Specac GS03940 User manual

Mini-Pellet Press

User Manual

2I-03940-6

Mini-Pellet Press

User Manual

2I-03940-6

User Manual

2

Mini-Pellet Press P/N GS03940

CONTENTS

1. INTRODUCTION ................................................................................. 3

2. CHECKLIST OF CONTENTS ................................................................. 4

3. OPERATION OF THE MINI-PELLET PRESS ........................................... 5

PREPARATION OF THE 7MM PELLET DIE ASSEMBLY ............................ 6

PRESSING THE 7MM PELLET DIE IN THE MINI-PELLET PRESS .............. 8

REMOVING THE 7MM PELLET DIE ASSEMBLY FROM THE MINI-PELLET

PRESS ........................................................................................... 10

POSITIONING THE KBR PELLET DIE RING HOLDER IN THE

SPECTROMETER ............................................................................. 11

CLEANING OF PELLET DIE PARTS AND KBR PELLET REMOVAL INTACT

FROM THE PELLET RING HOLDER ................................................... 12

4. SPARE PARTS FOR THE MINI-PELLET PRESS .................................... 14

5. LEGEND FOR THE MINI-PELLET PRESS ............................................. 15

© April 2016 Specac Ltd. All rights reserved.

Brilliant Spectroscopy™ is a trademark of Specac Ltd.

Other product names mentioned herein may be trademarks

of their respective owners.

Mini-Pellet Press

3

1. Introduction

Thank you for buying a product from Specac.

The Specac Mini-Pellet Press P/N GS03940 has been designed to

produce a maximum 2 tons load and when used with the 7mm Pellet

Die assembly P/N GS03950, provides a sufficient load for the

formation of excellent quality KBr pellets with a 7mm diameter, prior to

solid sample analysis by FTIR spectroscopy. The Mini-Pellet press and

7mm Pellet Die assembly items are an alternative to the use of,

typically, a 13mm diameter pellet die assembly within a 15 ton manual

hydraulic press to produce 13mm diameter KBr pellets/discs.

When the 7mm pellet die assembly with a KBr sample has been

placed in the Mini-Pellet Press, a 2 tons load can be easily and quickly

applied by turning of a pressure screw hand knob. This action

compresses a hydraulic fluid (oil) to raise a pressing piston and

compress a sample held in the pressing area. To assist in the turning

of the pressure screw knob an M8 (6mm A/F) size short handled Allen

key is included to fit the central socket screw for greater leverage if

required. To help in knowledge of the load being applied there is a

small pressure indicator gauge on the press body which shows the

actual pressure being applied and when to stop turning the hand knob.

The Mini-Pellet Press is small and relatively light enough in weight that

it could be held in the hand to turn the pressure screw knob if desired,

but for more secure use the press has been designed to sit and work

on a bench surface.

Warning: If you use the Mini-Pellet Press near the edge of a bench

surface to turn the pressure screw knob, be careful that as

much of the weight of the press as possible is on the bench

surface itself, to prevent the press from falling to the floor.

There is no requirement to permanently bolt the press to a work

surface to apply a load safely to a sample, thus enabling easy storage

of the press if needed.

User Manual

4

2. Checklist of Contents

Check that the following items have been supplied against P/N

GS03940:

Mini-Pellet Press

- P/N GS03940.

If a 7mm Pellet Die assembly P/N GS03950 has been ordered too

check that the following items have been included.

7mm Pellet Die assembly P/N GS03950

(including its own Pellet Ring Holder, Top

Anvil, Bottom Anvil and Perspex Extractor

Cap).

M8 Allen key for leadscrew and pressure knob handles.

Unpack the Mini-Pellet Press and die parts carefully (if ordered) and

prepare the items for use.

Mini-Pellet Press

5

3. Operation of the Mini-Pellet Press

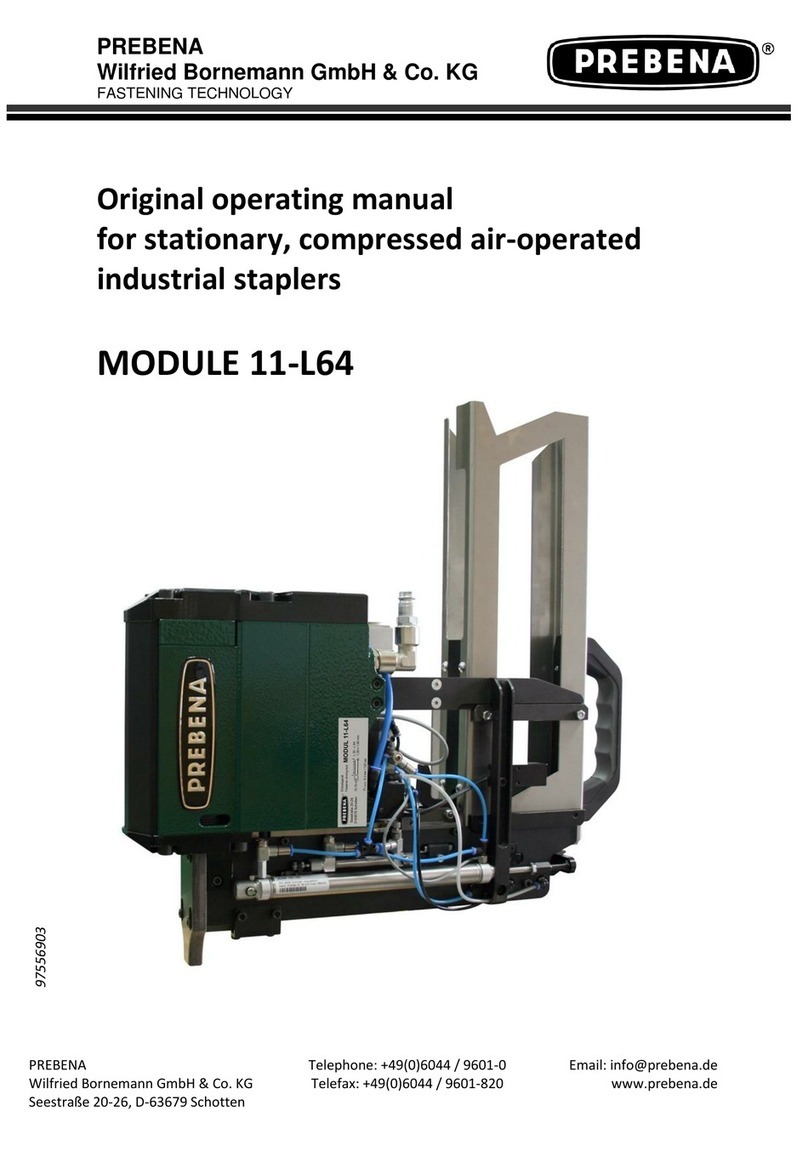

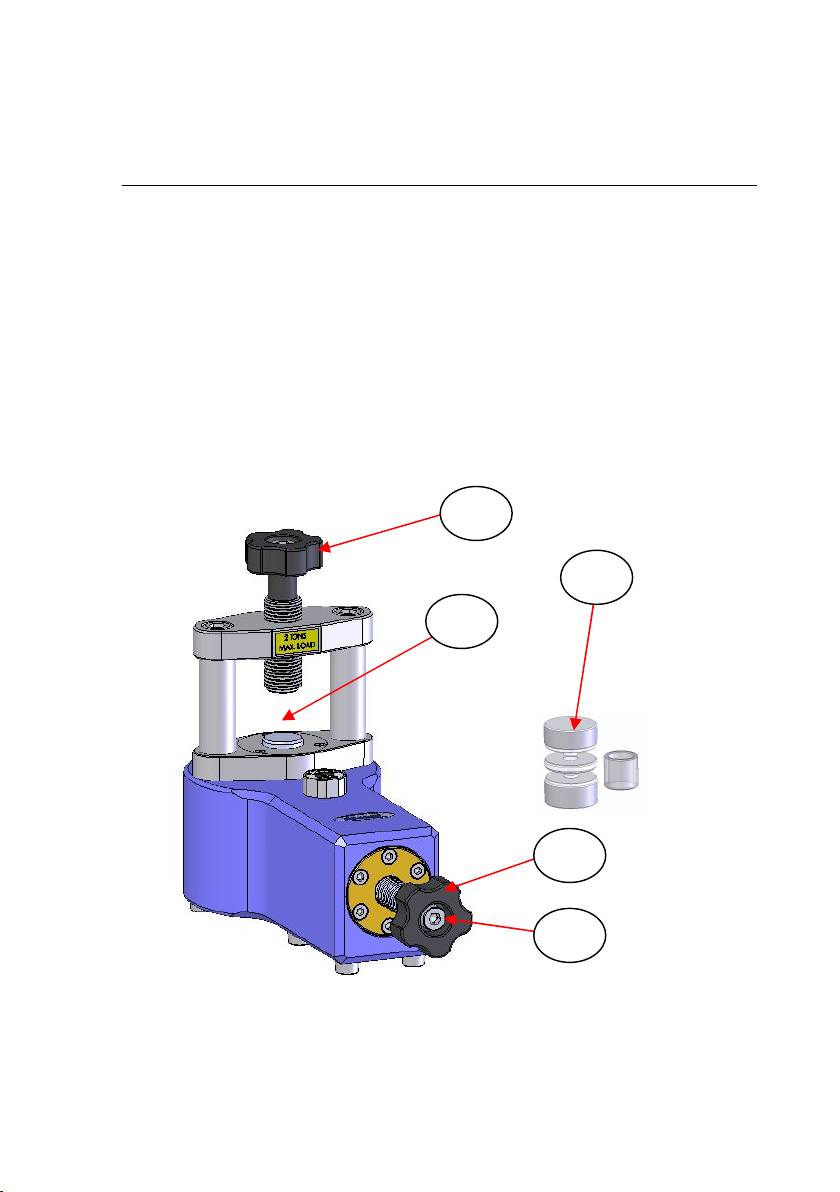

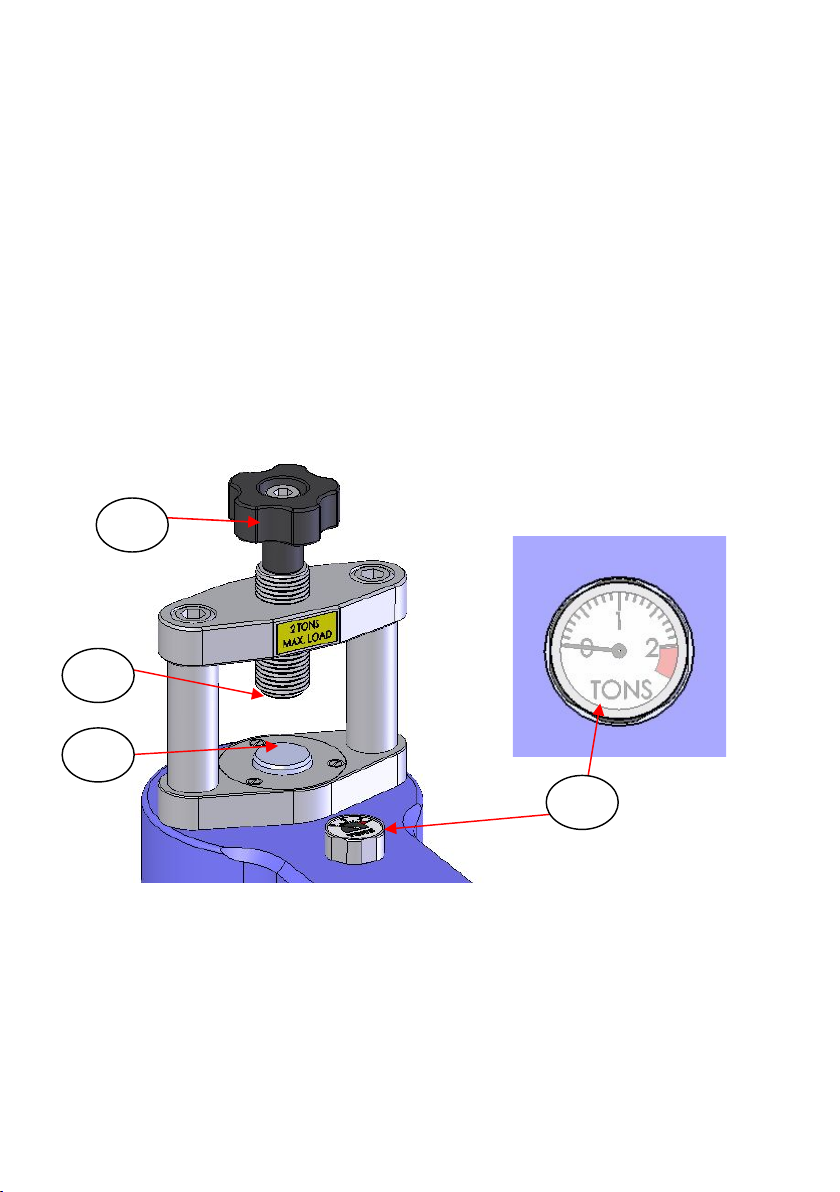

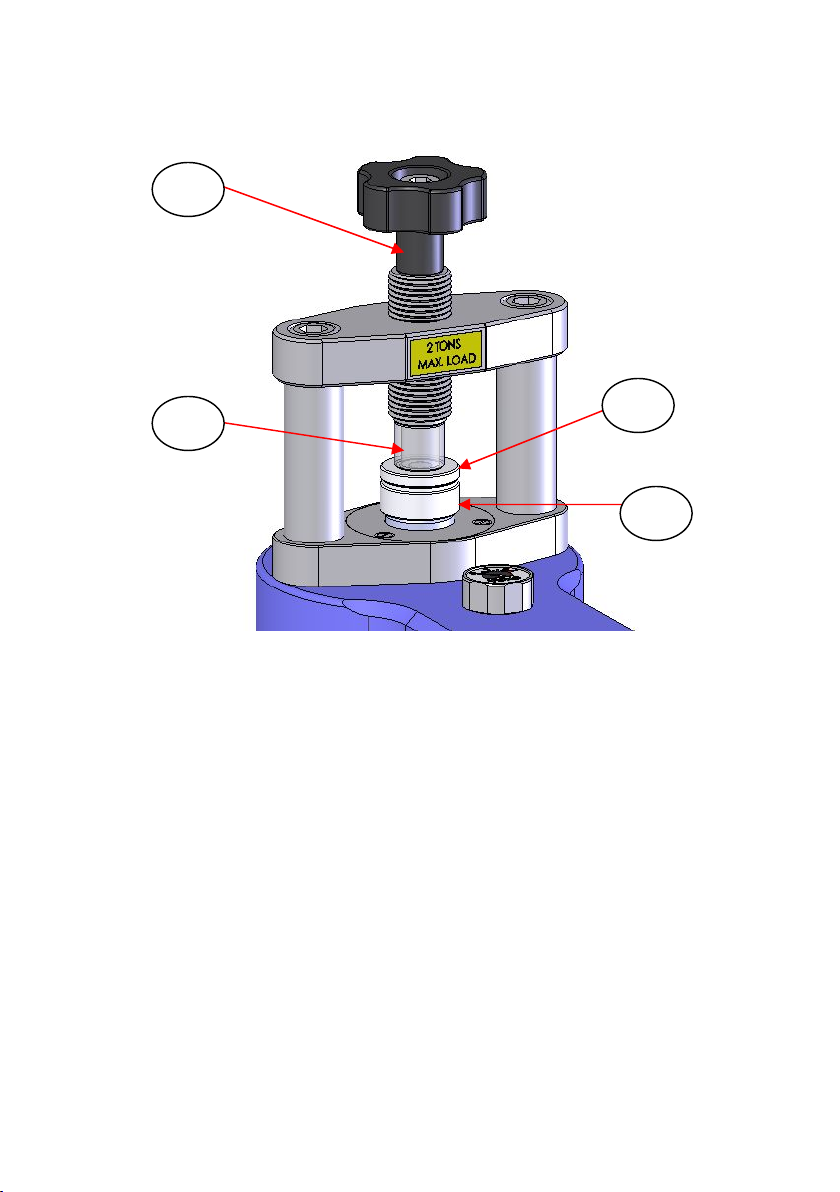

Pressing a sample in the Mini-Pellet Press is simple and quick. Taking

the 7mm pellet die assembly (P/N GS03950) (1) as an example die to

use, it is easily located within the pressing area of the Mini-Pellet Press

(2). The lead screw assembly (3) is turned until hand tight to secure

the 7mm pellet die assembly (1) in position in readiness to turn the

pressure screw hand knob assembly (4). Only a light force is needed

to turn the pressure hand knob (4) to provide a sufficient tonnage load,

but the M8 Allen key provided can be used to turn the central socket

screw (5) for greater leverage if desired. The produced 7mm KBr pellet

is retained within the pellet die ring holder body (6) and this is

transferred to a 3” x 2” slide mount (7) to fit in the spectrometer. (See

Fig 1.)

Fig 1. Mini-Pellet Press and 7mm Pellet Die Assembly

1

2

3

4

5

User Manual

6

Preparation of the 7mm Pellet Die Assembly

Prior to placing the 7mm pellet die assembly (1) into the Mini-Pellet

Press pressing area (2), a potassium bromide (KBr) powder mixture

with a solid sample is prepared. A suitable quantity of the solid sample

with an amount of KBr powder (P/N GS03610) in the usual ratio of 1

part sample to 300 parts KBr can be ground together using the agate

pestle and mortar (P/N GS03600) or an automatic grinding mill such as

the Specamill (P/N GS06000) with an agate capsule set (P/N

GS06200).

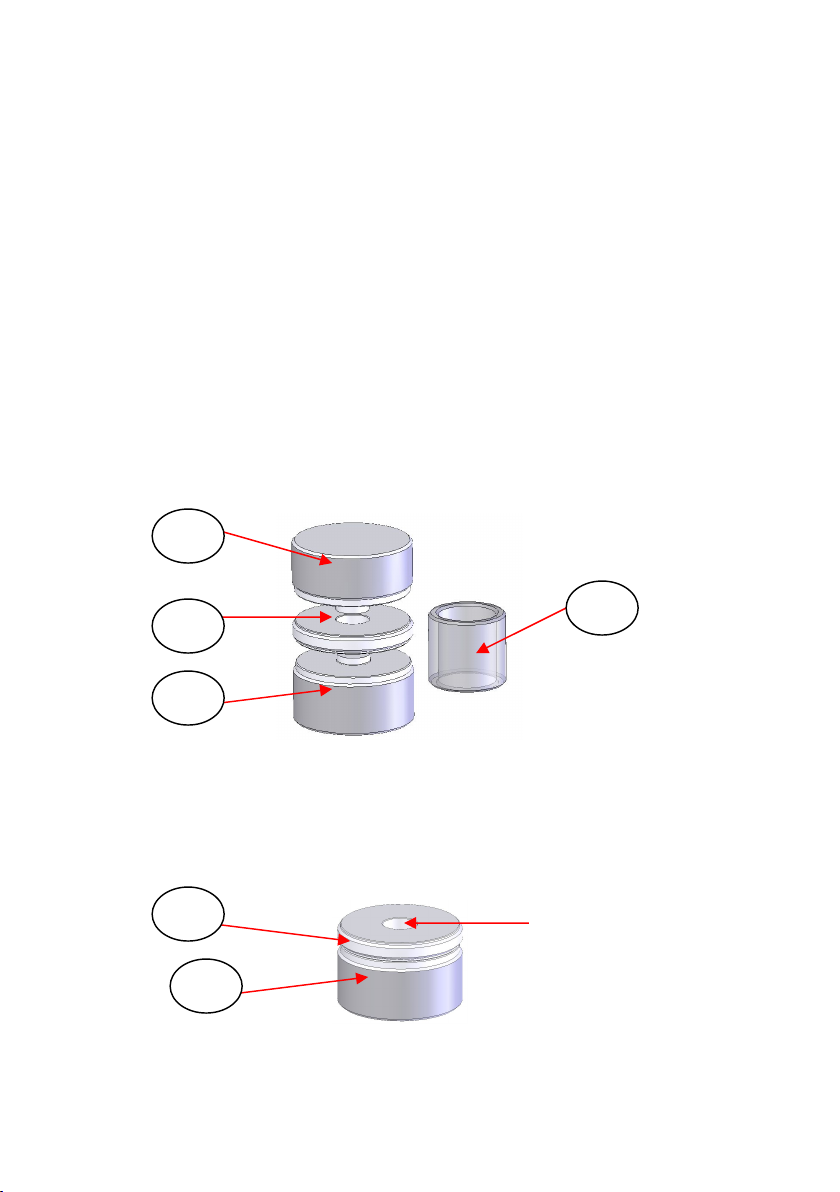

The 7mm pellet die assembly complete (1) consists of a central pellet

ring holder (6), top anvil (8), a bottom anvil (9) and a clear Perspex

extractor ring cap (10). (See Fig 2.) The top anvil (8) has a longer

central “plunger” section than the bottom anvil (9).

Fig 2. 7mm Pellet Die Assembly Complete

When the sample has been ground sufficiently, place some of the KBr

mixture into the central hole of the 7mm pellet die ring holder (6) as it

rests on the bottom anvil (9). (see Fig 3.)

Fig 3. 7mm Pellet Die Ring Holder (Body) on Bottom Anvil

10

8

6

9

6

9

KBr powder sample

mixture placed here

Mini-Pellet Press

7

Fill the aperture hole of the 7mm pellet die ring holder (6) with sufficient

KBr powder mixture to reach the top. Using a flat blade or the edge of

the spatula, level off the powder mixture such the top of the powder

mixture in the hole is flush with the 7mm pellet die ring holder’s (6) top

surface.

Now, take the top anvil (8) and place it carefully (plunger face

downwards) over the powder/7mm pellet die ring holder (6)/bottom

anvil (9) assembly. Locate the central plunger section of the top anvil

(8) over the powder sample within the aperture hole and use light

pressure from your hand to compact the powder mixture into the hole.

The mixture is sufficiently soft to allow the plunger part of the top anvil

(8) to fit and locate loosely into place in the aperture hole of the 7mm

pellet die ring holder (6).. (See Fig 4.)

Fig 4. 7mm Pellet Die Assembly with Sample Prior to Pressing

When this stage has been reached you can carefully transfer this

complete 7mm pellet die assembly (with sample) into the Mini-Pellet

Press for full pressing of the KBr powder sample.

Note: The bottom anvil (9) has a recessed underside surface with a

metal rim around its circumference. The recess allows for central

and correct positioning of the 7mm pellet die assembly (1) over

the piston (11) of the Mini-Pellet Press prior to any pressing.

8

6

9

KBr powder mixture is

now partially compacted

within this assembly

User Manual

8

Pressing the 7mm Pellet Die in the Mini-Pellet Press

Prepare the Mini Pellet Press to accept the 7mm pellet assembly (1) as

formed at the stage shown to Fig 4.

The lead screw (3) on the Mini-Pellet Press is retracted (turned

anticlockwise) so there is sufficient “daylight” between the pressing

face of the leadscrew (12) and the piston (11) of the Mini-Pellet Press.

The piston (11) will be at its rest position for the start of its travel. This

will be when there is no applied pressure on the system from the

pressure hand knob (4) or shown at the pressure/load gauge (13).

(See Fig 5.)

Fig 5. Mini-Pellet Press Piston Area and Pressure Gauge Reading

Before Applying a Load

Before applying any pressure (load), to the die assembly (1) when it is

placed into the press, the pressure screw hand knob assembly (4)

13

3

12

11

Mini-Pellet Press

9

should be fully unwound to its start position. Turn the pressure knob (4)

anticlockwise until it will turn no further such that the screw assembly

has reached its end stop. When the pressure screw hand knob

assembly (4) is fully retracted, the pressing piston (11) will be at its

correct start position for pressing.

When the Mini-Pellet Press pressing area has been set to accept the

7mm pellet die assembly (1), place the die assembly carefully and

centrally into the press and loosely clamp the die assembly into

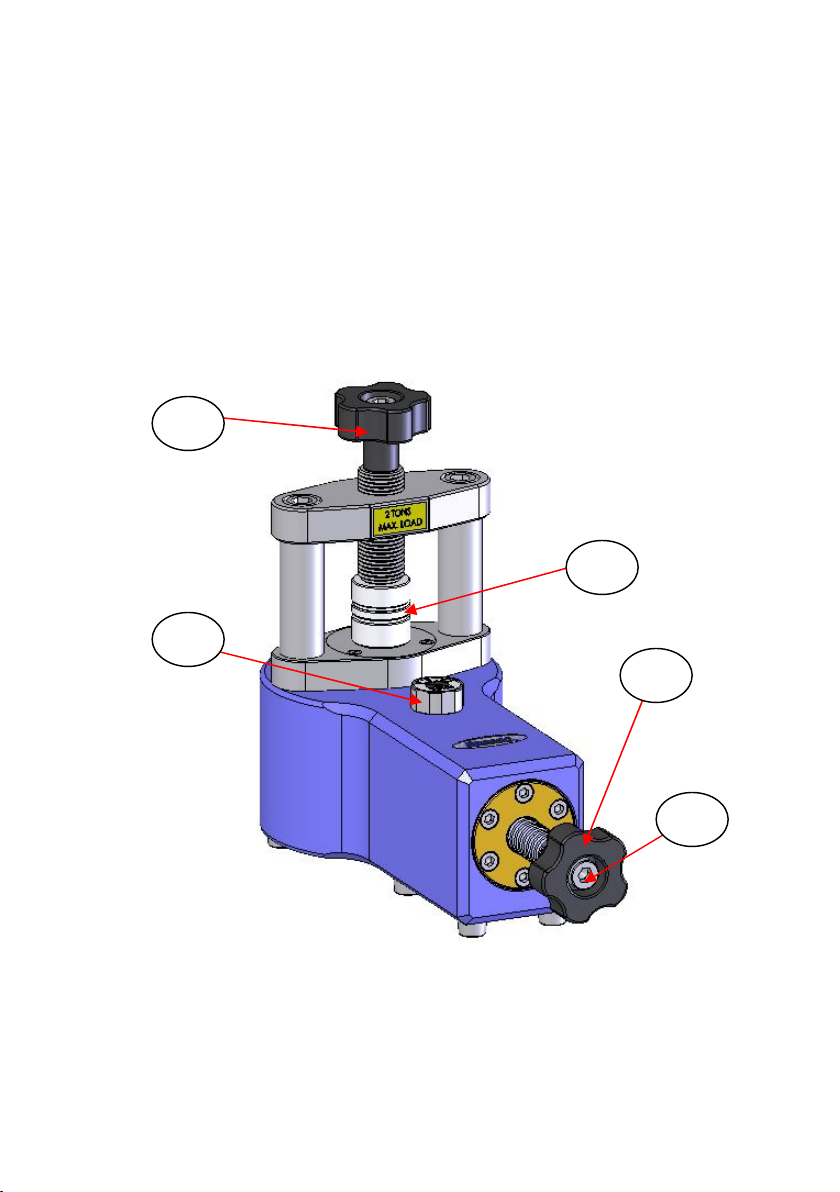

position by turning the lead screw assembly (3) clockwise. (See Fig 6.)

Fig 6. Mini-Pellet Press with 7mm Die Assembly in Position

3

1

4

13

5

User Manual

10

Before turning the pressure screw knob assembly (4) to apply a load,

tighten the lead screw handle assembly (3) a little further clockwise to

continue the initial compaction of the KBr powder mixture contained

within the die. When the lead screw (3) can no longer be hand

tightened, the KBr powder mixture is ready to be fully compressed by

application of a load provided by turning of the pressure knob screw

assembly (4). Begin applying a load by turning the pressure knob (4)

clockwise. It will be easy to turn at the start, but gets progressively

harder to turn as the pressure (a tonnage load) increases and is being

applied to the die assembly (1). (Use the M8 Allen Key supplied if

required in screw (5).) The increase in pressure will be indicated by the

pressure gauge (13) on the Mini-Pellet Press body.

Continue turning the pressure knob (4) until the pressure gauge (13)

needle is pointing at the 1.75 tons division indicator. At this tonnage

reading stop turning the pressure screw knob assembly (4). This will

be a sufficient tonnage load to have compacted the KBr powder

together to form a suitable pellet.

Note: On the pressure gauge (13) there is a red colour warning area

beyond the maximum 2 ton load reading. NEVER over-

pressurise the Mini-Pellet Press such that the indicator needle

has entered this red colour section of the pressure gauge.

Removing the 7mm Pellet Die Assembly from the Mini-

Pellet Press

When the 7mm pellet die assembly (1) has been compressed to a

sufficient tonnage load to form a solid KBr pellet within the pellet die

ring holder (6), the die assembly (1) can be removed from the Mini-

Pellet Press.

Remove the pressure (tonnage load) from the pellet die assembly (1)

by anticlockwise rotation of the pressure knob screw assembly (4).

When the pressure gauge (13) indicator needle drops to zero tons the

7mm pellet die assembly (1) should be free to be removed from the

pressing area (2). However, it is always best to fully retract the

pressure screw knob assembly (4) to its end stop, to ensure that the

piston (11) returns to its correct start/rest position for a new pressing.

Mini-Pellet Press

11

Positioning the KBr Pellet Die Ring Holder in the

Spectrometer

Having removed the compressed 7mm pellet die assembly (1) from the

Mini-Pellet Press, the top anvil (8) and bottom anvil (9) are

separated/removed from the die ring holder (6). Hold the knurled outer

edge of the die ring holder (6) with one hand and twist/turn the anvils

(8 and 9) by holding their knurled edges with the other hand. The

KBr/sample powder material will have been compacted into a 7mm

diameter pellet contained in the die ring holder (6) central aperture

hole.

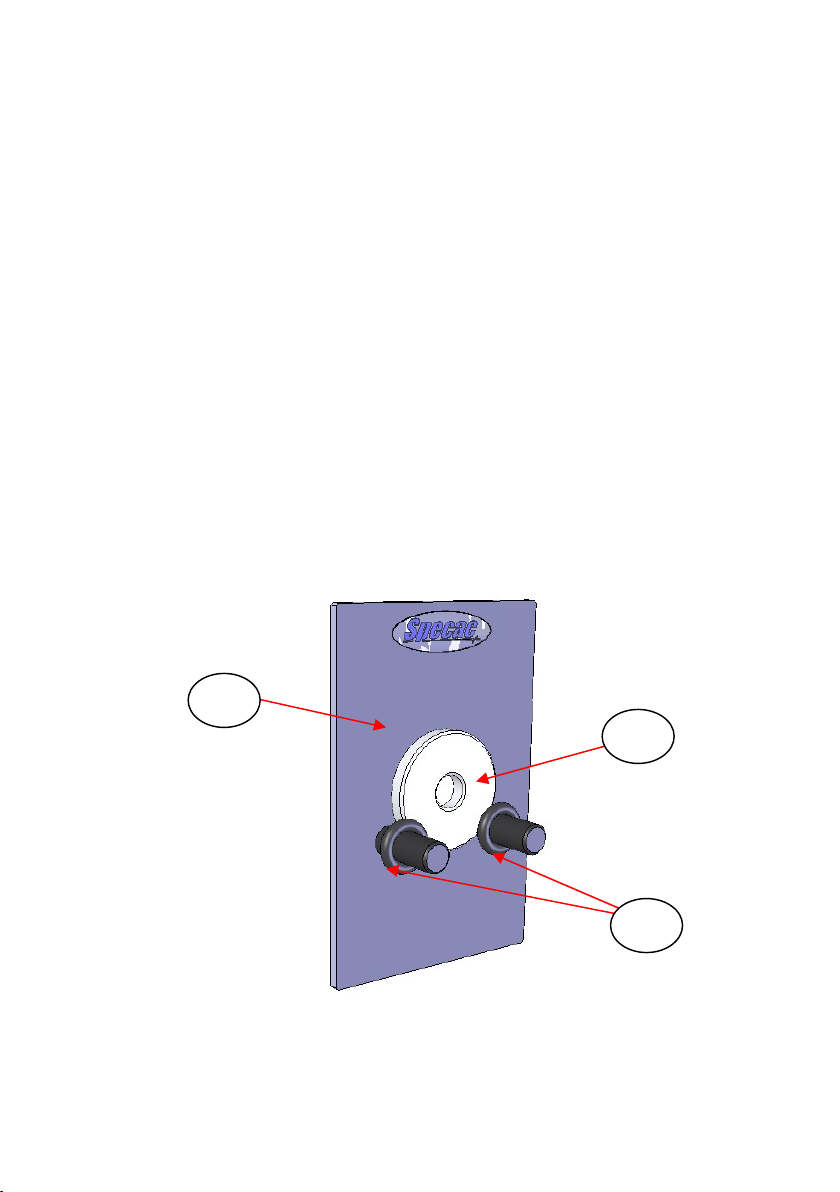

The complete die ring holder (6) with KBr pellet is now placed into an

infra red spectrometer system by use of the 3” x 2” slide mount holder

(P/N GS03960) (6). The die ring holder (6) rests simply on the two

support rods of the 3” x 2” slide mount holder (7) and is held tight

against the 3” x 2” slide plate by compression of the two O-rings (14)

supplied having been slid over the support rods as shown. (See Fig 7.)

Fig 7. 7mm Pellet Die Ring Holder on 3” x 2” Slide Mount

7

6

14

User Manual

12

Cleaning of Pellet Die Parts and KBr Pellet Removal

Intact from the Pellet Ring Holder

When the KBr pellet sample being held in the die ring holder (6) has

been analysed, the KBr sample must be removed from the die ring

holder (6) for pressing of a new sample into the same die ring holder.

To remove the KBr pellet, the entire KBr pellet and die ring holder (6)

assembly can be rinsed with cold or warm water to gradually dissolve

the KBr sample. When the KBr sample has been washed away from

inside the holder, the die ring holder (6) part can be further

washed/rinsed with methanol and then dried with tissues. Specac

would also then recommend that this part could be stored in dry

environment or placed on a heated surface (circa 30°C to 35°C) prior

to use for the next time.

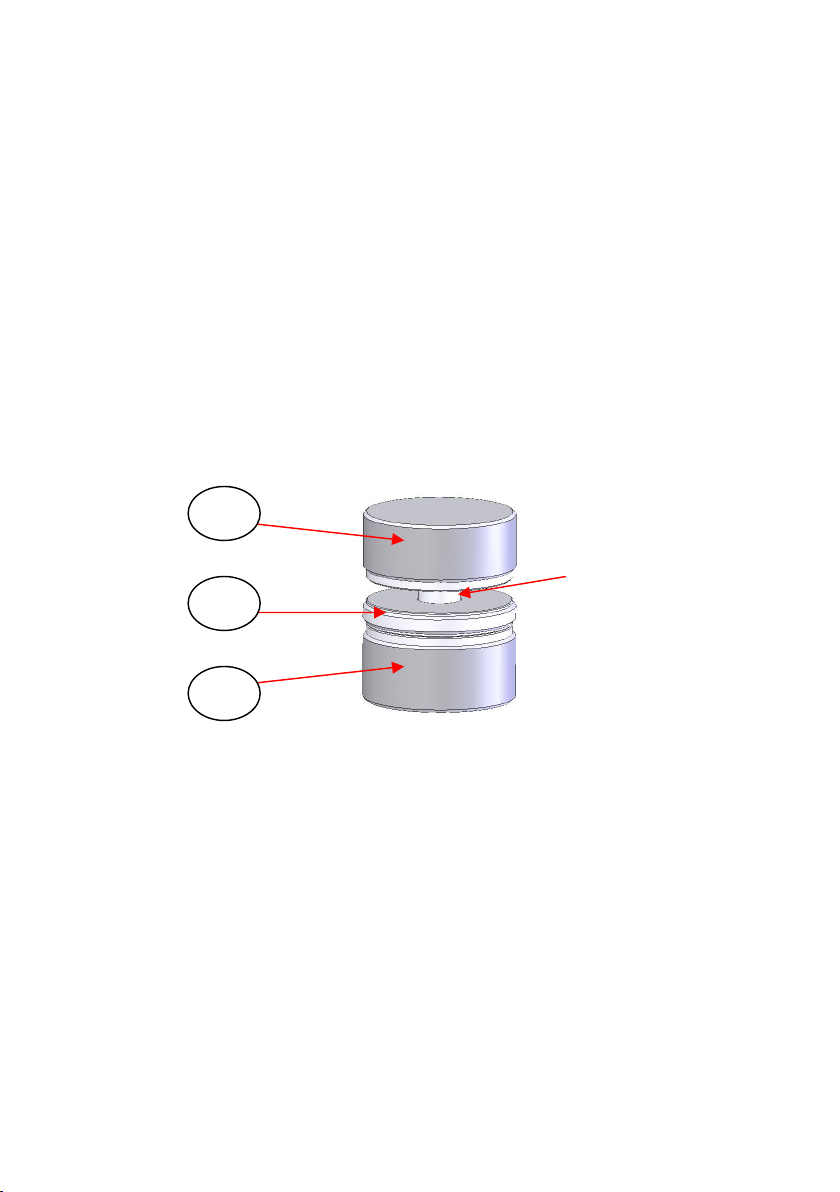

After initial pressing of the pellet into the die ring holder (6) (from

sample preparation stage), the top anvil (8) and bottom anvil (9) should

also be rinsed with water, then methanol, dried with tissues and stored

on a heated top plate surface ready for next use.

However, if you would wish to save the 7mm KBr pellet that has been

formed within the die ring holder (6) after it spectroscopic analysis,

then this KBr pellet can be removed intact from the die ring holder (6)

part, by use of the top anvil (8) with the longer plunger and the Perspex

die extractor cap piece (10).

Take the die ring holder (6) with KBr pellet and place the plunger of the

top anvil (8) into the aperture hole on one side of the die ring holder

(6). Place this combined assembly with the Perspex extractor cap (10)

in contact with other side of the die ring holder (6) into the Mini-Pellet

Press pressing area (2) as shown in Fig 8. Make sure that this

assembly of parts is placed centrally between the lead screw pressing

face (12) and the piston surface (11).

Mini-Pellet Press

13

Fig 8. 7mm Pellet Die Ring Holder, Top Anvil and Extractor Cap

Assembly in Position for KBr Pellet Extraction

Loosely hold the components together by turning the lead screw

assembly (3) clockwise and then continue turning the lead screw

assembly (3) to allow the top anvil (8) to push the KBr pellet out of the

die ring holder (6) and into the space created by the Perspex extractor

cap (10).When the KBr pellet has been pushed out of the die ring

holder (6), retract the lead screw assembly (3) by a couple of

anticlockwise turns and carefully remove the assembly of parts from

the Mini-Pellet Press pressing area (2) to gain access to the KBr pellet.

The intact KBr pellet can now be saved or used for any further purpose

and the die ring holder (6) and top anvil (8) parts can be cleaned

(water and then methanol rinses, then drying and placed on a hot

surface) as described previously, ready to be used again for the next

KBr sample pressing.

3

10 6

8

User Manual

14

4. Spare Parts for the Mini-Pellet Press

P/N GS03940 – Mini-Pellet Press.

P/N GS03950 - 7mm Pellet die assembly complete.

P/N GS03951 - 7mm Pellet die ring holder (body).

P/N GS03952 - 7mm Pellet die top anvil (long plunger).

P/N GS03953 - 7mm Pellet die bottom anvil (short plunger).

P/N GS03954 - 7mm Pellet die Perspex extractor cap.

P/N GS03600 - Pestle and Mortar.

P/N GS03610 - KBr powder (50g).

P/N GS03960 - 3” x 2” slide mount for 7mm pellet die ring holder.

Mini-Pellet Press

15

5. Legend for the Mini-Pellet Press

(1) 7mm Pellet die assembly.

(2) Pressing area of Mini-Pellet Press.

(3) Lead screw assembly.

(4) Pressure screw knob assembly.

(5) Pressure screw knob assembly.

(6) Pellet die ring holder (body).

(7) 3” x 2” slide mount.

(8) Top anvil (long plunger).

(9) Bottom anvil (short plunger).

(10) Perspex extractor cap.

(11) Lead screw pressing face.

(12) Piston.

(13) Pressure gauge.

(14) O-rings for ring holder fixing when fitted on 3” x 2” slide mount.

Specifications of the Mini-Pellet Press

Maximum load - 2 tons.

Pellet Die diameter 7mm.

Maximum space between pressing faces - 45mm.

Minimum space between pressing faces - 15mm.

Piston stroke - 0.5mm.

Upper pressing face area (lead screw diameter) - 17.0mm.

Lower pressing face area (piston diameter) - 21.6mm.

Dimensions (excluding leadscrew assemblies) - 110mm wide x 200mm

long x 155mm high.

Dimensions (including leadscrew assemblies) - 110mm wide x 265mm

long x 215mm high.

Weight - 4.2Kg.

User Manual

16

Blank Page - Notes for Use of Mini-Pellet Press

Worldwide Distribution

France

Eurolabo - Paris.

Tel.01 42 08 01 28

Fax 01 42 08 13 65

email: contact@eurolabo.fr

Germany

L.O.T. - Oriel GmbH & Co,

KG - Darmstadt

Tel: 06151 88060

Fax: 06151 880689

email:info@LOT-Oriel.de

Website: www.LOT-Oriel.com/de

Japan

Systems Engineering Inc. -Tokyo

Tel: 03 3946 4993

Fax: 03 3946 4983

email:systems-eng@systems-eng.co.jp

Website: www.systems-eng.co.jp

Spain

Teknokroma S.Coop C. Ltda

Barcelona

Tel: 93 674 8800

Fax: 93 675 2405

email: comercial@teknokroma.es

Switzerland

Portmann InstrumentsAG

Biel-Benken

Tel: 061 726 6555

Fax: 061 726 6550

email: info@portmann-instruments.ch

Website:www.portmann-instruments.ch

USA

SPECAC INC.

414 Commerce Drive

Suite 175,

Fort Washington,

PA 19034, USA

Tel: 215 793 4044

Fax: 215 793 4011

United Kingdom

Specac Ltd. - London

Unit 12, Science & Innovation Centre

Halo Business Park

Orpington

Kent BR5 3FQ

Tel:+44 (0) 1689 873134

Registered No. 1008689 England

Brilliant Spectroscopy™

www.specac.com

SPECAC INC.

414 Commerce Drive

Suite 175,

Fort Washington,

PA 19034, USA

Tel: 215 793 4044

Fax: 215 793 4011

SPECAC LTD.

Unit 12, Science & Innovation Centre

Halo Business Park

Orpington

Kent BR5 3FQ

Tel: +44 (0) 1689 873134

Registered No. 1008689 England

Other Specac Power Tools manuals

Specac

Specac Atlas Power 8Ton User manual

Specac

Specac Atlas Autotouch 40T User manual

Specac

Specac Atlas GS15800 User manual

Specac

Specac Apex 400 User manual

Specac

Specac Atlas 15T User manual

Specac

Specac Atlas Power 8Ton User manual

Specac

Specac Apex 400 Press User manual

Specac

Specac Atlas Lightweight Evacuable Pellet Die User manual

Specac

Specac Atlas Automatic 40 Ton User manual