4.3 Manually screw the regulator onto the cylinder valve (1). Tighten connection

gas-tight by using an appropriate spanner. Do not use any extension to the

spanner to increase momentum! In case of flammable and toxic gases attach a

relief line to the relief valve (4) and ensure a safety gas discharge. For cylinder

regulators with external purge gas connect the purge gas line.

4.4 Carry out the connections between the cylinder pressure regulator and the point

of use. Never allow cylinder pressure regulator to regulate into the open

atmosphere.

Wind PTFE tape (Art. No. 0321422) clockwise around NPT-screwed

connections (5 to 10 turns). Check all connections for leaks.

4.5 Release the pressure regulator spring with the hand knob (6) - open the cylinder

valve (1) (High pressure gauge 3 indicates the cylinder pressure) - Adjust the

required outlet pressure with hand knob (6). Correct the pressure setting in case

of a decrease of pressure.

!

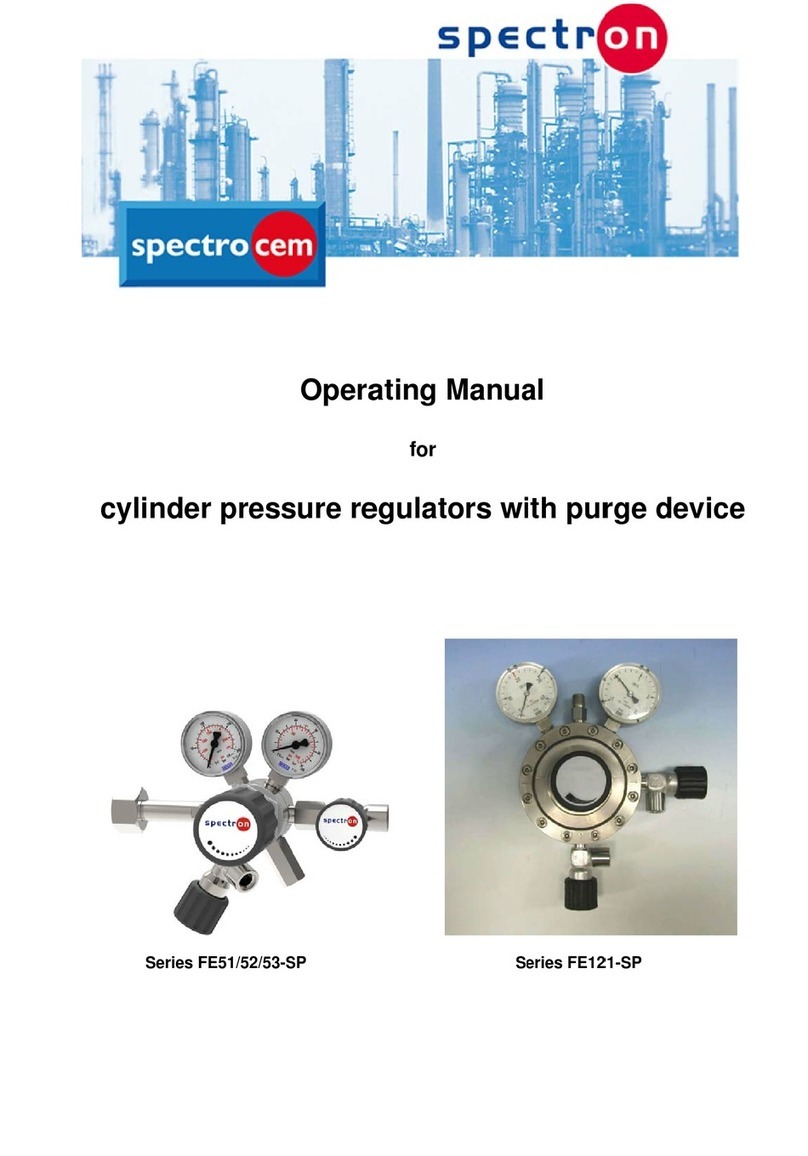

1 Cylinder valve to DIN 477 or the relevant national standard

2. Regulator connection to

DIN 477 or the relevant national standard

3. High-pressure gauge

4. Relief valve

5. Low-pressure gauge

6. Hand knob

4. Start-up

4.1 Before starting read the specifications of this instruction for use and observe it

while working.

4.2 Check, that the cylinder valve thread, pressure regulator, connector and

connection seals are without any damage (blow through if necessary).

In case of a damage, the cylinder pressure regulator must not be connected.

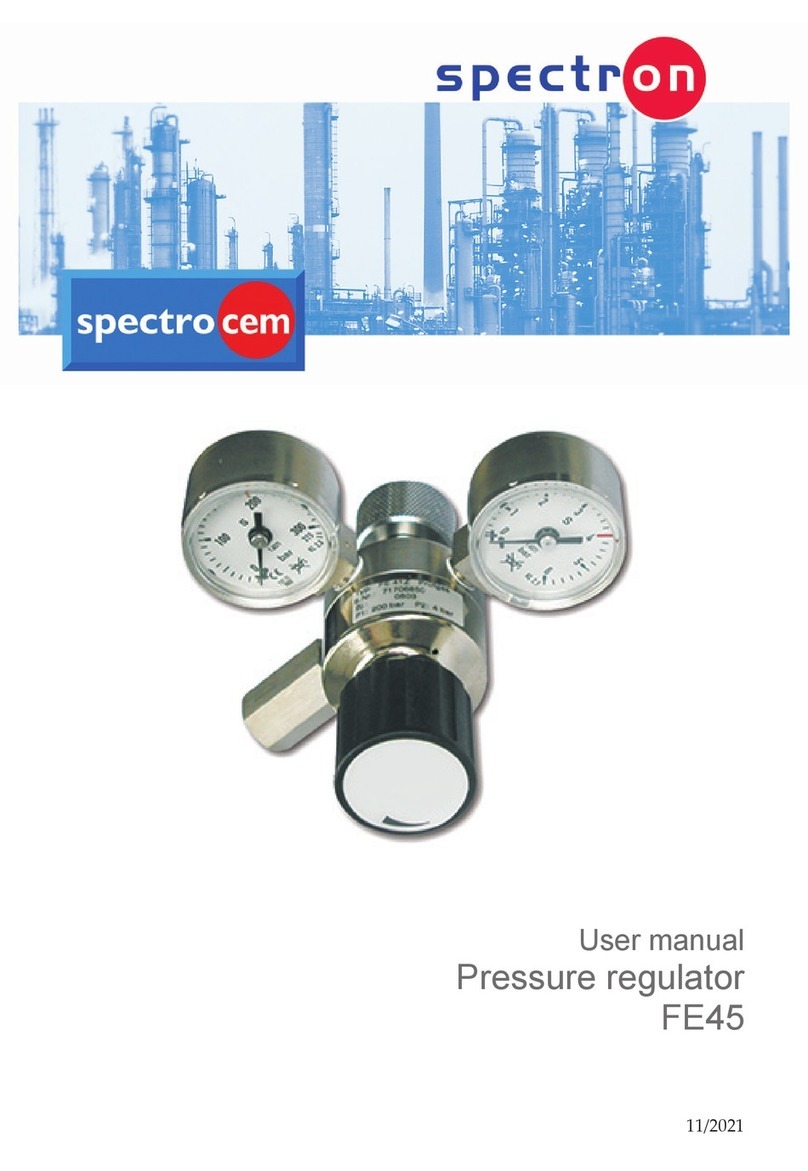

3. Labelling

1 Type

2 Gas type

3 Article no.

4 Max. inlet press.

5 Max. outlet press.

6 Date of manufacture

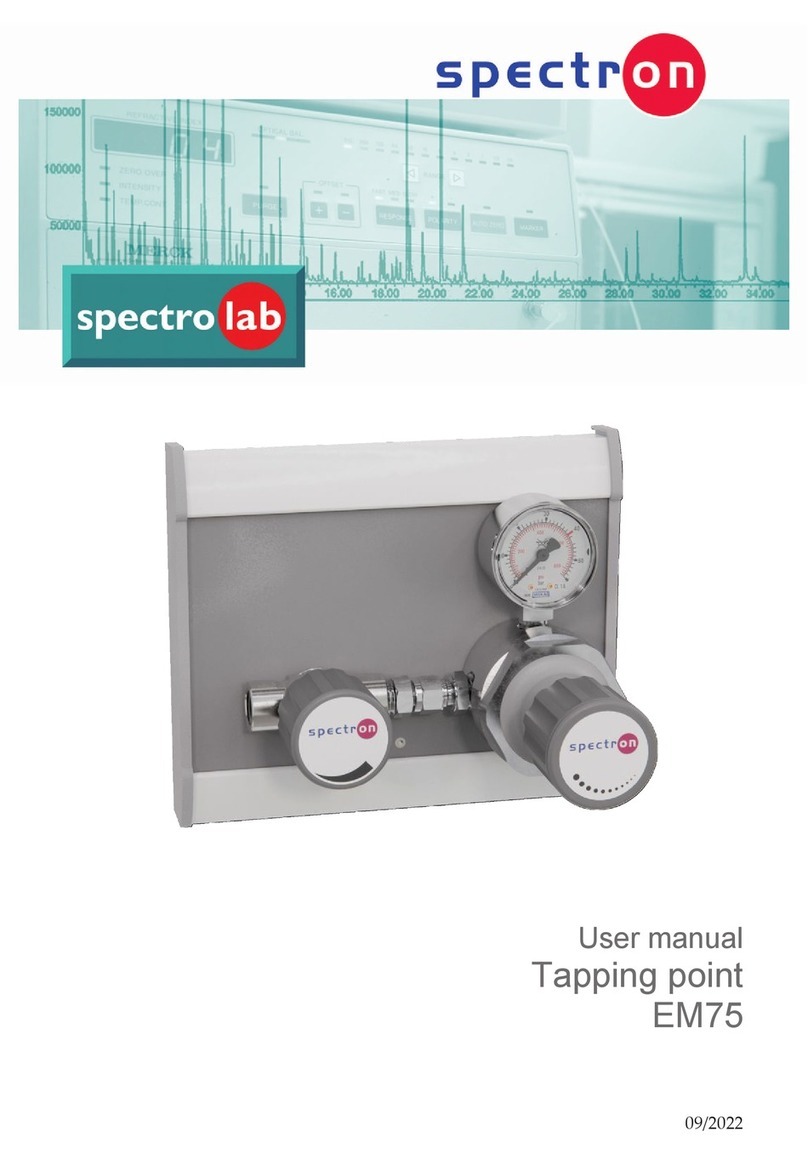

0 0,2 12 3 100,3 0,5 4 5

0

0,4

0,8

1,2

1,6

3

Flow rate Q [m /h air]

Outlet pressure P bar]

H[

Inlet pressure P = 4 bar

V

5. Operation and maintenance

5.1 Before commisioning check on the nameplate if the regulator is suitable for the

gas type. The designated gas type has to be marked on the nameplate using gas

type stickers or by writing the gas type into the space provided on the

nameplate.

FE 121 - O

P1: 25 bar P2: 1,5 bar

717. …

0601

1 2 3

456

1 2 345

6

SW 27

3

2. Safety instructions

- Guidelines for laboratories (Zh 1/119)

- Technical regulation (liquified pet. gas)

In case of flammable gases, thedischarge of the gas from the relief valve (4)

must be ensured. For this use connector 1/8-NPT/6mm pipe (art. no. 0291677).

No adapters must be used between the gas cylinder valve and the pressure

regulator.

2.1 All items of information marked with are valid as special safety instructions.

2.2 These pressure regulators adhere to state-of-the-art technology and

to the demands of the exsiting standards and regulations.

2.3 Changes or modifications are not allowed to be made to the pressure

regulator without the prior consent of the manufacturer.

2.4 The result of improper handling and improper use as intended can involve

risks for the user and other persons as well as damage to the device.

2.5 The equipment must be operated by suitable trained personnel only.

2.6 Regulations to be adhered to:

- BGV A1 (VBG 1), “General specifications”

- BGV B6 (VBG 61), “Gases"

- BGV B7 (VBG 62), “Oxygen”

Special attention has to be paid to the country specific laws, regulations

and procedures concerning the use of this type of equipment.

2.7 Use only for gas types the pressure regulator is labelled for (see item 3).

2.8

2.9 Do not use at temperatures below -30°C or above +60°C.

2.10 The valve has always to be opened slowly!

2.11 All parts coming into contact with oxygen must be kept in oil-free and

grease-free condition.

Fire or explosion hazard!

2.12 Smoking or open fire (e.g. candles) in the vicinity of the gas supply

system is strictly prohibited.

Fire and explosion hazard!

2.13 Protect gas cylinders against falling.

2.14

!

!

!

!

!

!