Specac GS15051 User manual

Low Tonnage Gauge Kits for

Atlas™ Manual Hydraulic Presses

User Manual

2I-15051-8

Low Tonnage Gauge Kits for

Atlas™ Manual Hydraulic Presses

User Manual

2I-15051-8

User Manual

2

Low Tonnage Gauge Kits for Atlas™ Manual

Hydraulic Presses P/N’s GS15051/52/55

CONTENTS –USER MANUAL

1. INTRODUCTION .................................................................................3

2. UNPACKING AND CHECKLIST .............................................................5

3. INSTALLATION OF THE LOW TONNAGE GAUGE KIT TO THE ATLAS™

MANUAL HYDRAULIC PRESS..............................................................6

PROCEDURE FOR FITTING.................................................................6

4. OPERATION OF THE ATLAS™MANUAL HYDRAULIC PRESS WITH A

LOW TONNAGE GAUGE FITTED........................................................10

SAFETY WARNINGS WHEN OPERATING THE PRESS ..........................10

BLEEDING AIR FROM THE LOW TONNAGE GAUGE KIT .......................10

SWITCHING ON AND OFF THE LOW TONNAGE GAUGE.......................13

5. LEGEND -BUBBLE NUMBER PART IDENTIFICATION ...........................14

6. SPARE PARTS FOR THE LOW TONNAGE GAUGE KITS........................14

© April 2016 Specac Ltd. All rights reserved.

Brilliant Spectroscopy is a trademark of Specac Ltd.

Other product names mentioned herein may be trademarks

of their respective owners.

Low Tonnage Gauge Kits for Atlas™ Manual Hydraulic Presses

3

1. Introduction

Thank you for buying a Specac product.

The Low Tonnage Gauge Kits enable a standard Atlas™ 15T or 25T

Manual Hydraulic Press (P/N GS15011 and P/N GS25011

respectively) to be used more accurately for the reading of a low

tonnage load that has been applied during a pressing. The low

tonnage gauge conversion kits for a 0 to 1 tons range (P/N GS15051),

0 to 2 tons range (P/N GS15052) and 0 to 5 tons range (P/N GS15055)

provide an ADDITIONAL low tonnage load gauge to be used along

with the standard 15 or 25 ton load gauge fitted on the press.

The appropriate low tonnage gauge kit is fitted by the user to allow

both gauges to be connected to the press and used in-line to register

an applied tonnage load. The lower tonnage gauge that has been fitted

in this way to a press can be independently switched off from the

pressure system, but any pressure of oil in the system will always be

registered as an appropriate applied tonnage load at the 15 or 25 ton

gauge fitted.

The lower tonnage load gauge has finer divisions for reading of an

applied load, so, for example, if it is important to know that you are

applying say 4.1 tons as opposed to possibly 4.5 tons, then the low

tonnage gauge kit for a 0 to 5 ton load range would be required for

fitting to the press.

Beware! When a low tonnage gauge kit option is fitted to a press, the

press itself can only be operated up to the maximum load

allowable when the particular low tonnage gauge is switched

on line for reading the load. (e.g. 2 tons maximum load for the

0 to 2 tons load gauge kit P/N GS15052).

As an operating safety precaution, to prevent accidental over-

pressurisation of a lower tonnage gauge when fitted (if it has not been

switched off-line when higher tonnage loads are to be applied),

Specac recommend that the pressure relief valve assembly situated

underneath the standard load gauge of the press is adjusted to vent off

User Manual

4

at the maximum tonnage load capability of the low tonnage gauge

fitted. Higher tonnage loads than the low tonnage gauge maximum can

still be obtained on the 15T or 25T press if they are to be applied, but

then the pressure relief valve assembly will have to be readjusted to

allow for a higher tonnage load to be hand pumped and contained on

the system and therefore the low tonnage load gauge control valve

MUST also be turned off.

As an example for use of the 0 to 5 ton low tonnage gauge kit P/N

GS15055 when fitted to an Atlas™ 15T Manual Hydraulic Press P/N

GS15011 (which can be operated to apply up to a 15 ton maximum

load), set the pressure relief valve accordingly such that a maximum

load for 5 tons can be hand pumped on the press. This maximum load

is indicated on both the standard 0 to 15 ton load gauge and 0 to 5 ton

low tonnage load gauges that have been fitted. Any further pulls on the

pump handle of the press results in an excess pressure being vented

off at the pressure relief valve. In this way the pressure relief valve acts

as a safety device to not only prevent overloading of and damage to

the low tonnage gauge mechanism, but also to any sample or die

assembly in the pressing area of the press itself.

If a tonnage load higher than 5 tons is needed for application, switch

off the low tonnage load gauge at its control valve and re-adjust the

pressure relief valve assembly for a higher tonnage load to be applied

and contained.

Therefore, use of an Atlas™ 15T Manual Hydraulic Press allows for

any tonnage load up to 15 tons to be applied to a sample or an

evacuable pellet die in the pressing area. However, if a finer reading of

the load applied up to a maximum of 5 tons is required, then the low

tonnage gauge kit P/N GS15055 can be fitted to the press and the

additional low tonnage gauge provided is switched on-line.

Low Tonnage Gauge Kits for Atlas™ Manual Hydraulic Presses

5

2. Unpacking and Checklist

On receipt of your Low Tonnage Gauge Kit please check that the

following parts have been supplied.

● 1 Manifold body (square tube) assembly

with 0 to 1, 0 to 2, or 0 to 5 tons

load gauge fitted.

● 1 Fixing bolt. (Fixing bolt with two Dowty

seals is already in position at base of

manifold body with a little red cap seal).

● 1 Open ended spanner (18mm A/F and 19mm A/F).

● 1 Spare (Dowty) seal for gauge connection part of press.

● 1 Instruction manual.

Carefully remove the parts from packaging and prepare the parts for

fitting to the Atlas™ Manual Hydraulic Press.

User Manual

6

3. Installation of the Low Tonnage Gauge Kit to

the Atlas™ Manual Hydraulic Press

The Low Tonnage Gauge Conversion Kit is an additional assembly

of parts that a user can fit to an Atlas™ 15T or 25T Manual Hydraulic

Press to provide a facility of a finer reading for any tonnage load being

applied, up to the maximum load capability of the particular low

tonnage gauge fitted.

Note: Specac recommend to test that the press you are using and

would wish to adapt with a low tonnage gauge kit is functioning

correctly to apply a tonnage load, before having to partially

dismantle some of the parts from the pump block assembly of

the press and rebuild it from the parts supplied with the low

tonnage gauge kit. If a subsequent fitting of new parts introduces

a problem of non-functionality (e.g. an airlock in the oil), you may

be able to pinpoint more readily what is needed to correct and to

get the new system operational.

Procedure for Fitting

To help in the explanation of the procedure for fitting a low tonnage

gauge kit to an Atlas™ manual hydraulic press, relevant parts in the

following diagrams (Figs.) have been identified with a “bubble” part

number that corresponds directly to the same part number as indicated

in the Atlas™ Manual Hydraulic Press’s own user instruction manual.

New parts from the low tonnage gauge kits have been “bubble” part

numbered accordingly for consistency with the press numbering

system.

The original load gauge (31) (15 or 25 tons) of the press is removed

from the pump block assembly of the press and fitted to the manifold

body (74) of the low tonnage gauge kit that already has the low

tonnage gauge (75) option (1 ton, 2 tons or 5 tons range) fitted. The

whole assembly of parts is then fitted onto the press at the pump block

assembly from where the 15 or 25 tons load gauge has been removed.

Low Tonnage Gauge Kits for Atlas™ Manual Hydraulic Presses

7

Loosen the gauge connector (39) fitting to the load gauge (31) by

unscrewing the top nut (N1) connection (see Fig 1.) using the 19mm

A/F end of the spanner supplied.

Note: The connection (39) nut at (N1) must be turned clockwise,

using the 19mm A/F spanner and holding the gauge (31) with

your other hand to separate the threaded parts.

Fig 1. Load Gauge Connector Part of Press

Carefully remove the load gauge (31) and put it by for safe keeping.

(See Fig 2.)

Fig 2. Removal of 15/25 Ton Load Gauge from Manual Press

31

39

48

N1

N2

39

30

User Manual

8

The gauge connector (39) is then removed from the pump block

assembly by unscrewing the lower nut (N2) connection by the “Dowty”

seal (48). (See Fig 1. and Fig 2.) (Unscrew - turn (N2) anticlockwise.)

Transfer the gauge connector (39) and Dowty seal (48) parts for fitting

to the bore opening (76) of the manifold body (74) by tightening of the

lower nut connection (N2). (See Fig 1. and Fig 3.) If the removed

Dowty seal (48) from the press is not suitable for re-use, then use the

spare seal provided with the low tonnage gauge kit.

Note: The bore opening (76) on the manifold body (74) will be plugged

with a transport screw to prevent dust from entering. Remove

this screw before fitting of the gauge connector (39) and Dowty

seal (48) parts.

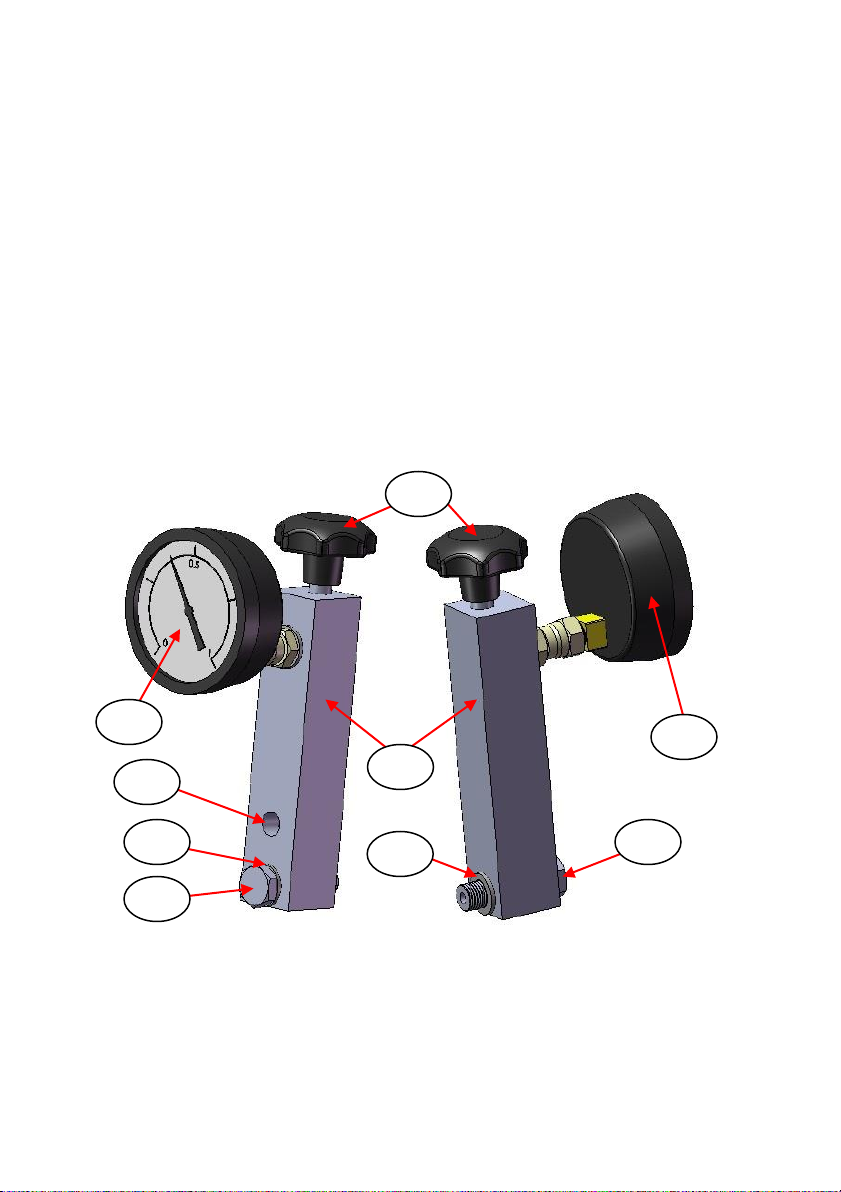

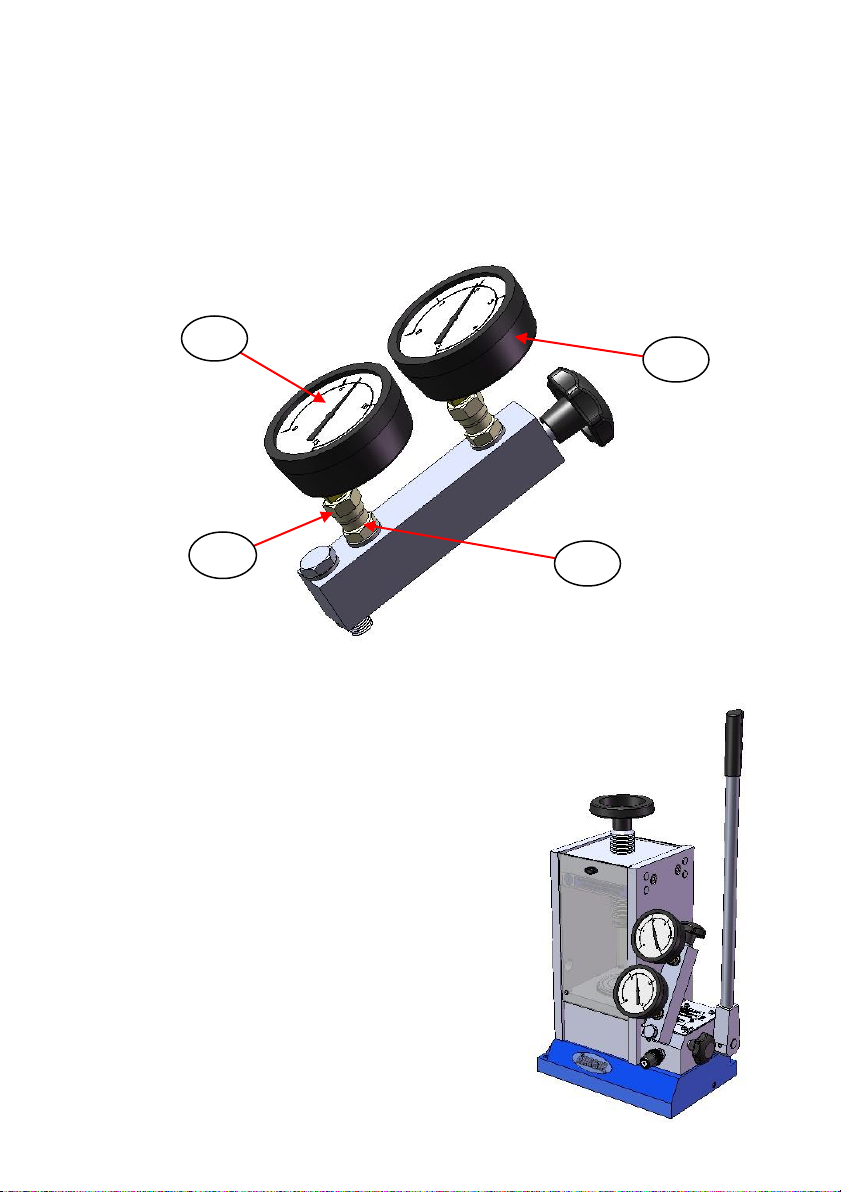

Fig 3. Front and Rear View of Low Tonnage Gauge Kit

Remove the dust cover cap from the fixing bolt (77) and Dowty seal

(78) parts at the base of the manifold assembly (74). (See Fig 3.)

75

76

78

79

74

78

75

77

77

Low Tonnage Gauge Kits for Atlas™ Manual Hydraulic Presses

9

When the gauge connector (39) has been fitted to the manifold tube

(74), fit the 15 or 25 ton load gauge (31) to the gauge connector by

tightening of the top nut (N1) connection. (See Fig 4.) Tighten together

by turning (N1) anticlockwise and holding the load gauge (31).

Fig 4. Both Gauges Fitted to the Manifold Block

Proceed to fit the complete manifold tube

assembly with the two gauges via the fixing

bolt (77) and Dowty seal (78) into position

on the pump block assembly of the press,

from where the original gauge (31) and

gauge connector (39) have been removed.

Tighten the fixing bolt (77) using the 19mm

A/F end of the spanner supplied. The

completed assembly of parts for a low

tonnage gauge kit as fitted to an Atlas™

manual hydraulic press is shown as Fig 5.

Fig 5. Complete Kit Assembly Fitted

to a Manual Press

39

75

31

N1

User Manual

10

4. Operation of the Atlas™ Manual Hydraulic

Press with a Low Tonnage Gauge Fitted

Safety Warnings When Operating the Press

Important: As mentioned in the Introduction, it is extremely important

that the Atlas™ manual hydraulic press is restricted to the

maximum load limit of any low tonnage gauge fitted

before use. Instructions how to set the load limit using the

pressure relief valve assembly are found in the user

instruction manual for the Atlas™ manual hydraulic press.

This setting will prevent any over-pressurisation to the low

tonnage load gauge (75) that would damage the gauge if

the open/close valve tap (79) for the low pressure gauge is

accidentally left open when higher tonnage loads are

wished to be pumped on the press.

Bleeding Air from the Low Tonnage Gauge Kit

Before the Atlas™ manual hydraulic press can be used to apply a

tonnage load with the fitting of a low tonnage gauge kit, any possibility

of air that might be trapped in the oil, preventing a pressure build up,

must be bled from the manifold body (77).

To bleed any trapped air from the oil, carry out the following procedure:

Place an “unyielding” sample/work (e.g. a cylindrical block of metal) to

press in the usual way, within the pressing area of the Atlas™ manual

hydraulic press. Ensure that the the metal block to press is loosely

clamped between the lead screw top bolster pressing face and the

lower bolster pressing piston face.

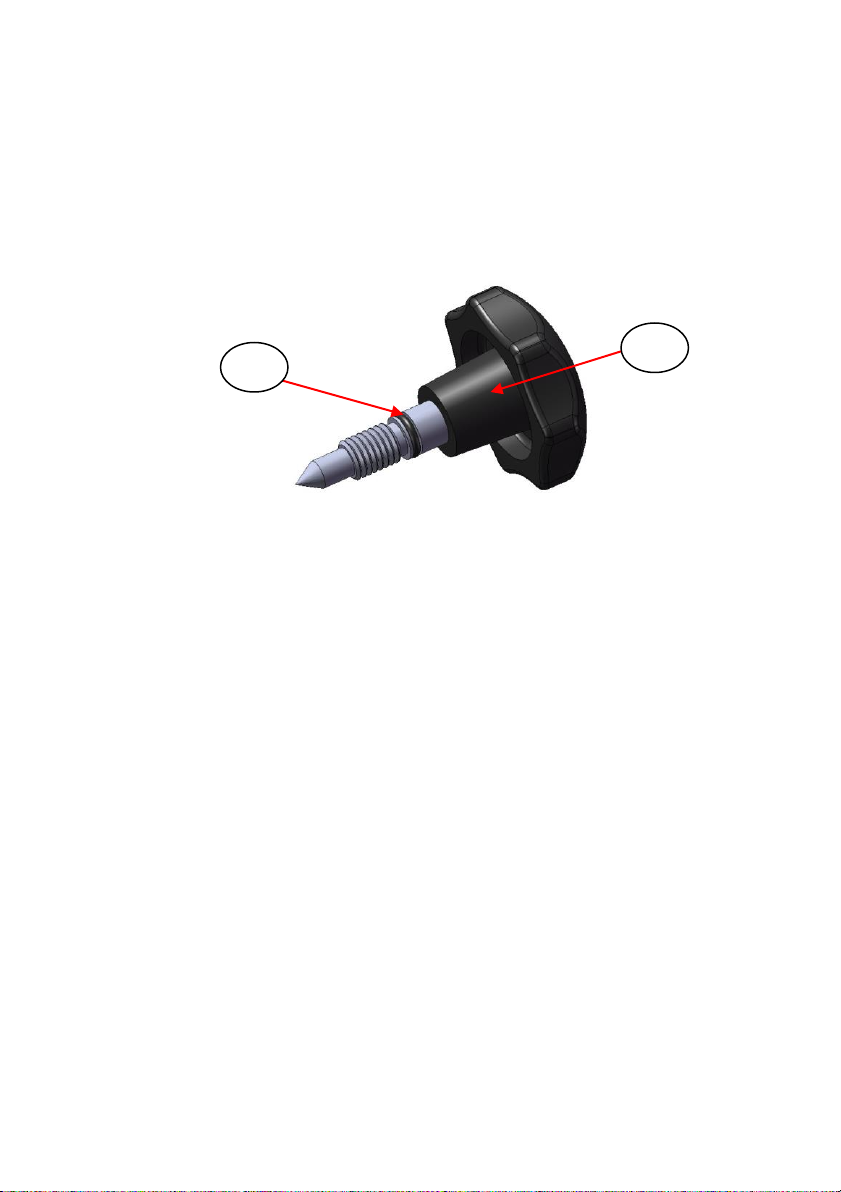

Ensure the open/close valve tap (79) on the manifold body (77) is

closed. Closing the valve tap (79) isolates the low tonnage gauge (75)

Low Tonnage Gauge Kits for Atlas™ Manual Hydraulic Presses

11

that has been fitted, to stop any oil pressure pumped on the system

from reaching it. The valve tap (79) is a tapered “needle” type fitting

and will be closed when the tap handle (79) is turned hand tight in a

clockwise direction. There is an O-ring (80) on the valve tap assembly

that makes an oil-tight seal when fully closed. (See Fig 6.)

Fig 6. Low Tonnage Gauge Open/Close Valve Tap Assembly

Close the pressure release handle (30) of the press by turning

clockwise (see Fig 2.) and begin to hand pump the press (slowly) in

the usual way. Oil will be pressurized and forced from the press

reservoir up and into the manifold body (77) to register at the higher

load tonnage gauge (31) fitted at the base of the manifold body (77)

and towards the shut off valve tap assembly (79). Pump to apply a

tonnage load of about 1 (one) ton (no more) against the metal block to

be registered at the higher tonnage load gauge (31) as fitted.

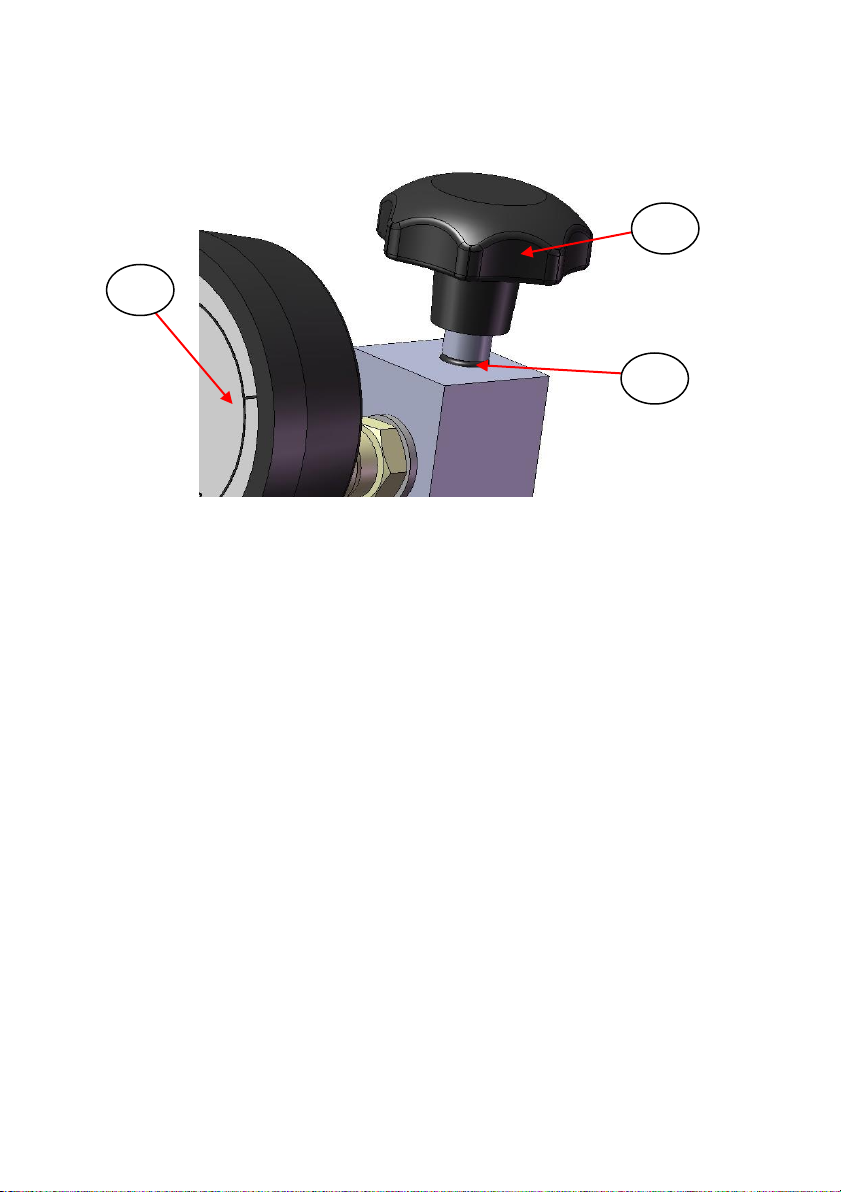

Now, very slowly open the valve tap (79) by anti-clockwise rotation of

the handle until the O-ring (80) is just beginning to emerge from the top

of the manifold body (77). (See Fig 7.) Any air that may be trapped in

the manifold body (77) will be forced out at the top past the opened

valve tap (79) and by the O-ring seal (80) from the oil pressure that has

been pumped on the system. When air and oil is observed at the valve

tap (79) by the O-ring (80), a slight decrease in the tonnage load that

has been applied at the higher tonnage load gauge (31) and a

registering of a low tonnage load at the low tonnage gauge (75) fitted

will also be observed.

80

79

User Manual

12

Fig 7. Opening of Valve Tap for Bleed of Air Procedure

Note: Be very careful when opening the valve tap (79). It is not

necessary to open it any further than when the O-ring appears

and any air bubbles emerge with release of some pressurised

oil. Applying a low tonnage reading of 1 ton to the metal block,

ensures there is sufficient oil pressure in the system to allow the

air to be bled off at this point of the manifold body (77) assembly.

It is also a safe load to apply if the LOWEST tonnage gauge of 0

to 1 tons range has been fitted to the manifold body (77) and

this gauge is switched on line to register an oil pressure from

the bleed of air procedure.

When the oil flows freely and no more air bubbles are observed,

tighten the valve tap (79) clockwise to close it fully again. The newly

fitted low tonnage gauge kit with twin gauges fitted to the press should

now have been successfully bled free of air.

Release the overall pressure in the system and hence load from the

metal block in the press by opening slowly and slightly (turn anti-

clockwise) the pressure release valve (30) on the press.

75

79

80

Open Valve Tap

Until O-ring Just

Shows

Low Tonnage Gauge Kits for Atlas™ Manual Hydraulic Presses

13

Now, still with the valve tap (79) closed, follow the procedure to adjust

the pressure relief valve assembly on the press to set a maximum

tonnage load achievable on the press that corresponds to the

maximum load capability of the low tonnage gauge (75) as fitted.

(1 ton, 2 tons or 5 tons range.) The procedure to adjust the pressure

relief valve is found in the user instruction manual for the Atlas™

manual hydraulic press.

Switching On and Off the Low Tonnage Gauge

To bring the low tonnage gauge “on line” for load reading, the valve tap

(79) on the manifold body (77) is opened. (79) is a needle type valve

(See Fig 6.) and the tap handle only needs a quarter to half turn

maximum anti-clockwise to open for the low tonnage gauge (75) to be

switched on to register a tonnage load.

Beware: If the valve tap (79) is opened too far from turning the handle

anti-clockwise for operation of the low tonnage gauge, there

is a risk that the O-ring (80) will not seal effectively and so oil

pressure in the system will be lost and there will be no

effective build-up of a tonnage load that can be applied to any

work/sample being held in the press.

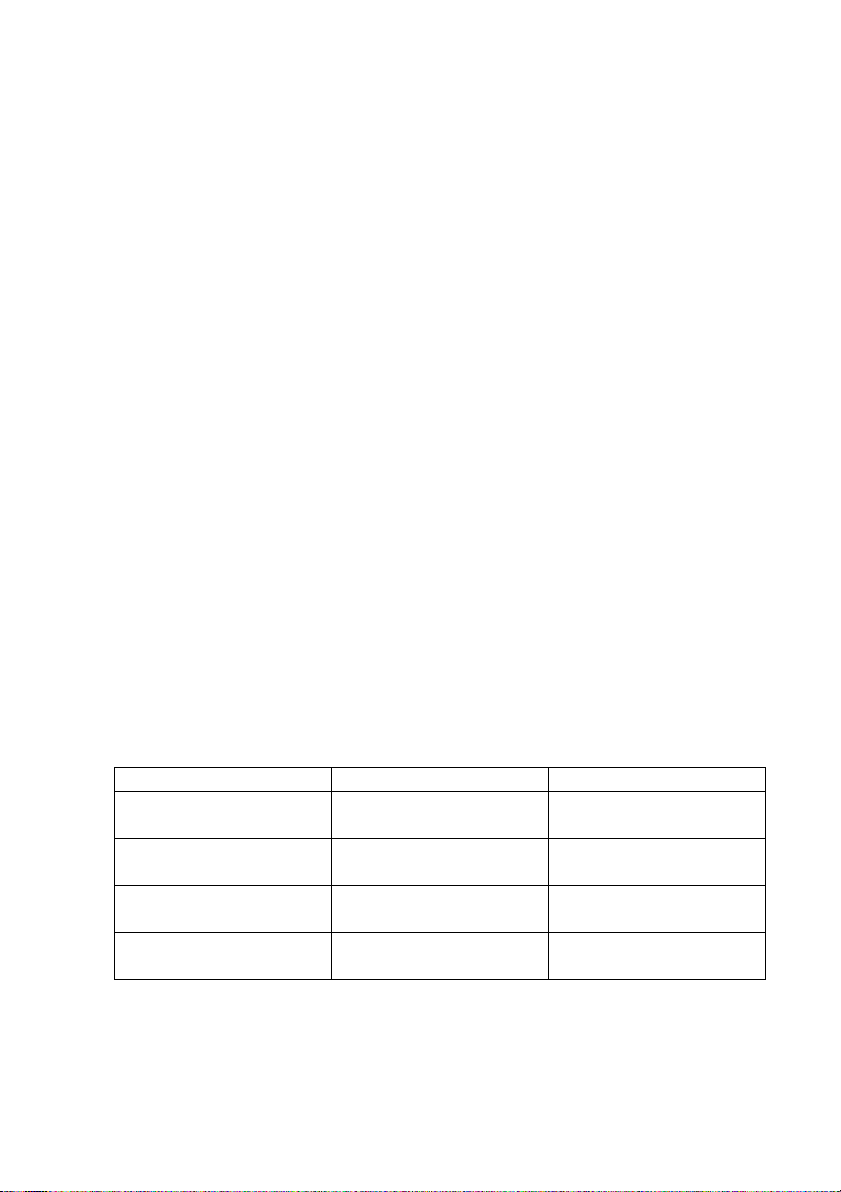

The following table shows the situation relating to which gauge is

working when the pressure release valve (30) on the press and the

valve tap (79) on the manifold body (77) are either open and/or closed.

Valve

Status of Valve

Gauge Being Used

(30)

(79)

Open

Open

Neither

(30)

(79)

Closed

Open

(31)

(75)

(30)

(79)

Closed

Closed

(31)

(30)

(79)

Open

Closed

Neither

User Manual

14

5. Legend –Bubble Number Part Identification

(30) Pressure release handle (valve) on press.

(31) Original 15 or 25 ton load gauge on press.

(39) Load gauge connector fitting on press.

(48) Dowty seal for gauge connector fitting on press.

(74) Manifold body of low tonnage gauge kit.

(75) Low tonnage gauge (0 to 1, 0 to 2, or 0 to 5 ton range option).

(76) Bore opening on manifold body.

(77) Manifold body fixing bolt.

(78) Dowty seal (2 off) for manifold body fixing bolt.

(79) Open/close valve tap assembly for low tonnage gauge.

(80) O-ring seal on valve tap assembly for low tonnage gauge.

6. Spare Parts for the Low Tonnage Gauge Kits

P/N GS15051 0 to 1 ton Low Tonnage Gauge Kit.

P/N GS15052 0 to 2 ton Low Tonnage Gauge Kit.

P/N GS15055 0 to 5 ton Low Tonnage Gauge Kit.

Notes for Use of Low Tonnage Gauge Kit

Notes for Use of Low Tonnage Gauge Kit

Worldwide Distribution

France

Eurolabo - Paris.

Tel.01 42 08 01 28

Fax 01 42 08 13 65

email: contact@eurolabo.fr

Germany

L.O.T. - Oriel GmbH & Co,

KG - Darmstadt

Tel: 06151 88060

Fax: 06151 880689

email:info@LOT-Oriel.de

Website: www.LOT-Oriel.com/de

Japan

Systems Engineering Inc. -Tokyo

Tel: 03 3946 4993

Fax: 03 3946 4983

email:systems-eng@systems-eng.co.jp

Website: www.systems-eng.co.jp

Spain

Teknokroma S.Coop C. Ltda

Barcelona

Tel: 93 674 8800

Fax: 93 675 2405

email: comercial@teknokroma.es

Switzerland

Portmann InstrumentsAG

Biel-Benken

Tel: 061 726 6555

Fax: 061 726 6550

email: info@portmann-instruments.ch

Website:www.portmann-instruments.ch

USA

SPECAC INC.

414 Commerce Drive

Suite 175,

Fort Washington,

PA 19034, USA

Tel: 215 793 4044

Fax: 215 793 4011

United Kingdom

Specac Ltd. - London

Unit 12, Science & Innovation Centre

Halo Business Park

Orpington

Kent BR5 3FQ

Tel:+44 (0) 1689 873134

Registered No. 1008689 England

Brilliant Spectroscopy™

www.specac.com

SPECAC INC.

414 Commerce Drive

Suite 175,

Fort Washington,

PA 19034, USA

Tel: 215 793 4044

Fax: 215 793 4011

SPECAC LTD.

Unit 12, Science & Innovation Centre

Halo Business Park

Orpington

Kent BR5 3FQ

Tel: +44 (0) 1689 873134

Registered No. 1008689 England

This manual suits for next models

1

Table of contents

Other Specac Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Festo

Festo YXC Series Description, Mechanical Installation

Balluff

Balluff BOS R254K-UUI-RH11-S4 Configuration guide

STABILUS

STABILUS ACE FRT-F2 Operating and mounting instructions

Big Daishowa

Big Daishowa KAISER CK PRESETTER Operation manual

ABB

ABB Relion 615 series manual

AMK

AMK SPINDASYN Device description