KENCO Mechanical Grapple Operation Manual

170 State Route 271

Ligonier, PA 15658

1-800-653-6069

Section V. Operation.

Before attempting to use the Mechanical Grapple ALWAYS perform a test lift on the

intended object(s) to confirm proper operation. DO NOT use a Mechanical Grapple to

handle objects beyond the rated capacity or range.

A. Operation:

1. Ensure that the Mechanical Grapple’s capacity and range are appropriate to the object to be handled.

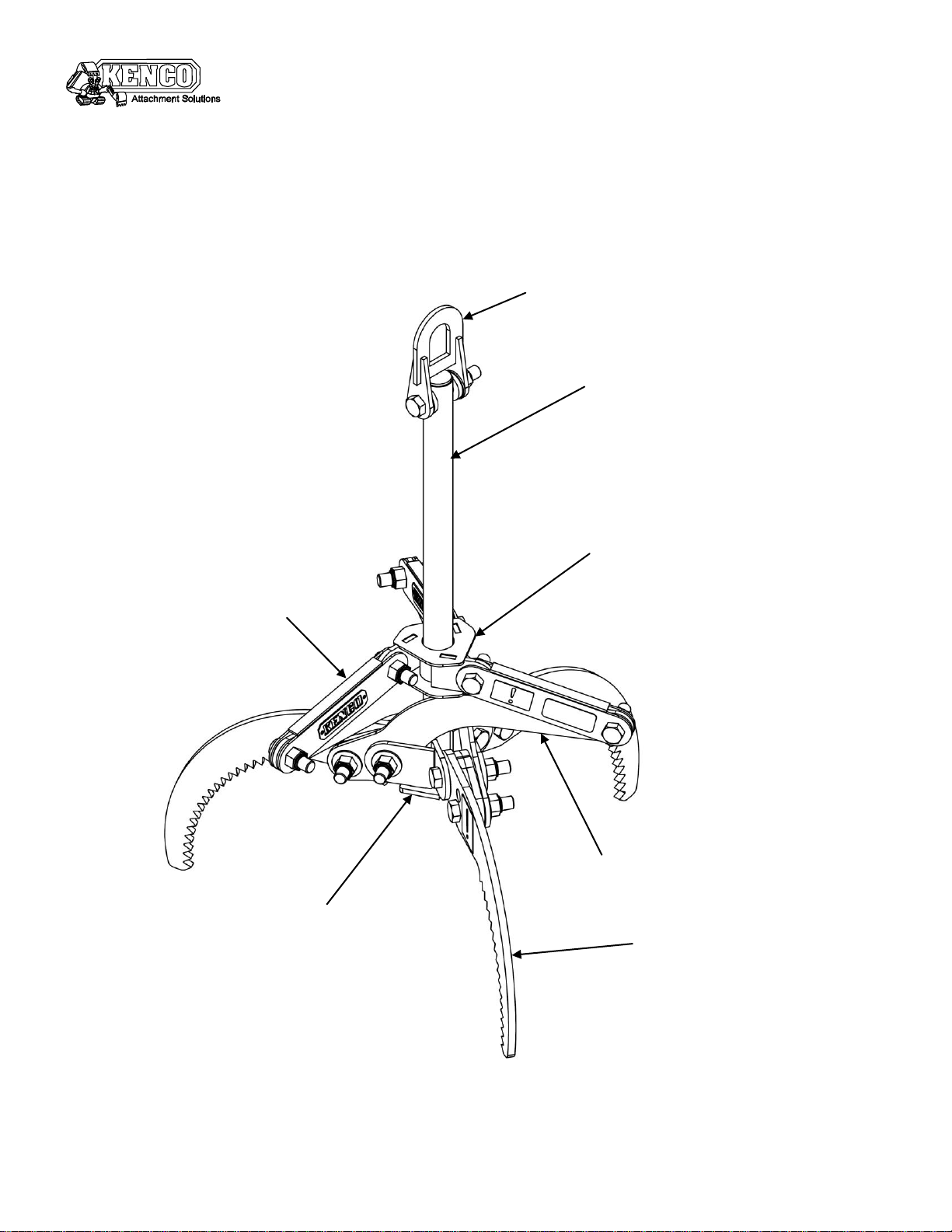

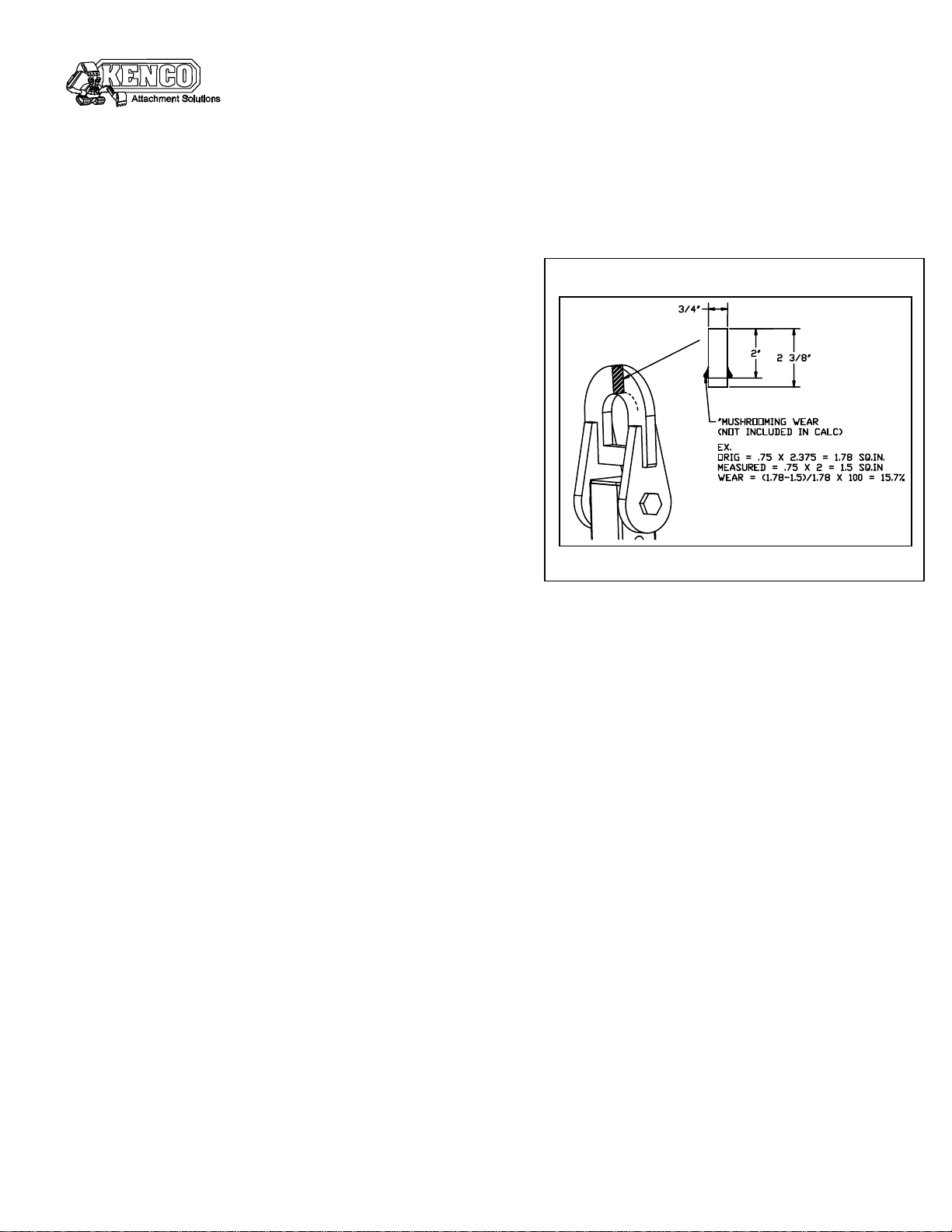

2. Adjust tine position by removing adjustment bolt and rotating the tine until holes in leg, spacer and tine

line up. Reinstall the adjustment bolt.

Position #1 is for objects approximately 0”-24” in diameter.

Position #2 is for objects approximately 14”-30” in diameter.

(See detail A on page 8 for clarity.)

3. Position Mechanical Grapple at or near center of object to be lifted.

4. Lower Mechanical Grapple onto object, taking care to minimize impact.

5. Ensure that all persons are clear of the Mechanical Grapple and the load.

6. Release tension on lift cable.

7. Raise the Mechanical Grapple and load in a smooth motion, do not “jerk”.

8. Deposit at desired location.

9. Release tension on lift cable. (Note: avoid undue slamming of the Mechanical Grapple into open

position to prolong actuator life.)

10. Remove Mechanical Grapple (Mechanical Grapple is latched in open position automatically)

B. Avoid Jarring, swinging, and otherwise unnecessary manipulation of the load.

C. Avoid handling of loads off center.

D. DO NOT USE THE MECHANICAL GRAPPLE TO PICK MULTIPLES OF ITEMS IN A SINGLE

PICK.

E. Observe all safety practices associated with operation of hoist machinery.

F. DO NOT USE MECHANICAL GRAPPLE TO DRAG LOADS.

G. DO NOT ALLOW LOAD TO CONTACT ANY SURFACE/OBJECT WHILE BEING HANDLED.

The Mechanical Grapple produces grip proportional

to and dependent on the weight of the load. It is for

this reason that while in operation the Mechanical

Grapple and wall NEVER be allowed to contact other

items.

Manipulation of the Mechanical Grapple by ground

personnel for the purpose of alignment with load shall only

be done with the Mechanical Grapple suspended above the

object. KEEP ALL HANDS AWAY FROM THE

MECHANICAL GRAPPLE DURING OPERATION.