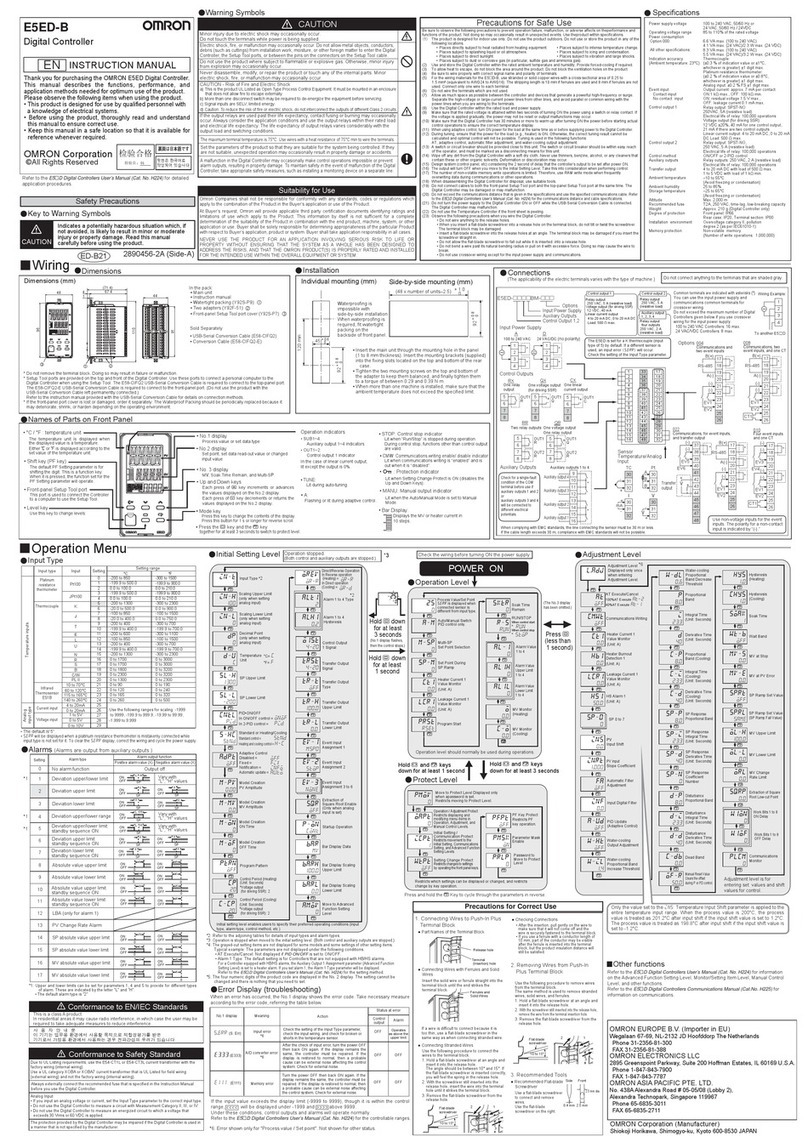

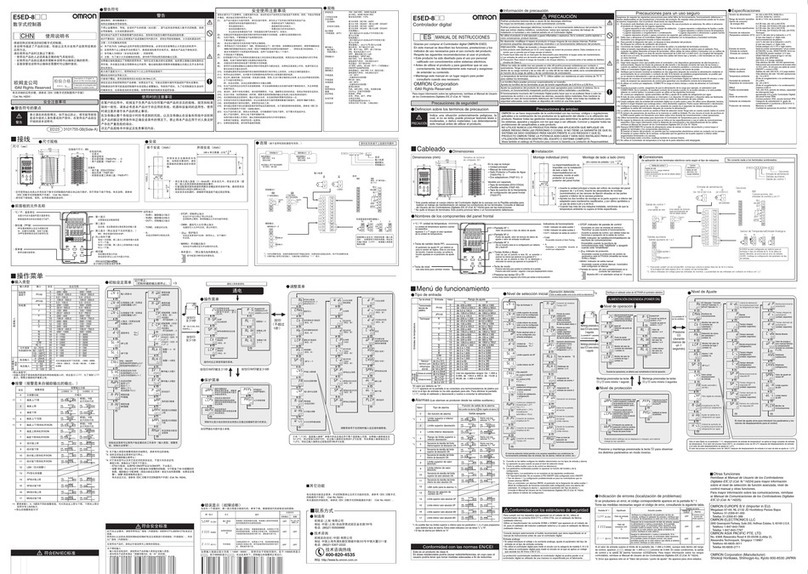

PRECAUTIONS ON SAFETY

PRECAUTIONS FOR SAFE USE

PRECAUTIONS FOR CORRECT USE

INSTRUCTION SHEET

Thank you for selecting OMRON product. This sheet primarily

describes precautions required in installing and operating the product.

Before operating the product, read the sheet thoroughly to acquire

sufficient knowledge of the product. For your convenience, keep the

sheet at your disposal.

© OMRON Corporation All Rights Reserved.

Model

ZW-7000□

2016

Controller for Fiber Coaxial Displacement Sensor

■Parts Names and Functions <Back>

No.

31

Name

DIN track mounting hook

Function

Used when securing the Controller to the DIN track.

<Bottom>

No.

32

Name

Mounting screw hole

Function

Used to secure the Controller with screws

■

Specifications

●

Meanings of Signal Words

●

Alert Statements in This Sheet

Do not use it exceeding the rated voltage.

There is a possibility of failure and �fire.

Do not connect amplifier units to AC power supply.

Risk of explosion.

Looking into the LED light continuously may cause visual

impairment.

Do not look directly into the LED light.

Indicates a potentially hazardous situation which, if

not avoided, will result in minor or moderate injury, or

may result in serious injury or death. Additionally,

there may be significant property damage.

WARNING

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury or

in property damage.

CAUTION

This product is not designed or rated for ensuring safety of

persons either directly or indirectly. Do not use it for such

purposes.

Do not disassemble the product. Doing so may cause electric shock due

to the high voltage portion. Burn also may result due to high

temperature.

Do not attempt to disassemble, deform by pressure, incinerate, repair,

or modify this product.

WARNING

CAUTION

Please observe the following precautions for safe use of the products.

1.Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/explosive gas.

•

To secure the safety of operation and maintenance, do not install the product close to high-voltage devices and power devices.

• Ensure clearances 30 mm or more wide and 10 mm or more wide on the top and both sides of the sensor controller main

unit for intaking and exhausting air, respectively.

• Hang the upper side of the groove on the back of the sensor controller on the DIN rail. After installing the sensor

controller, be sure to confirm that the controller is fixed surely.

• When fixing the sensor controller with mounting screws, tighten the screws to the specified torque (1.2 Nm) described in

this Instruction Sheet.

• Avoid installing in the place with the vibrations as much as possible.

• Do not install the product near any devices that generate noise. If there is no choice but to install the product in a noisy

environment, make sure to take noise prevention measures.

2.Power Supply and Wiring

• Be careful when using a power supply with the overcurrent detection function. This sensor uses a DC-DC converter for

the power supply circuit. The protection circuit may be activated due to surge current when using a power supply with the

overcurrent detection function.

Recommended power supply: S8VS-06024 (OMRON: 24 VDC 2.5 A 60 W)

• Do not apply voltages or AC power supplies that exceed the rated voltage (24 VDC±10%).

• Do not reverse the polarity of the power connection.

• Unstable voltage may cause unexpected operation of the sensor controller. If such condition is anticipated, use an UPS

(Uninterruptible Power Supply).

Recommended UPS: S8BA Series (OMRON)

• Open-collector outputs should not be short-circuited.

• Use a load that is equal to or less than the rating.

• High-Voltage lines and power lines must be wired separately from this product. Wiring them together or placing them in

the same duct may cause induction, resulting in malfunction or damage.

• Take sufficient safety measures such as fail-safe circuit to use the product.

• Use a wire of the specified size for wiring. Do not connect the wire other than the specified size to the terminal block.

• Fix the terminal block tightly to protect from accidental injury by pushing the release button on the attached terminal

block with a screwdriver.

• Supply power from a DC power supply for which measures have been applied to prevent high voltages (e.g., a safety

extra low voltage circuit).

• The length of the power supply cable should be as short as possible.

• For the frame ground terminals, the terminal screw and crimp terminal of the specified size must be used. Do not directly

connect the merely twisted wires to the frame ground terminals.

Terminal screw: M4

• Perform class D grounding (the ground resistance of 100 ohm or less). Set the grounding point as close as possible and the

length of the grounding wire as short as possible.

• Do not share the grounding wire with other device or do not connect the grounding wire to the beam of a building.

Otherwise an adverse effect may occur.

• Do not connect this product with the same power supply as applied to an apparatus which might cause noises.

• Tighten the mounting screw to the torque specified in this instruction sheet.

• Always turn off the power of the main unit before taking the following actions. Not doing so may result in malfunction.

• Connecting or wiring the cable

• Mounting or removing the connector

• Mounting or removing the Calibration ROM

•

Before turning on the power after the wiring is completed, verify that the power is correct, that there are no incorrect

connections such as a shorted load circuit, and that the load current is suitable. Incorrect wiring may cause damage and failures.

• When inserting or removing the EtherCAT cable, be careful not to stress the calibration ROM

• Handling of the fiber cable

Using the product without observing the following might damage the fiber cable.

• Use the fiber cable with a bend radius of 20 mm or more

• Avoid the root of the fiber connector from being stressed by the bend.

• Do not pull the fiber cable strongly.

• Do not step on the fiber cable or put anything heavy on it.

• Avoid applying torsional stress on the fiber cable.

3.Others

• Do not look into the light injection port directly.

• Do not use in safety circuits for atomic energy or that are critical for human life.

• Do not attempt to disassemble, deform by pressure, incinerate, repair, or modify this product.

• When disposing of the product, treat as industrial waste.

• Connect a dedicated device (Sensor Head, Calibration ROM, fiber cable or RS-232C cable). Use of other devices may

result in fire, explosion, malfunction or failure.

• Do not cut off the fiber cable. Otherwise, you might be injured by the glass of the cut portion. In addition, the controller

does not operate normally if the cable is cut off.

• If you notice an abnormal condition such as a strange odor, extreme heating of the unit, or smoke, immediately stop using

the product, turn off the power, and consult your dealer.

• Do not drop or impose shock on the product.

• Ensure that all components which have locking mechanisms are locked before using the product.

4.Regulations and standards

This sensor complies with EMC directive and EN standards as follows:

• EN61326-1

• Electromagnetic environment : Industrial electromagnetic environment (EN/IEC 61326-1 Table 2)

• The following condition is applied to the immunity test of this product:

While receiving electromagnetic interference, the voltage/current output might vary within ±3% of full scale.

• EMC Directive

No.2014/30/EU

Observe the following to prevent failure, malfunctioning, and adverse effects on performance and the device.

1.Installation site

Do not install in the following locations:

• Locations where the ambient temperature exceeds the rated temperature range.

• Locations subject to sudden temperature changes (where condensation will form).

• Locations where the relative humidity is below or above 35 to 85% RH.

• Locations where there are corrosive or flammable gases.

• Locations where there is dust, salt, or iron powder.

• Locations where the device will be subject to direct vibration or shock.

•

Locations where there is strong scattered light (laser light, arc welding light, ultraviolet light, etc.)

• Locations exposed to direct sunlight or next to a heater.

• Locations where there is splashing or spraying of water, oil, or chemicals.

• Locations where there is a strong electrical or magnetic field.

2.Power and cable connections

• When using a commercially available switching regulator, make sure that the Frame ground terminal is grounded.

• Wire without placing load on the cables/connectors.

• If there are surges on your power line, connect a surge absorber as appropriate for your conditions of use.

• Use the product with the specified voltage. Applying a voltage or AC voltage that exceed the rating may result in burning

or explosion of circuit components.

• To extend the fiber cable between the Sensor Head and Controller, an optional extension fiber cable (ZW-XF70□□R)

must be used. Only one extension fiber cable can be connected.

• Use the Sensor Head and Calibration ROM of the same serial number. Operation will fail if those with different serial

numbers are used.

• Use the dedicated Setup Software. Using the other software may result in malfunction of the product.

• Do not turn off the power supply while saving data into the Controller built-in memory. Doing so may damage the data.

• When the fiber cable is not connected, attach the provided protective caps to the fiber cable connector. Leaving the

product without the protective caps may result in malfunction caused by adhesion of a foreign material.

3.

Warming Up

After turning on the power supply, allow the Controller to stand for at least 30 minutes before use. The internal temperature

of the controller are unstable immediately after the power supply is turned on and attempting measurement may result in

inconsistent measurement values.

4.Maintenance

•

Do not use thinner, benzene, acetone or kerosene to clean the Sensor Head, fiber cable or Controller. If considerable foreign

matter or dust collects on the Sensor Head or receiver/emitter of the Controller, use a blower brush (for camera lenses) to blow

off the foreign matter. Avoid blowing it off with your breath. For a small amount of foreign matter or dust, gently wipe with a

soft cloth. Do not wipe hard. If the receiver/emitter is damaged, malfunction or measurement error may result.

•

Do not touch the end face of the fiber cable of the sensor head. Otherwise, performance deterioration might occur. If the end

face touches anything or becomes unclean, wipe off the dirt with option product ZW-XCL, the commercially available

dedicated fiber cleaner, or a dry soft cloth. Do not use cloth soaked in alcohol. Otherwise, dirt might adhere again.

•

To clean the fiber connector of the controller, use option product ZW-XCL or the commercially available dedicated fiber

cleaner.

•

If inserting/extracting the sensor head frequently, use of the repeatedly usable commercially available dedicated fiber cleaner is

recommended. For the recommended fiber cleaner, refer to the operation manual of the sensor head (ZW-S70□□).

• Clean the vent hole periodically so as not to be clogged with dust or particulate. If the vent hole is clogged, heat is not

dissipated from inside, leading a failure.

5.Sensing Object For Sensor Head

Depending on the material/shape of the object, the object cannot be measured or can be measured but accuracy is poor:

Transparent objects, objects with a low reflective sensor ratio, objects smaller than the spot diameter, objects with a large

curvature, excessively inclined objects, objects with thin film on the surface, etc.

6.Effects of surrounding lightings

Avoid installing the product at a location where the emitter/receiver of the Sensor Head is exposed to strong lighting. If the

objects

has reflective surface, malfunction of the product may occur due to light reflection. Prevent it by covering the

lighting.

7. Influence of air current

Measured values may vary due to slow air current around the Sensor Head. In such case, put a cover around the Sensor

Head.

8.Operation beyond the measurement range

As this sensor is sensitive, malfunction may occur beyond the measurement range (near side). In such case, shortening the

exposure time may solve the problem.

9.Service life of writing to sensor controller built-in EEPROM

When the zero resetting memory is preset ON, data are written in the EEPROM (non-volatile memory) in the sensor

controller every time the memory is reset to zero. The life of this EEPROM as a writable memory is approximately one

million times. So, if using the memory with setting it ON, be careful with the life of the writable memory.

The following notice applies only to products that carry the CE mark:

Notice:

This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take adequate

measures to reduce interference.

Manufacturer:

OMRON Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto. 600-8530 JAPAN

TRACEABILITY INFORMATION:

Importer in EU:

OMRON Europe B.V.

Wegalaan 67-69,

NL-2132 JD Hoofddorp

The Netherlands

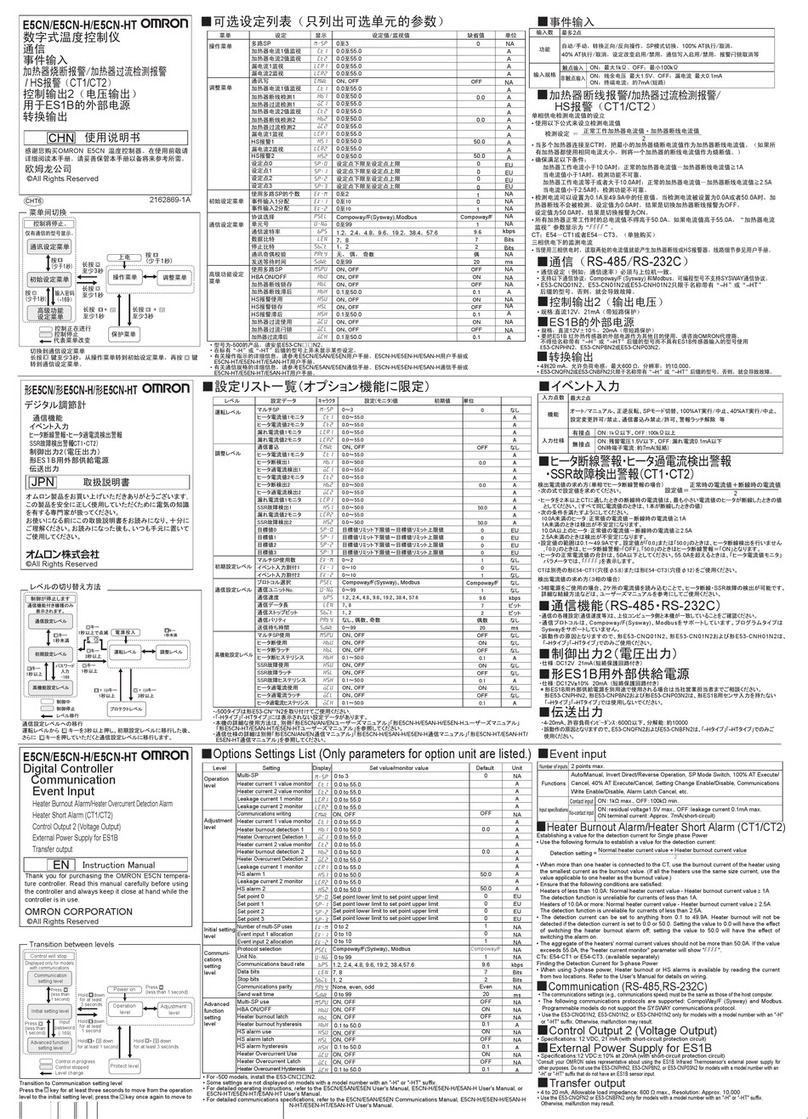

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Name(color)

HIGHindicator(Orange)

PASSindicator(Green)

LOWindicator(Orange)

STABILITYindicator(Green)

ZEROindicator(Green)

ENABLEindicator(Green)

Maindigitalindicator(White)

Subdigitalindicator(Green)

RUNindicator(Green)

THRESHOLD-Lindicator(Orange)

THRESHOLD-Hindicator(Orange)

ECATRUNindicator(Green)

L/AINindicator(Green)

L/AOUTindicator(Green)

ECATERRORindicator(Red)

Function

LightswhenthejudgmentresultisHIGH(HIGHthreshold<measuredvalue).

LightswhenthejudgmentresultisPASS

(LOWthreshold≤measuredvalue≤HIGHthreshold).

LightswhenthejudgmentresultisLOW(measuredvalue<LOWthreshold).

Lightswhenthefirstsurfaceiswithinthemeasuringrange.

TurnsOFFwhenthemeasuredvalueisoutsidethemeasuringrange.

Lightswhenzeroresetsettingismade.

Lightswhenmeasurementisenabled.Turnsoffwhenmeasurementisdisabled(e.g.whenthe

receivedlightamountisexcessiveorinsufficient,whentheCalibrationROMisnotconnected,

orwhenFUNCmodeisnotactiveformeasurement).

Showsameasurementvalueorfunctionname.

Showsthesupplementalinformationofthemeasurementvalueorsetvalueofthefunction.

LightsatRUNmodeandturnsoffatFUNCmode.

LightswhenaLOWthresholdisshownonthesubdigital.

LightswhenaHIGHthresholdisshownonthesubdigital.

LightswhenEtherCATcommunicationsisavailable.

LightswhenconnectedtotheEtherCATdevice,andblinksduringcommunications(datainputs).

LightswhenconnectedtotheEtherCATdevice,andblinksduringcommunications(dataoutputs).

LightswhentheEtherCATcommunicationserroroccurs.

●Connector/terminal

No.

21

22

23

24

25

26

27

28

29

30

Name

RS-232Cconnector

Ethernetconnector

EtherCATconnector(IN)

EtherCATconnector(OUT)

24Vinputterminalblock

32-poleexpansion

connector

Analogoutputterminalblock

Fiberadapter

ROMconnector

Framegroundterminal

Function

UsedwhenconnectingaPLCorPCviaRS-232Cport.

BesuretouseadedicatedRS-232Ccable.

Otherwisemalfunctionorfailuremayresult.

•ForPLC/programmableterminal:ZW-XPT2

•ForPC:ZW-XRS2

UsedtoconnectaPLCorPCviaEthernet.

BesuretouseacommercialEthernetcablethatsatisfiesthefollowingconditions:

•Category5eorhigher,length30morshorter

•RJ45connector(8-pinmodularjack)

•1:1connection:Selectacrosscable.

•ConnectionvianetworkHUB:Selectastraightcable.

UsedwhenconnectingtotheEtherCATcompatibledevice.

UsearecommendedEtherCATcable.

UsedwhenconnectingtotheEtherCATcompatibledevice.

UsearecommendedEtherCATcable.

Connectsthe24VDCpowersupplyofthecontroller.

ConnectsparallelI/O(judgmentoutput,ALARMoutput,BUSYoutput,

ENABLEoutput,bankNo.output,SYNCFLG/TRIGBUSYoutput,

STABILITYoutput,LOGSTAToutput,LOGERRoutput,TASKSTAToutput,

ZEROinput,RESETinput,TIMINGinput,LIGHTOFFinput,LOGGINGinput,

bankNo.selectinput,SYNC/TRIGinput) Ensurethatthecableis2morlesslong

Connectsananalogvoltageoutputandanalogcurrentoutput.

Connectsafiberconnector.

ConnectstheCalibrationROM.

Aterminalforframegrounding.Connectsagroundingwire.

●Operating section

No.

16

17

18

19

20

Name

ZERORST/ESCkey

←(LEFT)key

→(RIGHT)key

↑(UP)key

↓(DOWN)key

ZERO/SETkey

Modeswitchkey

Nodeaddresssettingswitch

(inhexadecimal)

Function

Functionsdifferdependingonoperatingmode.

UsedforstationaddresssettingsasanEtherCATcommunicationsdevice.

Thesettingrangeis0x01(1)to0xFF(255).

<Front>

●Display section

Main digital indicator

Sub digital indicator

Status indicator

EtherCAT display

Ethernet

EtherCAT

RS-232C

Analog output

terminal block

32-pole

expansion

connector

Exposure time

Measurement cycle *1

Specified materials

Measurement items

Filter processing

Outputs

Display

Total number of registrations

Task processing

System

Powersupplyvoltage

Currentconsumption

Insulationresistance

Dielecticstrength

Degreeofprotection

Vibrationresistance(destruction)

Shockresistance(destruction)

Ambienttemperaturerange

Ambienthumidityrange

Item

Input/output type

Total number of Sensor Heads connected

Operating Sensor Head

Light source for measurement

Safety of LED

Segment

display

LED

display

External

interface

Main

functions

Ratings

Environmental

immunity

Grounding

Material

Weight

Accessories

Bank output during

selection

(BANK_OUT1 to 3)

Bank selection

input

(BANK_SEL1 to 3)

Specifications

ZW-7000□

NPN/PNP

1

ZW-S70□□

White LED

Risk Group 3 (IEC 62471)

11-segment white display, 6 digits

11-segment green display, 6 digits

HIGH (Orange), PASS (Green), LOW (Orange), STABILITY (Green),

ZERO (Green), ENABLE (Green), THRESHOLD-H (Orange),

THRESHOLD-L (Orange), RUN (Green)

ECAT RUN (Green), L/A IN (Link/Activity IN) (Green)

L/A OUT (Link/Activity OUT) (Green), ECAT ERR (Red)

100BASE-TX\10BASE-T non-procedural(TCP/UDP), EtherNet/IP

EtherCAT-specific protocol 100BASE-TX

115,200 bps max.

-10 V to +10 V, output impedance: 100 Ω

4 mA to 20 mA, maximum load resistance: 300Ω

Transistor output method

Output voltage: 21.6 to 30 VDC

Load current: 50 mA max.

ON residual voltage: 2 V max.

OFF leakage current: 0.1 mA max.

DC input method

Input voltage: 24 VDC±10% (21.6 to 26.4 VDC)

Input current: 7 mA Typ. (24 VDC)

ON voltage/ON current: 19 V/3 mA min.

OFF voltage/OFF current: 5 V/1 mA max.

Transistor output method

Output voltage: 21.6 to 30 VDC

Load current: 50 mA max.

ON residual voltage: 2 V max.

OFF leakage current: 0.1 mA max.

DC input method

Input voltage: 24 VDC±10% (21.6 to 26.4 VDC)

Input current: 7 mA Typ. (24 VDC)

ON voltage/ON current: 19 V/3 mA min.

OFF voltage/OFF current: 5 V/1 mA max.

Auto/fixed

20

μ

s to 400

μ

s

Standard/mirror surface/rough surface

Height/thickness/operation

Median/average/differentiation/high-pass/low-pass/band-pass

Scaling/holds/zero reset/measurement value logging

Measurement value/threshold/analog output voltage value

or current value/judgment result/resolution/exposure time

Internal logging state/incident light peak level

Up to 8 banks

Multitasks (up to 4 tasks per bank)

Saving/initialization/measurement information display/ communication

setting/Sensor Head calibration/key lock/zero reset memory/timing input

21.6 V to 26.4 VDC (including ripple)

800 mA max.

Between all lead wires and FG terminal: 20 M

Ω

(250 VDC)

Between all lead wires and FG terminal: 500 VAC, 50/60 Hz, 1 min.

IP20 (IEC60529)

10 to 55 Hz, 0.35-mm half amplitude 50 min each in X, Y, and Z directions

150m/s

2

3 times each in six directions (up/down, left/right, forward/backward)

Operating: 0 to 40

°C

, Storage: -15 to +60

°C

(with no icing or condensation)

Operating and storage: 35% to 85RH% (with no condensation)

Class D grounding (grounding resistance 100 Ωmax.) * Conventional class 3 grounding

Case: PC

Approx. 900 g (main unit only),Approx. 150 g (parallel cable)

Parallel cable(ZW-XCP2E),10bottlesoffibercleaner(ZW-XCL),

Instruction Sheet(This Instruction Sheet),Membership Registration Sheet

The Export Trade Control Order compatible Controller (ZW-7000T) is available.

When using this Controller, the minimum resolution is 0.25 μm regardless of the connected Sensor Head and setting conditions.

*1 If an extension fiber cable 5 m long or more is connected, the setup range of measurement cycle (exposure time) must be

changed. For details, refer to "Setting Measurement Cycle" in the user's manual.

Item

Communications standards

Physical layer

Connector

Communication medium

Communication distance

Process data

Mail box (CoE)

Distributed clock

LED display

Specifications

IEC 61158 Type12

100BASE-TX (IEEE802.3)

RJ45×2 EtherCAT IN: EtherCAT input EtherCAT OUT: EtherCAT output

Category 5 or higher twisted pair cable

(Aluminum tape and woven double shielded straight cable is recommended.)

Distance between nodes: within 100m

Variable PDO mapping

Emergency message, SDO request, SDO response, SDO information

Synchronization in DC mode

L/A IN (Link/Activity IN)×1 L/A OUT(Link/Activity OUT)×1

ECAT RUN×1 ECAT ERR×1

●EtherCAT communications specifications

Analog voltage output (OUTV)

Analog current output (OUTA)

Judgment outputs

(HIGH/PASS/LOW)

Busy output (BUSY)

Alarm output (ALARM)

Enabling output (ENABLE)

Sync flag output(SYNFLG)

Trigger busy output(TRIGBUSY)

Logging state output (LOGSTAT)

Logging error output (LOGERR)

Stability output (STABILITY)

Task state output(TASKSTAT)

LIGHT OFF input

(LIGHT OFF)

Zero reset input (ZERO)

Timing input (TIMING)

Reset input (RESET)

Sync input (SYNC)

Trigger input (TRIG)

Logging input (LOGGING)

Bank

<Front> <Back>

<Bottom>

32

1

2

3

4

5

69

10

11

17

19

12

22

23

24

28

21

20

16

18

26

27

29

13

14

15

30

31

8

7

25

9532207-1C

8.5mmmax.

8.5mmmax.

Crimp terminal