4

Thank you for purchasing a WaterScout SMEC 300 Soil Mois-

ture Sensor. The moisture and nutrient status of your soil or

container substrate are key pieces of information. They allow

you to tailor your irrigation and fertilization program to suit

your crop's needs. They also help identify if it is necessary to

leach salts from the profile. The SMEC 300 combines afforda-

bility and accuracy into a sensor that is easy to install.

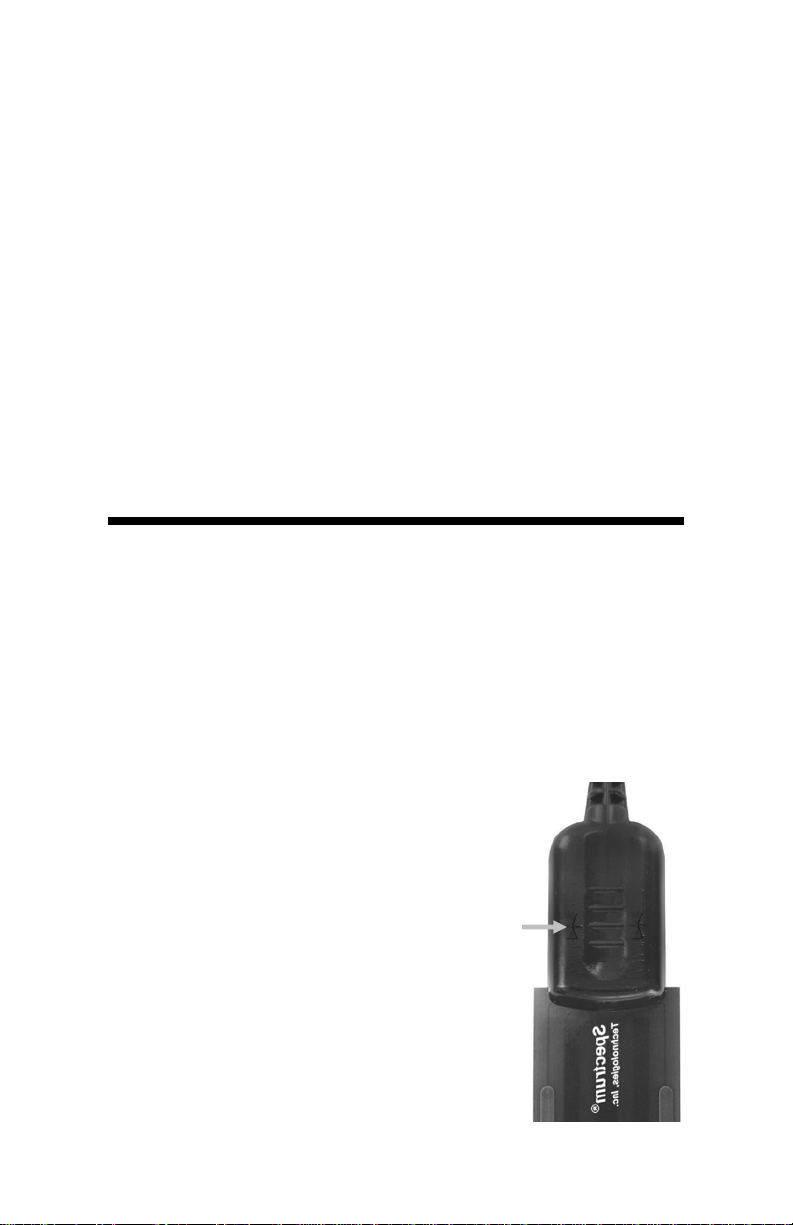

The soil moisture sensor consists of two electrodes that func-

tion as a capacitor, with the surrounding soil serving as the di-

electric. An 80 MHz oscillator drives the capacitor and a signal

proportional to the soil’s dielectric permittivity is converted to

the output signal. The dielectric permittivity of water is much

greater than air, soil minerals and organic matter. So, changes

in water content can be detected by the sensor circuitry and cor-

related to the soil’s moisture content.

The salinity of the soil solution, irrigation water or fertilizer

solution is an important parameter affecting the root zone envi-

ronment. Any of these factors can have a significant effect on

plant growth and physiology. The easiest way to monitor salin-

ity is by measuring the electrical conductivity (EC). EC is

strongly correlated to the salinity of the soil solution. EC meas-

urement is also affected by temperature and, to a lesser degree,

by soil moisture content. The SMEC 300 measures EC with a

pair of carbon ink electrodes which provide a large contact sur-

face with the soil solution. Temperature is measured with a

thermistor potted in the sensor molding.

The SMEC 300 is designed to be compatible with the Watch-

Dog®data loggers and weather stations as well as the Field

Scout®soil sensor reader. SpecWareTM software enables you to

view your data in graphical and tabular form as well as run re-

ports customized to your application.

General Overview