SPEEDY-LIFT SP-CHR17R User manual

SPEEDY-LIFT

INSTALLATION MANUAL

SP-CHR17R

CHRYSLER PACIFICA

PASSENGER SIDE

2017 & UP

SCALE 1:5

1 of 5

ITEM

PART NUMBER

QTY

DESCRIPTION

1

SP000

1

Mechanism Assembvly

2

SP100-01

1

Rail Assembly

3

SP600B

1

Housing Cover Assembly -Black-

4

SP700B

1

Hook Assembly -Black-

5

SP740

2

Wheelchair support

6

SL800

1

Electrical Kit -Alone-

7

SL-CHR17R-00

1

Floor Installation Kit -Right-

8

SL-CHR17R-01

1

Outside Floor Adapter -Right-

9

SL-CHR17-02

1

Inside Floor Adapter

10

PRD 110-104

4

Round washer head tapping screw #8 x 1/2

11

PRD 302-100P

1

Hex Cap Bolt Zinc Plated 1/4-20 x 1/2 G5

12

PRD 333-105M

1

Nylon Insert Locknut 1/4-20 Thin

13

PRD 337-211P

10

Button Head Socket Cap Screw Zinc Plated 5/16-18 x 1/2

14

PRD 2946

4

Flange Locknut Zinc Plated 5/16-18

SP-CHR17R

ADAPT SOLUTIONS

|[email protected]|866.641.0419|418.889.9838 fax

PART NUMBER

Speedy-Lift 2 Kit -Right-

DESCRIPTION

KIT SPEEDY-LIFT 2 CHRYSLER PACIFICA 2017+

SCALE 1:7

2 of 5

SCALE 1:6

SCALE 1:5

14

9

13

5

4

11

12

1

2

7

10

6

8

ITEM

PART NUMBER

QTY

DESCRIPTION

1

SL-CHR17R-01

1

Outside Floor Adapter -Right-

2

SL-CHR17-02

1

Inside Floor Adapter

3

SL-CHR17R-03

1

Rear Fixing -Right-

4

SL-CHR17-04

1

Front Fixing

5

SL-CHR17-05

1

Front Fixing

6

SL-CHR17-06

1

Front Fixing

7

SL-CHR17-07

1

Rear Fixing

8

PRD 110-104

3

Round washer head tapping screw #8 x 1/2

9

PRD 302-138P

4

Hex Cap Bolt Zinc Plated 5/16-18 x 3/4 G5

10

PRD 321-104P

1

Hex Nut Zinc Plated 3/8-16 G5

11

PRD 333-107

4

Nylon Insert Locknut 5/16-18

12

PRD 341-108P

4

Flat Washer Zinc Plated I.D. 3/8 USS

13

PRD 341-146P

8

Flat Washer Zinc Plated I.D. 11/32 SAE 5/16

14

PRD 2945

4

Flange Locknut Zinc Plated 3/8-16

SP-CHR17R

ADAPT SOLUTIONS

|[email protected]|866.641.0419|418.889.9838 fax

PART NUMBER

Speedy-Lift 2 Kit -Right-

DESCRIPTION

KIT SPEEDY-LIFT 2 CHRYSLER PACIFICA 2017+

SCALE 1:6

10

7

6

3

7

2

9

8

5

4

1

3 of 5

SCALE 1:9

ITEM

PART NUMBER

QTY

DESCRIPTION

1

SP000

1

Mechanism Assembvly

2

SP100-01

1

Rail Assembly

3

SP600B

1

Housing Cover Assembly -Black-

4

SL-UNI-07

4

Nut for SPEEDY-LIFT rail

5

SL-UNI-08

4

Rail Spacer

6

SL-UNI-09

4

Rail Spacer Washer

7

PRD 110-104

4

Round washer head tapping screw #8 x 1/2

8

PRD 302-100P

1

Hex Cap Bolt Zinc Plated 1/4-20 x 1/2 G5

9

PRD 333-105M

1

Nylon Insert Locknut 1/4-20 Thin

10

PRD BSHCS51618114P

4

Button Head Socket Cap Screw Zinc Plated 5/16-18 x 1 1/4

SP-CHR17R

ADAPT SOLUTIONS

|[email protected]|866.641.0419|418.889.9838 fax

PART NUMBER

Speedy-Lift 2 Kit -Right-

DESCRIPTION

KIT SPEEDY-LIFT 2 CHRYSLER PACIFICA 2017+

2

1

SCALE 1:5

SCALE 1:6

4 of 5

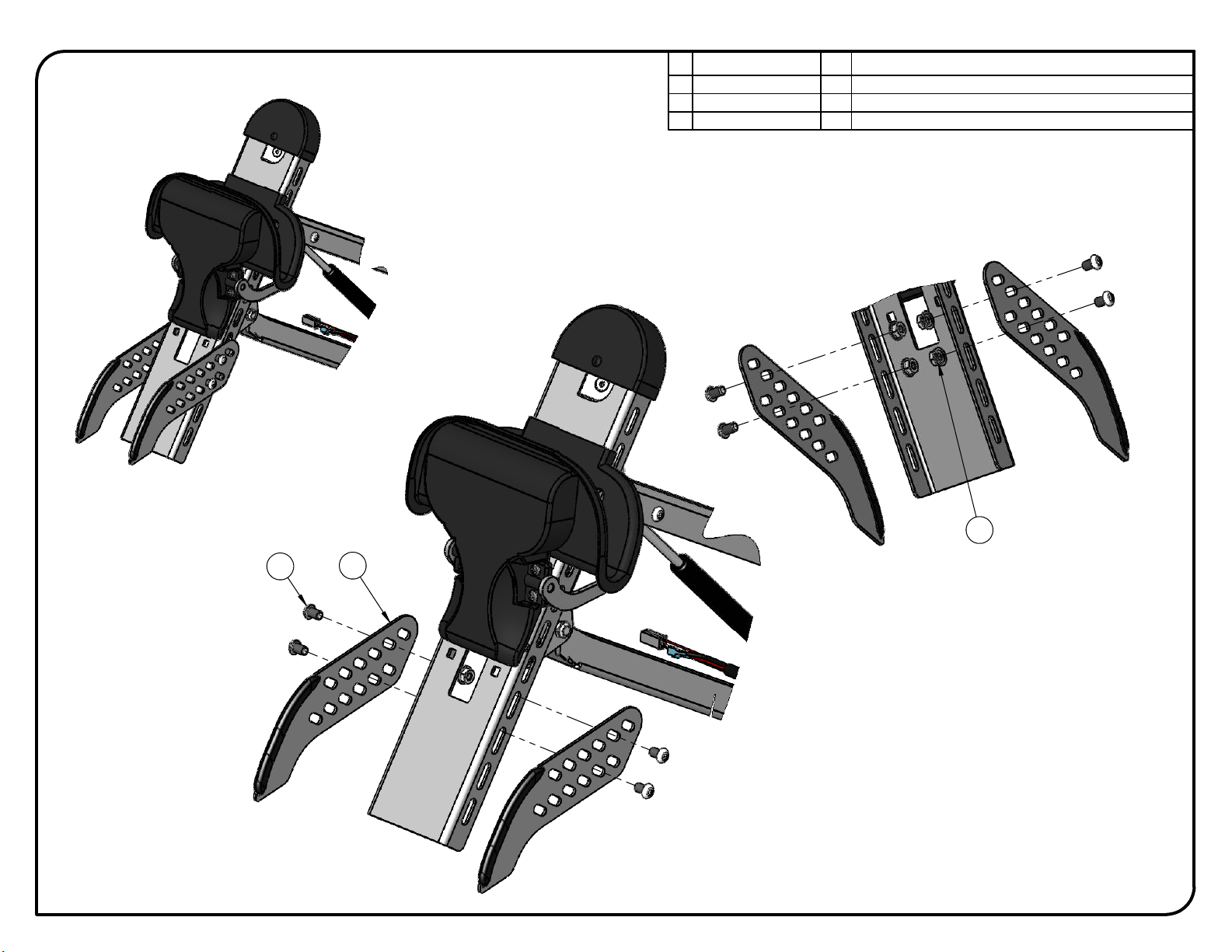

ITEM

PART NUMBER

QTY

DESCRIPTION

1

SP700B

1

Hook Assembly -Black-

2

PRD 337-211P

6

Button Head Socket Cap Screw Zinc Plated 5/16-18 x 1/2

SP-CHR17R

ADAPT SOLUTIONS

|[email protected]|866.641.0419|418.889.9838 fax

PART NUMBER

Speedy-Lift 2 Kit -Right-

DESCRIPTION

KIT SPEEDY-LIFT 2 CHRYSLER PACIFICA 2017+

SCALE 1:6

21

SCALE 1:4

SCALE 1:4

3

5 of 5

ITEM

PART NUMBER

QTY

DESCRIPTION

1

SP740

2

Wheelchair support

2

PRD 337-211P

4

Button Head Socket Cap Screw Zinc Plated 5/16-18 x 1/2

3

PRD 2946

4

Flange Locknut Zinc Plated 5/16-18

SP-CHR17R

ADAPT SOLUTIONS

|[email protected]|866.641.0419|418.889.9838 fax

PART NUMBER

Speedy-Lift 2 Kit -Right-

DESCRIPTION

KIT SPEEDY-LIFT 2 CHRYSLER PACIFICA 2017+

NOTE: If installing a LINK with a SPEEDY-LIFT, install the LINK floor adapter brakets at the same

time.

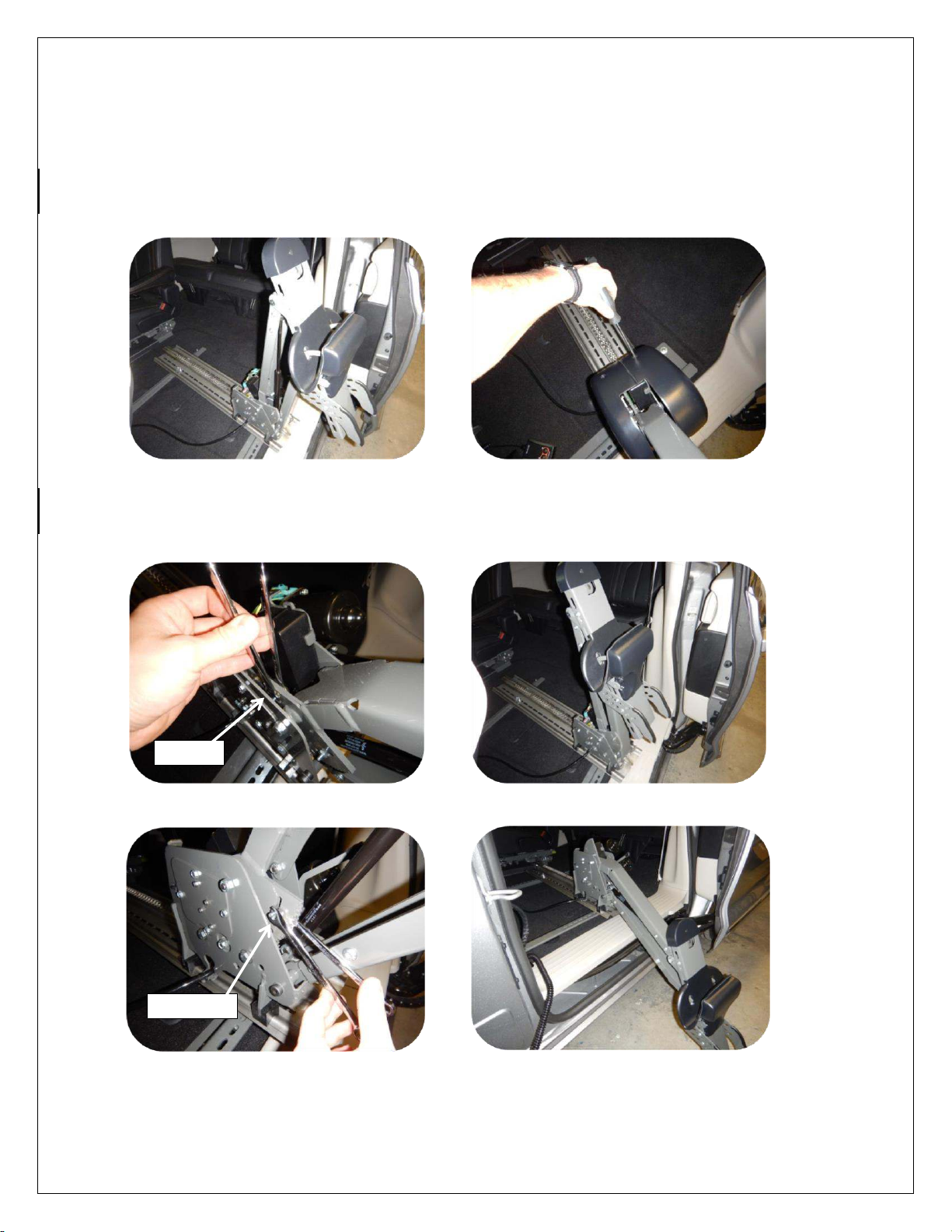

1. Stow the second row seats. Install the provided brackets # SL-CHR17-04 and # SL-CHR17-05 using the four

provided 5/16-18x3/4 bolts, nuts and washers. Align the protruding bolt with the hole in the stow and go cover,

then tighten down all the bolts.

2. Install the bolt # SL-CHR17-06 into the hole in the front left hand corner of the stow and go cover and secure in

place with the three 8x12 screws.

3. Remove the rear cover of the stow and go mechanism to gain access to the seat attachement bolts.

Remove the left hand bolt of the two central bolts and install the bracket # SL-CHR17R-03 aligning with the

slot then tighten down.

4. Using the remaning fixation bolt # SL-CHR17-07 insert it into the slotted hole at the outer end of the seat

fixation plate using the provided 3/8x16 nut to lock it in place.

5. Two coresponding holes will now have to be drilled 3/8 diameter in the rear cover to allow the bolts to

pass through. For the center hole, use the provided stencil. For the exterior hole, cut off the plastic clip

and drill the hole directly through the center of the clip. Reinstall the rear cover and close the stow and go

cover.

6. Install the exterior SPEEDY-LIFT floor bracket # SL-CHR17R-01 and the interior floor bracket # SL-CHR17-

02 using the provided 3/8 nuts and flat washers.

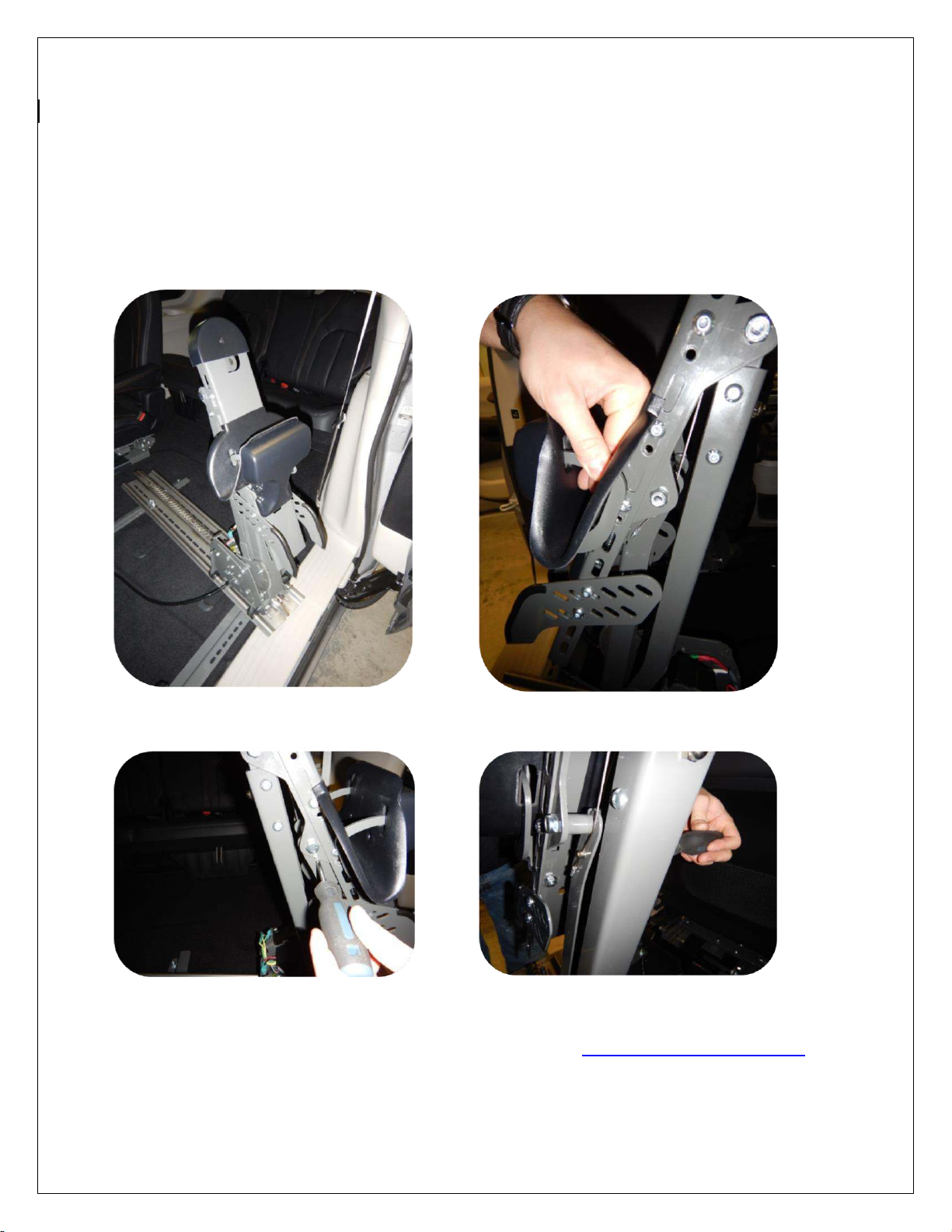

7. Place the SPEEDY-LIFT in the vehicle on the floor adaptors using the plastic shims between the

SPEEDY-LIFT and the floor adapters. Center the SPEEDY-LIFT in the door opening.Place the

SPEEDY-LIFT as close as possible to the door.

8. The SPEEDY-LIFT up/down and in out/motors can be disengaged manualy to slide the SPEEDY-

LIFT in and out and move the arm up and down. NOTE: while disengaging the arm, it will spring up as

the arm of the SPEEDY-LIFT is aided by a 100-lb gas shock, so, hold the arm firmly while

disengaging. To disengage, move the handle to the right and push down. This will disengage the two

motors and the arm will spring up. To reengage lift up the lever. You may have to move the arm and the

unit back and forth.

9. Place the washer over the SPEEDY-LIFT track and use the 5/16” X 1 1/4” button head bolts to lien

up the washer plate, the SPEEDY-LIFT track and the black plastic shim. Secure the SPEEDY-

LIFT to the floor adaptors using the threaded blocks SL-UNI-07.

10. Install the electrical wiring for the SPEEDY-LIFT. Follow the instructions found in the attached

document entitled: ELECTRICAL INSTALLATION FOR SPEEDY-LIFT.

11. Power the SPEEDY-LIFT all the way out. Attach the wheelchair hook and support assembly SP700 to

the head of the SPEEDY-LIFT. The height of the hook assembly may be adjusted depending on the

height or style of the wheelchair. Remove the plastic housing covers.

12. The stop up and stop down height may be adjusted using the bolts in the slotted holes on the up/down

gear. NOTE: The stop up bolt is pre-adjusted for maximum travel.

STOP UP

STOP DOWN

13. Press the ‘OUT’ button on the hand held pendant until the upper wheelchair support bracket is

positioned 1/4” to 1/2” below the rigidizer bar on the wheelchair. Adjust the stop down bolt so that the

arm stops in this position.

14. To properly position the lower support arms, back the wheelchair up over the upper wheelchair support

bracket. Press and hold the ‘IN’ button until the wheelchair barely starts lo to lift off the ground. Then

adjust the lower support arms to the wheelchair. Adjust the liftting angle of the wheelchair by sliding the

lower supports forward or back.

15. Adjust the locking mechanism. Remove the wheelchair from the SPEEDY-LIFT. Press and hold the

‘IN’button until the SPEEDY-LIFT is in its full up position. While holding the lock closed, pull the

cable tight and secure the cable lock. Cut off the excess lenght of cable. Test slowly to see if the locking

mechanism operates properly.

NOTE: The SPEEDY-LIFT must be in the full up position. Proper adjustment will ensure that the

locking mecanism and cable will not fail. If the cable is adjusted with the SPEEDY-LIFT not in the full

up possition, the cable will fail and the locking mecanism will no longer work.

FOR TECHNICAL SUPPORT CALL 866-641-0419 OR E-MAIL US TECH@ADAPTSOLUTIONS.COM

PLEASE HAVE THE SERIAL NUMBER OF THE UNIT ON HAND BEFORE PLACING YOUR CALL.

WARNING DECALS

After completing the installation of the SPEEDY LIFT, please take time to install the

warning decals. NOTE: The surface must be clean, dry and at ambient temperature for

the sticker to stick to the surface.

Start by locating a position to install the decals.

Clean the surface with the provided alcohol swab.

Peel off the backing of the sticker and then stick it to the cleaned surface.

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSES

SPEEDY LIFT

will not run

Bad electrical connections. Check and clean corrosion from all

connections including the car’s battery cable connections.

Hand pendant wire problem. Check hand pendant wire to make sure

it is properly plugged. Check the wire for any cuts. If so, replace the

wire.

Burnt out switch. Replace pendant.

Bad connection. Check the electronic module under the seat. Make

sure that all the wires are properly connected.

Burnt out electronic module. Contact Adapt-Solutions for

replacement module.

Burnt out actuator. Replace actuator.

Power Loss. The SPEEDY LIFT motor is not getting adequate

electrical power because of a loose connection. Check the SPEEDY

LIFT connections for tightness and corrosion (especially the ground

connection).

A partially discharged battery in the vehicle. Check the car’s battery

by trying the car lights or checking the voltage with a voltmeter

(should read 13.2 volts). Clean the car battery posts and cable clamps

thoroughly (remove the battery clamps off the battery posts and clean

them with a wire brush designed for that purpose). Coat the

connection with anticorrosion spray once reassembled. An

automotive battery may be weak, having enough power to start the

car but not enough power for continuous use.

ELECTRICAL INSTALLATION FOR SPEEDY-LIFT

1. Thread the lead power cable (red +) under the doorstep molding and through the

firewall. WARNING: Pass through a grommet in the firewall to prevent the cable from

chaffing.

2. Install the circuit breaker near the battery and then connect the battery to the circuit

breaker.

3. Attach the ground wire (black -) to the vehicle’s frame, under the doorstep molding

using a self-tapping screw. NOTE: It is preferable to locate it in a spot where the sheet

metal is doubled-up to insure a better ground.

4. Thread the hand held control wire under the doorstep molding and up under the

dash. Secure the wire in place under the dash with a tie wrap and secure the hand

held control on the dash using “Velcro”. WARNING: Place the hand held control in a

safe place so that the door does not risk cutting off the wire.

ELECTRICAL BOX CONNECTIONS

ASENTO with SPEEDY LIFT

SPEEDY LIFT ALONE

SPEEDY LIFT CORD

BLACK = GROUNDED TO

THE CHASSIS

RED = 12 V POWER

SUPPLY

ADAPT-SOLUTIONS #1 Ltd.

3 YEAR LIMITED WARRANTY

Adapt-Solutions # 1 Ltd. (Adapt Solutions), warrants to the original purchaser of an XL-BASE, XL-SEAT,

HI-LIFT, SPEEDY-LIFT, XL-BOARD, POWER-PULL or ASENTO that the equipment is free from

defects in material and workmanship for a period of three years from date of purchase.

During the first year of the warranty, Adapt Solutions will supply the replacement parts as well as a pre-set

monetary amount (determined by Adapt Solutions) for the repair if a defect in materiel or workmanship is

discovered. Labor claims must be approved by Adapt Solutions and an authorisation number (RMA) will

be given. Labor claims must be submitted within six (6) weeks of receiving the RMA to be processed. After

the initial year of this warranty, only parts and components are covered. This warranty does not cover

labor and other services after the initial year. Freight and other related repair charges will be the

responsibility of the original purchaser.

The only remedy for a defect in one of Adapt Solutions products shall be the repair or the replacement, at

the discretion of Adapt Solutions, of the defective part or component. If repair or replacement is not

commercially practical or cannot be timely made, Adapt Solutions may decide to refund the purchase

price of the equipment (XL-BASE; XL-SEAT; HI-LIFT; SPEEDY-LIFT; XL-BOARD; POWER- PULL;

ASENTO) instead of repairing or replacing the original equipment.

In no event shall Adapt Solutions be responsible for indirect, incidental or consequential damages, whether

such damages arise from claims based on contract, warranty, tort (including negligence), strict liability or

product liability.

All implied warranties, including any warranty of merchantability or fitness for a particular purpose, are

limited in their duration to the length of the warranty stated above for the affected component.

This warranty is to the original purchaser only, and excludes product damage due to installation error,

product misuse, product abuse, accidents, physical damage, damage in shipment, modifications not

made by Adapt Solutions, or repairs undertaken by anyone other than authorized distributors.

To obtain warranty parts or reimbursement, you must follow these procedures:

1. Obtain warranty authorization (RMA number) by calling your local Adapt Solutions dealer or Adapt

Solutions directly at 866-641-0419.

2. Return the faulty Adapt Solutions component/equipment, freight prepaid, to the address provided by

your Adapt Solutions dealer or Adapt Solutions with proof of purchase.

Adapt Solutions will pay for shipping back to the purchaser within the continental United States and

Canada if a defect in materiel or workmanship is discovered. Return freight and repair charges will be the

responsibility of the purchaser if the problem is not covered by warranty.

This warranty gives you specific legal rights, and you may also have other rights that vary from state to

state/ province to province. Adapt Solutions specifically does not authorize any person to extend the time

or scope of this warranty. For further information regarding this limited warranty, please contact us by

calling 1-866-641-0419 or by writing at the following address:

Adapt Solutions / Warranty Department

145 Damase-Breton

St-Lambert-de-Lauzon, Québec

G0S 2W0 Canada

Table of contents

Other SPEEDY-LIFT Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction