Speedaire Cast Iron Series User manual

E

N

G

L

I

S

H

E

S

P

A

Ñ

O

L

F

R

A

N

Ç

A

I

S

Operating Instructions Cast Iron Series

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Form 5S6024

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates an

imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates a

potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

NOTE:Information that requires special

attention.

Breathable Air Warning

This compressor/pump is NOT

equipped and should NOT be

used “as is” to supply breathing

quality air. For any application of

air for human consumption, you

must fit the air compressor/pump

with suitable in-line safety and

alarm equipment. This additional

equipment is necessary to properly

filter and purify the air to meet

minimal specifications for Grade

D breathing as described in

Compressed Gas Association

Commodity Specification G 7.1

- 1966, OSHA 29 CFR 1910. 134,

and/or Canadian Standards

Associations (CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR

IS USED FOR THE PURPOSE OF

BREATHING AIR APPLICATION

AND PROPER IN-LINE SAFETY

AND ALARM EQUIPMENT IS

NOT SIMULTANEOUSLY USED,

EXISTING WARRANTIES ARE VOID,

AND DAYTON ELECTRIC MFG.

CO. DISCLAIMS ANY LIABILITY

WHATSOEVER FOR ANY LOSS,

PERSONAL INJURY OR DAMAGE.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make sure

to tighten fittings, bolts, etc., before

putting unit into service.

Do not operate tool

if damaged during

shipping, handling or use. Damage

could result in bursting and cause

injury or property damage.

General Safety Information

CALIFORNIA PROPOSITION 65

This product or its

power cord may

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

You can

create

dust when you cut, sand, drill

or grind materials such as

wood, paint, metal, concrete,

cement, or other masonry. This dust

often contains chemicals known to

cause cancer, birth defects, or other

reproductive harm. Wear protective

gear.

IN613800AV 6/08

Printed in U.S.A.

02433

0608/176/VCPVP

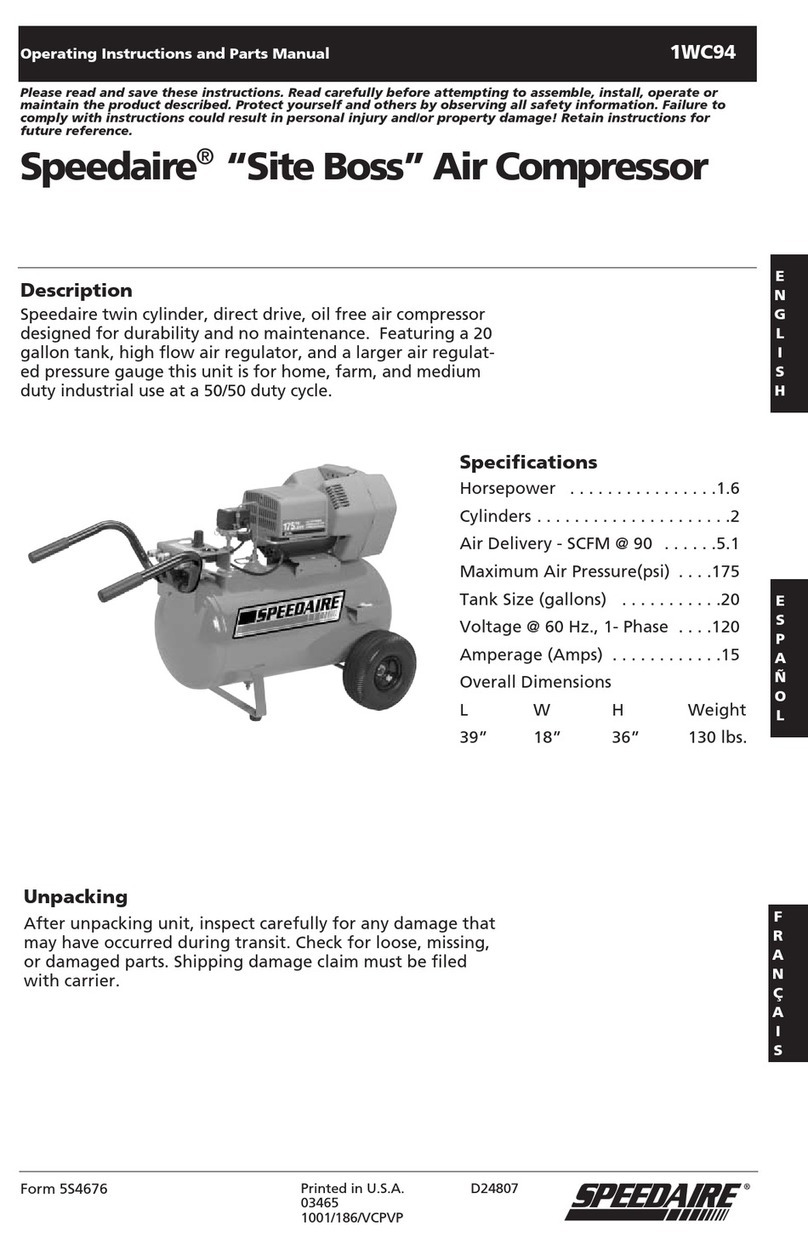

Description

Air compressor units are intended to provide compressed air to power pneumatic

tools and operate spray guns. The pumps supplied are oil lubricated. A small amount

of oil carryover is present in the compressed air stream. Applications requiring air

free of oil or water should have the appropriate filter installed. The air compressor

unit must be mounted on a solid floor or solid ground. Any other use of these units

will void the warranty and the manufacturer will not be responsible for problems or

damages resulting from such misuse.

Speedaire®Stationary

Air Compressors

For Warranty & Service call 1-888-606-5587

Do Not Return To Branch

2

E

N

G

L

I

S

H

Speedaire®Stationary Air

Compressors

Speedaire Operating Instructions

General Safety Information

(Continued)

GENERAL SAFETY

Since the air compressor and other

components (material pump, spray

guns, filters, lubricators, hoses, etc.)

used, make up a high pressure pumping

system, the following safety precautions

must be observed at all times:

1.

Read all manuals included

with this product carefully.

Be thoroughly familiar with

the controls and the proper

use of the equipment.

2. Follow all local electrical and safety

codes as well as the United States

National Electrical Codes (NEC) and

Occupational Safety and Health Act

(OSHA).

3.

Only persons well acquainted with

these rules of safe operation should be

allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and use

hearing protection when

operating the pump or

unit.

6. Do not stand on or use the pump or

unit as a handhold.

7.

Before each use, inspect compressed

air system and electrical components

for signs of damage, deterioration,

weakness or leakage. Repair or replace

defective items before using.

8. Check all fasteners at frequent

intervals for proper tightness.

Motors,

electrical

equipment and controls can

cause electrical arcs that will

ignite a flammable gas or

vapor. Never operate or repair in or near

a flammable gas or vapor. Never store

flammable liquids or gases in the vicinity

of the compressor.

Never

operate

compressor without a

beltguard. Compressors can

start automatically without

warning. Personal injury or property

damage could occur from contact with

moving parts.

9. Do not wear loose clothing or jewelry

that will get caught in the moving

parts of the unit.

Compressor parts may be hot

even if the unit is stopped.

10. Keep fingers away from a running

compressor; fast moving and hot parts

will cause injury and/or burns.

11. If the equipment should start to

abnormally vibrate, STOP the engine/

motor and check immediately for

the cause. Vibration is generally a

warning of trouble.

12. To reduce fire hazard, keep engine/

motor exterior free of oil, solvent, or

excessive grease.

An ASME code safety

relief valve with a

setting no higher than 150 psi MUST be

installed in the tank for this compressor.

The ASME safety valve must have

sufficient flow and pressure ratings to

protect the pressurized components from

bursting.

See compressor

specification decal

for maximum operating pressure. Do not

operate with pressure switch or pilot

valves set higher than the maximum

operating pressure.

13. Never attempt to adjust safety valve.

Keep safety valve free from paint and

other accumulations.

Never

attempt

to repair or modify a tank!

Welding, drilling or any other

modification will weaken the

tank resulting in damage from rupture

or explosion. Always replace worn or

damaged tanks.

Drain liquid from

tank daily.

14.

Tanks rust from moisture build-up,

which weakens the tank. Make sure

to drain tank regularly and inspect

periodically for unsafe conditions such

as rust formation and corrosion

.

15. Fast moving air will stir up dust and

debris which may be harmful. Release

air slowly when draining moisture or

depressurizing the compressor system.

SPRAYING PRECAUTIONS

Do not

spray

flammable materials in

vicinity of open flame or near

ignition sources including the

compressor unit.

16. Do not smoke when spraying paint,

insecticides, or other flammable

substances.

17. Use a face mask / respirator

when spraying and spray

in a well ventilated area

to prevent health and fire

hazards.

18. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to minimize

overspray accumulation on the

compressor.

19. When spraying or cleaning with

solvents or toxic chemicals, follow the

instructions provided by the chemical

manufacturer.

MANUAL

3

E

N

G

L

I

S

H

Cast Iron Series

Speedaire Operating Instructions

Introduction

Refer to Figure 1 to locate the following

items.

Pressure Switch - Auto/Off Switch.

On some models there is no manual

switch. The switch is permanently in

the auto mode. In the AUTO position,

the compressor shuts off automatically

when tank pressure reaches the

maximum preset pressure. In the OFF

position, the compressor will not

operate. This switch should be in the

OFF position when connecting or

disconnecting the power cord from the

electrical outlet or when changing air

tools.

For units without a manual switch,

whenever the procedures call for

turning the switch to the OFF position,

use the switch at the disconnect device

instead.

When the pressure switch turns the

motor off you will hear air leaking out

of the pressure switch unloader valve

for a short time. This releases the air

pressure from the discharge tube and

allows the compressor to restart easier.

ASME Safety Valve - This valve

automatically releases air if the tank

pressure exceeds the preset maximum.

Discharge Tube - This tube carries

compressed air from the pump to the

check valve. This tube becomes very hot

during use.

To avoid

the risk of

severe burns, never touch the

discharge tube.

Check Valve - One-way valve

that allows air to enter the tank, but

prevents air in the tank from flowing

back into the compressor pump

Belt Guard - Covers the belt, motor

pulley and flywheel.

Never

operate

compressor without a

beltguard. This unit can

start automatically without

warning. Personal injury or property

damage could occur from contact with

moving parts.

Tank Drain Valve - This valve is located

on the bottom of the tank. Use this

valve to drain moisture from the tank

daily to reduce the risk of corrosion.

Reduce tank pressure below 10 psi,

then drain moisture from tank daily to

avoid tank corrosion. Drain moisture

from tank(s) by opening the drain valve

located underneath the tank.

Assembly

Disconnect, tag and lock out

power source, then release

all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

OIL DRAIN EXTENSION

Some models include an oil drain

extension and cap (found with the

owner’s manual). Install the oil drain

extension and cap before adding oil

to the pump. To avoid oil leaks, it is

highly recommended to apply PTFE

thread sealant tape or thread sealant to

the threads on each end of the oil drain

extension. Screw the cap onto one end

of the extension. Remove the oil drain

plug from the base of the pump and

install the oil drain extension (See Figure

2).

Figure 1

Tank

Outlet

Pressure

Switch

Tank Drain Valve

Beltguard Check Valve

Discharge

Tube

Safety

Valve

Figure 2 Cap

Oil Sight Glass

Dipstick

Breather Fill Line

Add Oil

Dipstick

Oil Drain Extension

Drain

4

E

N

G

L

I

S

H

Speedaire®Stationary Air

Compressors

Speedaire Operating Instructions

NOTE: If your model is equipped with an

oil sight glass, add oil to the center (See

Figure 2).

Assembly (Continued)

LUBRICATION

THIS UNIT CONTAINS

NO OIL! Follow

lubrication instructions before

operating compressor.

Synthetic oil has proven to

provide superior lubrication and

is recommended for Speedaire air

compressors. Use 10W30 100%

synthetic oil such as Mobil 1 (Stock No.

4F743). Single viscosity, ISO100 (SAE 30)

non-detergent compressor oil such as

Mobil Rarus®(Stock No. 4ZF21), can also

be used. Both are available at your local

Grainger branch.

Do not use

petroleum based

automotive oil which has shown to

increase carbon deposits on the valves,

resulting in more frequent service and

reduced life.

If the compressor is run under humid

conditions for short periods of time, the

humidity will condense in the crankcase

and cause the oil to look creamy. Oil

contaminated by condensed water will

not provide adequate lubrication and

must be changed immediately. Using

contaminated oil will damage bearings,

pistons, cylinders and rings and is not

covered under warranty.

NOTE: To avoid water condensation in

the oil, periodically run the compressor

with tank pressure near 120 psi for

single stage compressors by opening

the drain cock or air valve connected to

the tank or hose.

Run the pump for an hour at a time at

least once a week or more often if the

condensation reoccurs.

ADDITIONAL HARDWARE NEEDED

Purchase necessary regulator, plumbing

and filtration devices to attach to

compressor. Make sure pressure ratings

of added components exceed that of the

compressor.

Installation

LOCATION

It is extremely important to install the

compressor in a clean, well ventilated

area where the surrounding air

temperature will not be more than 100°F.

A minimum clearance of 18 inches

between the compressor flywheel or fan

and a wall is required because objects

could obstruct air flow. Do not locate the

compressor air inlet near steam, paint

spray, sandblast areas or any other source

of contamination.

TANK MOUNTING

The tank should be bolted to a concrete

floor or on a separate concrete

foundation. Vibration isolators should be

used between the tank leg and the floor.

When using isolator pads, do not draw

bolts tight. Allow the pads to absorb

vibrations. A flexible coupling should be

installed between the tank and service

piping. The air compressor should be

mounted on a flat, even surface.

Never use the wood

shipping skids for

mounting the compressor.

INSTALLING A SHUT-OFF VALVE

A shut-off valve should be installed on

the discharge port of the tank to control

the air flow out of the tank. The valve

should be located between the tank and

the piping system.

Never install a shut-

off valve between

the compressor pump and the tank.

Personal injury and/or equipment damage

may occur.

PIPING

Never use

plastic

(PVC) pipe

for compressed air. Serious

injury or death could result.

ELECTICAL INSTALLATION

All wiring

and electrical

connections must be performed by a

qualified electrician. Installations must

be in accordance with local and national

codes.

GROUNDING

This product must be grounded. If the

unit comes with a factory installed cord,

plug the cord into a properly sized,

grounded outlet. For units that do not

have a factory installed cord, install

permanent wiring from the electrical

source to the pressure switch with a

ground conductor connected

to the grounding screw on the

pressure switch. A properly

sized cord with a ground

conductor and plug may also be installed

by the user.

Improperly

grounded motors are shock hazards.

Make sure all the equipment is properly

grounded.

WIRING

Local electrical wiring codes differ from

area to area. Source wiring, plug and

Model

Oil Capacity

(approx.)

4ME96 12 oz.

5

E

N

G

L

I

S

H

Cast Iron Series

Speedaire Operating Instructions

protector must be rated for at least the

amperage and voltage indicated on the

motor nameplate, and meet all electrical

codes for this minimum. Use a slow blow

fuse type T or a circuit breaker.

Installation (Continued)

Overheating, short-

circuiting and fire

damage will result from inadequate

wiring.

When the compressor unit is connected

to the electrical supply by permanent

wiring, an approved disconnect device

must be installed in the circuit.

Do not use the pressure switch as a

disconnect while performing service on

the compressor unit. A circuit break

may be used as a disconnect if it is visible

from the compressor and can be locked

in the open or off position.

If the motor does not have built-in

protection, an overload device must be

installed in the supply circuit. Consult

the approriate codes for acceptable

thermal protection. Some 3 Phase motor

installations will require a magnetic

starter as shown in Figure 3.

NOTE: Terminal configuration may vary.

Check the pressure switch markings on

your unit!

Operation

RECOMMENDED BREAK-IN PERIOD

The compressor should be run

continuously for one hour to allow

proper seating of the piston rings.

1. Open drain cock on the tank and

run the compressor unloaded for 60

minutes.

2. Turn off the compressor and close

drain cock. The compressor is now

ready for use.

START-UP (SEE FIGURE 2)

This compressor

pump must be filled

with oil before startup. See Lubrication

section.

Do not attach air

tools to open end of

the hose until start-up is completed and

the unit checks OK.

1. Remove the dipstick breather and

fill pump to the proper oil level. See

Lubrication section.

2. Turn pressure switch lever or knob to

OFF position and plug in power cord

(See Figure 4). Turn off disconnect

switch if there is no lever or knob on

the pressure switch.

3. Turn pressure switch lever or knob to

AUTO position and run unit for 30

minutes to break in the pump parts

(See Figure 4).

4. After use, turn pressure switch lever

or knob to the Off position.

5. If compressor is not used for a long

time period, bleed air from line

and use drain cock to drain water

from the tank. Then, follow the

maintenance schedule.

NOTE: Electric models are equipped

with a pressure switch that automatically

turns the motor OFF when the tank

pressure reaches a preset level. After

L1 L2

PRESSURE

SWITCH THERMAL

UNITS (3)

L3

T2

FUSED BREAKER

OR DISCONNECT

X2

MOTOR

OVER-

LOAD

COIL

T3T1

L1

L2

240V

GROUND

PRESSURE

SWITCH

LINE

M

MOTOR

Figure 3 - Single and 3 Phase Wiring Diagrams

A

U

T

O

/

O

F

F

Figure 4

Off

Auto

This manual suits for next models

1

Table of contents

Languages:

Other Speedaire Air Compressor manuals

Speedaire

Speedaire 787U78 Instructions for use

Speedaire

Speedaire 40HU29 User manual

Speedaire

Speedaire 787U77 Instructions for use

Speedaire

Speedaire 1WC94 User manual

Speedaire

Speedaire 4UP73 Instructions for use

Speedaire

Speedaire 787U76 Instructions for use

Speedaire

Speedaire 5Z598C Service manual

Speedaire

Speedaire 15D802 User manual

Speedaire

Speedaire 1WD36 Instructions for use

Speedaire

Speedaire 1WC95 Service manual