spectrotec TORNADO 2000 User manual

Contents

page

1 Application

1.1 Designates use 1

1.2 Non-designated use 1

1.3 Technical data 2

2. Safety instructions 2

3. Labelling 3

4. Start-up 3

5 Operation and maintenance 4

6 Shut-down 4

7 Repair 4

The system has to be used according to these instructions for use and especially

the safety instructions!

5. Operation and maintenance

5.1 Make shure that seals, sealing surfaces and pressure gauges are in good status.

5.2 Pressure regulators are always to be protect against damage (visual inspection in

regular intervals).

5.3 In case of malfunctions, e. g. an increase of the outlet pressure during the supply,

or in case of leakage versus atmosphere or a defective pressure gauge, shut down

the upstream gas supply and take the pressure regulator out of operation.

6. Shut-down

6. 1 For short-term interuption of work, it is sufficient to close the shut-off valve at

the consumer unit.

6. 2 For longer interuptions or to end the work, close shut-off valve (1) first. After the

pressure regulator has been depressurised, release the hand knob (4). Close shut-

off valve at the consumer unit.

6. 3 Before disassembling the pressure regulator, make sure that all pressure gauges

display zero.

!

!

1. Application

1.1 Designated use

Use the pressure regulator for tapping points TORNADO 2000 with an suitable

shut-off valve for gases dissolved under pressure, compressed or liquefied

gases. The pressure regulator TORNADO 2000 reduces an inlet pressure

1.2 Non-designated use

Do not use the pressure regulator for gases in the liquid phase.

to an

as constant as possible outlet pressure.

Do not use for unsuitable types of gas or corrosive gases.

Do not use at temperatures below -30°C or above +60°C.

!

!

!

7. Repair

7.1 Repairs may only be carried out by expert

persons.

7.2 Only original spare parts must be used. The materials have been adapted to the

gas type in each instance. So always specifiy the gas type.

7.3 In case of independent repairs, the use of non-original spare parts or changes on

the side of the user or a third party without the approval of the manufacturer, any

form of liability for resulting damages will expire as well as the manufacturers

warranty.

7.4 After being repaired, the pressure regulator must be checked with respect to

proper function, leak-tightness and cleanliness of the gas-wetted surfaces.When

the system is used again, a sufficient purging operation must be carried out first.

in authorized repair workshops

-4- -1-

Instructions for use

TORNADO 2000

Pressure regulator for tapping points

GES_ET2000-D Edition 0211

Subject to alteration without prior notice

© Spectron Gas Control Systems GmbH

tec

spectro

Tornado Class 1

P1: 40 bar P2: 10 bar

717. …

09.00

1 2 3

4 5 6

Gas Type: O

EN ISO 2503

7

1.3 Technical data

The pressure regulator TORNADO 2000 conforms to the latest standard DIN/EN/ISO 2503

For special versions, this standard is taken into account as appropriate.

For other gases, this flow rate is

multiplied by the following factors:

Nitrogen 1,05

Hydrogen 4,00

Argon 0,90

CO 0,85

2

Oxygen

Inlet pressure

3

Flow rate (Vn) [m /h]

at an outlet pressure (P) [bar]

1

40

20

10

5

(Pv) [bar] 2,5 4 10 20

15 30 40 50 60

15 15 15 -- --

10 10 10 -- --

15 20 25 30 --

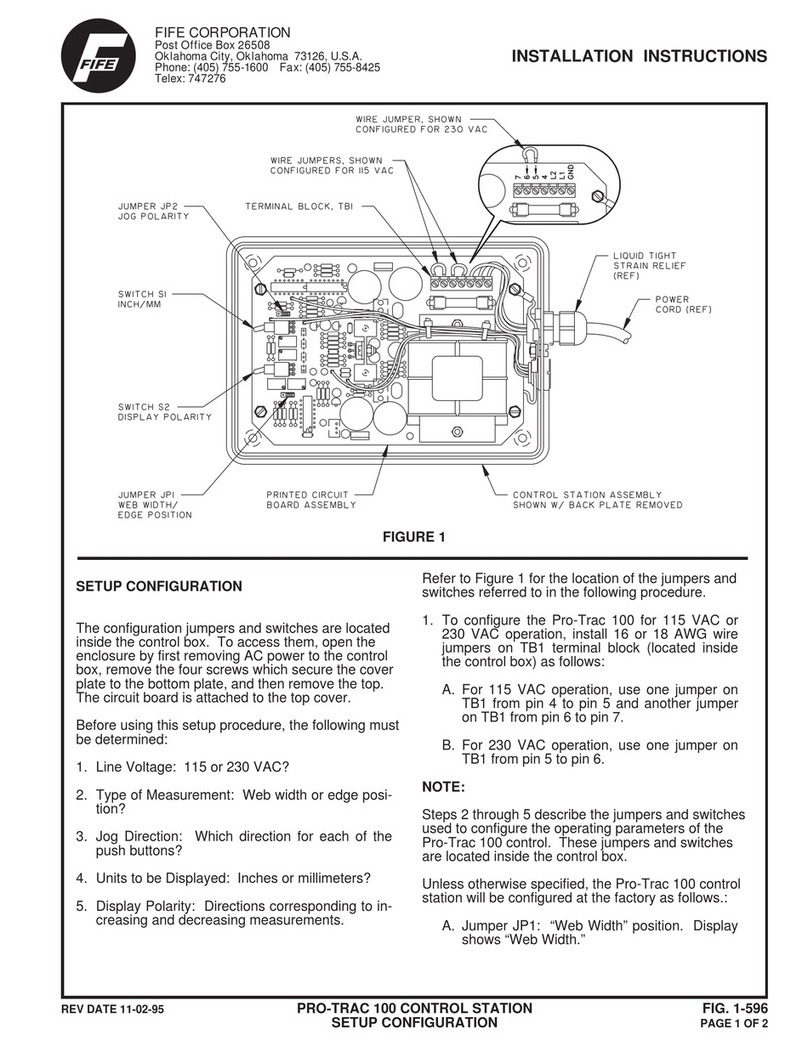

3. Labelling

1 Pressure regulator TORNADO 2000

2 Equipment class (s. list)

3 Article no

4 Max. inlet pressure

5 Max. outlet pressure

6 Gas type

7 Date of manufacture

Acetylene

Gas type Id. letter

Oxygen

Hydrogen

Compressed air

LPG

MPS

Natural gas

CO , Nitrogen, Noble gas

2

A

O

H

D

P

Y

M

N

1 Shut-off valve

2 Shut-off valve

connection

3 Pressure gauge

conform

to DIN/EN 562

4 Hand knob

5 Hose tail conform to

DIN/EN 560

4. Start-up

4.1 Before starting read the specifications of this instruction for use and observe it while

working.

4.2 Check, that the cylinder valve thread, the pressure regulator connector and the

connection seals are without any damage (blow through if nessesary).

Do not use the pressure regulator if damaged.

!

CO 2 0

1

6)

200 2

4

5)

2

5)

2

1) Cylinder pressure according to the max. cylinder filling pressure at 15°C.

3

2) General recommendations: Avoid flow rates above 1 m /h.

3) Steam pressure for MPS at 65°C. This value can change, depending on the components of the gas mixture.

4) Steam pressure for propane at 70°C.

5) Depending on the enviromental situations, a heating can be nessecary to reach the nominal flow rate when

using LPG and CO .

2

6) Pressure for CO at 70°C, at a filling level of 0,667

2

Flow rate

3

Q /(m /h)

1

Gas type Equipment

class

Max.Inlet pressure

-1

P / [bar] (10 MPa)

1

Max.Outlet pressure P / [bar]

2

-1

(10 MPa)

1,5

5

15

30

40

50

0.8

< 1.5

1

2)

5

MPS

Oxygen and

other sealed

gases up to

300 bar (30

Mpa)

Acetylen

LPG

1,5

4

1

5

5)

1

5)

5

0

1

0

1

2

3

4

5

1

2

0

1

0 up to 300

3)

25

25

4)

25

2

4

6

10

12.5

20

1,5

4

4.3 Connect the pressure regulator to the closed gas cylinder valve (1). Tighten it gas-tight

with a suitable spanner.

4.4 Release the positioning spring with hand knob (4); first close shut-off valve at the

consumer unit; open shut-off valve (1) slowly (High pressure gauge 3 indicate cylinder

pressure); adjust required outlet pressure with hand knob (4). Open slightly shut-off

valve at the consumer unit. Correct pressure setting in case of a decrease of pressure.

1 3 4

2 5

2. Safety instructions

Do not connect the pressure regulators for tapping points to a gas cylinder.

2.1 All items of informations marked with are valid as special safety instructions.

2.2 These pressure regulators adhere to state-of-the-art technology and

to the demands of the exsiting standards and regulations.

2.3 Changes or modifications are not allowed to be made to the pressure regulator

without the prior consent of the manufacturer.

2.4 The equipment must be operated by suitable trained personnel only.

2.5 The result of improper handling and improper use as intended can involve risks

for the user and other persons as well as damage to the device.

2.6 Regulations to be adhered to:

- BGV A1 (VBG 1), “General Specifications”

- BGV D1 (VBG 15), “Welding, Cutting and Related Procedures “

- BGV B7 (VBG 62), “Oxygene”

Special attention has to be paid to the country specific laws, regulations and

procedures concerning the use of this type of equipment.

2.7 Use only for gas types the pressure regulator is labelled for (see item 3).

2.8 Do not use at temperatures below -30°C or above +60°C.

2.9 The valve has always to be opened slowly!

2.10 All parts coming into contact with oxygen must be kept in oil-free and grease-

free condition.

Fire or explosion hazard!

2.11 Smoking or open fire (e.g. candles) in the vicinity of the gas supply system is

strictly prohibited.

Fire and explosion hazard!

2.12

2.13 Protect gas cylinder against falling.

!

!

!

!

!

!

!

-2- -3-