Speck pumpen BADU Jet Perla User manual

Inhaltsverzeichnis

05/2013 VG 766.2330.061 EN 35

EN Original Operating Instructions for

BADU®Jet

BADU®JetBADU®Jet

BADU®Jet

1 Manual Introduction

36 EN VG 766.2330.061 05/2013

Table of Contents

1Manual Introduction..................................................................38

1.1 Preface...............................................................................38

1.2 Related Documentation......................................................38

1.2.1 Icons and Symbols..................................................38

2Safety .........................................................................................40

2.1 Introduction ........................................................................40

2.1.1 Possible Misuse ......................................................40

2.2 Precautions and Qualifications...........................................40

2.3 Safety Regulations .............................................................41

2.4 Protective Cover.................................................................41

2.5 Structural Changes and Replacement Parts ......................41

2.6 Signs 41

2.7 Other Risks ........................................................................42

2.7.1 Falling Parts ............................................................42

2.7.2 Rotating Parts .........................................................42

2.7.3 Electrical Power ......................................................42

2.7.4 Hot Surfaces ...........................................................43

2.7.5 Entrapment Hazard.................................................43

2.7.6 Entrapment Hazard of sensitive body parts. ...........43

2.8 Malfunctions .......................................................................43

2.9 Prevention of Material Damage..........................................44

2.9.1 Leakage and Burst Pipes ........................................44

2.9.2 Protection against Running Dry ..............................44

2.9.3 Overheating ............................................................44

2.9.4 Seized Pump...........................................................44

2.9.5 Drainage .................................................................44

2.9.6 Frost protection .......................................................45

3Description ................................................................................46

4Transport and Interim Storage.................................................47

4.1 Lifting the counter swim unit...............................................47

5Installation .................................................................................48

5.1 Location..............................................................................48

5.1.1 Mounting site...........................................................48

5.1.2 Checklist .................................................................48

5.1.3 Position ...................................................................48

5.1.4 Securing the unit .....................................................48

5.1.5 Insert the brass dowels ...........................................48

5.1.6 Secure the unit........................................................48

1 Manual Introduction

05/2013 VG 766.2330.061 EN 37

5.1.7 Distance equalization..............................................48

5.1.8 Power supply ..........................................................48

5.2 Assembly Recommendation...............................................49

5.3 Electrical Connection..........................................................49

5.4 Additional parts required ....................................................50

6Start Up ......................................................................................51

Protection against Running Dry..........................................51

6.1 Filling the pump..................................................................51

6.2 Start-up after prolonged downtime .....................................52

6.3 Switching ON .....................................................................52

7Operation ...................................................................................53

7.1 Operating the overhang counter swim unit.........................53

7.1.1 Turning the unit ON and OFF..................................53

7.1.2 Air Regulation Function...........................................53

7.1.3 Light operation ........................................................53

7.1.4 Setting the ball nozzle.............................................53

7.1.5 Cover damage. .......................................................53

7.1.6 Optimal water level..................................................53

7.2 Massage hose....................................................................54

7.2.1 Instructions for the massage hose. .........................54

7.2.2 Air regulation and the massage hose......................54

8Malfunctions ..............................................................................55

8.1 Failures ..............................................................................55

8.1.1 Overload switch has triggered.................................56

9Maintenance/Service.................................................................57

9.1 Care Instructions ................................................................57

10 Appendix I..................................................................................58

10.1 Technical Information.........................................................58

10.2 Dimensions ........................................................................59

10.3 Wiring diagrams .................................................................60

10.4 Information on Safety Position Switch................................61

10.5 Securing the unit to the ground ..........................................62

10.6 Securing the unit with the telescopic support foot. .............64

10.7 Various Drawings ...............................................................65

1 Manual Introduction

38 EN VG 766.2330.061 05/2013

1 Manual Introduction

1.1 Preface.

This manual contains important information for reliable and efficient

operation of the overhang counter swim units. Compliance with the

operating instructions is of vital importance to ensure reliability and a

long service life of the product and to avoid any risks.

These units have been developed using state of-the-art-technology and

manufactured with utmost care and have been subjected to the strin-

gent Speck Pumpen testing facilities and continuous quality control.

Speck Pumpen Verkaufsgesellschaft GmbH does not accept any liabil-

ity for damage and injury caused by not observing the directions and

instructions in this manual. This also applies in cases of carelessness

during the installation procedure, use and maintenance of the product.

Non-compliance with the safety instructions can jeopardize the safety of

personnel, the environment and the product itself. Non-compliance with

the instructions will also lead to forfeiture of any and all rights to claims

for damages

Keep the instructions available for the life of the product.

Make sure the instructions are accessible to all operators and ser-

vice personnel.

Ensure the instructions are passed on to each owner or user of the

product.

1.2 Related Documentation

Replacement parts list

Packing list

1.2.1 Icons and Symbols

Icons and symbols are used to introduce safety instructions whose non-

observance can lead to personal injury.

Always read and follow the warnings.

Icons &

Symbol

Warning Meaning

DANGER Physical Danger

Non-observance can result in death

or severe injury.

1 Manual Introduction

05/2013 VG 766.2330.061 EN 39

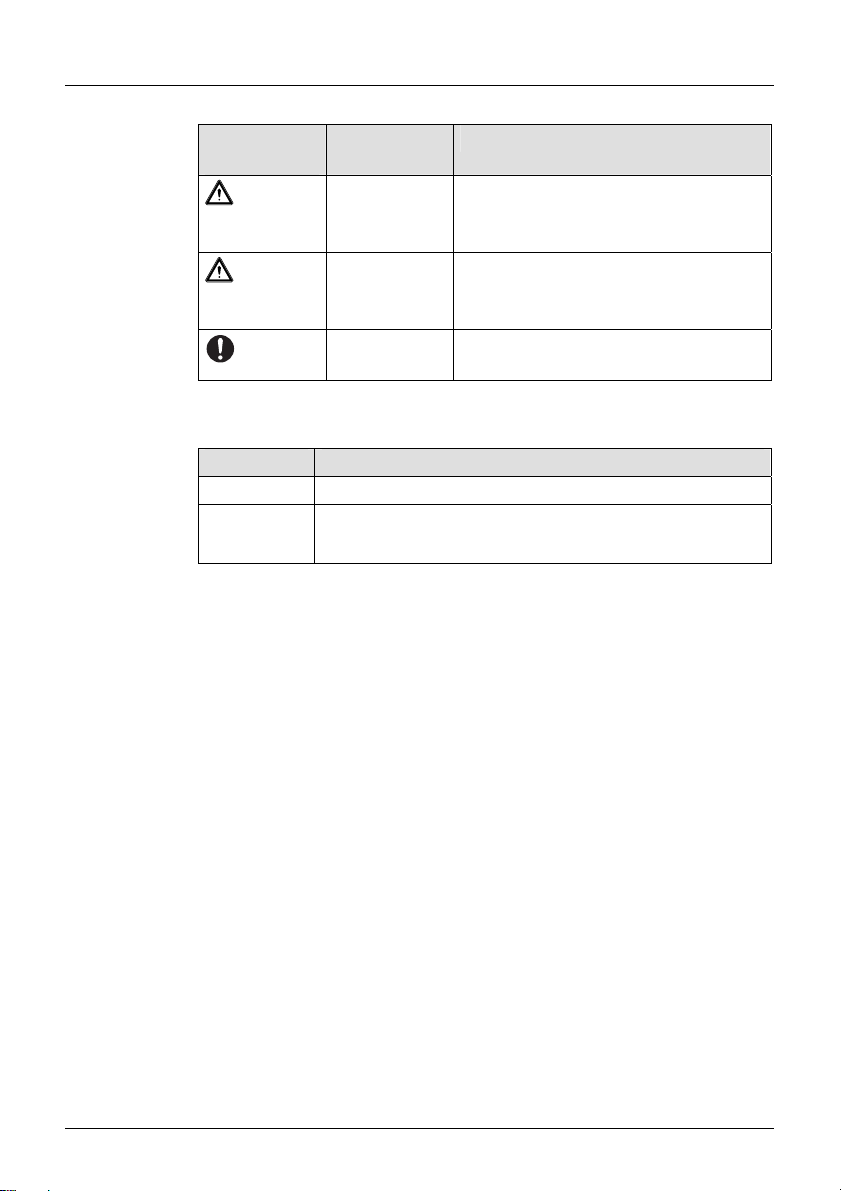

Icons &

Symbol

Warning Meaning

WARNING Physical Danger

Non-observance can result in death

or severe injury.

CAUTION Physical Danger

Non-observance can result in per-

sonal injury.

– Instructions to prevent material dam-

age, and optimize operation.

To ensure easy and correct operation, important technical information

in a step by step procedure have been highlighted.

Symbol Meaning

Single step action

1.

2.

Multi-step action

Follow the sequence of steps.

This manual suits for next models

2

Table of contents

Other Speck pumpen Lighting Equipment manuals