Contents Spectron Gas Control Systems GmbH

ii GES_EM75_0922

Contents

1 Introduction ................................................................................................................................................. 3

2 Description................................................................................................................................................... 4

2.1 Intended use ......................................................................................................................................... 4

2.2 Misuse................................................................................................................................................... 4

2.3 Identification / label ............................................................................................................................... 4

2.4 Environment .......................................................................................................................................... 5

2.4.1 Temperatures............................................................................................................................. 5

2.4.2 Degree of cleanliness ................................................................................................................ 5

2.4.3 Emissions................................................................................................................................... 5

2.5 Standards and laws............................................................................................................................... 5

3 Safety............................................................................................................................................................ 7

3.1 Basic information on the safety instructions.......................................................................................... 7

3.2 Safety instructions................................................................................................................................. 8

3.3 Emergencies and safety devices .......................................................................................................... 10

3.4 Qualification of the operating and maintenance personnel ................................................................... 10

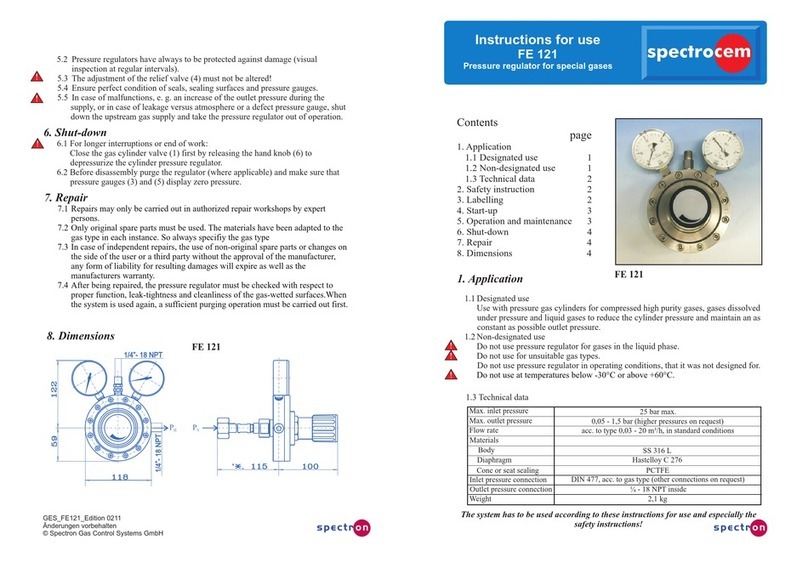

4 Design and function.................................................................................................................................... 11

4.1 Design ................................................................................................................................................... 11

4.2 Functional description ........................................................................................................................... 12

4.3 Technical data....................................................................................................................................... 12

4.4 Boundaries and interfaces .................................................................................................................... 12

5 Installation ................................................................................................................................................... 13

5.1 General information............................................................................................................................... 13

5.2 Installation work .................................................................................................................................... 13

5.2.1 Installation.................................................................................................................................. 13

5.2.2 Connecting the incoming and outgoing lines ............................................................................. 15

6 Commissioning ........................................................................................................................................... 16

6.1 Preparations for commissioning............................................................................................................ 16

6.2 Procedure for commissioning................................................................................................................ 16

7 Maintenance, cleaning and repairs............................................................................................................ 17

7.1 General information on maintenance .................................................................................................... 17

7.2 Regular maintenance work and cleaning .............................................................................................. 18

8 Repair ........................................................................................................................................................... 19

8.1 General information on repair work....................................................................................................... 19

8.2 Troubleshooting and fault rectification .................................................................................................. 20

9 Dismantling and disposal........................................................................................................................... 21

9.1 General information on dismantling ...................................................................................................... 21

9.2 Returns.................................................................................................................................................. 21

9.3 Disposal ................................................................................................................................................ 22