Specac Apex 400 Press User manual

644-003 2I-25200-2

Apex 400 Press

Hydraulic Presses

User Manual

User Manual

2

Apex 400 Press Hydraulic Press

CONTENTS

APEX 400 PRESS HYDRAULIC PRESS ....................................................2

LIST OF SAFETY SYMBOLS ....................................................................3

1. INTRODUCTION .................................................................................4

2. UNPACKING,CHECKING AND INSTALLATION........................................5

3. GENERAL SAFETY.............................................................................8

4. DIAGRAMS -APEX 400 PRESS.........................................................12

Front View.............................................................................................. 12

Back View............................................................................................... 13

Legend for Apex 400 Press Diagrams.................................................... 14

5. OPERATION -APEX 400 PRESS .......................................................15

General Procedure .............................................................................. 15

Display Screens, Function Buttons and Symbols ................................... 16

Operation – Steps to Press a Sample .......................................... 18

Powering up the Apex 400 Press........................................................ 18

Operation – Further Features of the Press ................................. 24

Piston Travel......................................................................................... 24

6. DISPLAY SCREENS –OPERATION,OPTIONS,PROGRAMMING,

DIRECTORY &EDITING........................................................................25

The Different Display Screen Environments.................................... 25

7. NON-ROUTINE PROCEDURES FOR THE PRESS..................................32

Aborting a Pressing Procedure.............................................................. 32

Work Becomes “Trapped” in the Pressing Area.................................... 32

No Sample in the Pressing Area............................................................. 32

8. FAULT FINDING,CAUSES AND REMEDY ............................................33

9. GENERAL PREVENTATIVE MAINTENANCE .........................................37

11. ACCESSORIES FOR APEX 400 PRESS ............................................39

Apex 400 Press Dies............................................................................... 39

12. SPECIFICATIONS OF THE APEX 400 PRESS.....................................39

Apex 400 Hydraulic Presses

3

List of Safety Symbols

Safety Symbol

Meaning

Caution

(Reference ISO 7000-0434B, 2004-01)

Caution – Possibility of Electric Shock

Indoor Use Only

© September 2023Specac Ltd. All rights reserved.

Brilliant Spectroscopy isa trademark of Specac Ltd.

Other product names mentioned herein may be

trademarks of their respective owners.

User Manual

4

1. Introduction

Thank you for purchasing a Specac product.

The Apex 400 Hydraulic Press is an automatic and programmable

400kN (40 tonnes) hydraulic press which has been designed for a wide

variety of pressing applications within the laboratory or heavy industrial

environments, to apply a load from 40kN to 400kN. These presses are

specifically suited to the preparation of solid sample discs, particularly

for pellets at 40mm diameter or pressing samples into steel rings.

The press includes a touch screen for setting up a pressing sequence.

The Apex press is provided with USB connectivity if it is a requirement

to operate the press remotely from a computer system. For remote

operation, please see Section 10 in this manual.

The Apex press is fully CE marked to comply with strict European

regulations.

WEEE Directive for Equipment Disposal

The symbol (above) on the back of the press indicates that this product

complies with the Waste Electrical and Electronic Equipment Directive

(WEEE). If this product is in use and was purchased within the European

Union, please contact your local sales agent or Specac to make

arrangements for disposal of this equipment.

The equipment must be cleaned and decontaminated before disposal.

Apex 400 Hydraulic Presses

5

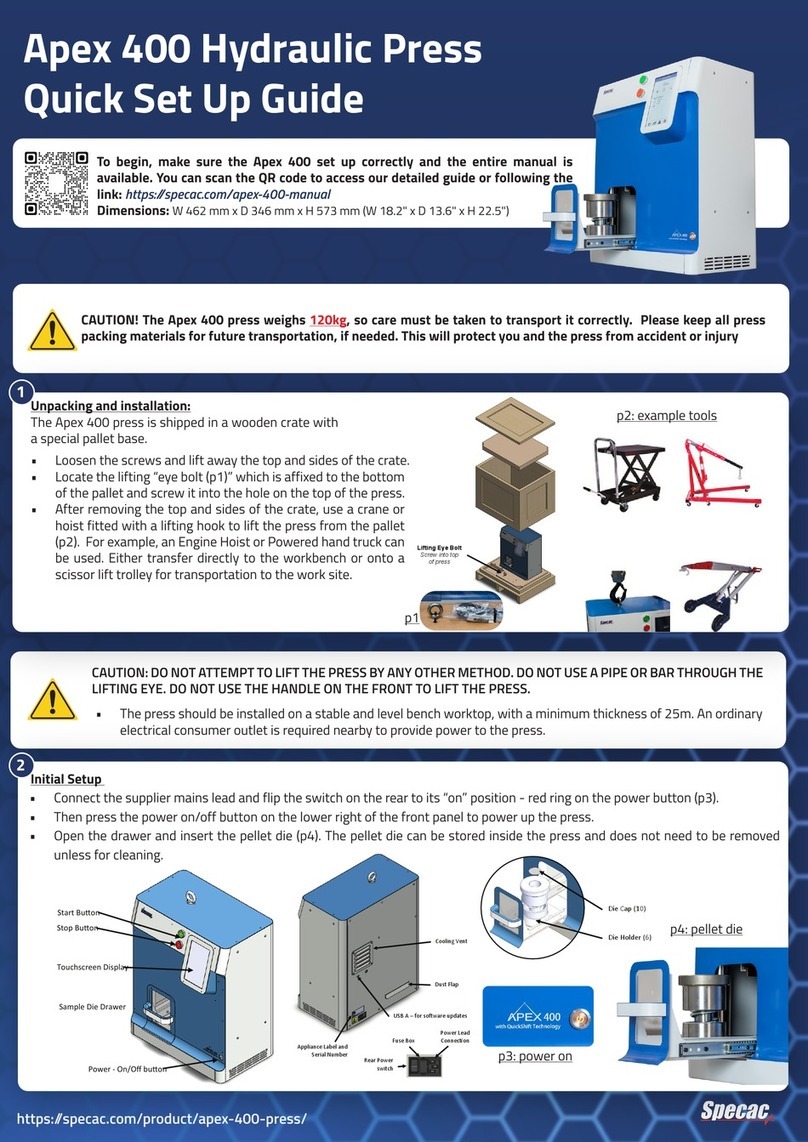

2. Unpacking, Checking and Installation

CAUTION! The Apex 400 press is 120kg and care must

be taken to transport it correctly. Please keep the press

packing materials for future transportation, if

necessary, by reversing the following procedure. This

will protect you and the press from accident or injury.

The Apex 400 press is shipped in a wooden crate with a special pallet

base. The lid of the crate and the sides of the crate can be removed by

removing the screws as shown. The press is packed with a lifting “eye

bolt” which needs screwing into the hole in the top of the press.

Screws

User Manual

6

Lifting Eye Bolt

Screw into top

of press

Apex 400 Hydraulic Presses

7

The press is now ready to be lifted out of the wooden crate.

CAUTION: The press MUST be lifted into its working

position using a suitable hoist (or crane) with a lifting

hook to pass through the eye bolt. DO NOT ATTEMPT

TO LIFT THE PRESS BY ANY OTHER METHOD. DO NOT

USE A PIPE OR BAR THROUGH THE LIFTING EYE. DO

NOT USE THE HANDLE ON THE FRONT TO LIFT THE

PRESS.

The press can now be lifted upwards and out of the crate using a crane

or hoist. For example, an Engine Hoist or Powered hand truck can be

used. If the crane is stationary, then the press can also be lifted onto a

scissor lift trolley for transport and then slid from the trolley onto the

workbench.

Place the press in its working position. The bench worktop should be of

a minimum thickness of 25mm, stable and level. The press needs to be

sited near to an electrical power supply to connect to the press for

operation.

CAUTION: The press should be positioned at least 25cm back, away

from the edge of the worktop, so that the drawer is over the worktop

when fully open.

The press is supplied filled with hydraulic oil (VG100, P/N GS25901) and

is ready to use.

Specac would strongly advise that the Apex 400 press packing materials

are retained and not destroyed, for future transportation should it be

User Manual

8

required. Using the purpose-built packaging is the safest way of moving

and containing the press to minimize for any possible damage in transit.

Replacing an Apex 400 press in its packaging is the reverse of the

procedure described previously.

The equipment must be cleaned and decontaminated before storing,

disposal or moving.

For any inquiries to Specac regarding the Apex 400 press, the serial

number must be quoted. The serial number is a five-digit number

preceded by a letter and it is found on the electrical appliance label

placed on at the rear of the press.

3. General Safety

Specac recommends that the following safety precautions should be

followed for any operational procedure of the Apex 400 press.

Safety Regulations

Testing has been performed by the application of the following

Regulations and Standards:

EN61010-1: 2010 +A1:2019 Safety requirements for laboratory

equipment

EN61326-1: 2021 EMC requirements for laboratory equipment.

CE Marking

This product bears the “CE” marking and complies with Machinery

Directive 2006/42/EC, EMC Directive 2014/30/EU, Low Voltage

Directive 2014/35/EU and RoHS 3 Directive EU 2015/863.

Apex 400 Hydraulic Presses

9

Electrical Safety

WARNING: The equipment must be connected to an earthed electrical

mains supply socket outlet. Do not use with an extension cable without

a protective earth connection.

WARNING: Any interruption of the protective conductor may result in

hazardous condition leading to possibility of an electrical shock hazard.

Always ensure that the mains cord is free from obstructions and the

appliance inlet is accessible to the user.

WARNING: Only use a suitably rated and approved mains cord set

(power cable) acceptable for the local national regulations and

standards.

CAUTION: Disconnect the mains power supply before cleaning and or

servicing. Wear protective gloves for cleaning. No user serviceable parts

within, refer all serving requirements to a suitably qualified electrician or

Specac approved representative.

CAUTION: When required, ensure that all fuses are replaced with the

correct voltage, operating characteristics and current rating as specified

in supporting documentation and on the rating label of the equipment.

CAUTION: Whenever it is likely that electrical protection has been

impaired, the press should be made inoperative and be secured against

unintended operation. Contact your local dealer or Specac for further

advise and servicing requirements.

If the equipment is used in a manner not specified within this manual,

the protection provided by the equipment may be impaired.

User Manual

10

Operational Safety

The drawer, containing sample die, is an important component and its

protection mechanism is linked to the operation of the press. When the

drawer is open the press operation is disabled.

WARNING: If the drawer shows any visible signs of damage this may

impair its effective performance for safe containment of parts within.

Specac recommends that the drawer is replaced if damaged to conform

to the correct safety standards.

CAUTION: If power supply is lost during operation of the press whilst a

load is being applied DO NOT OPEN the drawer to try and remove the

test sample. Should this occur please refer to the section on the Drawer

(see page 33) for the correct procedure under these circumstances.

WARNING: The power cord is the overall form of disconnection and

needs to be always kept accessible.

CAUTION: The die is heavy, so safety shoes should be worn if the die

is removed for cleaning.

Do not attempt to press potentially combustible materials or materials

with a low flash point temperature. Always consult your local safety and

laboratory operating procedures before use.

Do not operate the press in very hot or very cold environments. The

press is only intended to operate within its rated ambient temperature

range (+10°C to +40°C).

Do not operate the press in WET, DAMP or HUMID environments.

(Always allow enough time for condensation to evaporate before

connection to the supply, especially if the press has been stored in cold

conditions).

Do not operate the press if it shows any visible damage. The press may

have been dropped in transit or damaged in use.

Apex 400 Hydraulic Presses

11

Do not continue operating the press if it fails to perform the intended

tonnage and/or measurement of applied load.

Repair or Maintenance Safety

The Apex 400 Press must be disconnected from the mains supply

before removing equipment covers for adjustment, replacement of faulty

parts or general maintenance.

Any adjustment, maintenance or repair of the equipment while

connected to the mains supply should be avoided as far as possible and

if inevitable, should be carried out only by a qualified person who is

aware of the hazards involved and/or Specac authorized agent.

Please do not remove the drawer. For cleaning it can be opened and

wiped with a damp cloth or vacuumed.

These terms apply to and form part of the terms of use and any contract

between Specac Limited and any purchaser of the Apex 400 Press and

when issued shall supersede any other terms. Specac Limited shall not

be liable for any for any defects appearing in an Apex 400 Press sold or

supplied by Specac Limited to the extent that such defects arise as a

result of the purchaser or any user modifying or tampering with the

goods or failing to operate the Apex 400 Press in accordance with

instructions issued by Specac Limited from time to time in relation to

installation, operation, storage or maintenance. All warranties other than

those expressly given by Specac Limited in its conditions of sale, or

which are implied and may not be excluded by virtue of an applicable

statute or regulation shall be excluded to the fullest extent permitted by

law.

User Manual

12

4. Diagrams - Apex 400 Press

Front View

Start Button (11)

Stop Button (12)

Touchscreen Display (4)

Sample Die Drawer (5)

Front Power -

On/Off button (1)

Lifting Eye & Hole (7)

Die Holder (6)

Die Cap (10)

Apex 400 Hydraulic Presses

13

Back View

Cooling Vent

USB A (9) – for software updates

Dust Flap

Rear Power

switch (2)

Fuse Box (15)

Power Lead

Connection (3)

Appliance Label and

Serial Number (14)

User Manual

14

Legend for Apex 400 Press Diagrams

(1) Front On/off power switch.

(2) Rear power switch

(3) Power Lead connection.

(4) Touchscreen Display.

(5) Die Drawer.

(6) Die Holder.

(7) Lifting Eye & Hole.

(8) Pressure Plate

(9) USB A Socket

(10)Die Cap

(11) Start (apply load) button.

(12) Release (remove load) button.

(14) Appliance Label and Serial Number

(15) Mains fuse holder.

Apex 400 Hydraulic Presses

15

5. Operation - Apex 400 Press

General Procedure

The Apex 400 press is used to apply a constant load to a sample powder

contained within a die.

The Apex 400 press can apply a load by running program which can be

loaded from the Directory. The press is configured with a couple of

starter programs, but more can be added by the user.

When using a program, the 1st load to be applied can be quickly edited

from the main screen by touching the Adjust Load symbol of the

Display Screen (4) and then applied when the start button (11) is

pressed. A load between 40 kN to 400 kN can be set.

Programming and Editing the programs are explained in their own

sections of this instruction manual. (Please see Section 6.)

For the procedural description of operation in how to install, press and

remove a sample from an Apex 400 press, please refer to the diagrams

of the press for the part identification where mentioned.

CAUTION! Ensure that any loads used on the press

are within the maximum safety limit load of the die.

User Manual

16

Display Screens, Function Buttons and Symbols

Display Screens

All operations and the status of the Apex 400 press are shown on the

Display Screen (4). The Display Screen has five principal types of

display presentation.

These five “Display Screens” are:

1) Main Operation Screen

2) Settings Screen

3) Program Directory List Screen

4) Program Editing Screen

5) Event Viewer

Function Buttons

There are two function buttons on the front panel. The top green button

is the start (apply load) button (11) and the red lower is the stop (release

load) button (12).

Note: The stop button (12) should be considered a general “failsafe”

function button and can be pressed to cease all operations in

running of the press at any time or in case of emergencies.

During the actual running of any program if the stop button (12) is

pressed once, this action will:

A) Abort a program if the load is actually rising or releasing.

B) Release the load and retract the cylinder.

On rare occasions where no load has yet been applied and the program

is aborted, the cylinder may take a long time to retract. 5-10 min.

Apex 400 Hydraulic Presses

17

Status Symbols

The following shows the main status screen and common status

messages likely to be seen.

Main Operating Screen – Status Icons

Status Icon -The Pressure Plate is in the Sample

Loading state

Status Icon -The Pressure Plate is in the Sample

Release/Eject state

Status Icon -The Pressure Plate is moving or in

transitory state

Status Icon -Drawer is Open or Closed – The press will

only run with the drawer closed

Status Icon –Green color indicates if the oil

temperature is OK.

Current time

Load

Status Icons

Currently Loaded Program

Buttons – described below

User Manual

18

Operation – Steps to Press a Sample

Powering up the Apex 400 Press

Connect the press to a suitable electrical supply using the supplied

mains lead and plug at the rear into the power socket (3). Then switch

On the rear power switch (2) followed by turning on by pressing the front

power on/off switch (1). The switch illuminates red when the press is On.

From start up the display will load the Main Operation Screen. The last

used program will be loaded ready for use.

Note: On first start up or if the power has been lost the press may ask

for the current time to be set. This can be set or cancelled.

At initial start-up a typical operating screen will be presented as shown

below.

Note: If the drawer (5) is open, the drawer symbol will be shown

with a red exclamation. This means that all power to the

motor has been cut to prevent any accidental operation.

Load

Status Icons

Currently Loaded Program

Buttons

Apex 400 Hydraulic Presses

19

Changing the Language Display and the Units of Load

The Apex 400 press language can be changed in the Settings screen.

From the main screen, touch the followed by the .

The press can display the Units of load in kN, Tonnes or US Tons. This

is changed in the settings screen by touching the

Placing Work in the Apex 400 Press

After switching On, open the drawer (5).

Place the die in the drawer (5) in the support ring (6). This can be done

one part at a time in this order:

1. Plunger

2. Spring

3. Die Body – slowly, taking care to align the parts and not damage

them.

CAUTION: The dies supplied by Specac with the press are

designed specifically for this drawer and have the correct

height to be used with the press. Contact Specac before

using any other die.

Place powder sample into the die cavity and fit the die top cap (10).

Make sure the top cap is fitted securely.

Now close the drawer (5).

Recommended masses of sample

and load are provided here, adjust

mass and load to get thickness and

pellet quality as needed.

Sample:

Rock

Food

∅ 32 mm die

7 g

3 g

∅ 35 mm die

8 g

4 g

∅ 40 mm die

10 g

5 g

Starting Load:

200 kN

40 kN

User Manual

20

Applying a Load with the Apex 400 Press

Once the sample is correctly positioned and the drawer (5) has been

closed, a program can be run.

Touch the Directory symbol to change the program.

There are two main types of die, and they require programs set up in a

different way.

CAUTION: Applying too much load to certain sample types

can cause the die to stick. Start with lower loads and

increase until the pellet quality is acceptable.

Table of contents

Other Specac Power Tools manuals

Specac

Specac Atlas GS15800 User manual

Specac

Specac Apex 400 User manual

Specac

Specac Atlas Autotouch 40T User manual

Specac

Specac Atlas Power 8Ton User manual

Specac

Specac GS03940 User manual

Specac

Specac Atlas 15T User manual

Specac

Specac Atlas Power 8Ton User manual

Specac

Specac Atlas Lightweight Evacuable Pellet Die User manual

Specac

Specac Atlas Automatic 40 Ton User manual