SPERONI LC 1800 DC User manual

Gasoline Generator

Generatori a Benzina

Instruction manual

Libretto Istruzioni

CONTENTS

1. SAFETY........................................................................................................................................................................................................................................5

1) Safety Label Locations......................................................................................................................................................................................5

2) Safety Information ..................................................................................................................................................................................................6

2. COMPONENT IDENTIFICATION..................................................................................................................................................................8

3. CONTROLS.........................................................................................................................................................................................................................10

1) Engine Switch............................................................................................................................................................................................................10

2) Recoil Starter..............................................................................................................................................................................................................10

3) Fuel Valve........................................................................................................................................................................................................................10

4) Choke .................................................................................................................................................................................................................................11

5) Circuit Breaker ........................................................................................................................................................................................................12

6) Ground Terminal ...................................................................................................................................................................................................12

7) Oil Alert System .....................................................................................................................................................................................................12

4. GENERATOR USE ....................................................................................................................................................................................................13

1) Connections to a Building’s Electrical System................................................................................................................13

2) Ground System........................................................................................................................................................................................................13

3) AC Applications .....................................................................................................................................................................................................14

4) AC Operation..............................................................................................................................................................................................................15

5) DC Operation.............................................................................................................................................................................................................15

6) High Altitude Operation.................................................................................................................................................................................17

5. PREOPERATION CHECK..................................................................................................................................................................................17

1) Engine Oil........................................................................................................................................................................................................................18

2) Fuel.........................................................................................................................................................................................................................................19

6. STARTING/STOPPING THE ENGINE............................................................................................................................................... 21

7. MAINTENANCE............................................................................................................................................................................................................ 22

1) Maintenance Schedule................................................................................................................................................................................. 22

2) Tool Kit ............................................................................................................................................................................................................................ 23

3) Engine Oil Change.............................................................................................................................................................................................. 23

4) Air Cleaner Service............................................................................................................................................................................................. 24

5) Fuel Sediment Cup............................................................................................................................................................................................ 25

6) Spark plug ................................................................................................................................................................................................................... 25

7) Spark Arrester Maintenance ................................................................................................................................................................. 27

8. TRANSPORTING/STOREGE ....................................................................................................................................................................... 29

9. TROUBLESHOTTING ........................................................................................................................................................................................... 31

10. WIRING DIAGRAM .................................................................................................................................................................................................. 32

11. SPECIFICATIONS ..................................................................................................................................................................................................... 35

12. OPTIONAL PARTS ................................................................................................................................................................................................... 37

2

CONTENTS

GB

INDICE

1. SICUREZZA ....................................................................................................................................................................................... 40

1) ) Posizione delle targhette disicurezza ................................................................................................................. 40

2) Informazioni per la sicurezza........................................................................................................................................ 41

2. IDENTIFICAZIONE DEI COMPONENTI ....................................................................................................................... 43

3. COMANDI ............................................................................................................................................................................................. 45

1) Interruttore del motore......................................................................................................................................................... 45

2) Motorino di avviamento a corda ................................................................................................................................. 45

3) Valvola del carburante ......................................................................................................................................................... 45

4) Valvola dell’aria ......................................................................................................................................................................... 46

5) Interruttore salvavita ............................................................................................................................................................. 47

6) Morsetto di messa a terra ............................................................................................................................................... 47

7) Sistema di controllo dell’olio .......................................................................................................................................... 47

4. USO DEL GENERATORE ....................................................................................................................................................... 48

1) Collegamenti al sistema elettrico di un edificio ............................................................................................ 48

2) Sistema di messa a terra .................................................................................................................................................. 48

3) Apparecchi a corrente alternata AC......................................................................................................................... 49

4) Funzionamento con corrente alternata AC........................................................................................................ 50

5) Funzionamento con corrente diretta DC.............................................................................................................. 50

6) Funzionamento a quote elevate .................................................................................................................................. 52

5. CONTROLLO PREOPERATIVO ......................................................................................................................................... 53

1) Olio del motore ......................................................................................................................................................................... 53

2) Carburante..................................................................................................................................................................................... 54

6. ACCENSIONE/SPEGNIMENTO DEL MOTORE................................................................................................... 56

7. MANUTENZIONE .......................................................................................................................................................................... 57

1) Tabella di manutenzione.................................................................................................................................................... 57

2) Kit di attrezzi ............................................................................................................................................................................... 58

3) Cambio dell’olio del motore .......................................................................................................................................... 59

4) Manutenzione del filtro dell’aria ................................................................................................................................. 59

5) Pulizia della vasca di sedimentazione del carburante.............................................................................. 60

6) Manutenzione delle candele........................................................................................................................................... 60

7) Manutenzione del parascintille..................................................................................................................................... 62

8. TRASPORTO/CUSTODIA ...................................................................................................................................................... 64

9. INDIVIDUAZIONE ED ELIMINAZIONE DI GUASTI ........................................................................................... 66

10. SCHEMA DEL CABLAGGIO ................................................................................................................................................ 67

11. SPECIFICHE ...................................................................................................................................................................................... 70

12. COMPONENTI FACOLTATIVI ............................................................................................................................................ 72

INDICE

I

3

Thank you for purchasing our generator. We want to help you get the best results from

your new generator and to operate it safety.

This manual contains the information on how to do that; please read it carefully.

All information and specifications in this publication is based on the lastest product

information available at the time of printing.

DC type is equipped for DC outlet. DDC type is equipped for both eletric starting and

DC outlet.

This manual should be considered a permanent part of the generator and should

remain with it if is resold.

Safety Messages

Your safety and the safety of others are very important. We have provided important

safety messages in this manual and on the generator. Please read these messages

carefully.

A safety message alerts you to potential hazard that could hurt your or others. Each

safety message is proceded by a safety alert symbols and one of tree words:

DANGER, WARNING, or CAUTION. These mean:

Damage Prevention Messages

Other important messages are preceded by the word NOTICE. this word means:

The purpose of these messages is to help prevent damage to your generator, other

property, or the environment.

DANGER

WARNING

CAUTION

You WILL be KILLED or SERIOUSLY HURT if you don’t

follow instructions.

You CAN be KILLED or SERIOUSLY HURT if you don’t

follow instructions.

You can be HURT if you don’t follow instructions.

NOTICE Your generator or other property could be damaged if you

don’t follow instructions.

GB

4

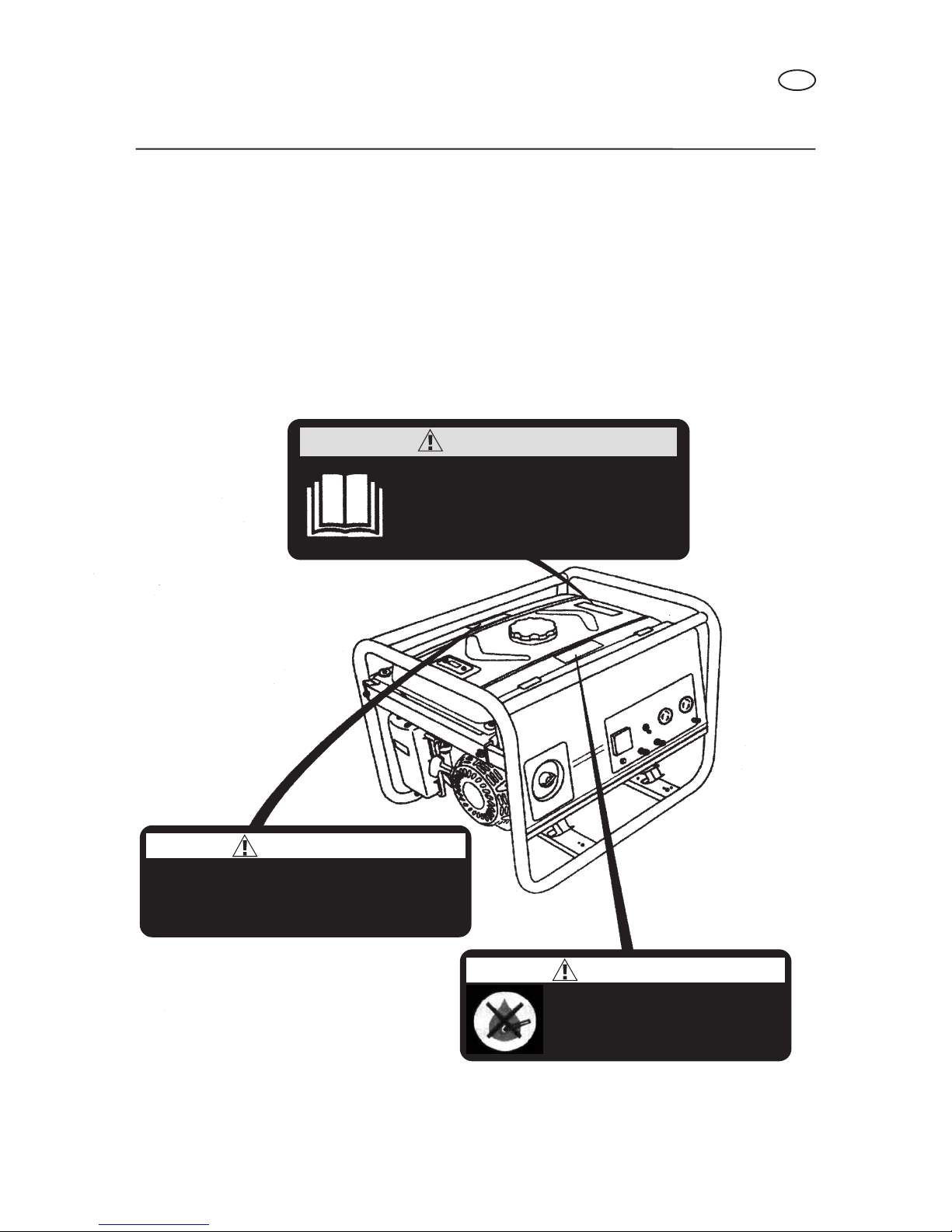

1. SAFETY

1) SAFETY LABEL LOCATION

These labels warn you of potential hazards that can cause serious injury. Read them

carefully.

If a label comes off or becomes hard to read, contact your generator dealer for a

replacement.

SAFETY

WARNING

Check that there is no any

fuel spilling or fuel leakage.

Filling fuel before stalling the

engine is forbidden.

Among engine exhaust emissions, there toxic

CO.so never use in an enclosed room without

good ventilation.

WARNING

Before operation, be sure to add specified

engine oil into the crankcase. Please refer

to the OWNER’S MANUAL for further

information

CAUTION

ST

GB

5

2) SAFETY INFORMATION

Our generator are designed to give safe and dependeble service if operated acording

to instructions. Read and understand this owner’s manual before operating your generator.

You can help prevent accidents by being familiar with your generator’s controls, and by

observing safe operating procedures.

Operator Responsability

• Know how to stop the generator quickly in case of emergency.

• Understand the use of all generator controls, output receptacles, and connections.

• Be sure that anyone who operates the generator receives proper instruction. Do not

let children operate the generator without parental supervision. Keep children and

pets away from the area of operation.

• Place the generator on a firm, level surface and avoid loose sand or snow. If the

generator is tilted or overturned, fuel spillage may result. Also, if the generator is

overturned or sinks into a soft surface, sand, dirt, or water may enter the generator.

SAFETY

CAUTION

HIGH TEMPERATURE PART! DONT TOUCH IT!

MUFFLER! HOT!

GB

6

Carbon Monoxide Hazards

• Exhaust contains poisonous carbon monoxide, a colorless and odorless gas.

Breating exhaust can cause loss of consciousness and may lead to death.

• If you run the generator in an area that is confined, or even partially enclosed, the air

you breathe could contain a dangerous amount of exhaust gas. To keep exhaust gas

from building up, provide adequate ventilation.

Eletric Shock Hazards

• The generator produces enough eletric power to cause a serious shock or

electrocution if misuded.

• Using a generator or electrical appliance in wet condictions, such as rain or snow,

or near a pool or sprinkler system, or when your hands are wet, could result in

electrocution. Keep the generator dry.

• If the generator is stored outdoors, unprotected from the weather, check all

electrical components on the control panel, before each use. Moisture or ice can cause

a malfunction or short circuit in eletrical conponents wich could result in electrocution.

• Do not connect to a building’s electrical system unless an isolation switch has been

installed by a qualified electrician.

Fire and Burn Hazards

• The exhaust system gets hot enough to ignite some materials.

- Keep the generator at least 1 meter (3 feet) away from buildings and other

equipment during operation.

- Do not enclose the generator in any structure.

- Keep flammable materials away from the generator.

• The muffler becomes very hot during operation and remains hot for a while after

stopping the engine. Be careful not to touch the muffler while it is hot. Let the engine

cool before storing the generator indoors.

• Gasoline is extremely flammable and is explosive under certain conditions. Do not

smoke or allow flames or sparks where the generator is refueled or where the gasoline

is stored. Refuel in a well-ventilaed area with the engine stopped.

• Fuel vapors are extremely flammable and may ignite after the engine has started.

Make sure that any spilled fuel has been wiped up beore starting the generator.

SAFETY

GB

7

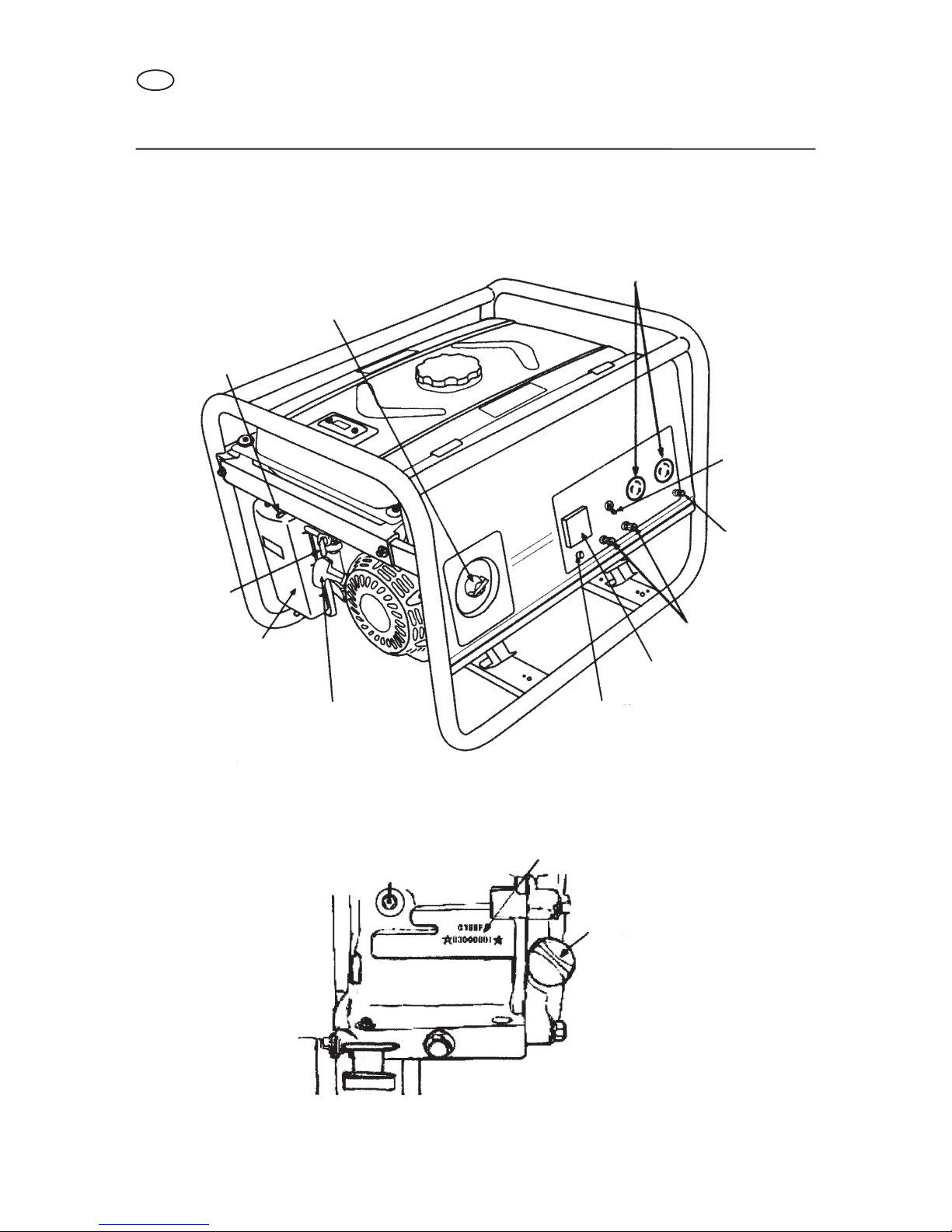

2. COMPONENT IDENTIFICATION

COMPONENT IDENTIFICATION

AC RECEPTACLES

AC CIRCUIT

BREAKER

GROUND

TERMINAL

DC RECEPTACLES

VOLTMETER

DC PROTECTOR

RECOIL STARTER GRIP

AIR CLEANER

FUEL VALVE

CHOKE LEVER

ENGINE SWITCH

ENGINE TYPE & SERIAL NUMBER

OIL FITER CAP

GB

8

Record the engine serial numbers for your future reference.

Refer to these serial number when ordering parts, and when making technical.

Engine serial number:

COMPONENT IDENTIFICATION

GROUND TERMINAL

FUEL TANK CAP

FUEL METER

MUFFLER

SPARK PLUG CAP

VOLMETER

CIRCUIT BREAKER RECEPTACLE

AC OUTPUT TERMINAL

THREE PHASE TYPE

GB

9

3. CONTROLS

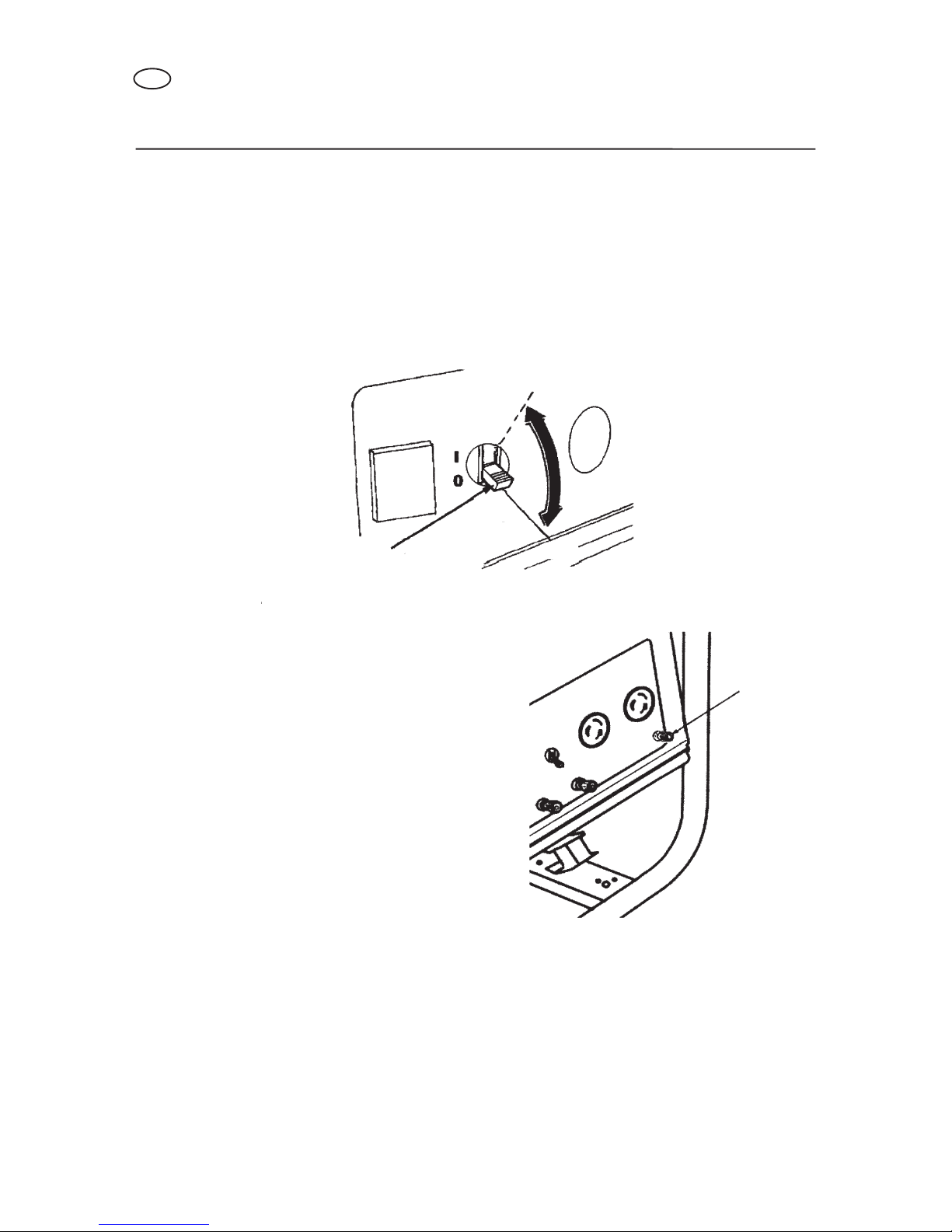

1) Engine Switch

The start and stop the engine.

Switch position:

OFF: To stop the engine.

ON: To run the engine.

To engine with electric starter, include the START position.

2) Recoil Starter

To start the engine, pull the starte grip lightly until resistance is felt, then pull briskly.

3) Fuel Valve

The fuel valve is located between the fuel tank and carburetor. When the valve lever is

in the ON position, fuel is allowed to flow from the fuel tank to the carburetor. Be sure

to return the lever to OFF after stopping the engine.

CONTROLS

ENGINE SWITCH

OFF

ON

ENGINE SWITCH

OFF

ON

ENGINE SWITCH

OFF

ON

NOTICE Do not allow the starter to snap back aganist the engine.

Return it gently to prevent damage to the starter.

STARTER GRIP

STARTER GRIP

GB

10

4) Choke

The choke is used to provide an enriched fuel mixture when starting a cold engine. It

can be opened and closed by operating the choke lever or choke rod manually.

Move the lever or the rod to the CLOSE position to enrich the mixture.

CONTROLS

Valve lever

ON

OFF

Valve lever

CHOKE ROD

OPEN

CLOSE

CHOKE LEVER

CLOSED

CHOKE LEVER

OPEN

ON

OFF

OPEN

CLOSE

OPEN

GB

11

4) Circuit Breaker

The circuit breaker will automatically switch OFF if there is a short circuit or a significant

overlaod of the generator at the receptacle. If the circuit breaker is switched OFF

automatically, check that the appliance is working properly and does not exceed the

rated load capacity of the circuit before swicthing the circuit breaker ON again.

The circuit breaker may be used to switch the generator power ON or OFF.

6) Ground Terminal

The generator ground terminal is connected

to the panel of the generator, the metal

non-current carrying parts of the generator,

and the ground terminals of each receptacle.

Before using the ground terminal, consult a

qualified electrician, eletrical inspector or

local agency having jurisdiction for local

codes or ordinances that apply to the

intended use of the generator.

7) Oil Alert System

The oil alert system is designed to prevent engine damage caused by an insufficient

amount of oil in the crankcase. Before the oil level in the crankcase can fall below a

safe limit, the oil alert system will automatically shut down the engine (the engine

switch wil remain in the ON position). The oil alert system shuts down the engine and

the engine will not start. If this occurs, please check engine oil first.

CONTROLS

CIRCUIT BREAKER

GROUND

TERMINAL

OFF

ON

GB

12

4. GENERATOR USE

1) Connections to a Building’s Electrical System

Connections for standby power to a building’s electrical system must be made by a

qualified electrician. The connection must isolate the generator power from utility power,

and must comply with all applicable laws and electrical codes.

Improper connections to a building’s electrical syatem, can allow

electrical current from the generator to backfeed into the utility lines.

Such backfeed may electrocute utility company workers or others who contact the

lines during a power outage. Consult the utility company or a qualified electrician.

Improper connections to a building’s electrical system can allow

electrical current from the utility company to backfeed into the

generator. When utility power is restored , the generator may explode, burn, or

cause fires in the building’s electrical system.

2) Ground System

To prevent electrical shock from faulty applicances, the generator should be grounded.

Connect a lenght of heavy wire between the ground terminal and the ground source.

The generators have a system ground that connects generator frame components to

the ground terminals in the AC output receptacles. The system ground is not connected

to the AC neutral wire. If the generator is tested by a receptacle tester, it will not show

the same ground circuit condition as for a home receptacle.

Special Requirements

There may be Federal or State Occupational Safety and Health Administration (OSHA)

GENERATOR USE

GROUND

TERMINAL

WARNING

CAUTION

GB

13

regulation, local codes, or ordinances that apply to the intended use of the generator.

Please consult a qualified electrician, elctrical inspector, or the local agency having

jurisdiction.

• In some areas, generators are required to be registered with local utility companies.

• If the generator is used at a construction site, there may be additional regulations

which must be observed.

3) AC Applications

Before connecting an appliance or power cord to the generator:

• Make sure that it is in good working order. Faulty appliances or power cords can

create a potential for electrical shock.

• If an appliance begins to operate abnormally, becomes sluggish or stops suddenly,

turn it off immediately. Disconnect the appliance, and determine whether the problem

is the appliance, or if the rated load capacity of the generator has been exceeded.

• Make sure that the electrical rating of the tool or appliance does not exceed that of

the generator. Never exceed the maximum power rating of the generator. Power levels

between rated and maximum may be used for no more than 30 minutes.

Substantial overloading will switch off the circuit breaker.

Exceeding the time limit maximum power operation or slightly

overloading the generator may not switch the circuit breaker OFF, but will

shorten the service life of the generator.

Limit operation requiring maximum power to 30 minutes.

Maximum power of the LC 1800 DC generator is: 1.5 kW

Maximum power of the LC 2500 DC generator is: 2.2 kW

Maximum power of the LC 3800 DDC generator is: 3.1 kW

Maximum power of the LC 5000 DDC generator is: 4.4 kW

Maximum power of the LC 6500 DDC generator is: 5.5 kW

For continuos operation, do not exceed the rated power.

Rated power of the LC 1800 DC generator is: 1.3 kW

Rated power of the LC 2500 DC generator is: 2.0 kW

Rated power of the LC 3800 DDC generator is: 2.8 kW

Rated power of the LC 5000 DDC generator is: 4.0 kW

Rated power of the LC 6500 DDC generator is: 5.0 kW

In either case, the total power requirements (kW) of all appliances connected must be

GENERATOR USE

NOTICE

GB

14

considered. Appliance and power tool manufacturers usually list rating information near

the model number or serial number.

4) AC Operation

1Start the engine.

2Switch the AC circuit breaker ON.

Rated current of the AC circuit breaker:

LC 1800 DC: 7 A

LC 2500 DC: 10 A

LC 3800 DDC: 13 A

LC 5000 DDC: 19 A

LC 6500 DDC: 23 A

3Plug in the appliance.

Most motorized appliances require more than their rated wattage for startup.

Do not exeed the current limit specified for any one receptacle. If an overload circuit

causes the AC circuit breaker to switch OFF, reduce the electrical load on the circuit,

wait a few minutes and then reset the circuit breaker.

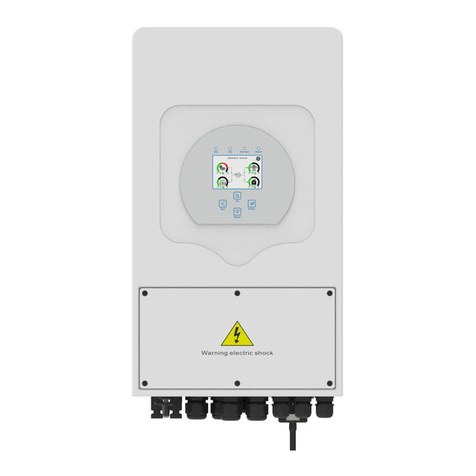

5) DC OPERATION

DC terminals

The DC terminals may ONLY be used

for charging 12 volt automative type

batteries.

The terminal are colored red identify the positive (+) terminal and black to identify

the negative (-) terminal. The battery must be connected to the generator DC terminals

with the proper polarity (battery positive to generator red terminal and battery negative

to the generator black terminal).

GENERATOR USE

NEGATIVE TERMINAL (BLACK)

POSITIVE TERMINAL (RED)

DC PROTECTOR

GB

15

DC Circuit Protector

The DC circuit protector (rated current: 10A) automatically shuts off the DC battery

charging circuit when the DC circuit is overloaded, when there is a problem with the

battery, or the connections between the battery and the genrator are improper.

The indicator inside the DC circuit protector button will pop to show that the DC circuit

protector has switched off. Wait a few minutes and push the button in to reset the DC

circuit protector.

Connecting the battery cables:

1Before connecting charging cables to a battery that is installed in a vehicle, disconnect

the vehicle’s grounded battery cable.

The battery gives off explosive gases; keep sparks, flames and cigarettes

away. Provide adequate ventilation when charging or using batteries.

2Connect the positive (+) battery cable to the battery positive (+) terminal.

3Connect the other end of the positive (+) battery cable to the generator.

4Connect the negative (-) battery cable to the battery negative (-) terminal.

5Connect the other end of the negative (-) battery cable to the generator.

6Start the generator.

Do not start the vehicle while the battery charging cables are

connected and the generator is running. The vehicle or the

generator may be damaged.

An overload DC circuit, excessive current draw by the battery, or a wiring problem

will trip the DC circuit protector (PUSH button extends out). If this happens, wait a few

minutes before pushing in the circuit protector to resume operation. If the circuit

protector continues to go OFF, discontinue charging and see your authorized generator

dealer.

GENERATOR USE

NOTICE

WARNING

GB

16

Disconnecting the battery cables:

1Stop the engine.

2Disconnect the negative (-) battery cable from the generator negative (-) terminal.

3Disconnect the other end of the negative (-) battery cable from the battery negative

(-) terminal.

4Disconnect the positive (+) battery cable from the generator positive (+) terminal.

5Disconnect the other end of the positive (+) battery cable to the battery positive (+)

terminal.

6Connect the vehicle ground cable to the battery negative (-) terminal.

7Reconnect the vehicle grounded battery cable.

6) High Altitude Operation

At high altitude, the standard carburetor air-fuel mixture will be excessively rich.

Performance will decrease, and fuel consumption will increase.

High altitude performance can be improved by installing a smaller diameter main fuel

jet in the carburetor and readjusting the pilot screw. If you always operate the engine

at

altitudes higher than 5000 feet (1500 meters) above sea level, have an authorized

generator dealer perform this carburetor modification.

Even with suitable carburetor jetting, engine horsepower will decrease approzimately

3.5% for each 1000 foot (300 meters) increase in altitude. The effect of altitude on

horsepower will be greater than this if no carburetor modification is made.

If a engine jetted for high altitude is used at a lower altitude,

the lean air fu mixture will reduce performance and may over-

heat and seriously damage the engine.

GENERATOR USE

NOTICE

GB

17

5. PRE-OPERATION CHECK

1) Engine Oil

Engine oil is a major factor affecting engine performance and

service life. Non-detergent and 2-stroke engine oils will damage

the engine and are not recommended.

Check the oil level BEFORE EACH USE with the generator on a level surface with the

engine stopped.

Use 4-stroke oil, premium quality motor oil certified to meet or exceed U.S. automobile

manufacturer’s requirements for Service Classification SG, SF/CC, CD. Motor oils

classified SG, SF/CC, CD will show this

designation on the container.

SAE 10W-30 is recommended for general,

all-temperature use. Other viscosities

shown in the chart may be used when the

average temperature in your area is within

the indicated range.

1. Remove the oil filter cap and wipe the dipstick clean.

2. Check the oil level by inserting the dipstick into the filler neck without screwing it in.

3. If the level is low, add the reccommended oil to the upper mark on the dipstick.

PRE-OPERATION CHECK

NOTICE

AMBIENT TEMPERATURE

OIL FILLER HOLE OIL FILLER CAP

UPPER LEVEL

OIL FILLER CAP

GB

18

2) Fuel

1. Check the fuel level gauge, or check the fuel level after opening the fuel tank cap.

2. Refill the tank if the fuel level is low. Do not fill above the shoulder of the fuel stranier.

• KEEP OUT OF REACH OF CHILDREN.

• Gasoline is extremely flammable and is explosive under certain

conditions.

•Refuel in a well-ventilated area with the engine stopped. Do not smoke or allow

flames or sparks in the area where the engine is refueled or where gasoline is

stored.

•Do not overfill the fuel tank (there should be no fuel in the filler neck). After

refueling, make sure the tank cap is closed properly and securely. Be careful not

to spill fuel when refueling. Spilled fuel vapor may ignite. If any fuel is spilled,

make sure the area is dry before starting the engine.

•Avoid repeated or prolonged contact with skin or breathing of vapor.

Fuel tank capacity:

LC 1800 DC - LC 2500 DC is: 15.0 L

LC 3800 DDC - LC 5000 DDC - LC 6500 DDC is: 25.0 L

Use gasoline with a pump octane rating of 90 or higher.

We recommend unleaded gasoline because it produces fewer engine and spark plug

deposits and extends exhaust system life.

Never use stale or contaminated gasoline or oil/gasoline mixture. Avoid getting dirt or

water in the fuel tank.

Occasionally you may hear light “spark knock” or “pinging” (metallic rapping noise)

while operating under heavy loads. This is no cause for concern.

PRE-OPERATION CHECK

FUEL LEVEL GAUGE

EMPTY

FUEL TANK CAP

UPPER FUEL LEVER

WARNING

OPEN CLOSE

GB

FULL

19

If spark knock or pinging occurs at a steady engine speed, under normal load, change

brands of gasoline. If spark knock or pinging persists, see an authorized generator

dealer.

Running the engine with persistent spark knock or pinging can

cause engine damage.

Running the engine with persistent spark knock or pinging is misuse, and the Distributor’s

Limited Warranty does not cover parts damaged by misuse.

Oxygenated Fuels

Some gasoline are blended with alcohol or an ether compound to increase the octane.

These gasoline are collectively referred to as oxygenated fuels. Some areas of the United

States use oxygenated fuels to help meet clean air standards.

If you use an oxygenated fuel, be sure its pump octane rating is 86 or higher.

Ethanol (ethyl or grain alcohol)

Gasoline containing more than 10% ethanol by volume may cause starting and/or

performance problems. Gasoline containing ethanol may be marketed under the name

“Gasohol”.

Methanol (methyl or wood alcohol)

Gasoline containing methanol must contain cosolvents and corrosion inhibitors to

protect the fuel system. Gasoline containing more than 5% methanol by volume may

cause starting and/or performance problems and may damage metal, rubber and

plastic parts of your fuel system.

MTBE (methyl tertiary butyl ether)

You may use gasoline containing up to 5% MTBE by volume.

Before using an oxygenated fuel, try to confirm the fuel’s contents. Some states (provinces

in Canada) require this information to be posted on the pump. If you notice any undesirable

operating symptoms, switch to a conventional unleaded gasoline. Fuel system damage

or performance problems resulting from the use of an oxigenated fuel are not the

responsibility of manufacturer and are not covered under warranty.

Oxygenated fuels can damage paint and plastic. Be careful not

to spill fuel when filling your fuel tank. Damage caused by spilled

fuel is not covered under warranty.

PRE-OPERATION CHECK

NOTICE

NOTICE

GB

20

This manual suits for next models

4

Table of contents

Languages: