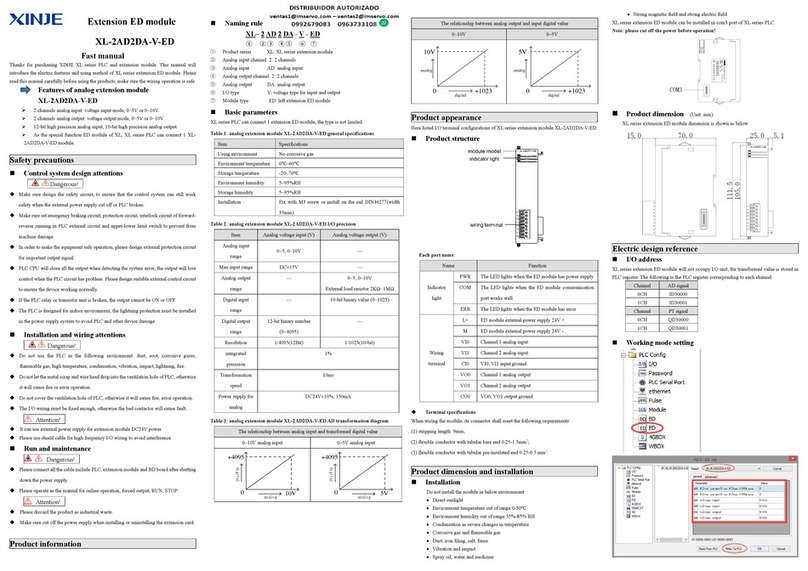

Catalog

Preface.....................................................................................................................................................7

1. Product overview ................................................................................................................................8

1. 1 Product features............................................................................................................................8

1.2 Model Composition and list..........................................................................................................8

1.2.2 Model list ...............................................................................................................................8

1.3 Description of each part ................................................................................................................9

1.3.1 XSA330-W series structure composition...............................................................................9

1.3.2 LED indicator light ................................................................................................................9

1.3.3 Shut down button .................................................................................................................10

1.3.4 Reset button..........................................................................................................................10

1.3.5 Power supply input...............................................................................................................10

1.3.6 DP interface.......................................................................................................................... 11

1.3.7 Ethernet interface (LAN) .....................................................................................................12

1.3.8 USB interface.......................................................................................................................13

1.3.9 Serial port.............................................................................................................................14

1.3.10 I/O terminals ......................................................................................................................15

1.3.11 Encoder ..............................................................................................................................15

2. Specification parameters...................................................................................................................16

2.1 General specification...................................................................................................................16

2.2 Performance ................................................................................................................................16

2.3 Dimension ...................................................................................................................................17

3. System composition ..........................................................................................................................18

3.1 system composition.....................................................................................................................18

3.2 Programming software................................................................................................................19

3.3 Unpacking inspection..................................................................................................................19

3.4 Packing list..................................................................................................................................20

3.5 Production installation ................................................................................................................20

3.6 Power supply...............................................................................................................................21