Spectec XP2 Series User manual

THUNDERBIRD INTERNATIONAL CORPORATION

P.O. Box 360, Emigrant, MT 59027-0360

406-333-4967 ∙ FAX 406-333-4259

INSTRUCTION MANUAL

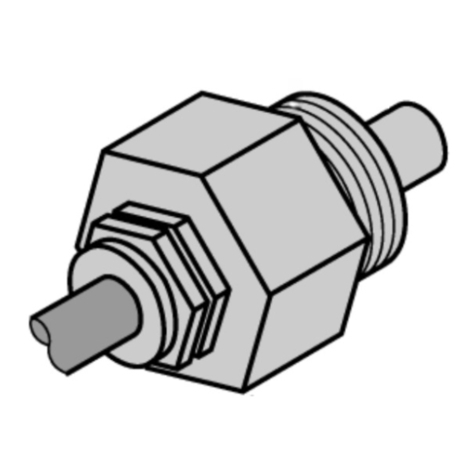

XP2 Series, Conduit Style

Active Speed Sensors 85047X

Engineering Approval: Date: 03-18-2019 Revision: 1

PROPRIETARY, COPYRIGHTED INFORMATION DO NOT DUPLICATE OR DISTRIBUTE TO THIRD PARITES UNLESS AUTHORIZED BY SPECTEC

Approval agency controlled document. Do not alter without authorization. Page 1 of 3

Introduction

SPECTEC's Explosion Proof / Flame Proof sensors are designed for

installation in hazardous locations. They are offered in a wide

variety of configurations. See the XP2 Bulletin for specifications

and configuration options.

Marking

Unit Type No.: XP2-xxxxxx

Date Code: WW/YY (Week/Year)

Conduit Size: 1/2- NPT or M20x1.5

Electrical Rating: xx to xx V DC @ ≤xx mA (marked according to

sensor type, see XP2 Bulletin)

Codes: CL I DIV 1 GP ABCD T6...T3

CL I ZN 1 AEx/Ex db IIC T6...T3 Gb

T3@ Ta = -50°C...+140°C (marked)

T4@ Ta = -50°C...+112°C

T5@ Ta = -50°C...+77°C

T6@ Ta = -50°C...+62°C

II 2 G Ex db IIC T6...T3 Gb

T3@ Ta = -55°C...+140°C (marked)

T4@ Ta = -55°C...+112°C

T5@ Ta = -55°C...+77°C

T6@ Ta = -55°C...+62°C

Certificate No.: FM16US0288X & FM16CA0147X

FM16ATEX0086X & IECEx FMG 16.0035X

CE Marking: 2809

Warnings: SEAL ALL CONDUITS WITHIN 18 INCHES

DISCONNECT POWER BEFORE OPENING

FERMER TOUS LES CONDUITS SOUS 18 POUCES

(.45m) MAXIMUM

DÉBRANCHER L’ALIMENTATION ELECTRIQUE

AVANT L'OUVERTURE

Specific Conditions of Use

1. Refer to these instructions for complete temperature ratings

and suitability.

2. No external grounding is provided. The sensor must be

mounted as part of a bonded structure.

3. The wiring shall be mechanically protected as required by the

applicable area electrical code and shall be terminated in a

suitable terminal or junction facility.

Warnings

1. A poured conduit seal must be applied within 18 inches

(0.45m) of the sensor.

2. Disconnect power before opening or removing the sensor.

Compatibility

Refer to the listed certification and temperature ratings for

suitability. The intended environmental and operating conditions

should be verified to be in compliance with these ratings.

Housing: 303 or 304 series Stainless Steel

Cable: PTFE insulated (Polytetrafluoroethylene)

or FEP insulated (Fluorinated ethylene propylene)

NOTE: For Canadian installations, only female NPT or metric entries

are permissible per CSA C22.2 No. 0.5 & 30.

Type Approval Standards

The XP2 product series have certificates issued by FM Approvals

and have been approved to the following standards:

United States of America (USA) Standards:

FM Class 3600:2011 General Requirements

FM Class 3615:2006 Explosionproof General Requirements

FM Class 3810:2005 General Requirements

ANSI/ISA61010-1:2012 Safety General Requirements

ANSI/ISA60079-0:2013 General Requirements

ANIS/UL60079-1:2015 Flameproof Enclosures 'd'

Canadian Standards:

CSA C22.2 No. 0.4-04: R2013 Bonding of Electrical Equipment

CSA C22.2 No. 0.5:2016 Threaded Conduit Entries

CSA C22.2 No. 61010-1:2012 Safety General Requirements

CSA C22.2 No. 30-M1986:R2012 Explosion-proof Encl.

CSA C22.2 No. 60079-0:2012 General Requirements

CSA C22.2 No. 60079-1:2016 Flameproof Enclosures 'd'

ATEX Standards:

EN60079-0:2012 + A11:2013 General Requirements

EN60079-1:2014 Flameproof Enclosures 'd'

IECEX Standards:

IEC60079-0:2011 General Requirements

IEC60079-1:2014 Flameproof Enclosures 'd'

Installation Requirements

The installation shall be carried out by suitably trained personnel.

The sensor must be installed in accordance with the latest issue of

the following standards:

US installations:

follow the National Electrical Code ANSI/NFPA 70,

Canadian installations:

follow the Canadian Electrical Code CSA C22.1,

ATEX installations: follow EN 60079-14,

IECEx installations: follow IEC 60079-14.

The installation must also be in accordance with any local codes

and national regulations that apply.

JE

Approved May 9th, 2019

THUNDERBIRD INTERNATIONAL CORPORATION

P.O. Box 360, Emigrant, MT 59027-0360

406-333-4967 ∙ FAX 406-333-4259

INSTRUCTION MANUAL

XP2 Series, Conduit Style

Active Speed Sensors 85047X

Engineering Approval: Date: 03-18-2019 Revision: 1

PROPRIETARY, COPYRIGHTED INFORMATION DO NOT DUPLICATE OR DISTRIBUTE TO THIRD PARITES UNLESS AUTHORIZED BY SPECTEC

Approval agency controlled document. Do not alter without authorization. Page 2 of 3

Installation Procedure

Mounting

1. Thread the sensor into a suitable bracket or housing with the

Sensing Surface aimed toward the Target.

2. Set the Air Gap (shortest distance from Target to Sensing

Surface) at a typical distance of .020" to .040" (0.5 to 1.0mm).

Be sure to account for any eccentricity of the Target to avoid

damage to the sensor which can affect safety. This distance

should be >.010" (0.25mm) over the eccentricity of the Target.

NOTE: Rotate the alignment mark to point at the gear for Dual

Output and Directional Sensor Types.

3. Securely lock the sensor at the correct Air Gap using a jam

nut or other suitable means. Do not over torque the mounting

thread. Recommended tightening torque is listed below.

4. A poured conduit seal must be applied within 18 inches

(0.45m) of the sensor.

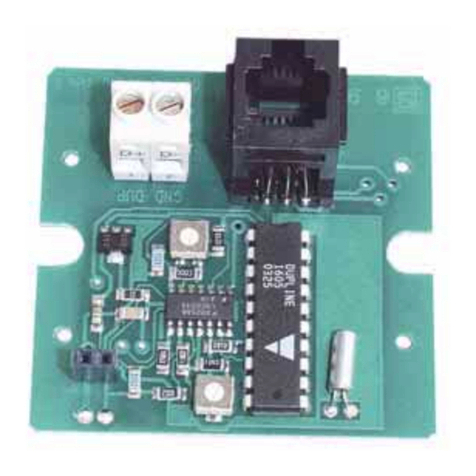

Wiring

The wiring is provided as either shielded cable or individual leads.

Make all wire connections before applying power to the circuit.

The appropriate DC (direct current) power supply for each Sensor

Type is detailed on the XP2 Bulletin and marked on each sensor.

The wiring shall be mechanically protected as required by the

applicable area electrical code and shall be terminated in a

suitable terminal or junction facility.

Control Equipment connected to this equipment must not use or

generate more than 250V.

Wire Color codes are as follows:

Red - + Power, DC Voltage positive

Black - – Common, DC Voltage negative

White - Signal A output, referenced from Common

Green - Internal Housing Ground (connect to earth)

Bare - Cable shield (connect to instrument ground)

Yellow - Signal B output, as applicable

Blue - Direction Signal output, as applicable

Cable and individual leads temperature range is -55°C to +200°C.

Earthing / Grounding

The green (or green with yellow stripe) wire of the sensor is an

internal connection to the metal housing. This wire must be

connected to an earth ground to maintain the safety of the

sensor. Additionally, no external ground is provided so the sensor

must be mounted as part of a bonded structure.

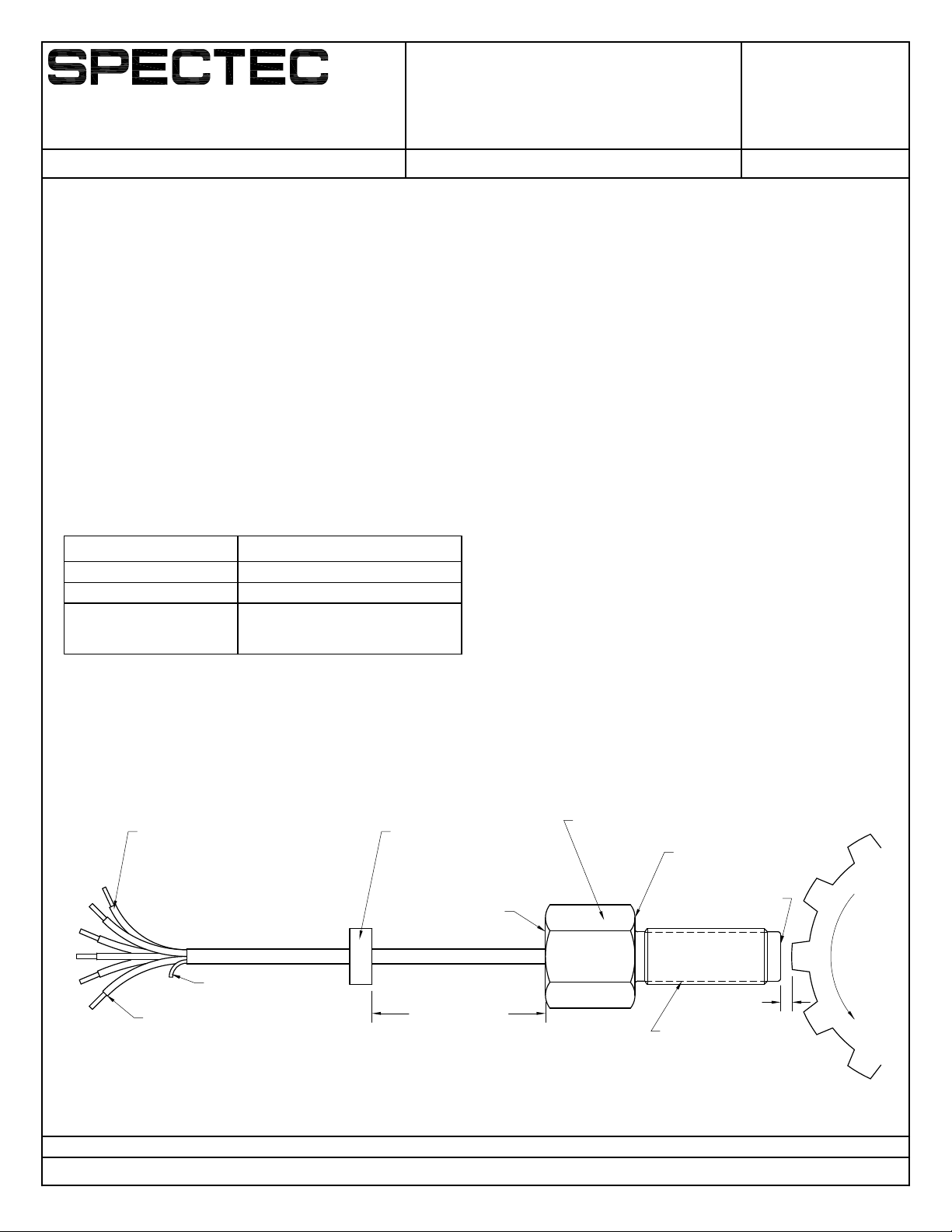

Air Gap

Classification

Marking

Housing Ground

MUST BE TIED TO EARTH

GROUND

Green or Green with Yellow

(May be included as separate lead)

* 18" (.45m)

MAX.

* POURED

CONDUIT SEAL

Power and

Signal Leads

Cable Shield (Bare)

Directional Mark

(only on some units)

Target

(forward)

Sensing Surface

Mounting

Thread

Mounting Thread Recommended Maximum Torque

1/2-20 UNF, M12x1-6g 11.0 lbf·ft (14.9 N·m)

5/8-18 UNF, M16x1.5-6g 19.0 lbf·ft (25.7 N·m)

11/16-24 UNEF, 3/4-16 UNF,

3/4-20 UNEF,

M18x1.0-6g, M18x1.5-6g

33.0 lbf·ft (44.7 N·m)

JE

Conduit

Thread

* A POURED CONDUIT SEAL MUST BE APPLIED

WITHIN 18" (0.45m) MAXIMUM OF THE

SENSOR

Approved May 9th, 2019

THUNDERBIRD INTERNATIONAL CORPORATION

P.O. Box 360, Emigrant, MT 59027-0360

406-333-4967 ∙ FAX 406-333-4259

INSTRUCTION MANUAL

XP2 Series, Conduit Style

Active Speed Sensors 85047X

Engineering Approval: Date: 03-18-2019 Revision: 1

PROPRIETARY, COPYRIGHTED INFORMATION DO NOT DUPLICATE OR DISTRIBUTE TO THIRD PARITES UNLESS AUTHORIZED BY SPECTEC

Approval agency controlled document. Do not alter without authorization. Page 3 of 3

Sensor Type Notes

DIGISPEC Hall Effect Sensor

H Type Magnet Actuated

This zero speed sensor is triggered by a magnet or a magnetic

field and offers sensing over larger air gaps. This Sensor Type is

typically used on gear meters or magnet wheels. Dual and

directional output options are also available. It is available in the

following types:

Ho - Omnipolar (north or south pole activation)

Hs - South pole only activation

Hn - North pole only activation

H - Bipolar Latch (requires alternating north and south poles)

HF Type Gear Actuated

This zero speed sensor is triggered by a ferrous metal target (bolt,

keyway, or typically a gear tooth). The HF Sensor Type is usually

used in motor RPM and camshaft timing. Dual and directional

output options are also available. An HFd Type differential sensor

(for high vibration environments) is also available as an option.

DIGISPEC Magnetic VRS Sensor

This Sensor Type also requires a ferrous metal target. A smaller air

gap and a minimum surface speed are required to operate

properly. It is usually used on flowmeters because it can detect

more precisely and with lower magnetic drag than HF Type

sensors.

DIGISPEC RF Sensor

This Sensor Type operates on the Eddy Current principle and

interacts with a ferrous or aluminum target without imposing a

magnetic drag. SPECTEC's RF sensors are specifically designed for

precision Turbine Flowmeters where no magnetic drag can be

tolerated. They are also used for high pressure applications with

the ability to sense through a non-magnetic stainless steel wall.

They also function close to zero speed, but are typically limited to

5kHz maximum frequency.

See the XP2 Bulletin for details on the supply voltage range,

frequency range, and maximum Air Gap for each Sensor Type.

Operation and Usage

Operation

1. Verify that the sensor is properly mounted and all electrical

connections are made (including earthing).

2. Switch on the DC supply voltage and allow the Target to

move. The sensor should now produce an output signal.

3. If a signal is not produced, verify that the Target is moving

faster than the minimum detectable frequency of the Sensor

Type. If a signal is still not produced, follow the steps in the

Adjustment process detailed below.

4. The output signal will switch state when a target enters or

leaves the detection area. For the NPN output options, the

signal will be High (5V, 10V, or the supply voltage) without a

target in the detection area. The output will switch Low when

a target enters the detection area. For the PNP output option,

the output will be inverted from the above.

5. Directional Hall Effect sensors will output a High signal on the

Direction Output when the target is rotating in the Forward

direction. If the correct signal is not produced, follow the

Directional Alignment process detailed below.

Adjustment

1. Stop the rotation or movement of the Target.

2. Loosen the jam nut or other locking device.

3. Decrease the Air Gap by .005 - .010" (0.12 - 0.25mm). Be sure

to account for any eccentricity in the rotation and movement

of the Target. Otherwise the sensor may be damaged.

4. Re-tighten the jam nut or locking device and check again for

an output signal.

Directional Alignment (only applicable to some Sensor Types)

1. The Target should approach the Directional Mark when

moving in the forward direction. However, with smaller targets

the alignment may need adjusted.

2. Loosen the jam nut or other locking device.

3. Rotate the Directional Mark of the sensor slightly away from

the approaching Target until the signal has the correct 90°

electrical phasing (easily viewed on an oscilloscope).

4. Re-tighten the jam nut or locking device and check again for

an output signal.

Removal

Removing or Uninstalling the sensor is the reverse of the Installation

Procedure.

WARNING: Before separating connections, the target must be

stopped and the sensor should be de-energized.

Service and Repair

The sensor cannot be serviced or repaired in the field. Please

contact sales to purchase a replacement.

WARNING: Do not remove plugs, fittings, cable glands, or blanking

elements installed by the manufacturer.

JE

Approved May 9th, 2019