Table of contents Spectron Gas Control Systems GmbH

ii GES_FS4_0520

Table of contents

1 Introduction.................................................................................................................................................. 4

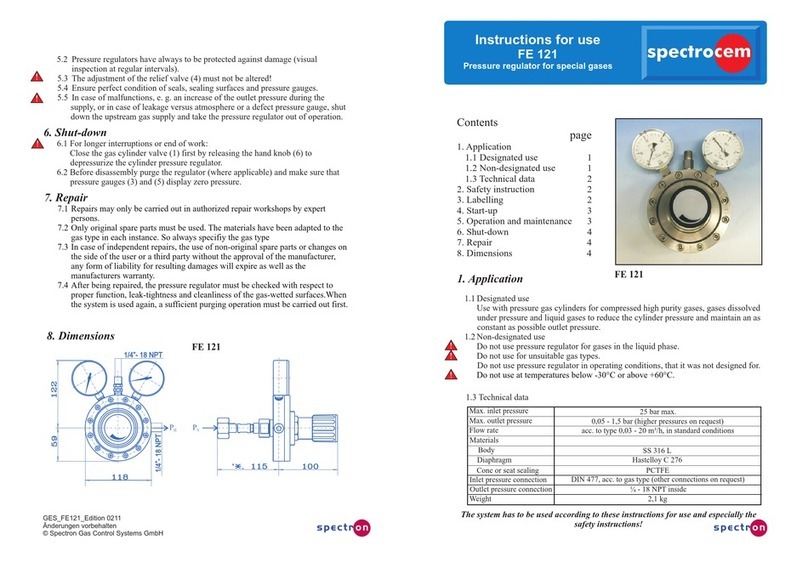

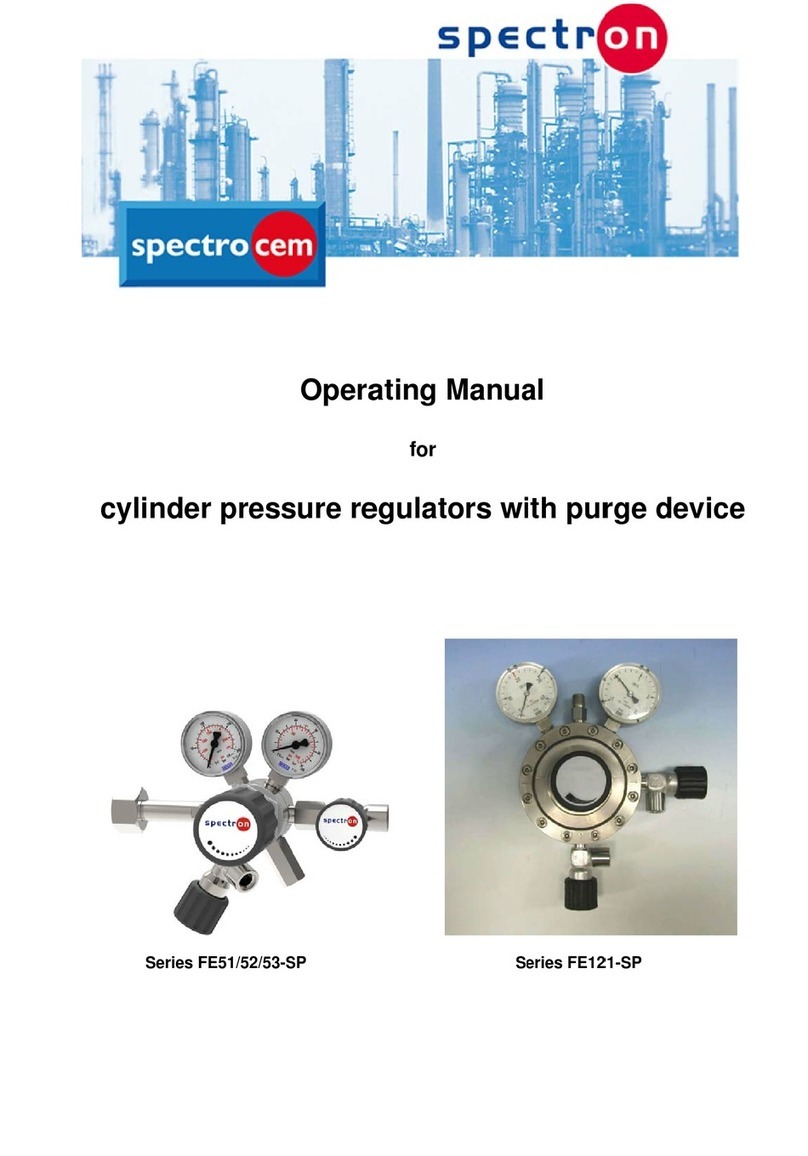

2 Description................................................................................................................................................... 5

2.1 Intended use ......................................................................................................................................... 5

2.2 Misuse .................................................................................................................................................. 5

2.3 Identification / label ............................................................................................................................... 5

2.4 Environment.......................................................................................................................................... 5

2.4.1 Temperatures............................................................................................................................. 5

2.4.2 Degree of cleanliness ................................................................................................................ 6

2.5 Standards and laws .............................................................................................................................. 6

3 Safety............................................................................................................................................................ 7

3.1 Basic information on the safety instructions ......................................................................................... 7

3.2 Safety instructions ................................................................................................................................ 8

3.3 Emergencies and safety devices .......................................................................................................... 10

3.3.1 Emergency stop (emergency shut-off)....................................................................................... 10

3.4 Qualification of the operating and maintenance personnel................................................................... 10

4 Design and function .................................................................................................................................... 12

4.1 Design................................................................................................................................................... 12

4.2 Functional description........................................................................................................................... 13

4.3 Technical data ...................................................................................................................................... 14

4.4 Boundaries and interfaces .................................................................................................................... 14

5 Installation.................................................................................................................................................... 15

5.1 General information .............................................................................................................................. 15

5.2 Electrical connection............................................................................................................................. 15

5.2.1 Digital inputs .............................................................................................................................. 16

5.2.2 Analogue inputs ......................................................................................................................... 17

5.2.3 Relay outputs ............................................................................................................................. 17

5.3 Pneumatic connection .......................................................................................................................... 18

6 Commissioning............................................................................................................................................ 20

6.1 Preparations for commissioning ........................................................................................................... 20

6.2 Procedure for commissioning ............................................................................................................... 20

7 Operation...................................................................................................................................................... 21

7.1 General information on operation ......................................................................................................... 21

7.2 Configuration ........................................................................................................................................ 21

7.2.1 Language options ...................................................................................................................... 23

7.2.2 User management ..................................................................................................................... 24

7.2.3 System configuration ................................................................................................................. 25

7.2.4 Real Time Clock......................................................................................................................... 27

7.2.5 Analogue inputs ......................................................................................................................... 28

7.2.6 Digital inputs .............................................................................................................................. 31

7.2.7 Label valves ............................................................................................................................... 33

7.2.8 Assignment of the analogue inputs............................................................................................ 33

7.2.9 Tare setting ................................................................................................................................ 34

7.3 Commissioning a valve......................................................................................................................... 35

7.4 Putting the valve in standby mode........................................................................................................ 36

7.5 Automatic switchover............................................................................................................................ 37