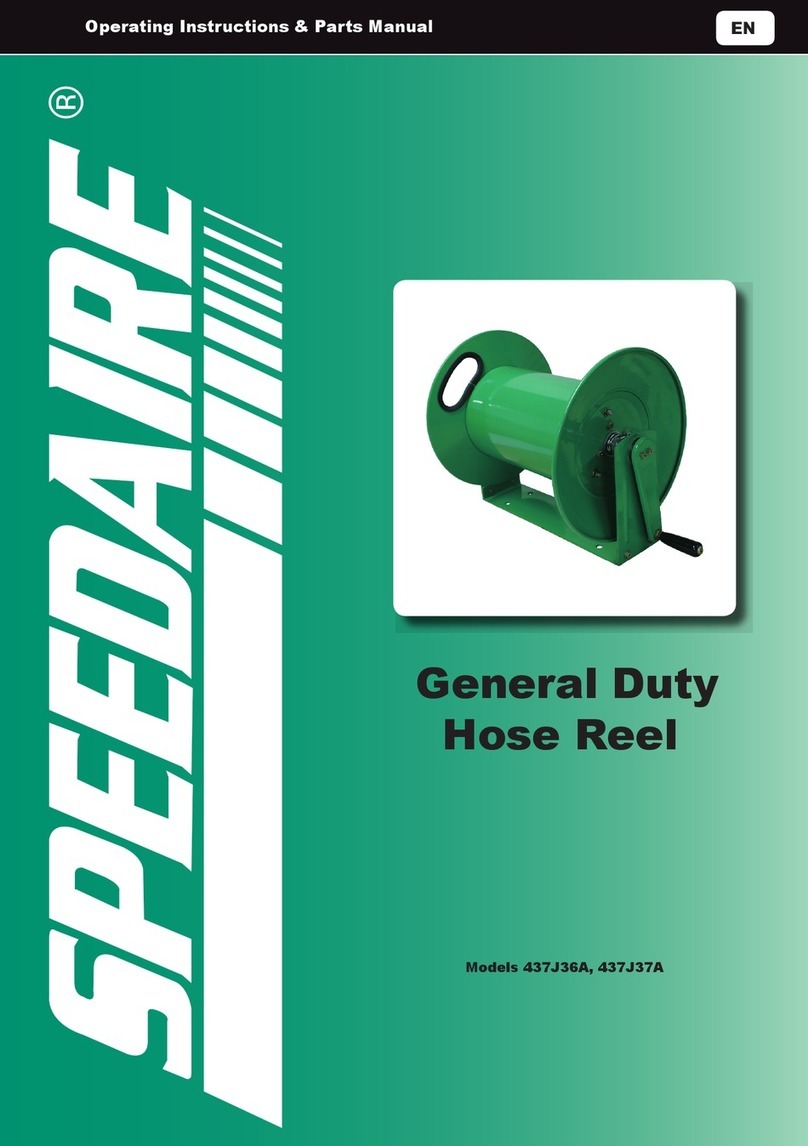

Speedaire 437J35A Instructions for use

General Duty

Hand Crank

Hose Reel

Operating Instructions & Parts Manual EN

Model 437J35A

PLEASE READ AND SAVE

THESE INSTRUCTIONS.

READ CAREFULLY

BEFORE ATTEMPTING

TO ASSEMBLE, INSTALL,

OPERATE OR MAINTAIN THE

PRODUCT DESCRIBED.

PROTECT YOURSELF AND

OTHERS BY OBSERVING ALL

SAFETY INFORMATION. FAILURE

TO COMPLY WITH INSTRUCTIONS

COULD RESULT IN PERSONAL

INJURY AND/OR PROPERTY

DAMAGE! RETAIN INSTRUCTIONS

FOR FUTURE REFERENCE.

PLEASE REFER TO BACK COVER

FOR INFORMATION REGARDING

SPEEDAIRE`S WARRANTY AND OTHER

IMPORTANT INFORMATION.

Model #:

Serial #:

Purch. Date #:

Printed in Korea

Version 0 12/2017

©2013 Dayton Electric Manufacturing Co.

All Rights Reserved

1

Description

BEFORE YOU BEGIN

Tools Needed:

UNPACKING

Contents:

Inspect:

These Speedaire®Industrial Hose Reels feature an internal spring for

automatic hose rewind. The locking ratchet design provides easy hose

positioning.

● Adjustable Wrench for installation

● Screwdriver

●

Speedaire

®

Hose Reel (1)

●

Operating Instructions and Parts Manual (1)

●

After unpacking the reel, carefully inspect for any damage that may

have occurred during transit. Check for loose, missing, or damaged

parts. Shipping damage claims must be filed with the carrier.

●

See General Safety Instructions on page 2, and Cautions and Warnings as shown

GETTING STARTED SAFETY /

SPECIFICATIONS OPERATION

ASSEMBLY /

INSTALLATION TROUBLESHOOTING MAINTENANCE /

REPAIR

PLEASE READ AND SAVE

THESE INSTRUCTIONS.

READ CAREFULLY

BEFORE ATTEMPTING

TO ASSEMBLE, INSTALL,

OPERATE OR MAINTAIN THE

PRODUCT DESCRIBED.

PROTECT YOURSELF AND

OTHERS BY OBSERVING ALL

SAFETY INFORMATION. FAILURE

TO COMPLY WITH INSTRUCTIONS

COULD RESULT IN PERSONAL

INJURY AND/OR PROPERTY

DAMAGE! RETAIN INSTRUCTIONS

FOR FUTURE REFERENCE.

PLEASE REFER TO BACK COVER

FOR INFORMATION REGARDING

SPEEDAIRE`S WARRANTY AND OTHER

IMPORTANT INFORMATION.

Model #:

Serial #:

Purch. Date #:

Printed in Korea

Version 0 12/2017

©2013 Dayton Electric Manufacturing Co.

All Rights Reserved

2

GENERAL SAFETY INSTRUCTIONS

Read the following precautions and instructions before you begin assembly or use.

Failure to comply with these instructions could result in personal injury or property damage.

Regarding the pressure of inlet, do not exceed the maximum pressure of the reel.

Use a flexible hose for connecting the inlet and do not use rigid plumbing.

Make sure the line pressure does not exceed the rated operating pressure of the

hose reel, refer to the specifications.

Exposure of the skin directly to pressurized air or fluid could result in severe

bodily injury.

Before carrying out any maintenance, turn off and disconnect the supply line to the

reel and carefully release the hose line pressure.

GETTING STARTED

SAFETY /

SPECIFICATIONS

OPERATION ASSEMBLY /

INSTALLATION

TROUBLESHOOTING

MAINTENANCE /

REPAIR

3

4000

3/8

100

31

3/8

3/8

3/8

225

SPECIFICATIONS

A (inch)

B (inch)

C (inch)

D (inch)

E (inch)

F (inch)

G (inch)

21-15/32

11-13/16

22-13/64

13-51/64

7-3/32

7-3/32

25/32

437J35A

Maximum Operating

Pressure (PSI)

Hose I.D

(inch)

Hose Length

(ft)

Weight

(lbs)

Hose Outlet

NPT Male (inch)

Reel Outlet

NPT Female (inch)

Maximum Operating

Temperatures(°F)

Reel Inlet

NPT Female (inch)

Figure 1

Applications

Housing Material

Housing Colour

Air, Water

STEEL

Green

GETTING STARTED SAFETY /

SPECIFICATIONS OPERATION

ASSEMBLY /

INSTALLATION TROUBLESHOOTING MAINTENANCE /

REPAIR

2

GENERAL SAFETY INSTRUCTIONS

Read the following precautions and instructions before you begin assembly or use.

Failure to comply with these instructions could result in personal injury or property damage.

Regarding the pressure of inlet, do not exceed the maximum pressure of the reel.

Use a flexible hose for connecting the inlet and do not use rigid plumbing.

Make sure the line pressure does not exceed the rated operating pressure of the

hose reel, refer to the specifications.

Exposure of the skin directly to pressurized air or fluid could result in severe

bodily injury.

Before carrying out any maintenance, turn off and disconnect the supply line to the

reel and carefully release the hose line pressure.

GETTING STARTED

SAFETY /

SPECIFICATIONS

OPERATION ASSEMBLY /

INSTALLATION

TROUBLESHOOTING

MAINTENANCE /

REPAIR

4

ASSEMBLY INSTALLATIONS

1 Unpack and inspect reel for any damage. Turn the reel by hand to check whether the reel is

2 The swing bracket was packed separated with the reel in the box.

3 There are twelve holes in each base of the swing bracket and reel.

4 Disassemble the bolts and nuts fastened to the swing bracket base.

5 Align the holes in the base of the reel and swing bracket, and fasten the bolts

and nuts that were disassembled in step 4 to the four holes in the corner.

6 After installing the swivel mounting bracket with anchor brackets

(if welding is required, it should be welded), then install the reel by placing the pin between

the reel and swivel mounting bracket.

7 Reel are supplied with plastic crank handle to prevent damage on the move, the handle is

packaged folded. When using the handle, please unfold it.

8 Apply thread sealant to inlet hose and connect to the swivel joint on reel

operating smoothly or not.

Typical mounting position

Lock Function

When the reel is mounted to the wall it should

be mounted correctly.

If the hose is taken out when the reel is not mounted correctly, the reel

can fall down and become damaged. The user can also be injured.

Wall Mounting

Figure 2

Figure 3 Figure 4

When the user opens the box, the lock on the

swing bracket is unlocked.

In order to use the reel to one direction, the lock

must be locked.

Turn the reel in the desired direction and align

the holes of base of the reel and the the bracket.

Pull the knob downward, turn it 90 degrees

counterclockwise, put the knob in the hole of

desired direction inserting the end of knob into

the groove.

GETTING STARTED

SAFETY /

SPECIFICATIONS

OPERATION ASSEMBLY /

INSTALLATION

TROUBLESHOOTING

MAINTENANCE /

REPAIR

5

TROUBLESHOOTING GUIDE

Symptom

Air Leakage 1. Worn inlet hose

2. Worn O-Ring

3. Coupler problem

1. Tighten hose clamp or replace the hose

2. Replace O-Ring

3. Tighten coupler or replace

1. 1.

..

fully fit on drum of

reel

.

.

. /cable

meets the maximum outside

.

Caution

1. 1.

.

GETTING STARTED SAFETY /

SPECIFICATIONS OPERATION

ASSEMBLY /

INSTALLATION TROUBLESHOOTING MAINTENANCE /

REPAIR

4

ASSEMBLY INSTALLATIONS

1 Unpack and inspect reel for any damage. Turn the reel by hand to check whether the reel is

2 The swing bracket was packed separated with the reel in the box.

3 There are twelve holes in each base of the swing bracket and reel.

4 Disassemble the bolts and nuts fastened to the swing bracket base.

5 Align the holes in the base of the reel and swing bracket, and fasten the bolts

and nuts that were disassembled in step 4 to the four holes in the corner.

6 After installing the swivel mounting bracket with anchor brackets

(if welding is required, it should be welded), then install the reel by placing the pin between

the reel and swivel mounting bracket.

7 Reel are supplied with plastic crank handle to prevent damage on the move, the handle is

packaged folded. When using the handle, please unfold it.

8 Apply thread sealant to inlet hose and connect to the swivel joint on reel

operating smoothly or not.

Typical mounting position

Lock Function

When the reel is mounted to the wall it should

be mounted correctly.

If the hose is taken out when the reel is not mounted correctly, the reel

can fall down and become damaged. The user can also be injured.

Wall Mounting

Figure 2

Figure 3 Figure 4

When the user opens the box, the lock on the

swing bracket is unlocked.

In order to use the reel to one direction, the lock

must be locked.

Turn the reel in the desired direction and align

the holes of base of the reel and the the bracket.

Pull the knob downward, turn it 90 degrees

counterclockwise, put the knob in the hole of

desired direction inserting the end of knob into

the groove.

GETTING STARTED

SAFETY /

SPECIFICATIONS

OPERATION ASSEMBLY /

INSTALLATION

TROUBLESHOOTING

MAINTENANCE /

REPAIR

6

MAINTENANCE AND INSPECTION INSTRUCTION

Any repairs or replacements must be done by a

qualified person or authorized service center only.

An inspection should be conducted periodically.

Also the maintenance record should be updated

periodically. When a problem occurs, it should be

repaired after the pressure has been released.

Leakage Inspection

Regarding the media (fluid) which is used for the hose reel, checking for leaks should be

done periodically.

After taking out the hose, fully apply the soapy water on the connected point.

(Such as housing or shaft).

If the connected point is bubbling up, the user should suspect phenomenon of leakage.

●When a leak occurs, the sealing of the housing or shaft should be replaced.

●When a leak occurs because of hose damage, the hose should be replaced.

Swivel Seal Replacement

●Remove the hose from the swivel.

●Remove the snap ring with dedicated pliers.

●Remove the swivel by pulling it towards user.

●Attach the new swivel to the reel.

●Attach the snap ring to the new swivel with the dedicated pliers.

●Connect the input hose to the new swivel.

GETTING STARTED

SAFETY /

SPECIFICATIONS

OPERATION ASSEMBLY /

INSTALLATION

TROUBLESHOOTING

MAINTENANCE /

REPAIR

7

REPAIR PARTS ILLUSTRATION FOR 437J35A

24 hours a day - 365 days a year

Please provide following information:

-Model number

-Serial number (if any)

-Part description and number as shown in parts list

Locking Device

Locking Device

GETTING STARTED SAFETY /

SPECIFICATIONS OPERATION

ASSEMBLY /

INSTALLATION TROUBLESHOOTING MAINTENANCE /

REPAIR

6

MAINTENANCE AND INSPECTION INSTRUCTION

Any repairs or replacements must be done by a

qualified person or authorized service center only.

An inspection should be conducted periodically.

Also the maintenance record should be updated

periodically. When a problem occurs, it should be

repaired after the pressure has been released.

Leakage Inspection

Regarding the media (fluid) which is used for the hose reel, checking for leaks should be

done periodically.

After taking out the hose, fully apply the soapy water on the connected point.

(Such as housing or shaft).

If the connected point is bubbling up, the user should suspect phenomenon of leakage.

●When a leak occurs, the sealing of the housing or shaft should be replaced.

●When a leak occurs because of hose damage, the hose should be replaced.

Swivel Seal Replacement

●Remove the hose from the swivel.

●Remove the snap ring with dedicated pliers.

●Remove the swivel by pulling it towards user.

●Attach the new swivel to the reel.

●Attach the snap ring to the new swivel with the dedicated pliers.

●Connect the input hose to the new swivel.

GETTING STARTED

SAFETY /

SPECIFICATIONS

OPERATION ASSEMBLY /

INSTALLATION

TROUBLESHOOTING

MAINTENANCE /

REPAIR

8

REPAIR PARTS LIST FOR 437J35A

Reference

Number Description Part Number Product Number Qty.

(PC/Unit) Remarks

1437J35A

VITON(R)+

TEFLON

2

3

4

437J35A

BRASS

437J35A

STEEL+MC

SUS

437J35A

454Z37

454Z28

454Z09

454Z24

1

1

2

1

SWIVEL

SEALING

BOLT SHAFT

HANDLE ASS'Y

GETTING STARTED

SAFETY /

SPECIFICATIONS

OPERATION ASSEMBLY /

INSTALLATION

TROUBLESHOOTING

MAINTENANCE /

REPAIR

9

NOTES.

GETTING STARTED SAFETY /

SPECIFICATIONS OPERATION

ASSEMBLY /

INSTALLATION TROUBLESHOOTING MAINTENANCE /

REPAIR

8

REPAIR PARTS LIST FOR 437J35A

Reference

Number Description Part Number Product Number Qty.

(PC/Unit) Remarks

1437J35A

VITON(R)+

TEFLON

2

3

4

437J35A

BRASS

437J35A

STEEL+MC

SUS

437J35A

454Z37

454Z28

454Z09

454Z24

1

1

2

1

SWIVEL

SEALING

BOLT SHAFT

HANDLE ASS'Y

GETTING STARTED

SAFETY /

SPECIFICATIONS

OPERATION ASSEMBLY /

INSTALLATION

TROUBLESHOOTING

MAINTENANCE /

REPAIR

SPEEDAIRE ONE-YEAR LIMITED WARRANTY

SPEEDAIRE ONE-YEAR LIMITED WARRANTY.

All Speedair

@

product models covered in this manual are warranted by Dayton Electric Mfg. Co.

(“Dayton”) to the original user against defects in workmanship or materials under normal use for one year after date of purchase. If the Speedair Product

is part of a set, only the portion that is defective is subject to this warranty. Any product or part which is determined to be defective in material or

workmanship and returned to an authorized service location, as Dayton or Dayton’s designee designates, shipping costs prepaid, will be, as the exclusive

remedy, repaired or replaced with a new or reconditioned product or part of equal utility or a full refund given, at Dayton’s or Dayton’s designee’s option,

at no charge. For limited warranty claim procedures, see “Warranty Service” below. This warranty is void if there is evidence of misuse, mis-repair,

mis-installation, abuse or alteration. This warranty does not cover normal wear and tear of Speedair Products or portions of them, or products or portions

of them which are consumable in normal use. This limited warranty gives purchasers specific legal rights, and you may also have other rights which vary

from jurisdiction to jurisdiction.

WARRANTY DISCLAIMERS AND LIMITATIONS OF LIABILITY RELATING TO ALL CUSTOMERS FOR ALL PRODUCTS

LIMITATION OF LIABILITY. TO THE EXTENT ALLOWABLE UNDER APPLICABLE LAW, DAYTON’S LIABILITY FOR CONSEQUENTIAL AND INCIDENTAL

DAMAGES IS EXPRESSLY DISCLAIMED. DAYTON’S LIABILITY IN ALL EVENTS IS LIMITED TO AND SHALL NOT EXCEED THE PURCHASE PRICE

PAID.

WARRANTY DISCLAIMER.

A DILIGENT EFFORT HAS BEEN MADE TO PROVIDE PRODUCT INFORMATION AND ILLUSTRATE THE SPEEDAIRE

PRODUCTS IN THIS LITERATURE ACCURATELY; HOWEVER, SUCH INFORMATION AND ILLUSTRATIONS ARE FOR THE SOLE PURPOSE OF

IDENTIFICATION, AND DO NOT EXPRESS OR IMPLY A WARRANTY THAT THE SPEEDAIRE PRODUCTS ARE MERCHANTABLE, OR FIT FOR A

PARTICULAR PURPOSE, OR THAT THE SPEEDAIRE PRODUCTS WILL NECESSARILY CONFORM TO THE ILLUSTRATIONS OR DESCRIPTIONS.EX-

CEPT AS PROVIDED BELOW, NO WARRANTY OR AFFIRMATION OF FACT, EXPRESSED OR IMPLIED, OTHER THAN AS STATED IN THE “LIMITED

WARRANTY” ABOVE IS MADE OR AUTHORIZED BY DAYTON.

PRODUCT SUITABILITY.

MANY JURISDICTIONS HAVE CODES AND REGULATIONS GOVERNING SALES, CONSTRUCTION, INSTALLATION,

ANDI OR USE OF PRODUCTS FOR CERTAIN PURPOSES, WHICH MAY VARY FROM THOSE IN NEIGHBORING AREAS. WHILE ATTEMPTS ARE

MADE TO ASSURE THAT SPEEDAIRE PRODUCTS COMPLY WITH SUCH CODES, DAYTON CANNOT GUARANTEE COMPLIANCE, AND CANNOT BE

RESPONSIBLE FOR HOW THE PRODUCT IS INSTALLED OR USED. BEFORE PURCHASE AND USE OF A PRODUCT, REVIEW THE SAFETYI

SPECIFICATIONS, AND ALL APPLICABLE NATIONAL AND LOCAL CODES AND REGULATIONS, AND BE SURE THAT THE SPEEDAIRE PRODUCT,

INSTALLATION, AND USE WILL COMPLY WITH THEM.

CONSUMERS ONLY.

CERTAIN ASPECTS OF DISCLAIMERS ARE NOT APPLICABLE TO CONSUMER PRODUCTS SOLD TO CONSUMERS; (A)

SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU; (B) ALSO, SOME JURISDICTIONS DO NOT ALLOW A LIMITATION ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU; AND (C) BY LAW, DURING THE PERIOD OF THIS LIMITED

WARRANTY, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE APPLICABLE TO CONSUMER

PRODUCTS PURCHASED BY CONSUMERS, MAY NOT BE EXCLUDED OR OTHERWISE DISCLAIMED.

THIS LIMITED WARRANTY ONLY APPLIES TO SPEEDAIRE PRODUCTS PURCHASED BY UNITED STATES PURCHASERS FOR DELIVERY IN THE

UNITED STATES.

WARRANTY SERVICE

To obtain warranty service if you purchased the covered product directly from W.W. Grainger, Inc. (“Grainger”), (i) write or call or visit the local Grainger

branch from which the product was purchased or another Grainger branch near you (see www.grainger.com for a listing of Grainger branches); or (ii) contact

Grainger by going to www.grainger.com and clicking on the “Contact Us” link at the top of the page, then clicking on the “Email us” link; or (iii) call Customer

Care (toll free) at 1-888-361-8649. To obtain warranty service if you purchased the covered product from another distributor or retailer, (i) go to

www.grainger.com for Warranty Service; (ii) write or call or visit a Grainger branch near you; or (iii) call Customer Care (toll free) at 1-888-361-8649. In any

case, you will need to provide, to the extent available, the purchase date, the original invoice number, the stock number, a description of the defect, and

anything else specified in this Speedaire One-Year Limited Warranty. You may be required to send the product in for inspection at your cost. You can follow

up on the progress of inspections and corrections in the same ways.Title and risk of loss pass to buyer on delivery to common carrier, so if product was

damaged in transit to you, file claim with carrier, not the retailer, Grainger or Dayton. For warranty information for purchasers andIor delivery outside the

United States, please contact:

Dayton Electric Mfg. Co.,

100 Grainger Parkway, Lake Forest, IL 60045 U.S.A. or

call +1-888-361-8649

Manual de instrucciones operativas y de las piezas ES

Modelo 437J35A

Carrete de

manguera de

función general

con manivela

SPEEDAIRE ONE-YEAR LIMITED WARRANTY

SPEEDAIRE ONE-YEAR LIMITED WARRANTY.

All Speedair

@

product models covered in this manual are warranted by Dayton Electric Mfg. Co.

(“Dayton”) to the original user against defects in workmanship or materials under normal use for one year after date of purchase. If the Speedair Product

is part of a set, only the portion that is defective is subject to this warranty. Any product or part which is determined to be defective in material or

workmanship and returned to an authorized service location, as Dayton or Dayton’s designee designates, shipping costs prepaid, will be, as the exclusive

remedy, repaired or replaced with a new or reconditioned product or part of equal utility or a full refund given, at Dayton’s or Dayton’s designee’s option,

at no charge. For limited warranty claim procedures, see “Warranty Service” below. This warranty is void if there is evidence of misuse, mis-repair,

mis-installation, abuse or alteration. This warranty does not cover normal wear and tear of Speedair Products or portions of them, or products or portions

of them which are consumable in normal use. This limited warranty gives purchasers specific legal rights, and you may also have other rights which vary

from jurisdiction to jurisdiction.

WARRANTY DISCLAIMERS AND LIMITATIONS OF LIABILITY RELATING TO ALL CUSTOMERS FOR ALL PRODUCTS

LIMITATION OF LIABILITY. TO THE EXTENT ALLOWABLE UNDER APPLICABLE LAW, DAYTON’S LIABILITY FOR CONSEQUENTIAL AND INCIDENTAL

DAMAGES IS EXPRESSLY DISCLAIMED. DAYTON’S LIABILITY IN ALL EVENTS IS LIMITED TO AND SHALL NOT EXCEED THE PURCHASE PRICE

PAID.

WARRANTY DISCLAIMER.

A DILIGENT EFFORT HAS BEEN MADE TO PROVIDE PRODUCT INFORMATION AND ILLUSTRATE THE SPEEDAIRE

PRODUCTS IN THIS LITERATURE ACCURATELY; HOWEVER, SUCH INFORMATION AND ILLUSTRATIONS ARE FOR THE SOLE PURPOSE OF

IDENTIFICATION, AND DO NOT EXPRESS OR IMPLY A WARRANTY THAT THE SPEEDAIRE PRODUCTS ARE MERCHANTABLE, OR FIT FOR A

PARTICULAR PURPOSE, OR THAT THE SPEEDAIRE PRODUCTS WILL NECESSARILY CONFORM TO THE ILLUSTRATIONS OR DESCRIPTIONS.EX-

CEPT AS PROVIDED BELOW, NO WARRANTY OR AFFIRMATION OF FACT, EXPRESSED OR IMPLIED, OTHER THAN AS STATED IN THE “LIMITED

WARRANTY” ABOVE IS MADE OR AUTHORIZED BY DAYTON.

PRODUCT SUITABILITY.

MANY JURISDICTIONS HAVE CODES AND REGULATIONS GOVERNING SALES, CONSTRUCTION, INSTALLATION,

ANDI OR USE OF PRODUCTS FOR CERTAIN PURPOSES, WHICH MAY VARY FROM THOSE IN NEIGHBORING AREAS. WHILE ATTEMPTS ARE

MADE TO ASSURE THAT SPEEDAIRE PRODUCTS COMPLY WITH SUCH CODES, DAYTON CANNOT GUARANTEE COMPLIANCE, AND CANNOT BE

RESPONSIBLE FOR HOW THE PRODUCT IS INSTALLED OR USED. BEFORE PURCHASE AND USE OF A PRODUCT, REVIEW THE SAFETYI

SPECIFICATIONS, AND ALL APPLICABLE NATIONAL AND LOCAL CODES AND REGULATIONS, AND BE SURE THAT THE SPEEDAIRE PRODUCT,

INSTALLATION, AND USE WILL COMPLY WITH THEM.

CONSUMERS ONLY.

CERTAIN ASPECTS OF DISCLAIMERS ARE NOT APPLICABLE TO CONSUMER PRODUCTS SOLD TO CONSUMERS; (A)

SOME JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU; (B) ALSO, SOME JURISDICTIONS DO NOT ALLOW A LIMITATION ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU; AND (C) BY LAW, DURING THE PERIOD OF THIS LIMITED

WARRANTY, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE APPLICABLE TO CONSUMER

PRODUCTS PURCHASED BY CONSUMERS, MAY NOT BE EXCLUDED OR OTHERWISE DISCLAIMED.

THIS LIMITED WARRANTY ONLY APPLIES TO SPEEDAIRE PRODUCTS PURCHASED BY UNITED STATES PURCHASERS FOR DELIVERY IN THE

UNITED STATES.

WARRANTY SERVICE

To obtain warranty service if you purchased the covered product directly from W.W. Grainger, Inc. (“Grainger”), (i) write or call or visit the local Grainger

branch from which the product was purchased or another Grainger branch near you (see www.grainger.com for a listing of Grainger branches); or (ii) contact

Grainger by going to www.grainger.com and clicking on the “Contact Us” link at the top of the page, then clicking on the “Email us” link; or (iii) call Customer

Care (toll free) at 1-888-361-8649. To obtain warranty service if you purchased the covered product from another distributor or retailer, (i) go to

www.grainger.com for Warranty Service; (ii) write or call or visit a Grainger branch near you; or (iii) call Customer Care (toll free) at 1-888-361-8649. In any

case, you will need to provide, to the extent available, the purchase date, the original invoice number, the stock number, a description of the defect, and

anything else specified in this Speedaire One-Year Limited Warranty. You may be required to send the product in for inspection at your cost. You can follow

up on the progress of inspections and corrections in the same ways.Title and risk of loss pass to buyer on delivery to common carrier, so if product was

damaged in transit to you, file claim with carrier, not the retailer, Grainger or Dayton. For warranty information for purchasers andIor delivery outside the

United States, please contact:

Dayton Electric Mfg. Co.,

100 Grainger Parkway, Lake Forest, IL 60045 U.S.A. or

call +1-888-361-8649

POR FAVOR, LEA Y GUARDE

ESTAS INSTRUCCIONES.

LEA CON ATENCIÓN

ANTES DE INTENTAR

ENSAMBLAR, INSTALAR,

OPERAR O MANTENER EL

PRODUCTO DESCRIPTO.

PROTÉJASE Y PROTEJA A

OTROS AL CUMPLIR CON TODA LA

INFORMACIÓN DE SEGURIDAD.

¡EL INCUMPLIMIENTO DE LAS INSTRUCCIONES

PODRÍA OCASIONAR LESIONES PERSONALES Y /

O DAÑO A LA PROPIEDAD!

GUARDE LAS INSTRUCCIONES

PARA FUTURA REFERENCIA.

POR FAVOR, CONSULTE

LA CONTRATAPA PARA

OBTENER INFORMACIÓN ACERCA DE

LA GARANTÍA DE SPEEDAIRE Y

OTRA INFORMACIÓN

IMPORTANTE.

# de modelo:

# de serie:

# de fecha de compra:

Impreso en Corea

Versión 0 12 / 2017

© 2013 Dayton Electric Manufacturing Co.

Todos los derechos reservados

1

Descripción :

ANTES DE COMENZAR

Herramientas necesarias :

DESEMPAQUE

Contenidos :

Inspeccione :

Los carretes de manguera industriales Speedaire®cuentan con un resorte interno

para rebobinar la manguera automáticamente.

El diseño de trinquete de bloqueo proporciona un posicionamiento fácil de la

manguera.

● Llave inglesa ajustable para la instalación

● Destornillador

●

Carrete de manguera Speedaire

®

(1)

● Manual de instrucciones operativas y de piezas (1)

●

Después de desembalar el carril, inspeccione cuidadosamente para detectar cualquier

daño que pueda haber ocurrido durante el tránsito.

Verifique si hay piezas sueltas, faltantes o dañadas. Las reclamaciones de daños de

envío se deben presentar al transportista.

●

Consulte las Instrucciones de seguridad generales en la página 2 y las precauciones y

advertencias que se muestran

CÓMO COMENZAR SEGURIDAD /

ESPECIFICACIONES FUNCIONAMIENTO

MONTAJE /

INSTALACIÓN

SOLUCIÓN DE

PROBLEMAS

MANTENIMIENTO /

REPARACIÓN

POR FAVOR, LEA Y GUARDE

ESTAS INSTRUCCIONES.

LEA CON ATENCIÓN

ANTES DE INTENTAR

ENSAMBLAR, INSTALAR,

OPERAR O MANTENER EL

PRODUCTO DESCRIPTO.

PROTÉJASE Y PROTEJA A

OTROS AL CUMPLIR CON TODA LA

INFORMACIÓN DE SEGURIDAD.

¡EL INCUMPLIMIENTO DE LAS INSTRUCCIONES

PODRÍA OCASIONAR LESIONES PERSONALES Y /

O DAÑO A LA PROPIEDAD!

GUARDE LAS INSTRUCCIONES

PARA FUTURA REFERENCIA.

POR FAVOR, CONSULTE

LA CONTRATAPA PARA

OBTENER INFORMACIÓN ACERCA DE

LA GARANTÍA DE SPEEDAIRE Y

OTRA INFORMACIÓN

IMPORTANTE.

# de modelo:

# de serie:

# de fecha de compra:

Impreso en Corea

Versión 0 12 / 2017

© 2013 Dayton Electric Manufacturing Co.

Todos los derechos reservados

2

INSTRUCCIONES GENERALES DE SEGURIDAD

Lea las siguientes precauciones e instrucciones antes de comenzar a ensamblar o usar.

El incumplimiento de estas instrucciones puede ocasionar lesiones personales o daños a la propiedad.

En lo que se refiere a la presión de entrada, no exceda la presión máxima del carrete.

Use una manguera flexible para conectar la entrada y no use plomería rígida.

Asegúrese de que la presión de la línea no exceda la presión de operación nominal del

carrete de la manguera, consulte las especificaciones.

La exposición de la piel directamente al aire o al fluido presurizado podría ocasionar

lesiones corporales graves.

Antes de realizar cualquier tarea de mantenimiento, apague y desconecte la línea de

suministro al carrete y libere con cuidado la presión de la línea de la manguera.

PRECAUCIÓN

PRECAUCIÓN

PRECAUCIÓN

PRECAUCIÓN

PRECAUCIÓN

CÓMO COMENZAR

SEGURIDAD /

ESPECIFICACIONES

FUNCIONAMIENTO MONTAJE /

INSTALACIÓN

SOLUCIÓN DE

PROBLEMAS

MANTENIMIENTO /

REPARACIÓN

3

4000

3/8

100

31

3/8

3/8

3/8

225

ESPECIFICACIONES

A (pulgada)

B (pulgada)

C (pulgada)

D (pulgada)

E (pulgada)

F (pulgada)

G (pulgada)

21-15/32

11-13/16

22-13/64

13-51/64

7-3/32

7-3/32

25/32

437J35A

Máxima presión de funcionamiento

(PSI)

ID de la manguera

(pulgada)

Longitud de la manguera

(pies)

Peso

(libras)

Salida de manguera

GHT Macho (pulgada)

Salida del carrete

NPT Hembra (pulgada)

Máximas temperaturas

de funcionamiento (°F)

Entrada del carrete

NPT hembra (pulgada)

Figura 1

Aplicaciones

Material de la carcasa

Color de la carcasa

Aire, agua

ACERO

Verde

CÓMO COMENZAR SEGURIDAD /

ESPECIFICACIONES FUNCIONAMIENTO

MONTAJE /

INSTALACIÓN

SOLUCIÓN DE

PROBLEMAS

MANTENIMIENTO /

REPARACIÓN

2

INSTRUCCIONES GENERALES DE SEGURIDAD

Lea las siguientes precauciones e instrucciones antes de comenzar a ensamblar o usar.

El incumplimiento de estas instrucciones puede ocasionar lesiones personales o daños a la propiedad.

En lo que se refiere a la presión de entrada, no exceda la presión máxima del carrete.

Use una manguera flexible para conectar la entrada y no use plomería rígida.

Asegúrese de que la presión de la línea no exceda la presión de operación nominal del

carrete de la manguera, consulte las especificaciones.

La exposición de la piel directamente al aire o al fluido presurizado podría ocasionar

lesiones corporales graves.

Antes de realizar cualquier tarea de mantenimiento, apague y desconecte la línea de

suministro al carrete y libere con cuidado la presión de la línea de la manguera.

PRECAUCIÓN

PRECAUCIÓN

PRECAUCIÓN

PRECAUCIÓN

PRECAUCIÓN

CÓMO COMENZAR

SEGURIDAD /

ESPECIFICACIONES

FUNCIONAMIENTO MONTAJE /

INSTALACIÓN

SOLUCIÓN DE

PROBLEMAS

MANTENIMIENTO /

REPARACIÓN

4

MONTAJE INSTALACIONES

Típica posición de montaje

Función de bloqueo

Montaje en el suelo

Figura 2

Figura 3 Figura 4

Cuando el usuario abre la caja, se destraba el

bloqueo en el soporte oscilante.

Para usar el carrete en una dirección, el bloqueo

debe estar trabado.

Gire el carrete en la dirección deseada y alinee los

orificios de la base del carrete y del soporte.

Tire de la perilla hacia abajo, gírela 90 grados en

sentido contrario a las agujas del reloj, coloque la

perilla en el orificio de la dirección deseada

insertando el extremo de la perilla en la ranura

ADVERTENCIA

1 Desempaque e inspeccione el carrete para verificar que no haya ningún daño. Gire el carrete a

mano para verificar si el carrete funciona o no funciona correctamente.

2 El soporte oscilante se embaló por separado con el carrete en la caja.

3 Hay doce orificios en cada base del soporte oscilante y del carrete.

4 Desmonte los pernos y las tuercas fijados a la base del soporte oscilante.

5 Alinee los orificios en la base del carrete y el soporte giratorio y ajuste los pernos y las tuercas

que se desmontaron en el paso 4 en los cuatro orificios en la esquina.

6 Después de instalar el soporte de montaje giratorio con los soportes de anclaje (si se requiere

soldadura, se debe soldar), instale el carrete colocando el pasador entre el carrete y el soporte

de montaje giratorio.

7 El carrete se suministra con manivela de plástico para evitar daños en movimiento, la manivela

está embalada plegada. Cuando use la manivela, por favor despliéguela.

8 Aplique sellador de roscas en la manguera de entrada y conéctelo a la junta giratoria del carrete.

Cuando el carrete está montado en el la pared,

se debe montar correctamente.

Si se saca la manguera cuando el carrete no está montado correctamente,

el carrete se puede caer y se puede dañar.

CÓMO COMENZAR

SEGURIDAD /

ESPECIFICACIONES

FUNCIONAMIENTO MONTAJE /

INSTALACIÓN

SOLUCIÓN DE

PROBLEMAS

MANTENIMIENTO /

REPARACIÓN

5

GUÍA PARA RESOLVER PROBLEMAS

Síntoma Causa (s) posible (s) Acción correctiva

Fuga de aire 1. Manguera de entrada

desgastada

2. Junta tórica desgastada

3. Problema del acoplador

1. Ajuste la abrazadera de la manguera o

reemplace la manguera

2. Reemplace la junta tórica

3. Ajuste o reemplace el acoplador

Fugas de fluido del

pivote

1. Las juntas giratorias están

dañadas o desgastadas.

1. Reemplace las juntas giratorias.

Consulte el “reemplazo de junta giratoria”

Advertencia : ¡asegúrese de que la fuga no esté

en la conexión de la manguera!

El conjunto giratorio no

se mueve libremente o

se bloquea

1. Se ha apretado demasiado

la conexión de la manguera

de entrada

2. La manguera de entrada no

es flexible y causa fuerza

lateral en el pivote.

1. Retire y examine el montaje giratorio para

ver si hay daños. Reemplace si es

necesario. Ajuste debidamente la

manguera de entrada. Ajuste a mano la

conexión, más 1/2 giro con la llave inglesa.

1. La manguera / cable es

más largo que lo

especificado

2. El diámetro exterior de la

manguera es más grande

que la especificación.

3. La manguera / el cable no

se colocó a mano sobre el

carrete y enrolló de manera

uniforme en el tambor

La manguera / cable

no encajará

completamente en el

tambor del carrete

1. Corte la manguera / cable para cumplir con

la capacidad especificada de los carretes

2. Reemplace la manguera / cable con una

manguera que cumpla con los requisitos

máximos de diámetro exterior especificados.

3. Coloque la manguera / cable a mano en el

tambor para envolver de manera uniforme

mientras se enrolla en el carrete.

CÓMO COMENZAR SEGURIDAD /

ESPECIFICACIONES FUNCIONAMIENTO

MONTAJE /

INSTALACIÓN

SOLUCIÓN DE

PROBLEMAS

MANTENIMIENTO /

REPARACIÓN

4

MONTAJE INSTALACIONES

Típica posición de montaje

Función de bloqueo

Montaje en el suelo

Figura 2

Figura 3 Figura 4

Cuando el usuario abre la caja, se destraba el

bloqueo en el soporte oscilante.

Para usar el carrete en una dirección, el bloqueo

debe estar trabado.

Gire el carrete en la dirección deseada y alinee los

orificios de la base del carrete y del soporte.

Tire de la perilla hacia abajo, gírela 90 grados en

sentido contrario a las agujas del reloj, coloque la

perilla en el orificio de la dirección deseada

insertando el extremo de la perilla en la ranura

ADVERTENCIA

1 Desempaque e inspeccione el carrete para verificar que no haya ningún daño. Gire el carrete a

mano para verificar si el carrete funciona o no funciona correctamente.

2 El soporte oscilante se embaló por separado con el carrete en la caja.

3 Hay doce orificios en cada base del soporte oscilante y del carrete.

4 Desmonte los pernos y las tuercas fijados a la base del soporte oscilante.

5 Alinee los orificios en la base del carrete y el soporte giratorio y ajuste los pernos y las tuercas

que se desmontaron en el paso 4 en los cuatro orificios en la esquina.

6 Después de instalar el soporte de montaje giratorio con los soportes de anclaje (si se requiere

soldadura, se debe soldar), instale el carrete colocando el pasador entre el carrete y el soporte

de montaje giratorio.

7 El carrete se suministra con manivela de plástico para evitar daños en movimiento, la manivela

está embalada plegada. Cuando use la manivela, por favor despliéguela.

8 Aplique sellador de roscas en la manguera de entrada y conéctelo a la junta giratoria del carrete.

Cuando el carrete está montado en el la pared,

se debe montar correctamente.

Si se saca la manguera cuando el carrete no está montado correctamente,

el carrete se puede caer y se puede dañar.

CÓMO COMENZAR

SEGURIDAD /

ESPECIFICACIONES

FUNCIONAMIENTO MONTAJE /

INSTALACIÓN

SOLUCIÓN DE

PROBLEMAS

MANTENIMIENTO /

REPARACIÓN

6

INSTRUCCIONES DE MANTENIMIENTO E INSPECCIÓN

Inspección de fugas

Reemplazo del sellado del pivote

● Retire el carrete del pivote.

● Retire el anillo de plástico con las pinzas específicas.

● Retire el pivote tirando hacia el usuario.

● Ajuste el Nuevo pivote al carrete.

● Ajuste el anillo de plástico al nuevo pivote con las pinzas específicas.

● Conecte la entrada de la manguera al nuevo pivote.

ADVERTENCIA

ADVERTENCIA

Cualquier reparación o reemplazo las debe realizar solamente una

persona calificada o un centro de servicio autorizado

Se debe realizar una inspección de manera periódica.

Asimismo, se debe actualizar de manera periódica el registro de

mantenimiento.

Cuando ocurre un problema, se debe reparar después de liberar la

presión.

En lo que respecta al medio (fluido) que se utiliza para el carrete de la manguera, se debe realizar una

verificación de fugas de manera periódica

Después de sacar la manguera, aplique completamente el agua jabonosa en el punto conectado.

(Tal como armazón o eje).

Si el punto conectado hace burbujas, el usuario debe sospechar un fenómeno de fuga.

● Cuando ocurre una fuga, se debe reemplazar el sellado de la carcasa o del eje.

● Cuando se produce una fuga debido a daños en la manguera, se debe reemplazar la manguera.

CÓMO COMENZAR

SEGURIDAD /

ESPECIFICACIONES

FUNCIONAMIENTO MONTAJE /

INSTALACIÓN

SOLUCIÓN DE

PROBLEMAS

MANTENIMIENTO /

REPARACIÓN

Table of contents

Languages:

Other Speedaire Tools manuals

Popular Tools manuals by other brands

Solera

Solera TB7427/3 Instructions for use and safety

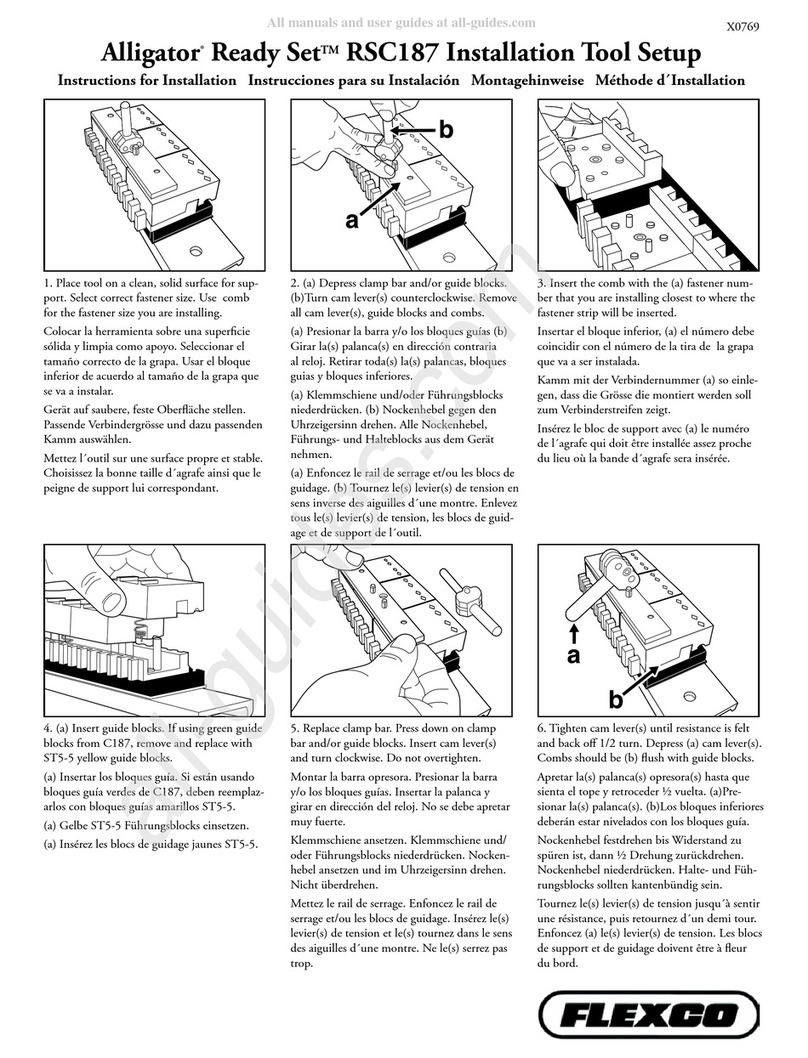

Flexco

Flexco Alligator Ready Set RSC187 Instructions for installation

Eastwood

Eastwood Elite 65500 Set up and operating instructions

Ace

Ace ATK-200 Technical sheet

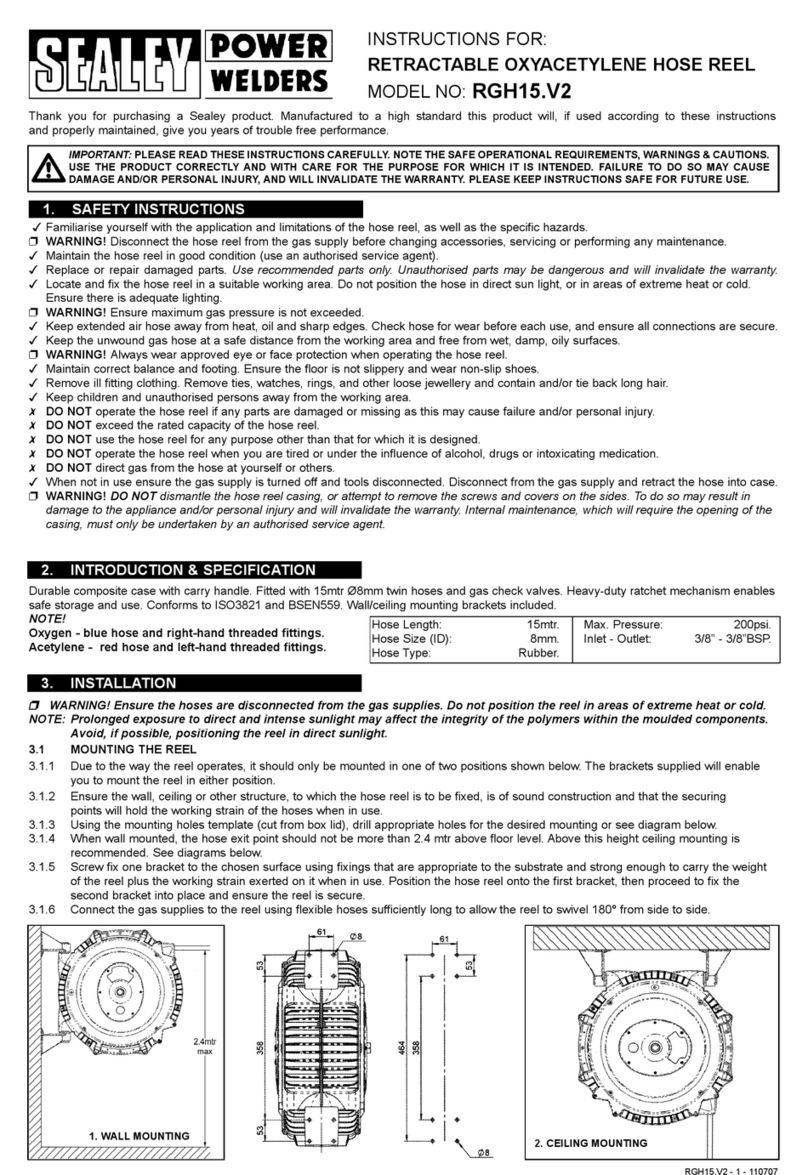

Sealey

Sealey RGH15.V2 instructions

Astro Pneumatic Tool

Astro Pneumatic Tool 78244 manual