Specac Atlas 15T User manual

Atlas™ Manual 15Ton (15T) and 25Ton

(25T) Hydraulic Press

User Manual

2I-15011 Issue 13

Atlas™ Manual 15T and 25T Hydraulic Press

3

Atlas™ Manual 15Ton (15T) and

25Ton (25T) Hydraulic Press

User Manual

2I-15011 Issue 13

User Manual

4

Atlas™ Manual 15T and 25T Hydraulic Press

MANUALLY OPERATED HYDRAULI PRESS, (15 AND 25 TON)

CONTENTS - USER MANUAL

1.

I

NTRODUCTION

................................................................................. 5

2.

S

PECIFICATIONS OF THE

A

TLAS

™

M

ANUAL

H

YDRAULIC

P

RESS

. .......... 6

3.

U

NPAC ING AND

I

NSTALLATION

......................................................... 7

4.

S

AFETY

C

ONSIDERATIONS WHEN

O

PERATING THE

P

RESS

................. 11

5.

O

PERATION OF THE

P

RESS

............................................................. 12

C

ONTROL OF A

M

AXIMUM APPLIED

L

OAD

.......................................... 15

L

EADSCREW

A

SSEMBLY

.................................................................. 17

6.

F

AULT

F

INDING

,

C

AUSES AND

R

EMEDY

............................................ 18

L

OSS OF

P

RESSURE IN THE

P

UMPING

S

YSTEM

................................. 18

B

LEEDING

A

IR FROM THE

P

UMP BLOC

A

SSEMBLY

........................... 20

B

LEEDING

A

IR FROM THE

P

ISTON

A

SSEMBLY

................................... 22

P

ISTON

D

OES

N

OT

R

ETURN

W

HEN

P

RESSURE IS

R

ELEASED

............ 23

7.

L

EGEND

......................................................................................... 24

S

PARE

P

ARTS

................................................................................. 25

© April 2014 Specac Ltd. All rights reserved.

Brilliant Spectroscopy is a trademark of Specac Ltd.

Other product names mentioned herein may be trademarks

of their respective owners.

Atlas™ Manual 15T and 25T Hydraulic Press

5

1. Introduction

Thank you for purchasing a Specac product.

The Specac Atlas™ Manual 15T and 25T Hydraulic Presses have

been designed for a wide variety of pressing applications, but they are

specifically suited to the preparation of Br discs using Specac

evacuable pellet die assemblies.

The presses can be adapted to provide heated pressing surfaces with

Specac Heated Platens and a Temperature Controller (P/N GS15515).

These heated pressing surfaces can be used for the preparation of thin

films in conjunction with use of the Constant Thickness Film Maker

Accessory (P/N GS15640). The High Temperature Film Maker

Accessory (P/N GS15800) can also be used with the Specac presses.

(The Heated Platens P/N GS15515 are not required for use with the

High Temperature Film Maker Accessory P/N GS15800 as this

accessory has its own heated pressing surfaces).

The Atlas™ 15T and 25T manual presses work by hand pumping a

hydraulic fluid (oil) to raise a piston and compress a sample held in the

pressing area. The press consists of a pump block assembly, where

the oil is pressurized by the simple pumping action from a handle, and

the sample pressing side, where the pressurized oil is forced under the

piston assembly. When resistance is offered by a sample, the pressure

build up in the system is shown on the 15 or 25 Ton load gauge,

located on the pump block assembly.

In addition to the standard versions of the press providing maximum

tonnage loads of 15 and 25 tons, there are low tonnage gauge

conversion kits available for allowing finer load readings over smaller

ranges. These ranges are from 0-1 tons, 0-2 tons and 0-5 tons. The

lower tonnage gauges are connected additionally in line with either the

standard 15 or 25 ton gauge. With these lower tonnage gauges

switched on, the press can only be used up to the maximum tonnage

load limit of the lower gauge that has been fitted.

User Manual

6

2. Specifications of the Atlas™ Manual

Hydraulic Press

E Marking ompliance

The Atlas™ Manual Hydraulic 15T and 25T Presses do not require and

indeed must not be CE Marked. Under the Pressure Directive

97/23/EC regulations, because these presses fall below the stated

pressure and volume limits, Specac adopts SEP (Standard

Engineering Practice) to ensure the safety in use of these products.

Maximum Height (at pump handle) 610 mm

Maximum Width 310 mm

Maximum Depth 190 mm

Weight 50 g

Lower Piston Stroke 25.4 mm

Upper Lead Screw Travel 89 mm

Minimum Daylight (Distance Between Pressing Faces) 38 mm

Maximum Daylight (Distance Between Pressing

Faces)

152 mm

Lower Pressing Face Diameter 86 mm

Upper Pressing Face Diameter 32 mm

Maximum Width Of Sampling Area (side to side) 134 mm

Maximum Depth Of Sampling Area (back to front) 141 mm

Oil Capacity 0.284 Liters

(0.5 Pint)

Oil Type CL 37

Atlas™ Manual 15T and 25T Hydraulic Press

7

3. Unpac ing and Installation

Beware! This press is very heavy and care must be taken

to transport it properly. This will protect you and the press

from accidental damage or injury.

The press leaves the factory in specially designed packaging. It sits on

a wooden pallet and has a thick outer cardboard casing held to the

pallet by three tie straps. There are direction arrows on the casing

indicating which way up the press is to be handled.

To unpack the press first cut the three straps with a sharp knife and lift

up the outer cardboard casing from the pallet.

Fig 1. Atlas™ Manual Hydraulic Press Provided as Packaged

The press has internal transport packing around the top, by the lead

screw handle. (See Fig 1.) This packing is four pieces of cardboard

stacked on top of each other, held tight by the lead screw handle and

Leadscrew

Handle

Four Packing

Pieces to Remove

Wooden

Pallet

Pump

Handle

Pressure/Load

Gauge

User Manual

8

supporting the pump handle in an upright position. To remove these

four pieces loosen the lead screw handle (turn anticlockwise) and then

carefully lift them up and over the lead screw handle.

The press is now ready to be lifted off of the wooden pallet. There are

two holes in the upright frame supports on the sample pressing side of

the press (used for vacuum tubing when an evacuable pellet die is in

the press – see Fig 2.). These two holes can be used to lift up and

position the press by passing strong nylon rope through them to

provide a sling. If available, a hoist can be used to lift the press via this

sling. If a hoist is not available, then a minimum of two people will be

required to lift the press. Use heavy-duty gloves and lift the press from

underneath by the base casting. DO NOT ATTEMPT TO LIFT THE

PRESS BY THE LEAD S REW HANDLE OR PUMP HANDLE.

Fig 2. Lifting Holes and Base asting Fixing Holes

Place the press in its working position. In certain circumstances, it may

be necessary to attach the press permanently to a laboratory bench.

Two 10 mm diameter holes are provided in the base casting for this

Holes i

n Frame

Supports that

can be used for

Lifting

Base asting

Fixing Holes

(Other in

Opposite orner)

Atlas™ Manual 15T and 25T Hydraulic Press

9

purpose. (See Fig 2.) It is recommended that M8 diameter bolts are

used to secure the press and that the bench top is at least 25 mm thick

to take the weight of the press.

The press is supplied filled with hydraulic oil and is ready to use. The

only preparation required before operation is to remove the nylon vent

screw (37) from the pump plate (36) of the pump block assembly.

Fig 3. Nylon Vent Screw (Transportation Screw) to Remove

Note: A light smearing of oil is applied around the main pressing piston

area (4 and 5) when the press is supplied as new. It is perfectly

normal and not a sign that oil is leaking.

Please keep the press packing materials for future transportation.

Replacing a press in its packaging is the reverse of the procedure

described previously.

For any inquiries to Specac regarding the press the serial number

must be quoted. The serial number is a five digit number preceded by

a letter of the alphabet e.g. H, and is found engraved on the press at

the rear of the pump block assembly. The serial number is also on the

Test Certificate found at the rear of this manual.

36

37

User Manual

10

If you need to contact Specac regarding a service or repair issue

relating to an Atlas™ Manual Hydraulic Press, please be as specific as

possible regarding the nature of the enquiry. Please quote the serial

number for the press, identify how the press is being used and provide

as much information as you can.

Where possible, if contacting by email, please provide photographs too

as these can help greatly to understand the nature of the enquiry.

Fig 4. Rear View of 15/25 Ton Atlas™ Manual Hydraulic Press

Serial Number

Location

Atlas™ Manual 15T and 25T Hydraulic Press

11

4. Safety Considerations When Operating the

Atlas™ Manual Hydraulic Press

Under the Pressure Directive 97/23/EC, because these presses fall

below the stated pressure and volume limits, EC Marking compliance

is exempt. Therefore Specac adopts SEP (Standard Engineering

Practice) to ensure safety in use of these products.

The Atlas™ Manual Hydraulic Press is provided with front and rear

safety guards (65). These must be kept closed (lowered) at all times

when a sample is being pressed. The guards will fall to the lowered,

safe position if not purposefully raised or kept open by other means.

Note: The use of press guards is a

requirement for any high tonnage load

applications. hen using the Specac Film

Making Accessories P/N's GS15640 and

GS15800, although the tonnage loads to

apply are typically 1 to 2 tons, Specac

advise that the safety guards are used

wherever possible.

hen using a Film Making Accessory it is

a requirement that the pressure relief

valve assembly (66 to 72) on the Atlas™

Manual Hydraulic Press is adjusted to

read a 2 tons maximum load at the load

gauge (31) for safety and prevention

of tonnage overloading to the Film Making

Accessory itself.

If you ever need to move or reposition the press, always lift it from

underneath the base casting (1). Do not move it by pulling or lifting the

pump handle (32), load gauge (31), or lead screw handle (20). It is

recommended that a minimum of two people are used to lift or move

the press.

65 1

User Manual

12

5. Operation of the Press

(The text for “bubble part” number identification also refers to the 2D

Diagrams Figs 13. to 18.found at the back of this manual).

The press is supplied filled with hydraulic oil and is ready to use. The

only preparation required before operation is to remove the nylon vent

screw (37) from the pump plate (36) of the pump block assembly.

(Please refer to Fig 3. on page 9.)

Fig 5. Front View of 15/25 Ton Atlas™ Manual Hydraulic Press

21

65

23

5

20

30

33

31

32

4

Atlas™ Manual 15T and 25T Hydraulic Press

13

Raise the front safety guard (65) and place the work to be pressed on

the lower bolster pressing face (5) covering the piston (4). Ensure that

the work is positioned centrally and lower the safety guard. Screw

down the top bolster pressing face (23) attached to the lead screw

(21), by turning the lead screw handle (20) clockwise.

Important: Ensure that all the components of the work to be pressed

(usually a die set) have been squeezed tightly together

before starting to pump a pressure. However, leave a 1mm

gap between the top of the die set and the top bolster (23)

pressing surface to allow for some initial travel of the

pressing piston (4) on the press.

Rotate the pressure release handle (30) clockwise until it has tightened

firmly. This closes the pumping system so that it is ready for you to

build up the pressure with the pump handle grip (33).

Warning: Ensure that the safety guard is lowered before pumping.

Now start to pump the press by pulling and pushing gently, but

smoothly, on the pump handle grip (33). (The correct leverage and

force is applied by holding at the rubber handle.) It will take a few

strokes to build up pressure in the oil, but once resistance is offered by

the work to the raising of the piston, the load will be indicated on the

load gauge (31). eep on pumping until the required load is achieved.

There is a maximum piston (4) travel of 25 mm. There is a red ring

around the piston (4) showing when the limit is reached (See Fig 6.)

DO NOT ONTINUE PUMPING WHEN THIS RED RING SHOWS.

If you do not stop pumping, you will cause damage to the press

mechanism.

There is an internal spring stud (16) within the piston (4) assembly that

is designed to break, protecting the press if the allowed piston travel is

exceeded. This spring stud (16) allows the action of the piston spring

(19) to pull the piston (4) back down when the oil pressure in the

system is released. If the stud (16) breaks, the spring (19) is not

compressed when the piston (4) is pumped, consequently the piston

will not return easily to the start position once the pressure is released.

User Manual

14

Fig 6. Maximum Limit of Piston (4) Travel (Red Ring Showing)

If the work (e.g. a sample in a die set) is compressing to the extent that

the piston (4) has travelled to show the red line but the compression

load has not been reached, release the pressure by turning the

pressure release handle (30) anticlockwise (slowly) by about one

complete rotation. This will allow the piston (4) to return to rest. The

work will sink down with retraction of the piston (4) and a gap will be

created between the work and the top bolster pressing face (23). Turn

the lead screw handle (20) clockwise to bring the top bolster pressing

face onto the work again, and reapply the load from the piston (4) -

retighten the release handle (30) and pump via pump handle (33).

Note: This procedure should be followed with samples that are highly

compacted when compressed within an evacuable pellet die.

When the required load is indicated on the load gauge (31), stop

pumping. The pressure and applied tonnage load against the work will

be held for as long as required. You may observe a slight decrease in

the pressure applied, indicated at the load gauge (31), as the work

(sample) being pressed may relax over time. You can bring the

pressure back up to the required load if desired by pulling gently on the

pump handle grip (33) again.

31

23

5

4

Red

Ring

Atlas™ Manual 15T and 25T Hydraulic Press

15

Note: If the applied tonnage load set at the load gauge (31) drops by

more than one ton over a 15 minute period, this may indicate

that there is a fault in the system for holding the applied

pressure, rather than from any relaxation in the work being

pressed. The press system may require bleeding of any trapped

air in the oil to function correctly. (See Fault Finding, Causes and

Remedy, Section 6, page 20.)

To release the load on the work turn the pressure release handle (30)

anticlockwise, slowly, by about one complete rotation. (There is no

need to turn this handle completely open.) Slow rotation of the release

handle (30) allows for a gradual and controllable release of the

pressurised oil within the system (indicated by a gradual drop of the

applied tonnage load at the load gauge (31)), to drain back into the oil

reservoir and helps to reduce the possibility of any bubbles that might

form in the oil from a rapid release of pressure.

ontrol of a Maximum Applied Load

Beneath the pressure gauge (31) there is a pressure relief valve

assembly (66 to 72) which may be set so that any load between 0-15

tons or 0-25 tons is the maximum load that can be obtained.

(See Fig 7.) The relief valve set knob (69) can be rotated clockwise to

increase the maximum pressure in the system, and hence the applied

load, or rotated anticlockwise to decrease the pressure in the system.

Note: hen supplied the pressure relief valve will be set for a 10 ton

load on the 15 ton press and a 15 ton load on the 25 ton press.

To set a specific maximum load, first rotate the relief valve set knob

(69) anticlockwise until it is held loosely by a couple of screw threads.

(Be careful, as if you unscrew the knob completely the relief valve ball

bearing (70) held behind the knob (69) could fall out of position and be

lost. (If the ball bearing (70) does fall out just simply place it into the

knob (69) head recess and screw back into position.)

Place a piece of work to be pressed in the usual way, close the

pressure release handle (30) and start to pump. If the pressure relief

User Manual

16

Fig 7. Pressure Relief Valve for Setting a Maximum Load

valve is fully open, there will be no pressure build up in the system (the

pressure/load gauge (31) indicator will not rise and show a load) and

excess pressure being pumped will vent off at the relief valve. Now,

start to turn the relief valve set knob (69) clockwise, (one complete

rotation at a time) and continue pumping. Eventually, pressure will

begin to build up in the system and the gauge (31) indicator will rise to

show a tonnage load. Once the load limit for the setting of the pressure

relief valve knob (69) has been reached, excess pressure will once

again vent off at the relief valve. Continue to turn the relief valve set

knob (69) clockwise until the required pressure/load is reached.

If you overshoot the pressure and hence load limit you require from

over-adjustment clockwise of the knob (69) and continuous pumping of

the handle (32), simply release the pressure from the system by

opening the pressure release handle (30) and then closing the release

handle again. Turn the pressure relief valve knob (69) anticlockwise to

reduce the load limit and re-pump the press via the handle (32).

Repeat the process as necessary to achieve the maximum applied

load setting required.

31

30

66-72

32

69

Atlas™ Manual 15T and 25T Hydraulic Press

17

Tip: This is a useful feature for pressing applications where a

maximum load limit is required. For example, 10 Tons maximum

for 13 mm evacuable pellet dies P/N GS03000.

Beware! ith the pressure relief valve set knob (69) turned fully

clockwise it is possible that the press will reach and go

beyond the maximum load rating for the press; that is beyond

the 15 and 25 ton gauge divisions. Therefore, the pressure

relief valve knob (69) m st only be turned clockwise as far as

to obtain the 15 ton or 25 ton gauge division indication when

a maximum load is being applied.

Over press rization of the press re ga ges will ca se

damage to the ga ge mechanism res lting in the need for

replacement.

Lead Screw Assembly

In operation the leadscrew assembly (handle (20) and leadscrew (21))

is used to adjust for the height of the work to be pressed. Rotating the

leadscrew clockwise lowers the leadscrew bolster (23) pressing face

towards the work and turning the leadscrew anticlockwise raises the

bolster (23) away from the work.

Fig 8. Leadscrew Assembly and Top Bolster Parts of the Press

The bolster (23) push fits into the hollow of the leadscrew (21) and is

retained by an O-ring (22). Any pressing of work must always be

carried out using the bolster (23) pressing face suitably attached

into the leadscrew (21) assembly via the O-ring (22) fixing.

23

22 20

21

User Manual

18

6. Fault Finding, Causes and Remedy

The Atlas™ Manual 15T and 25T Hydraulic Presses should give years

of trouble free operation, if used and cared for correctly. If there is a

failure of the press operation, it is recommended that you contact your

local Specac representative immediately, particularly if your press is

still within a warranty period of usage. It will be a requirement to

identify your press from its unique serial number found at the rear of

the press and provide a brief and clear description of the fault. For

technical faults Specac may be contacted via email at

techsuppor[email protected].uk.

However, certain faults can be easily identified and repaired without

the potential need for return of the press to Specac. The following

information is provided to identify faults and carry out the necessary

repairs and adjustments should you decide to do so.

Fault: Loss of Pressure in the Pumping System

ause 1: Oil Seal or Gasket Has Failed. This will be evident by

excessive oil leaks around the piston, cylinder block, or

pump block.

Remedy: It may only be necessary to re-tighten the six cylinder

block securing screws (3), and/or the four pump block

securing screws (29). If the oil leak continues, it will be

necessary to renew the individual seal(s) and gasket(s),

depending on age and usage. (Seals and gaskets that

may need replacing are numbered (8), (9) (2 off), (11),

(27), (28), (38), (43), (44), (48), (53), (57) and (67).

Instructions on how to replace these seals and gaskets

are found in the Atlas™ Manual Hydraulic Press

Servicing Guide.

ause 2: Non-Return Valve is Leaking. (This is a ball bearing (50)

trapped in position by the load gauge (31).) It is likely that

the non-return valve ball bearing (50) is not seating

correctly due to foreign matter adhering to the seat or the

ball.

Atlas™ Manual 15T and 25T Hydraulic Press

19

Remedy: By pumping the press without the pressure release handle

(30) tightened, the foreign matter may be removed from

the valve seat by a flow of oil washing through the system.

Pump the press about ten times. If this does not work,

then you will need to gain access to the non-return valve

ball bearing (50) for inspection. The procedure to gain

access to this ball bearing is found in the Atlas™ Manual

Hydraulic Press Servicing Guide.

ause 3: Release Valve Leaking. (This is a ball bearing (58)

trapped behind the pressure release handle (30).) It is

likely that the ball bearing (58) is not seating correctly due

to foreign matter adhering to the seat or to the ball.

Remedy: Similar to the non-return valve procedure, pumping the

press without the pressure release handle (30) tightened

may remove the foreign matter from the valve seat by a

flow of oil washing through the system. Pump the press

about ten times. If this does not work, you will need to

gain access to the ball bearing (58) for inspection.

Unscrew the pressure release handle (30) completely. A

small dribble of oil may flow from the hole when the

release handle assembly (30) is removed, but the amount

lost is not significant. Check the O-ring (57) for signs of

wear or cracks etc and replace if necessary. The ball

bearing (58) can be seen inside the hole resting in the

area of the valve seat. To remove the ball bearing the

press needs to be tipped over slightly, allowing the ball to

roll out. Be careful when lifting the press as it is heavy,

and also be careful not to lose the ball bearing if it rolls out

onto the work bench. Inspect the ball bearing, clean and

replace in the hole. Ensure that it rolls back into its valve

seat area. Replace the pressure release handle (30),

tighten and re-pump.

Fault: Failure to achieve pressure in the pumping system

ause 4: The oil filter (55) is blocked.

User Manual

20

Remedy: The procedure to gain access to the oil filter (55) for

cleaning and/or replacement is found in the Atlas™

Manual Hydraulic Press Servicing Guide.

ause 5: Airlock in Pump Assembly.

Remedy: The pump block assembly and possibly the piston side of

the press must be bled of air trapped within the oil. The

procedure can be split into two distinct operations:

Bleeding air from the pump block assembly and bleeding

air from the piston assembly.

Bleeding Air from the Pump Block Assembly

To gain access to the oil bleed screw (40), the pump plate (36) must

first be removed. (In Fig 9. the transport screw (37) is shown but

normally this has been removed for use.)

Fig 9. Pump Plate Removal

Loosen and remove the four securing screws and lift the pump plate

and the pump block upper gasket (38) clear. Be careful not to tear the

gasket material. Loosen, but do not remove the oil bleed screw (40) by

turning anticlockwise. (See Fig 10.)

Pump Plate

Securing

Screws

36

37

This manual suits for next models

1

Table of contents

Other Specac Power Tools manuals

Specac

Specac GS03940 User manual

Specac

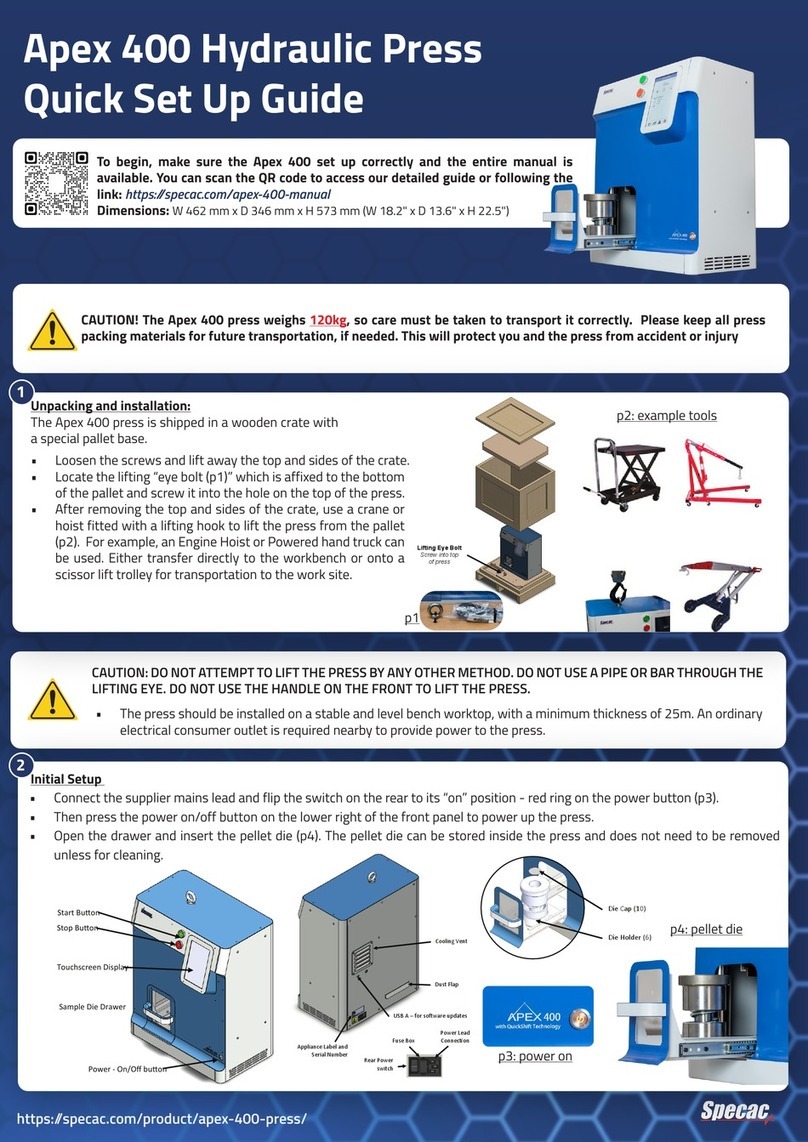

Specac Apex 400 Press User manual

Specac

Specac Atlas Lightweight Evacuable Pellet Die User manual

Specac

Specac Atlas Autotouch 40T User manual

Specac

Specac Atlas Power 8Ton User manual

Specac

Specac Apex 400 User manual

Specac

Specac Atlas Power 8Ton User manual

Specac

Specac Atlas GS15800 User manual

Specac

Specac Atlas Automatic 40 Ton User manual