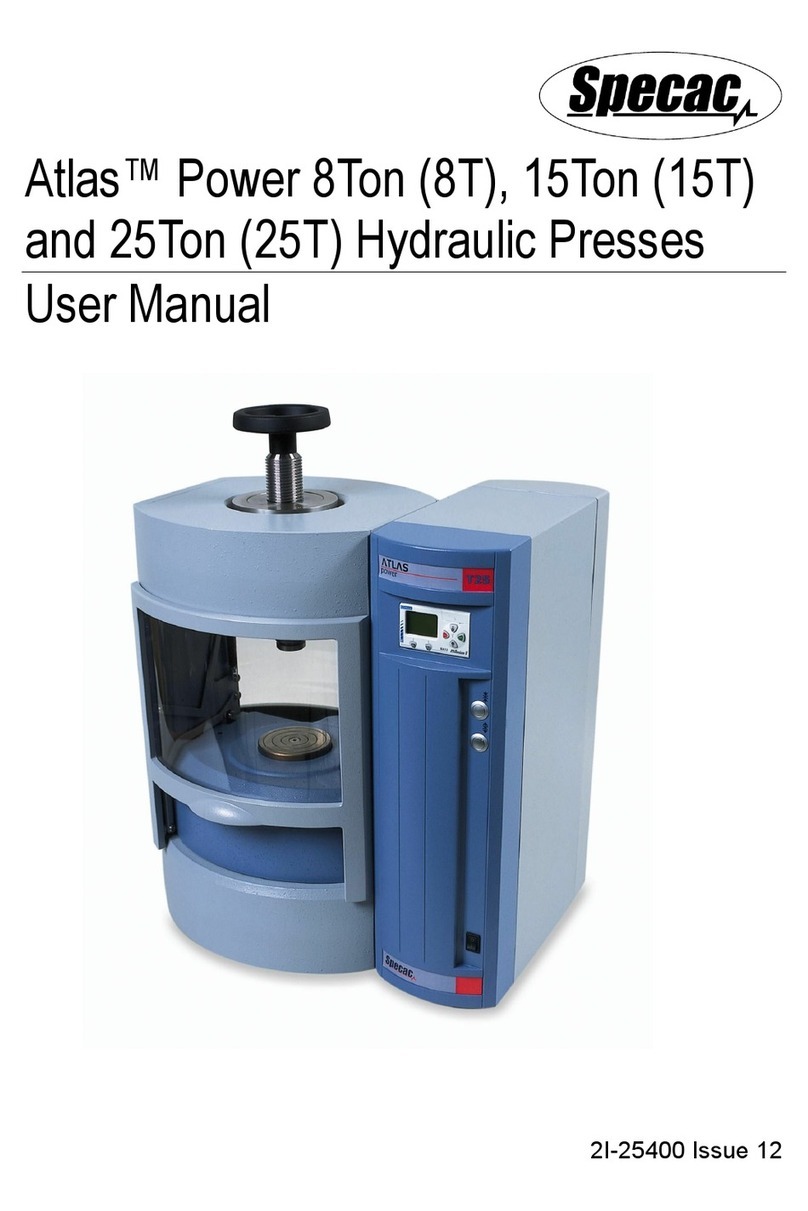

Atlas™ Autotouch 8T, 15T and 5T Hydraulic Presses

5

1. Introduction

Thank ou for purchasing a Specac product.

The Atlas™ Autotouch 8Ton (8T), 15Ton (15T) and 25Ton (25T)

H draulic Presses are automatic and programmable h draulic presses

which have been designed for a wide variet of pressing applications

within the laborator or heav industrial environments, to appl a load

up to 8 tons on the 8T, 15 tons on the 15T and 25 tons on the 25T.

These presses are specificall suited to the preparation of solid sample

discs using Specac Atlas™ evacuable pellet die assemblies, but the

ma also be adapted to provide heated pressing surfaces b

installation of Specac Atlas™ Heated Platens P/N GS15515. (The

heated platens are limited to 15 tons maximum load.)

The Atlas™ Autotouch 8T/15T/25T presses enable the controlled

application and release of an applied load via push button or

programmable timed functionalit and can accommodate large

samples up to 220mm in diameter and 155mm tall. The operations to

set a specific load to appl or create a program for a load application

sequence for its duration of hold are carried out via a touch sensitive

displa screen. There are two ph sical buttons on the front panel to

push for actual operation of the press – a start button to appl a load

and a stop button to release the load.

The press works b automatic motorised pumping of a h draulic fluid

(oil) to raise a piston and compress a sample held in the pressing area.

The press consists of a motor, pump and oil reservoir assembl from

where the oil is transferred across to the base of the pressing area and

forced under the piston assembl . As the oil pressure builds up in the

press s stem the load being applied to the sample will be registered on

the electronic displa . The application of a load will continue until the

required load is reached and then held until released b the operator.

Alternativel , the load can be applied in a series of load stages via a

specific program and automaticall released from a programmed time

hold function and controlled release rate. The power unit is extremel

quiet and operates below 62 dB(A) making the presses ideal for use in

all environments.