WE WILL MAKE IT RIGHT FOR YOU!

We guarantee all Spectrum products to be free of all defects in materials and workmanship, for the original owner, for a period of ten years.

Any item deemed defective by Spectrum or the original manufacturer, under normal use conditions, will be repaired or replaced at

Spectrum’s discretion. This warranty applies to all products manufactured and distributed by Spectrum except the products listed below.

DESIGNED FOR INDOOR USE ONLY - Spectrum’s products have been designed and constructed for indoor use only. Moving or using

outdoors, or on excessively rough surfaces, may cause damage to the products and may void the warranty. If an outdoor application is

desired please contact us to discuss potential custom design solutions.

Spectrum is committed to provide complete customer satisfaction. Each of our products are manufactured from the best materials available

and each product is stringently monitored throughout the production process through our P.A.C.E. program (Product Assurance to meet

Customer Expectations).

Our Customer Service Help Line 1-800-235-1262 is ready to provide immediate attention to any questions, comments or concerns. Weare

available to answer your calls Monday through Friday from 7 am to 5 pm CST. In addition your product comments or concerns are welcome

via e-mail at: spectrum@spectrumfurniture.com.

Items that have a varying warranty include, but are not limited to, the following:

• Adjustable Crank/Electric Desk Legs (1 yr)

• Flat Panel Desk Gas Cylinders (1 yr)

• Adjustable Height Chair Parts – including frames, gas cylinders, wood and plastic parts, and control handles (7 yrs)

• Adjustable Height Chair Parts Casters (2 yrs)

• Adjustable Height Chair Upholstery - In-Stock Upholstery (2 yrs)

• Adjustable Height Chair Upholstery - Graded-In Fabrics and C.O.M (no warranty)

• Height Adjustable Columns and Lifts (1 yr)

• General Use Casters (1 yr)

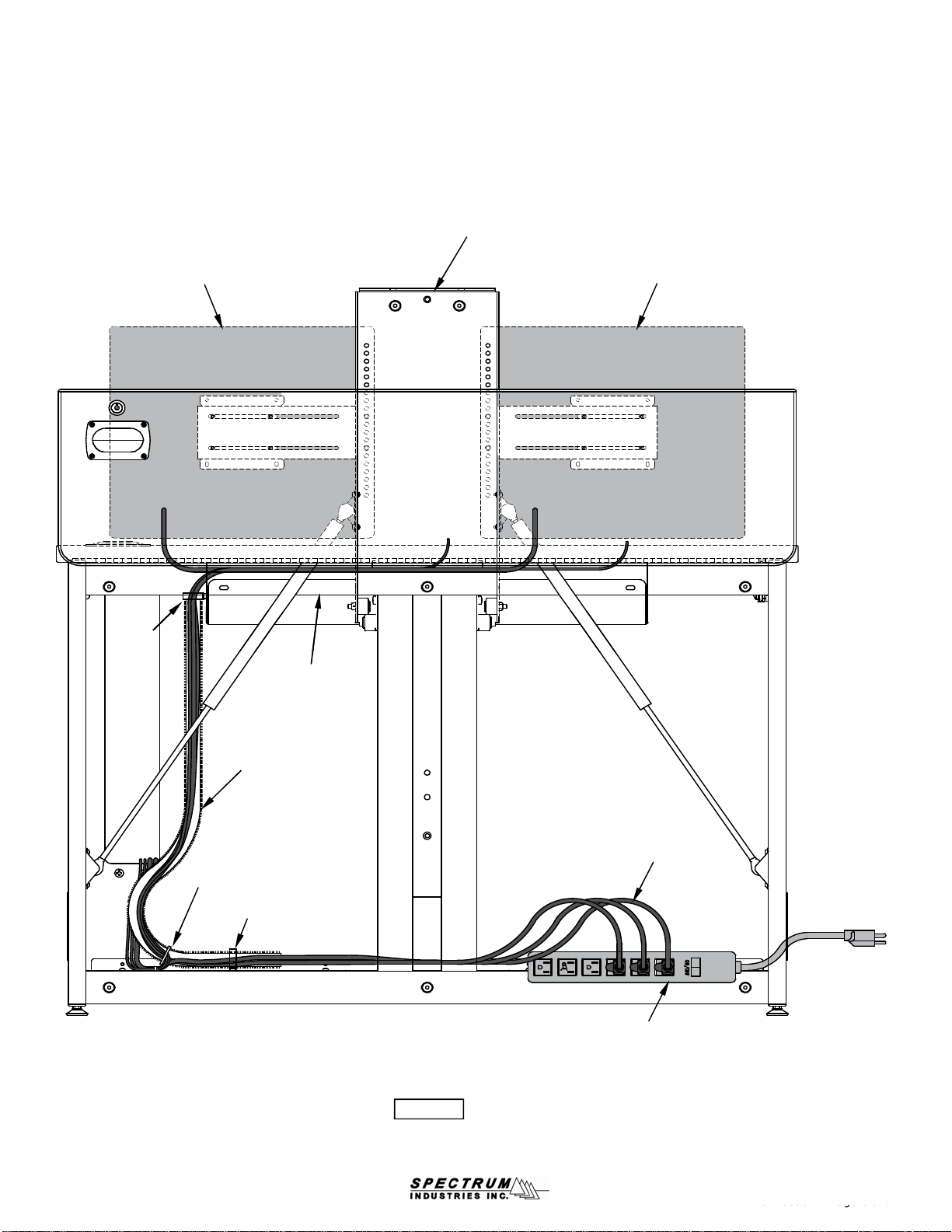

• Electrical – ECA (1 yr)

• Electrical - Power Strips (1 yr)

• Electrical Surge Suppressors (lifetime)

• Electrical - Retractable Power Cords (1 yr)

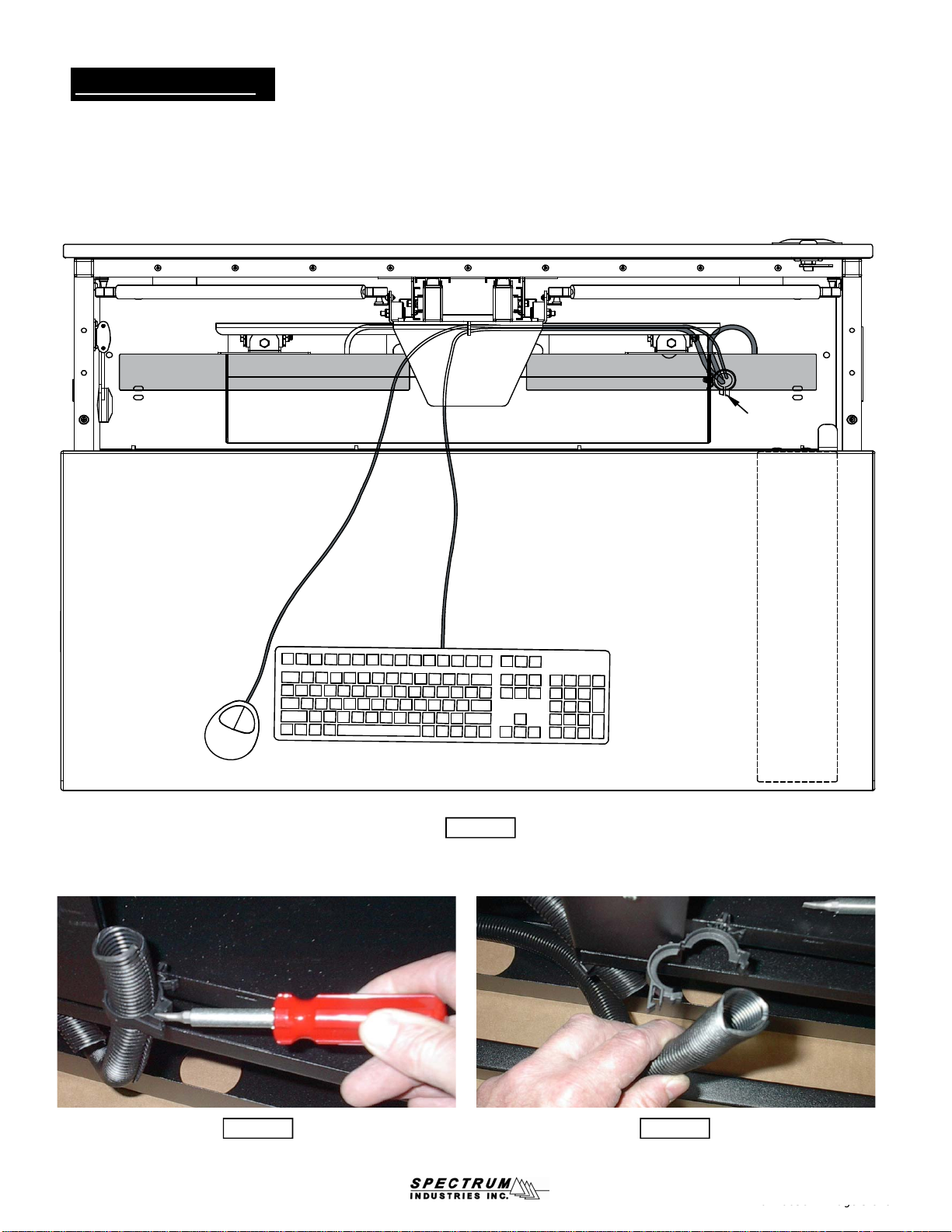

• Keyboard/Mouse Trays (1 yr)

• Flat Panel Monitor Arm – General Parts (5 yrs)

Warranty

0110658R1 Pa

e 9 of 9

•

a

ane

on

or

rm

as

y

n

ers

yrs

• CRT Monitor Arm (1 yr)

The warranty, as stated above, is effective as of 05/28/2009