphire tipped rod assembly.

Liquid sample injector consisting of an insulated 16-gauge

hypodermic needle and glass syringe.

Plastic funnel

Allen key (2mm).

Allen key (3mm).

Hex head ball driver (3mm).

Long T bar type Allen key (5mm).

Packet of glass filled PTFE gaskets (5).

Packet of high thermal transfer gaskets (20)

Spare Viton ‘O’ ring seal.

An Essential Spares Kit of parts (P/N GS10550)

Carefully remove the equipment from their packaging and proceed to

install into your spectrometer system.

User Manual

8

3. Safety of Use

WARNING – Low Temperature / Freezing conditions

The Low Temperature Golden Gate™ ATR system requires the use of

liquid nitrogen (LN2) for operation at sub ambient temperatures. When

using refrigerants, ensure all local laboratory safety procedures are

followed and wear appropriate personal protective equipment (PPE).

Recommended PPE gloves and glasses should be worn at all times

when operating this equipment.

Always use a suitable plastic funnel assembly for filling of the dewar

with liquid refrigerant to avoid accidental spillage to other areas of the

equipment. The funnel supplied (7) can be used either for introduction

of a liquid refrigerant through the small hole (8) or the crescent shaped

cut out (9) in the dewar cap (10). (See Fig 2).

Fig 2. Dewar Cap and Funnel Parts of Low Temperature Golden

Gate™ ATR Accessory

7

10

9

8

Low Temperature Golden Gate™ ATR

9

CAUTION! It is important to read any associated safety

information in the accessory manual before operating this

equipment.

Caution: Always follow local laboratory safety protocols

and procedures when using potential toxic or flammable

substances with this equipment. The equipment is

intended for use by suitably trained personnel only.

Caution: If the equipment is used in a manner not

specified within this manual, the protection provided by

the equipment may be impaired

Only clean with a soft, lightly dampened cloth. Do not use harsh

and/or abrasive cleaners on any Specac product. Consult Specac or

their authorized agent if in any doubt.

Always check before use that the safety protection provided have not

been compromised or impaired. The temperature controller should be

made inoperative and secured against unintended operation if in any

doubt.

The protection is likely to be impaired if for example if:

• Shows visible damage.

• Fails to perform its intended use.

• Has been subjected to adverse storage conditions.

• Has been subjected to severe transport stresses.

End of Lifetime Equipment Use

If any parts have reached their limit of lifetime and need to

be replaced, use appropriate WEEE and other local

regulations for the safe disposal of electrical equipment

and toxic chemicals.

User Manual

10

4. Installation

For the Low Temperature Golden Gate™ ATR system, P/N GS10592

the system is fully assembled before shipping (See Fig.3).

Fig 3. Low Temperature Golden Gate™ ATR System

Once installed into the host spectrometer, connect the heater and

thermocouple cables to the 4000 Series Temperature Controller (Not

shown). Refer to the 4000 Series 150W temperature controller

instruction manual for further details.

10

4

11

13

14

2

Low Temperature Golden Gate™ ATR

11

For Low Temperature Golden Gate™ ATR top plate upgrade (P/N

GS10590), the heated top plate is attached to the dewar assembly

before shipment. The dewar assembly and will need to be separated

from the heated top plate to enable fitment of the Golden Gate™

optical unit. The dewar assembly is then re-installed to complete the

assembly.

Fig 4. Separation of Low Temperature Golden Gate™ Dewar

Assembly from Heated Top Plate and Optical Unit Assembly

Remove the dewar assembly fixing screws (4) (See Fig 4.) using the

long T bar type Allen Key (5mm) allowing separation of the dewar from

the Golden Gate™ heated top plate.

2

4

11

3 5

User Manual

12

The heated top plate assembly (3) attaches to the Golden Gate™

optical unit (11) with the two new M4 x 16mm screws (12) supplied

(See Fig 5.). The new screws replace of the original thumb screws and

are shorter in length to allow the fixing of the dewar assembly to the

flat stainless steel heated top plate (Refer to P/N GS10500 Golden

Gate™ instruction manual for further details).

Fig 5. Low Temperature Golden Gate™ Heated Top Plate

and Optical Unit

When the heated top plate assembly (3) has been fitted to Golden

Gate™ optical unit (11) with the two M4 x 16mm screws (12), the cold

dewar assembly (2) can be re-fitted using the four fixing screws (4).

When tightening down the dewar fixing screws (4) ensure that the two

surfaces between the cold dewar assembly (2) and heated top plate

(3) remain parallel and even to ensure the correct thermal contact and

sealing of the thermal transfer gasket (5) between the dewar assembly

(2) and the diamond tungsten carbide puck (1).

3

11

5

12

Low Temperature Golden Gate™ ATR

13

Caution! Before tightening the dewar assembly to the heated top plate

assembly ensure that the correct thermal transfer gasket (5) (choice of

a white glass filled PTFE or grey graphite gasket) has been placed

correctly into position over the diamond/tungsten carbide puck. In

addition, ensure the gasket (5) does not get dislodged and cover /

obscure the diamond crystal while fitting the dewar assembly (2) over

the heated top plate assembly (3).

Additional Information:

When conducting the alignment procedure on the optical components

(mirrors and lenses) within the Golden Gate™ optical unit, ensure that

the cold dewar assembly (2) and the thermal transfer gasket (5) has

been tightened/screwed down correctly to the heated top plate

assembly (11). The diamond/puck assembly (1) has been designed to

be supported under sprung loaded tension and may move slightly

when the cold dewar assembly (2) is placed into position. Therefore,

optimum light beam throughput is achieved when the cold dewar

assembly (2) is fixed correctly in the working position over the diamond

(1). See alignment procedure in the Golden Gate™ instruction manual

P/N GS10500 for further details.

When the Low Temperature Golden Gate™ ATR Accessory has been

supplied under P/N GS10592, a white glass filled PTFE thermal gasket

(5) fitted by default.

User Manual

14

5. Operation of the Low Temperature Golden

Gate™ ATR Top Plate

Important Note for Operation

When using the Low Temperature Golden Gate™ ATR accessory at

temperatures below the ambient dew point, it is essential to use and

establish a nitrogen purge within the Golden Gate™ optical unit (11)

before any refrigerant is poured into the dewar chamber (6). This is to

prevent condensation or frost forming on the internal optics of the

Golden Gate™ optical unit. The purge can be established by using a

spectrometers own purge facility (if available) by using the purge

bellows (P/N GS10707) to bridge the gap between the Golden Gate™

apertures (13) and the input and output ports of the Spectrometer.

(See Purging the Golden Gate in the P/N GS10500 manual.)

Alternatively, with the purge bellows fitted to the aperture ports (13),

the optical unit (11) can be purged via the two, purge port hose

connectors (14) on the front of the Golden Gate™ optical unit (11)

using a dedicated dry nitrogen gas supply. (See Fig 3.)

Dewar Cap (10) Nitrogen Purge Connections

A nitrogen purge that is required to prevent frosting of the optical

components in the Golden Gate™ optical unit (11) during low

temperature operation is also needed for the central internal area of

the dewar assembly (15) above the diamond/tungsten carbide puck (1)

when taking reference background spectra for sub-ambient

temperature conditions. See Fig 6.

When the dewar cap (10) is placed into position, to cover the dewar

chamber (6), a supply of nitrogen gas can be introduced through one

of the 3.5mm diameter purge gas flow holes (16) in the dewar cap (10).

Similar to the optical unit (11) gas purge requirement, a purge gas

though the dewar cap (10) must be established before introduction of

any refrigerant. The inner chamber area (15) below the cap (10) will be

filled with the nitrogen gas and a flow of the gas will minimize any risk

Low Temperature Golden Gate™ ATR

15

of condensation forming and possibly freezing to the surface of the

diamond ATR crystal. See Fig 7.

Fig 6. Low Temperature Golden Gate™ Dewar area with

Dewar Cap removed. (Inner and Outer Dewar Chambers)

Fig 7. Low Temperature Golden Gate™ Dewar Cap Purge Holes

6

15

16

User Manual

16

CAUTION! Use of alternative refrigerants

The minimum recommended operating temperature is -150°C when

used in combination with liquid nitrogen (LN2) and the graphite high

thermal transfer gasket. Other types of refrigerant mixture are listed in

the table below.

Table of Refrigerant types

Refrigerant Type

Mixed Temperature

(a)

Main Hazard

C

K

Ice Water 0 273 Cold surfaces

Sodium Chloride/Ice (33g salt/81g ice) -21 252 Cold surfaces

Calcium Chloride/Ice (100g salt/81g ice) -40 233 Cold surfaces

Chloroform/Liquid Nitrogen (slush)

-64 209 Cold surfaces

(b)Solid CO2/Ether -78 195 Fire/Explosion

(b)Solid CO2/Acetone -78 195 Fire/Explosion

(b)Solid CO2/Isopropanol -78 195 Fire/Explosion

(b)

Toluene/Liquid Nitrogen (slush)

-95 178 Fire/Explosion

(b)

Pentane/Liquid Nitrogen (slush) -130 143 Fire/Explosion

Liquid Air (<21% oxygen)

-147 126 Cold surfaces

(b)

Isopentane/Liquid Nitrogen (slush) -160 113 Fire/Explosion

(b)Liquid Oxygen -182 91 Fire/Explosion

Liquid Nitrogen (LN2) -196 77 Cold surfaces,

Asphyxiation

(a) These figures are approximate as actual mixture temperatures are

affected by impurities.

(b) Appropriate safety risk assessments and laboratory procedures

need to be implemented before use of other alternative refrigerants.

Low Temperature Golden Gate™ ATR

17

For optimum temperature control in operation, you should choose the

refrigerant mix closest to the temperature you wish to study. From the

examples above, the natural freezing point of LN2 is -196°C, but the

lowest temperature achievable for the system overall is -150°C using

this refrigerant with an appropriate grey coloured graphite high thermal

transfer gasket (5). It will be a matter of experimentation for the best

choice of a refrigerant and gasket (5) combination, depending upon the

minimum and maximum temperatures to be achieved and the

temperature degree of control required.

In general, for temperature operation between -100°C and -150°C the

high thermal transfer graphite gasket (5) must be used. This gasket

material allows for these low temperatures to be reached but does not

have the same degree of temperature control offered by the low

thermal transfer white PTFE gasket (5).

For temperature operation between ambient and -100°C the low

thermal transfer white PTFE gasket (5) should be used, if a finer

degree of temperature control and thermal stability is required.

Preparation for Use and General Operation

The successful use of the Low Temperature Golden Gate™ ATR

accessory depends on the correct balancing of a specific refrigerants

“heat removing” capability against the energy (heat) input from the

electrical block heaters (17), built into the heated top plate assembly

(3) at the base of the dewar assembly (2). See Fig 8. The type of

experiment being carried out also determines a method of use and,

most importantly, the choice of thermal transfer gasket (5) between the

dewar assembly (2) and the diamond/tungsten carbide puck (1).

Note: In any experiment it is advisable to take a reference background

Spectrum (or spectra) at the same actual temperature

conditions when collecting a spectrum (or spectra) for the

sample. This is to obtain the optimum spectral results when the

background spectrum is subtracted from the sample spectrum.

User Manual

18

Fig 8. Low Temperature Golden Gate™ Heated Top Plate

Assembly underside view

If it is a requirement to obtain spectra for a sample at two different

physical states, solid and liquid, depending upon the freezing point of a

liquid sample it may be preferable to use the graphite high thermal

transfer gasket (5) in position. This gasket material will permit

operation down to the minimum temperature obtainable with this

accessory to -150ºC. By using this high thermal transfer gasket (5) the

sample can be quickly frozen using only a small amount of LN2

refrigerant, allowing it to boil off as soon as the desired temperature is

reached. This will minimize condensation and icing on the dewar (2).

Procedure Using a High Thermal Transfer Gasket

To ensure freezing of the LN2 refrigerants lowest temperature

capability (circa -150°C with a graphite high thermal transfer gasket (5)

being used), the block heaters (17) must be switched off by selecting a

lower set temperature on the controller (e.g. at least 10°C less than the

value showing for any actual temperature from the LN2 refrigerants

cooling action). Therefore, a suggested set temperature at the start of

experimentation is -150°C on the controller, as the accessory overall

will never get colder than this temperature value.

17

3

Low Temperature Golden Gate™ ATR

19

Reference Spectrum Collection

For collection of a background reference spectrum, at room

temperature conditions, establish the nitrogen purge gas conditions in

the optical unit (11) and within the internal sample chamber area (15)

from connection of the purge gas via a suitable flow pipe or tubing

through one of the dewar cap purge gas holes (16), before any

refrigerant is added.

Introduce some LN2 into the dewar chamber (6) using the funnel (7)

through the funnel hole (8) or crescent shaped cut out (9) in the dewar

cap (10). Initially, there will be some fuming of the LN2 as it boils off

when contacting with a warmer environment, but by adding small

amounts of LN2, after time the actual temperature on the controller

display will begin to drop fairly, quickly indicating the effect of the LN2

refrigerant action to the sample area for temperature measurement.

When the actual temperature has dropped to a value that is to be used

for study, stop adding any further LN2 refrigerant. If only small

amounts of LN2 have been added, once the remaining residual LN2

has boiled off from the dewar chamber (6), and because the heaters

(17) will still be inactive as the actual temperature will be higher than

the set temperature (-150°C), the accessory will start to warm up

naturally from the general ambient surroundings. At this stage when

the temperature value becomes relatively stable, a background ATR

spectrum can be collected and stored for use against an ATR

spectrum taken for a sample at the same temperature and conditions

of use.

If the refrigerant effect of the LN2 in combination with a high thermal

transfer graphite gasket (5) is causing the temperature to be too low in

value, (i.e. towards the minimum -150°C value), then the heaters (17)

may need to be activated to balance the cooling effect and raise the

temperature to the value desired. Therefore, if say a temperature of

-100°C is required, change the set temperature value to -100°C on the

controller. If the actual temperature is indicating a temperature value

lower than -100°C, the heaters (17) will activate (the heater light pulses

on the controller display) and the temperature will rise.

User Manual

20

Note: It is important for this type operation at very low temperatures to

ensure the LN2 refrigerant level is kept topped up to provide the

“balancing effect” against the power from the heaters (15).

Sample Spectrum Collection

When a reference spectrum at a particular low temperature value has

been collected the procedure of operation needs to be repeated, but

with some subtle changes.

To place a sample into position on the diamond crystal (1) after

collection of a reference spectrum, the Low Temperature Golden

Gate™ ATR accessory must be allowed to warm up to ambient

conditions. When the accessory is near to, or has reached room

temperature, dry off any external condensation using tissues. It may be

easier to dry the unit thoroughly by disconnecting the 4000 Series

Temperature Controller and removing the Low Temperature Golden

Gate™ accessory from the spectrometer and to place it on a

workbench.

When cleaned and dried, and re-installed in the spectrometer, at room

temperature conditions establish the nitrogen purge gas conditions in

the optical unit (11) and within the internal sample chamber area (15),

before any refrigerant is added, a liquid sample is placed in position to

cover the diamond of the diamond/tungsten carbide puck (1). Included

with the accessory is a liquid sample injector consisting of an insulated

16 gauge hypodermic needle and glass syringe that can be used for

delivery of a liquid sample at the base of the internal chamber area

(16) and over the diamond (1).

When the liquid sample is in place, re-position the dewar cap (10) and

you may then wish to re-establish a nitrogen purge flow to the internal

chamber (15) by use of a nitrogen flow tube through one of the dewar

cap holes (16). It depends upon the stability of the liquid sample to be

analysed (its relative volatility), if this nitrogen purge over the sample

may be necessary.

Introduce some LN2 into the dewar chamber (6) using the funnel (7)

through the funnel hole (8) or crescent shaped cut out (9). Initially,

Other manuals for Golden Gate

1

Table of contents

Other Specac Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT575817 Operation manual

Graco

Graco LineLazer V Standard Series Installation

ABB

ABB TPS52 Series Operation manual

Beijer Electronics

Beijer Electronics iX Panel K100 installation manual

Allied Systems

Allied Systems LONG REACH CR Series Installation maintenance and service manual

Siemens

Siemens SIMATIC NET RUGGEDCOM RX5000 Equipment manual

Genie

Genie RAIL EXTENSION KIT Supplement Instructions

Alipa

Alipa CODIPRO QLR instruction manual

nystrom

nystrom PTX Installation, operation & maintenance manual

Milwaukee

Milwaukee 4792 Operating instructions and parts list

KAKA Industrial

KAKA Industrial TR-60 Operation manual

ABB

ABB HT563009 Operation manual